-

摘要:

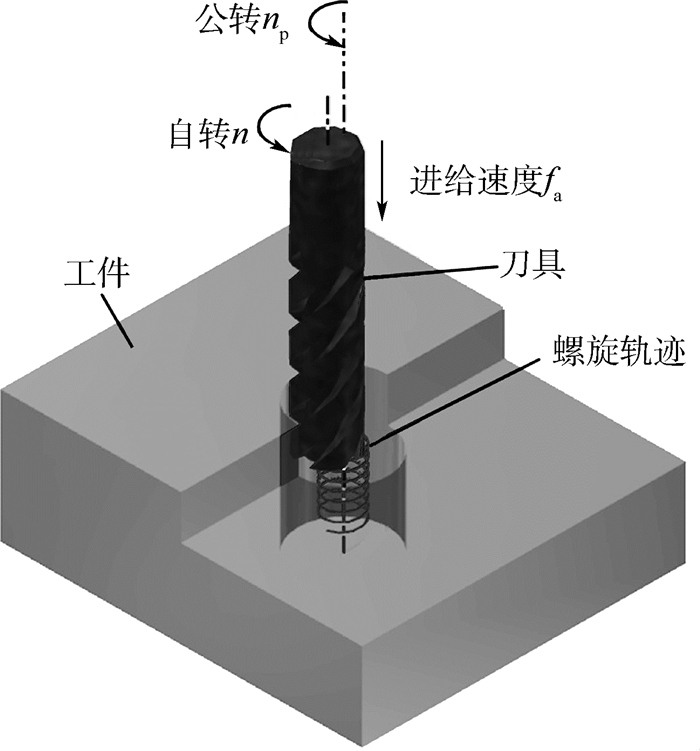

碳纤维增强环氧树脂基体(C/E)复合材料具有优异的性能,广泛用于制造飞行器结构件。在加工C/E复合材料连接孔过程中容易出现分层、撕裂等加工缺陷,而切削温度过高是导致加工缺陷的主要原因之一。螺旋铣孔作为新的制孔技术,加工C/E复合材料时表现出许多优于传统钻孔的特点,受到广泛关注。本文采用专用加工装备开展了C/E复合材料制孔试验,利用红外热像仪实时监测切削温度,分析了螺旋铣孔加工参数对切削温度的影响规律。根据螺旋铣孔运动学规律和切削原理,从未变形切屑形状特点入手分析了螺旋铣孔切削温度的来源和影响因素。研究结果可对深入理解螺旋铣孔加工机理、制定合理的螺旋铣孔加工工艺提供依据。

Abstract:Carbon/epoxy (C/E) composites are widely used in manufacture of aircraft structural components because of its excellent properties. It is easy to delaminate and tear when processing C/E composites, and the high cutting temperature is the main cause of defects. As a new hole-machining method, helical milling attracted plenty of attention owning to its advantages in processing C/E composites compared with traditional drilling. The helical milling experiments were performed with specially designed helical milling equipment on C/E composite. A thermal infrared imager is used to measure the cutting temperature after precision calibration using a thermocouple in a constant temperature oven. The effects of the processing parameters on the cutting temperature are analyzed. According to the kinematic principle of helical milling and the cutting principle, the origin and influence factor of temperature are analyzed based on the shape and size of the undeformed chip. The results are helpful in understanding the machining mechanism of helical milling, and determining the reasonable processing parameters of helical milling.

-

Key words:

- helical milling /

- C/E composites /

- cutting temperature /

- undeformed chip /

- hole-machining

-

表 1 螺旋铣孔加工参数

Table 1. Processing parameters of helical milling

加工参数 n/(r·min-1) np/(r·min-1) fa/(mm·min-1) 自转转速 3 000, 5 000, 7 000, 9 000, 11 000 60 10 公转转速 5 000 30,40,50,60 10 进给速度 5 000 30 6,8,10,12,14 表 2 温度标定结果

Table 2. Results of temperature calibration

热烘箱温度/℃ 150 175 200 225 250 热电偶测温/℃ 153.8 182.1 208.0 233.1 260.4 红外热像仪测温/℃ 157.7 182.1 206.8 230.2 254.6 热电偶及红外热像仪测温相对误差/% 2.6 0 0.6 1.2 2.2 -

[1] WHINNEM E, LIPCZYNSKI G, ERIKSSON I.Development of orbital drilling for the Boeing 787[C]//Aerospace Manufacturing and Automated Fastening Conference and Exhibition.Warrendale, PA:SAE International, 2008:811-816. [2] NI W.Orbital drilling of aerospace materials[C]//AeroTech Congress and Exhibition.Warrendale, PA:SAE International, 2007. [3] SADEK A, MESHREKI M, ATTIA M H.Characterization and optimization of orbital drilling of woven carbon fiber reinforced epoxy laminates[J].CIRP Annals-Manufacturing Technology, 2012, 61(1):123-126. doi: 10.1016/j.cirp.2012.03.089 [4] KOLOOR S S R, ABDUL-LATIF A, GONG X J, et al.Evolution characteristics of delamination damage in CFRP composites under transverse loading[M]//TAMIN M N. Damage and fracture of composite materials and structures.Berlin:Springer, 2012:17, 45-59. [5] HINTZE W, HARTMANN D.Modeling of delamination during milling of unidirectional CFRP[J].Procedia CIRP, 2013, 8:444-449. doi: 10.1016/j.procir.2013.06.131 [6] QIN X D, WANG B, WANG G, et al.Delamination analysis of the helical milling of carbon fiber-reinforced plastics by using the artificial neural network model[J].Journal of Mechanical Science and Technology, 2014, 28(2):713-719. doi: 10.1007/s12206-013-1135-2 [7] DENKENA B, BOEHNKE D, DEGE J H.Helical milling of CFRP-titanium layer compounds[J].CIRP Journal of Manufacturing Science and Technology, 2008, 1(2):64-69. doi: 10.1016/j.cirpj.2008.09.009 [8] YASHIRO T, OGAWA T, SASAHARA H.Temperature measurement of cutting tool and machined surface layer in milling of CFRP[J].International Journal of Machine Tools and Manufacture, 2013, 70:63-69. doi: 10.1016/j.ijmachtools.2013.03.009 [9] BRINKSMEIER E, FANGMANN S, RENTSCH R.Drilling of composites and resulting surface integrity[J].CIRP Annals-Manufacturing Technology, 2011, 60(1):57-60. doi: 10.1016/j.cirp.2011.03.077 [10] LIU J, CHEN G, JI C, et al.An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics (CFRP)[J].International Journal of Machine Tools and Manufacture, 2014, 86:89-103. doi: 10.1016/j.ijmachtools.2014.06.008 [11] LIU J, REN C, QIN X, et al.Prediction of heat transfer process in helical milling[J].The International Journal of Advanced Manufacturing Technology, 2014, 72(5-8):693-705. doi: 10.1007/s00170-014-5662-5 [12] BRINKSMEIER E, FANGMANN S, MEYER I.Orbital drilling kinematics[J].Production Engineering, 2008, 2(3):277-283. doi: 10.1007/s11740-008-0111-7 [13] DENKENA B.New production technologies in aerospace industry[M].5th ed.Hannover:Elsevier, 2014:137-143. [14] 张厚江.碳纤维复合材料(CFRP) 钻削加工技术的研究[D].北京:北京航空航天大学, 1998:23-29.ZHANG H J.Study on the drilling technology of CFRP[D].Beijing:Beihang University, 1998:23-29(in Chinese). [15] SAHRAIE J A, BAHR B.An analytical method for predicting cutting forces in orthogonal machining of unidirectional composites[J].Composites Science and Technology, 2010, 70(16):2290-2297. doi: 10.1016/j.compscitech.2010.09.005 [16] BHATNAGAR N, RAMAKRISHNAN N, NAIK N K, et al.On the machining of fiber reinforced plastic (FRP) composite laminates[J].International Journal of Machine Tools and Manufacture, 1995, 35(5):701-716. doi: 10.1016/0890-6955(95)93039-9 [17] 王海艳.难加工材料螺旋铣孔动力学研究[D].天津:天津大学, 2012:51-88.WANG H Y.Study on dynamics in helical milling of difficult-to-cut materials[D].Tianjin:Tianjin University, 2012:51-88(in Chinese). [18] WANG H Y, QIN X D, LI H, et al.Analysis of cutting forces in helical milling of carbon fiber-reinforced plastics[J].Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manufacture, 2013, 227(1):62-74. doi: 10.1177/0954405412464328 [19] WANG H Y, QIN X D, REN C Z, et al.Prediction of cutting forces in helical milling process[J].The International Journal of Advanced Manufacturing Technology, 2012, 58(9-12):849-859. doi: 10.1007/s00170-011-3435-y [20] WANG H Y, QIN X D.A mechanistic model for cutting force in helical milling of carbon fiber-reinforced polymers[J].The International Journal of Advanced Manufacturing Technology, 2016, 82(9):1485-1494. https://www.researchgate.net/publication/282499200_A_mechanistic_model_for_cutting_force_in_helical_milling_of_carbon_fiber-reinforced_polymers -

下载:

下载: