Experiment and numerical simulation of liquid nitrogen tank atmospheric ground parking

-

摘要:

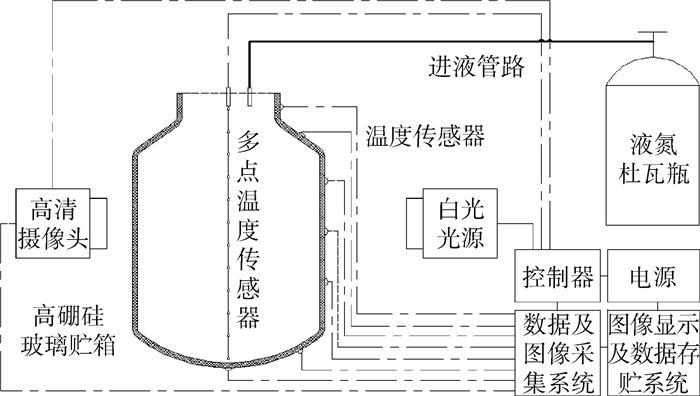

为研究低温推进剂的常压停放过程,设计了可视化液氮贮箱实验系统。实验中研究充填率和环境温度对液氮汽化量的影响,并测量贮箱内流体和贮箱外壁面的温度随时间和位置的变化。实验得出贮箱常压停放过程,相变主要在壁面和气液界面产生,并且气枕区存在温度分层,距出口位置越近温度越高;而液体区温度基本一致,处于饱和状态。贮箱外壁面在轴向的温度分布显著不同,处于液体区壁面温度低。运用分子动力学推导出的Hertz-Knudsen公式作为气液相变的传热传质源项,并据实验测得温度边界条件,采用混合物模型对贮箱常压停放状态进行30 min的数值仿真。仿真得到结果显示体积汽化速率与实验数据的偏差在5%以内,液体区的温度仿真与实验的偏差在0.15 K左右。

Abstract:In order to study the progress of the cryogenic propellant during atmospheric ground parking, a visualization liquid nitrogen tank experiment system was designed. The experiment researched how the filling rate and ambient temperature affected the evaporation mass of liquid nitrogen, and measured the fluid inside tank and the wall temperature outside tank which changed with the time and location. The experimental results show that during atmospheric ground parking the phase transition mainly happens in the wall and gas-liquid interface, air pillow zone has temperature levels, and the air pillow temperature increases with the decrease of the distance from the exit. The liquid stays in the saturated state with almost consistent temperature, and the outer wall temperature distribution of the tank is significantly different in the axial direction and lower in liquid zone. The heat and mass transfer between liquid and gas is deduced from the Hertz-Knudsen equation based on the molecular dynamics theory. According to the temperature boundary conditions acquired from the experiment, physical process of 30 min in liquid nitrogen tank during atmospheric ground parking was simulated using mixture model. The simulation results show that the deviation of volume vaporization rate between simulation and experiment is within 5%, and the deviation of temperature simulation and experiment in the liquid zone is about 0.15 K.

-

Key words:

- cryogenic tank /

- atmospheric ground parking /

- phase transition /

- heat and mass transfer /

- mixture model

-

表 1 贮箱液位与体积变化关系

Table 1. Variation of volume of tank with liquid level

液位/cm 体积/L 充填率/% 总体积/L 0 1.607 7.6 5 4.907 23.3 10 8.207 39.0 21.03 15 11.507 54.7 20 14.807 70.4 25 18.107 86.1 -

[1] STOCHL R J, KNOLL R H. Thermal performance of a liquid hydrogen tank multilayer insulation system at warm boundary temperatures of 630, 530, and 152 R[C]//AIAA, SAE, ASME, and ASEE, 27th Joint Propulsion Conference. Reston: AIAA, 1991: 1-20. [2] BARSI S, KASSEMI M, PANZARELLA C H, et al. A tank self-pressurization experiment using a model fluid in normal gravity[C]//AIAA Aerospace Sciences Meeting and Exhibit. Reston: AIAA, 2005: 1-13. [3] SEO M, JEONG S.Analysis of self-pressurization phenomenon of cryogenic fluid storage tank with thermal diffusion model[J].Cryogenics, 2010, 50(9):549-555. doi: 10.1016/j.cryogenics.2010.02.021 [4] DAS S P, CHAKRABORTY S, DUTTA P.Studies on thermal stratification phenomenon in LH2 storage vessel[J].Heat Transfer Engineering, 2004, 25(4):54-66. doi: 10.1080/01457630490443767 [5] WANG C L, LI Y, WANG R S.Performance comparison between no-vent and vented fills in vertical thermal-insulated cryogenic cylinders[J].Experimental Thermal and Fluid Science, 2011, 35(2):311-318. doi: 10.1016/j.expthermflusci.2010.09.013 [6] 聂中山, 李青, 洪国同, 等.车载液氢杜瓦蒸发率理论与试验研究[J].低温工程, 2004(4):55-58. http://d.old.wanfangdata.com.cn/Periodical/dwgc200404011NIE Z S, LI Q, HONG G T, et al.Theoretical and experimental investigation of evaporation rate in vehicle liquid hydrogen dewar[J].Cryogenics, 2004(4):55-58(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/dwgc200404011 [7] 王贵仁. 低温容器内压力变化规律的研究[D]. 兰州: 兰州理工大学, 2008: 28-40. http://cdmd.cnki.com.cn/Article/CDMD-10731-2008113656.htmWANG G R. The research on variation law of pressure in cryogenic vessel[D]. Lanzhou: Lanzhou University of Technology, 2008: 28-40(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10731-2008113656.htm [8] 乔国发. 影响LNG储存容器蒸发率因素的研究[D]. 东营: 中国石油大学, 2007: 73-87. http://cdmd.cnki.com.cn/Article/CDMD-10425-2008199207.htmQIAO G F. The study on the influential factors of evaporation rate of the liquefied natural gas tank[D]. Dongying: China University of Petroleum, 2007: 73-87(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10425-2008199207.htm [9] 代予东, 赵红轩.运用数学方法模拟推进剂贮箱增压[J].火箭推进, 2003, 29(3):34-40. http://d.old.wanfangdata.com.cn/Periodical/hjtj200303007DAI Y D, ZHAO H X.Numerical modeling of pressurization of a propellant tank[J].Journal of Rocket Propulsion, 2003, 29(3):34-40(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hjtj200303007 [10] ESTEY P N, LEWIS D H, CONNOR M.Prediction of a propellant tank pressure history using state space methods[J].Journal of Spacecraft and Rockets, 1983, 20(1):49-54. doi: 10.2514/3.28355 [11] PANZARELLA C H, KASSEMI M.On the validity of purely thermodynamic descriptions of two-phase cryogenic fluid storage[J].Journal of Fluid Mechanics, 2003, 484:41-68. doi: 10.1017/S0022112003004002 [12] 刘展, 孙培杰, 李鹏, 等.地面停放低温液氧贮箱热物理过程研究[J].西安交通大学学报, 2016, 50(9):36-42. doi: 10.7652/xjtuxb201609006LIU Z, SUN P J, LI P, et al.Research on the thermal physical process of cryogenic liquid oxygen tank in ground parking[J].Journal of Xi'an Jiaotong University, 2016, 50(9):36-42(in Chinese). doi: 10.7652/xjtuxb201609006 [13] CHEN L, LIANG G Z.Simulation research of vaporization and pressure variation in a cryogenic propellant tank at the launch site[J].Microgravity Science and Technology, 2013, 25(4):203-211. doi: 10.1007/s12217-013-9340-2 [14] FADHL B, WROBEL L C, JOUHARA H.CFD modelling of a two-phase closed thermosyphon charged with R134a and R404a[J].Applied Thermal Engineering, 2015, 78:482-490. doi: 10.1016/j.applthermaleng.2014.12.062 [15] 陈亮, 梁国柱, 邓新宇, 等.贮箱内低温推进剂汽化过程的CFD数值仿真[J].北京航空航天大学学报, 2013, 39(2):264-268. http://bhxb.buaa.edu.cn/CN/abstract/abstract12543.shtmlCHEN L, LIANG G Z, DENG X Y, et al.CFD numerical simulation of cryogenic propellant vaporization in tank[J].Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(2):264-268(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract12543.shtml [16] Fluent A. ANSYS I: Fluent theory guide[EB/OL]. Canonbury: ANSYS Inc., 2010. https: //support. ansys. com/. [17] 刘泉. 纯蒸气及含不凝气蒸气冷凝的数值研究[D]. 合肥: 中国科学技术大学, 2015: 73-87. http://cdmd.cnki.com.cn/Article/CDMD-10358-1015615597.htmLIU Q. Numerical investigation on condensation with and without non-condensable gas[D]. Hefei: University of Science and Technology of China, 2015: 73-87(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10358-1015615597.htm [18] KNUDSEN M, PARTINGTON J R.The kinetic theory of gases:Some modern aspects[J].The Journal of Physical Chemistry, 1935, 39(2):307. http://www.worldcat.org/title/kinetic-theory-of-gases-some-modern-aspects/oclc/1806782 [19] DE SCHEPPER S C K, HEYNDERICKX G J, MARIN G B.Modeling the evaporation of a hydrocarbon feedstock in the convection section of a steam cracker[J].Computers and Chemical Engineering, 2009, 33(1):122-132. doi: 10.1016/j.compchemeng.2008.07.013 [20] LIU Z, SUNDEN B, YUAN J.VOF modeling and analysis of filmwise condensation between vertical parallel plates[J].Heat Transfer Research, 2012, 43(1):47-68. doi: 10.1615/HeatTransRes.v43.i1 [21] LEE W H. A pressure iteration scheme for two-phase flow modeling: LA-UR-79-975[R]. New Mexico: Los Alamos National Laboratory, 1979. [22] 陈国邦.低温工程材料[M].杭州:浙江大学出版社, 1998:195-201.CHEN G B.Cryogenic engineering materials[M].Hangzhou:Zhejiang University Press, 1998:195-201(in Chinese). [23] ISHⅡ M, HIBIKI T.Thermo-fluid dynamics of two-phase flow[M].Berlin:Springer, 2011:361-395. [24] 陈国邦, 黄永华, 包锐.低温流体热物理性质[M].北京:国防工业出版社, 2006:190-200.CHEN G B, HUANG Y H, BAO R.Cryogenic fluid thermos physical properties[M].Beijing:National Defense Industry Press, 2006:190-200(in Chinese). -

下载:

下载: