-

摘要:

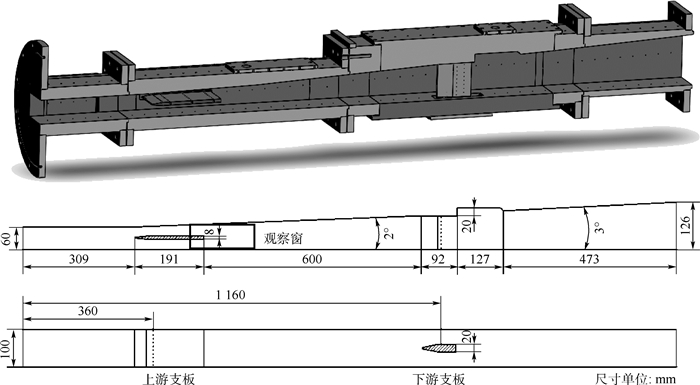

为研究分级喷注超燃冲压发动机火焰稳定、燃烧状态及火焰传播特性,以双支板超燃燃烧室为基本构型,开展了当量比连续调节试验研究。模拟低飞行马赫数5.5工况,燃烧室入口马赫数为2,总温1 436 K,试验表明:燃烧室单独上游喷注熄火当量比为0.19,该值不受下游燃烧的影响;单独下游喷注熄火当量比为0.46,上游火焰会削弱下游当量比变化对壁面压力的影响,并且会使下游熄火当量比值降低。通过调节上游当量比可实现燃烧状态的转换,转换过程存在迟滞。模拟高飞行马赫数6.5工况,燃烧室入口马赫数为3,总温1 899 K,试验表明:随着总温的增加,单独上游喷注可实现点火和稳焰,上游火焰发生抬举,燃烧室抗反压能力增强,可喷注更多燃料。

Abstract:In order to investigate the flame stabilization, combustion state and flame propagation characteristics of scramjet, based on a dual-struts supersonic combustor with staged injections, experiments with continuously adjusted equivalence ratio were conducted. Experiments with combustor inlet Mach number of 2 and total temperature of 1 436 K were conducted to simulate flight Mach number of 5.5. The results show that when injecting fuel is solely from the upstream strut, the extinction equivalence ratio is 0.19 and it is not affected by the downstream combustion. When injecting fuel is solely from the downstream strut, the extinction equivalence ratio is 0.46, and the effect of downstream equivalence ratio change on wall pressure would be reduced by upstream flame, with which the extinction equivalence ratio would be decreased. Transformation between two combustion states could be realized by adjusting the upstream equivalence ratio, and hysteresis could be observed in the transformation process. Experiments with combustor inlet Mach number of 3 and total temperature of 1 899 K were conducted to simulate flight Mach number of 6.5. The results show that as the total temperature of incoming flow increases, ignition and stable flame can be realized by fuel injection solely at the upstream strut, the upstream flame is lifted, back-pressure capability of the combustor can be strengthened, and more fuel can be injected into the flow.

-

Key words:

- scramjet /

- combustion /

- strut /

- equivalence ratio /

- hysteresis

-

表 1 入口参数

Table 1. Inlet parameters

入口参数

类别总质量流量/

(kg·s-1)模拟飞行

马赫数马赫数 总温/K 总压/MPa a 2.655 5.5 2.0 1 436 0.78 b 2.044 6.5 3.0 1 899 2.13 表 2 试验工况

Table 2. Experiment condition

工况 入口参数类别 上游当量比(线性匀速调节) 下游当量比(线性匀速调节) 当量比调节时间/s Case 1 a 0.3减少至0.1 0.7 3 Case 2 a 0 0.6减少至0.3 2 Case 3 a 0.3减少至0.1 0 3 Case 4 a 0.3减少至0.1 0.6,点火后变至0 3 Case 5 a 0.4 0.6减少至0.3,再增加至0.6 2.4 Case 6 a 0.4减少至0.1,再增加至0.4 0.7 2.4 Case 7 b 0.5减少至0.3,再增加至0.5 0 2.4 -

[1] 徐旭,陈兵,徐大军.冲压发动机原理及技术[M].北京:北京航空航天大学出版社,2014:202-204.XU X,CHEN B,XU D J.Principle and technology of ramjet[M].Beijing:Beihang University Press,2014:202-204(in Chinese). [2] ROGERS R C, CAPRIOT TI D P, GUY R W.Experimental supersonic combustion research at NASA Langley:AIAA-1998-2506[R].Reston:AIAA,1998. [3] 宋冈霖,冮强,王辽,等.碳氢燃料超燃冲压发动机支板凹腔一体化稳焰性能研究[J].推进技术,2013,34(11):1499-1506. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201311008.htmSONG G L,GANG Q,WANG L,et al. Studies of strut-cavity flameholder performance in scramjet combustor with hydrocarbon fuel[J]. Journal of Propulsion Technology,2013,34(11):1499-1506(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201311008.htm [4] TABEJAMAAT S,KOBAYASHI H,NIIOKIA T.Numerical and experimental studies of injection modeling for supersonic flame-holding[J].Journal of Propulsion and Power,2005,21(3):504-511. doi: 10.2514/1.8307 [5] 范周琴,刘卫东,林志勇,等.支板喷射超声速燃烧火焰结构实验[J].推进技术,2012,33(6):923-927. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201206015.htmFAN Z Q, LIU W D,LIN Z Y,et al. Experimental investigation of supersonic combustion flame structure with strut injectors[J].Journal of Propulsion Technology,2012,33(6):923-927(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201206015.htm [6] 苏义,刘卫东.支板阻力特性实验[J].航空动力学报,2009,24(12):2643-2648. http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200912001.htmSU Y, LIU W D.Experimental investigation on drag of strut[J].Journal of Aerospace Power,2009,24(12):2643-2648(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-HKDI200912001.htm [7] TOMIOKA S, MURAKAMIT A,KUDO K,et al.Effects of injection scheme on performance of a staged supersonic combustor:AIAA-1999-2107[R].Reston:AIAA,1999. [8] TOMIOKA S,KOBAYASHI K,KUDO K,et al.Distributed injection for performance improvement of a supersonic combustor with multi-staged wall-injections:AIAA-2003-6991[R].Reston:AIAA,2003. [9] TOMIOKA S, MURAKAMI A,KUDO K,et al.Combustion tests of a staged supersonic combustor with a strut[J].Journal of Propulsion and Power,2001,17(2):293-300. doi: 10.2514/2.5741 [10] VELLARAMKALAYIL J J,SCHEUERMANN T.Analysis of a two-staged supersonic combustion chamber using experiments and simulations:AIAA-2011-2247[R].Reston:AIAA,2011. [11] FUHRMANN S,HUPFER A,KAU H P.The investigations on multi-stage supersonic combustion in a model combustor:AIAA-2011-2332[R].Reston:AIAA,2011. [12] NAKAYA S,HIKICHI Y,NAKAZAWA Y,et al.Ignition and supersonic combustion behavior of liquid ethanol in a scramjet model combustor with cavity flame holder[J].Proceedings of the Combustion Institute,2015,35(2):2091-2099. doi: 10.1016/j.proci.2014.07.023 [13] HANDE R O,MARATHE A G.A computational study on supersonic combustion with struts as flame holder:AIAA-2008-4712[R].Reston:AIAA,2008. [14] 宗有海.基于支板喷射技术的液体碳氢燃料超声速燃烧组织研究[D].哈尔滨:哈尔滨工业大学,2013. http://cn.bing.com/academic/profile?id=d3740275a45fca37bda26c88d3046c9c&encoded=0&v=paper_preview&mkt=zh-cnZONG Y H. Combustion organization of liquid hydrocarbon fueled scramjet based on strut injection technology[D]. Harbin:Harbin Institute of Technology,2013(in Chinese). http://cn.bing.com/academic/profile?id=d3740275a45fca37bda26c88d3046c9c&encoded=0&v=paper_preview&mkt=zh-cn [15] FAN X J,YU G,LI J G. Performance of supersonic model combustors with distributed injection of supercritical kerosene:AIAA-2007-5406[R].Reston:AIAA,2007. [16] 冮强,周乐仪,覃正,等.液体碳氢燃料超燃冲压发动机支板凹槽稳焰技术试验[J].推进技术,2011,32(5):680-683. http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201105014.htmGANG Q,ZHOU L Y,QIN Z,et al.Experimental investigation of strut-cavity flameholder technology in liquid hydrocarbon fueled scramjet combustor[J].Journal of Propulsion Technology,2011,32(5):680-683(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201105014.htm -

下载:

下载: