Zero-dimensional modeling for transient response of non-adiabatic cavity with single opening

-

摘要:

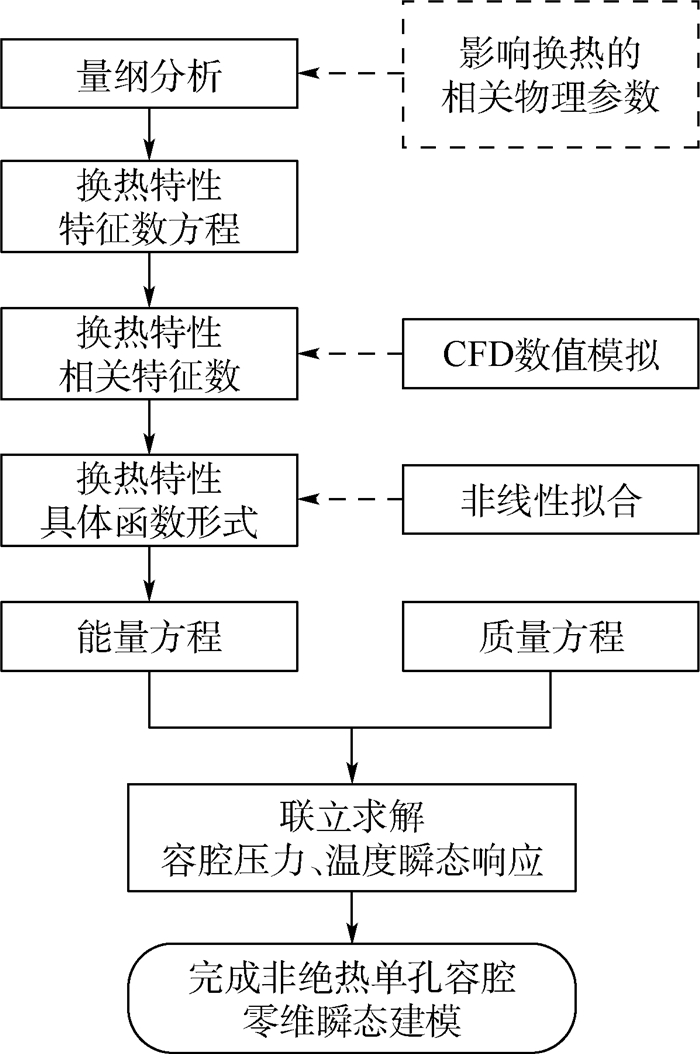

针对换热情况下理想绝热单孔容腔模型瞬态响应预测误差大的现状,提出一种考虑换热对容腔瞬态响应影响的非绝热单孔容腔零维瞬态建模方法。通过研究影响气体与容腔壁面换热的因素,采用量纲分析推导了与换热相关的特征数方程,利用CFD数值模拟确定特征数方程的具体函数形式,显示表达了绝热单孔容腔模型未考虑的换热项,建立了非绝热单孔容腔零维瞬态模型。通过与数值模拟进行对比分析,结果表明:非绝热单孔容腔零维瞬态模型与CFD数值模拟计算的压力和温度的响应规律吻合很好,最大相对误差不超过0.8%,验证了模型的准确性和建模方法的可行性;绝热单孔容腔零维瞬态模型计算结果较CFD数值模拟结果的最大相对误差达6%,表明非绝热模型较绝热模型能够更精确地反映容腔真实响应规律。此外,非绝热单孔容腔零维瞬态模型与CFD数值模拟相比,在1%的精度水平下,降低了3个维度,也大幅降低了单孔容腔瞬态响应模拟的计算量,可以有效地支撑航空发动机空气系统中的容腔高精度建模。

Abstract:With the present condition that there are errors in predicting transient response of cavity with single opening using the ideal adiabatic cavity model in the presence of heat transfer, a zero-dimensional transient modeling method applied to a single opening cavity with the consideration of the effect of heat transfer on cavity transient response was proposed. In virtue of researching the factors influencing the heat transfer between the gas and the cavity wall, the characteristic equation related to heat transfer was deduced by dimensional analysis, and the concrete function of it was determined by CFD numerical simulation. The heat transfer term which was not considered by adiabatic model of cavity with single opening was expressed explicitly, and a non-adiabatic zero-dimensional transient model of cavity with single opening was established. The model was compared with CFD simulation and the results show that:Good agreement is achieved by comparing the responses of pressure and temperature calculated by non-adiabatic zero-dimensional transient model of cavity with single opening with that calculated by CFD simulation, and the maximum relative error is no more than 0.8%. The accuracy of the model and the feasibility of the modeling method are verified; The maximum relative error between the adiabatic model of cavity with single opening and CFD simulation results is 6%, which indicates that the non-adiabatic model can reflect the real response more accurately than the adiabatic model. In addition, the non-adiabatic model reduces three dimensions within the accuracy of 1% compared with the CFD simulation, and also significantly lowers the computational cost of non-adiabatic cavity with single opening simulation, which can effectively support zero-dimensional transient modeling of cavity with high accuracy in aero-engine air system.

-

Key words:

- cavity /

- non-adiabatic /

- transient response /

- zero-dimensional model /

- heat transfer

-

表 1 参数量纲

Table 1. Dimension of parameters

参数 量纲 k ML/(ΘT3) μ M/(LT) ρi M/L3 cp L2/(ΘT2) d L ui L/T Tv Θ h M/(ΘT3) 表 2 初始边界和计算边界条件参数

Table 2. Initial boundary and computational boundary condition parameters

位置 压力/Pa 温度/K t=0 t>0 t=0 t>0 进口 101 325 191 504 288.15 288.15 壁面 323.15 323.15 腔内 101 325 323.15 -

[1] SEHRA A K, JR WHITLOW W.Propulsion and power for 21st century aviation[J].Progress in Aerospace Sciences, 2004, 40(4-5):199-235. doi: 10.1016/j.paerosci.2004.06.003 [2] 刘传凯, 李圆圆, 李艳茹, 等.涡轮轴断裂条件下空气系统强瞬变过程分析[J].北京航空航天大学学报, 2016, 42(1):47-53. http://bhxb.buaa.edu.cn/CN/abstract/abstract13672.shtmlLIU C K, LI Y Y, LI Y R, et al.Dynamic analysis of air system with fast transients in shaft failure event[J].Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(1):47-53(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract13672.shtml [3] DUTTON J C, COVERDILL R E.Experiments to study the gaseous discharge and filling of vessels[J].International Journal of Engineering Education, 1997, 13(2):123-134. https://www.researchgate.net/publication/251283119_Experiments_to_Study_the_Gaseous_Discharge_and_Filling_of_Vessels [4] THORNCROFT G, PATTON J S, GORDON R. Modeling compressible air flow in a charging or discharging vessel and assessment of polytropic exponent[C]//ASEE Annual Conference. Honolulu: ASEE, 2007: 1-18. [5] NARDINI G, PARONCINI M.Heat transfer experiment on natural convection in a square cavity with discrete sources[J].Heat and Mass Transfer, 2012, 48(11):1855-1865. doi: 10.1007/s00231-012-1026-6 [6] DENG Q H.Fluid flow and heat transfer characteristics of natural convection in square cavities due to discrete source-sink pairs[J].International Journal of Heat and Mass Transfer, 2008, 51(25-26):5949-5957. doi: 10.1016/j.ijheatmasstransfer.2008.04.062 [7] NASSAR N N, MEHROTRA A K.Design of a laboratory experiment on heat transfer in an agitated vessel[J].Education for Chemical Engineers, 2011, 6(3):83-89. doi: 10.1016/j.ece.2011.06.001 [8] OWCZAREK J A, PROGELHOF R C.Rapid discharge of a gas from a cylindrical vessel through a nozzle[J].American Institute of Aeronautics and Astronautics, 1963, 1(9):2182-2183. doi: 10.2514/3.2034 [9] CHOW W L, TING A A L, TSAI P H.Discharge from a vessel through an axisymmetric control valve[J].Journal of Applied Mechanics, 1987, 54(2):447-452. doi: 10.1115/1.3173035 [10] 陈光, 洪杰.航空燃气涡轮发动机结构[M].北京:北京航空航天大学出版社, 2010:170-171.CHEN G, HONG J.Structure of aircraft gas turbine engine[M].Beijing:Beihang University Press, 2010:170-171(in Chinese). [11] HORLOCK J H, WOODS W A. The thermodynamics of charging and discharging processes[C]//Proceedings of the Institution of Mechanical Engineers, London: IMechE, 1965, 180(310): 16-24. [12] 刘传凯, 刘海明, 李艳茹, 等.强瞬变空气系统的模块化仿真建模[J].航空动力学报, 2015, 30(8):1826-1833. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_hkdlxb201508005LIU C K, LIU H M, LI Y R, et al.Modularized simulation of air system with fast transient[J].Journal of Aerospace Power, 2015, 30(8):1826-1833(in Chinese). http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_hkdlxb201508005 [13] 潘锦珊, 单鹏.气体动力学基础[M].北京:国防工业出版社, 2011:87-90.PAN J S, SHAN P.Fundamentals of gasdynamics[M].Beijing:National Defense Industry Press, 2011:87-90(in Chinese). [14] 骆广琦, 桑增产, 王如根, 等.航空燃气涡轮发动机数值仿真[M].北京:国防工业出版社, 2007:84-86.LUO G Q, SANG Z C, WANG R G, et al.Numerical methods for aviation gas turbine engine simulation[M].Beijing:National Defense Industry Press, 2007:84-86(in Chinese). [15] 邹滋祥.相似理论在叶轮机械模型研究中的应用[M].北京:科学出版社, 1984:17-24.ZOU Z X.Application of similarity theory in turbomachinery model[M].Beijing:Science Press, 1984:17-24(in Chinese). -

下载:

下载: