Optimization of inspection and repair of multi-state system under imperfect characteristics

-

摘要:

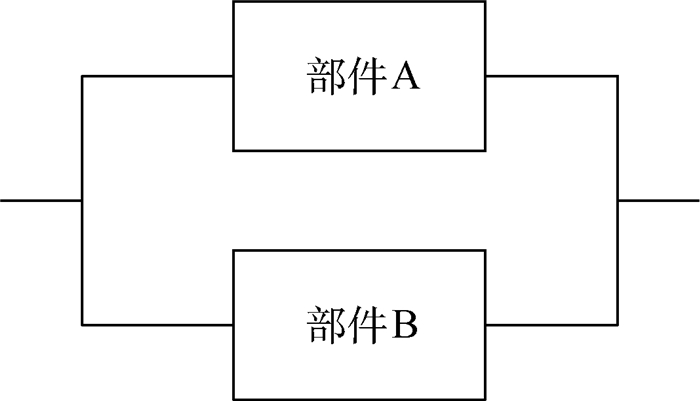

对于带有周期检测的系统进行维修优化时,不仅需要考虑系统自身可靠性信息,还应该充分利用检测数据并优化检测周期。以多状态并联可修系统为研究对象,考虑非完美检测和非完美维修,以降低系统运行成本率为目标实现系统检测和维修优化。利用非齐次马尔可夫链建立系统可靠性模型,对系统退化、检测和维修进行蒙特卡罗仿真。利用粒子滤波融合系统模型与检测数据并估计系统剩余寿命。设置寿命相关门限触发系统维修,以成本率期望仿真结果为目标函数,使用遗传算法优化检测周期和维修阈值。通过算例证明该方法可有效克服检测误差并实现检测和维修优化。

Abstract:For repair optimization of system with periodic inspection, we need to not only consider the system reliability information, but also make full use of the inspection data and optimize the inspection period. A multi-state parallel repairable system was taken as the research object, and the system inspection and repair optimization were realized considering the imperfect inspection and imperfect repair with the objective of reducing operation cost rate. System reliability model was established by non-homogeneous Markov chains, and Monte Carlo simulation was carried out for system degradation, detection and repair. Particle filter was used for fusing the system model and inspection data, and the residual life of the system was estimated. Life related thresholds used for triggering repairs were set, and simulation results of the expecting cost rate were used as the objective function for a genetic algorithm to achieve optimization of the inspection period and the thresholds. It is proved that this method can effectively overcome the inspection error and achieve the optimization of system repair and inspection.

-

Key words:

- multi-state system /

- repair optimization /

- imperfect inspection /

- particle filter /

- genetic algorithm

-

-

[1] LAI M T, CHEN Y C.Optimal periodic replacement policy for a two-unit system with failure rate interaction[J]. The International Journal of Advanced Manufacturing Technology, 2006, 29(3-4):367-371. doi: 10.1007/s00170-004-2486-8 [2] 范江川, 刘子先.基于故障相关与外部冲击的两部件系统机会维修研究[J].天津理工大学学报, 2014, 30(4):1-5. http://www.cnki.com.cn/Article/CJFDTOTAL-TEAR201404001.htmFAN J C, LIU Z X.Opportunistic replacement policy for a two-unit system with failure interaction and external shocks[J]. Journal of Tianjin University of Technology, 2014, 30(4):1-5(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TEAR201404001.htm [3] 张卓琦, 吴甦, 李斌锋.考虑故障相关的两部件系统机会维修策略[J].清华大学学报(自然科学版), 2012, 52(1):122-127. http://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201201025.htmZHANG Z Q, WU S, LI B F.Opportunistic maintenance policy for a two-unit system with failure interactions[J]. Journal of Tsinghua University(Science and Technology), 2012, 52(1):122-127(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201201025.htm [4] LISNIANSKI A, FRENKEL I, DING Y.Multi-state system reliability analysis and optimization for engineers and industrial managers[M]. New York:Springer Science & Business Media, 2010:1-7. [5] JARDINE A K, LIN D, BANJEVIC D.A review on machinery diagnostics and prognostics implementing condition-based maintenance[J]. Mechanical Systems and Signal Processing, 2006, 20(7):1483-1510. doi: 10.1016/j.ymssp.2005.09.012 [6] GRALL A, BÉRENGUER C, DIEULLE L.A condition-based maintenance policy for stochastically deteriorating systems[J]. Reliability Engineering & System Safety, 2002, 76(2):167-180. [7] WANG W, HUSSIN B, JEFFERIS T.A case study of condition based maintenance modelling based upon the oil analysis data of marine diesel engines using stochastic filtering[J]. International Journal of Production Economics, 2012, 136(1):84-92. doi: 10.1016/j.ijpe.2011.09.016 [8] YANG B S.An intelligent condition-based maintenance platform for rotating machinery[J]. Expert Systems with Applications, 2012, 39(3):2977-2988. doi: 10.1016/j.eswa.2011.08.159 [9] 成国庆, 李玲, 唐应辉.多态退化串联可修系统的最优维修更换策略[J].系统工程理论与实践, 2012, 32(5):1118-1123. doi: 10.12011/1000-6788(2012)5-1118CHENG G Q, LI L, TANG Y H.Optimal replacement policy for a deteriorating series repairable system with multi-state[J]. Systems Engineering—Theory & Practice, 2012, 32(5):1118-1123(in Chinese). doi: 10.12011/1000-6788(2012)5-1118 [10] 胡康. 基于Markov过程的多状态可维修系统可靠性建模与仿真[D]. 赣州: 江西理工大学, 2013: 10-13.HU K.Reliability modeling and simulation of multi-state repairable system based on Markov process[D]. Ganzhou:Jiangxi University of Science and Technology, 2013:10-13(in Chinese). [11] 尹晓伟, 钱文学, 谢里阳.基于贝叶斯网络的多状态系统可靠性建模与评估[J].机械工程学报, 2009, 45(2):206-212. http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200902036.htmYIN X W, QIAN W X, XIE L Y.Multi-state system reliability modeling and assessment based on Bayesian networks[J]. Journal of Mechanical Engineering, 2009, 45(2):206-212 (in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200902036.htm [12] LEVITIN G, LISNIANSKI A.Optimization of imperfect preventive maintenance for multi-state systems[J]. Reliability Engineering & System Safety, 2000, 67(2):193-203. http://www.sciencedirect.com/science/article/pii/S0951832099000678 [13] SORO I W, NOURELFATH M, AÏT-KADI D.Performance evaluation of multi-state degraded systems with minimal repairs and imperfect preventive maintenance[J]. Reliability Engineering & System Safety, 2010, 95(2):65-69. http://www.sciencedirect.com/science/article/pii/S0951832009002063 [14] LIU Y, HUANG H Z.Optimal replacement policy for multi-state system under imperfect maintenance[J]. IEEE Transactions on Reliability, 2010, 59(3):483-495. doi: 10.1109/TR.2010.2051242 [15] VLKV GVRLER, KAYA A.A maintenance policy for a system with multi-state components:An approximate solution[J]. Reliability Engineering & System Safety, 2002, 76(2):117-127. [16] HUANG C C, YUAN J.A two-stage preventive maintenance policy for a multi-state deterioration system[J]. Reliability Engineering & System Safety, 2010, 95(11):1255-1260. [17] GUO B, ZHOU W.Maintenance strategy for two-unit multi-state deteriorating systems concerned with failure interactions[C]//Prognostics and System Health Management Conference.Piscataway, NJ:IEEE Press, 2011:1-6. [18] TANG D, YU J, CHEN X, et al.An optimal condition-based maintenance policy for a degrading system subject to the competing risks of soft and hard failure[J]. Computers & Industrial Engineering, 2015, 83(C):100-110. http://www.sciencedirect.com/science/article/pii/S0360835215000509 [19] LU Z, CHEN M, ZHOU D.Periodic inspection maintenance policy with a general repair for multi-state systems[C]//Chinese Automation Congress (CAC).Piscataway, NJ:IEEE Press, 2015:2116-2121. [20] MALEFAKI S, KOUTRAS V P, PLATIS A N.Optimizing the availability and the operational cost of a periodically inspected multi-state deteriorating system with condition based maintenance policies[C]//Availability, Reliability and Security (ARES).Piscataway, NJ:IEEE Press, 2014:403-411. [21] LE M D, TAN C M.Optimal maintenance strategy of deteriorating system under imperfect maintenance and inspection using mixed inspection scheduling[J]. Reliability Engineering & System Safety, 2013, 113(1):21-29. [22] MOGHADDASS R, ZUO M J.Condition-based replacement policy for a device using interval-censored inspection data[C]//Reliability and Maintainability Symposium (RAMS), 2013 Proceedings-Annual.Piscataway, NJ:IEEE Press, 2013:1-6. [23] BROWN M, PROSCHAN F.Imperfect repair[J]. Journal of Applied Probability, 1983, 20(4):851-859. doi: 10.1017/S0021900200024153 [24] MYÖTYRI E, PULKKINEN U, SIMOLA K.Application of stochastic filtering for lifetime prediction[J]. Reliability Engineering & System Safety, 2006, 91(2):200-208. [25] CARR M J, WANG W.Modeling failure modes for residual life prediction using stochastic filtering theory[J]. IEEE Transactions on Reliability, 2010, 59(2):346-355. doi: 10.1109/TR.2010.2044607 [26] SI X S, WANG W, HU C H, et al.Remaining useful life estimation-a review on the statistical data driven approaches[J]. European Journal of Operational Research, 2011, 213(1):1-14. doi: 10.1016/j.ejor.2010.11.018 [27] CAI B, LIU Y, ZHANG Y, et al.Dynamic Bayesian networks based performance evaluation of subsea blowout preventers in presence of imperfect repair[J]. Expert Systems with Applications, 2013, 40(18):7544-7554. doi: 10.1016/j.eswa.2013.07.064 -

下载:

下载: