Defect suppression mechanism and experimental study on rotary ultrasonic-assisted drilling of CFRP

-

摘要:

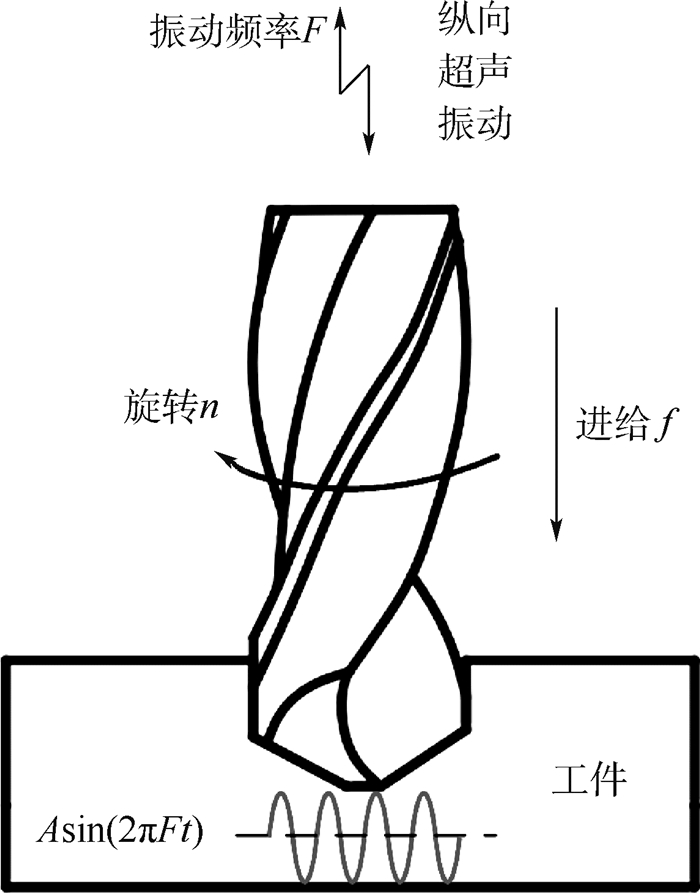

针对碳纤维增强树脂基复合材料(CFRP)在普通切削(CD)过程中因切削力及扭矩较大而产生的分层撕裂、孔壁纤维损失等缺陷,采用了旋转超声辅助钻削(RUAD)制孔方法。首先,分析了CFRP CD的孔缺陷类型及产生机理,并结合超声振动加工的特性,给出了RUAD的孔缺陷抑制机理。然后,搭建了包含非接触式感应供电旋转超声振动系统、立式加工中心和测力系统的实验平台。最后,在相同的工艺参数下,对比了CD和RUAD两种工艺下的切削力和扭矩、孔缺陷及孔壁质量。实验结果表明:相对CD,RUAD的切削力和扭矩分别降低41.46%~46.32%和41.61%~48.94%,且CFRP孔出入口及孔壁分层撕裂、纤维损失等缺陷得到了有效抑制,极大地改善了CFRP的钻孔质量。实验结果有效地验证了CFRP钻孔缺陷产生机理及超声振动抑制机理的正确性,RUAD可以用于CFRP低损伤制孔。

-

关键词:

- 碳纤维增强树脂基复合材料(CFRP) /

- 旋转超声辅助钻削(RUAD) /

- 缺陷抑制机理 /

- 切削力 /

- 孔质量

Abstract:To solve the delamination, tearing and fiber losing of carbon fiber reinforced plastic (CFRP) hole induced by large cutting force and torque during conventional drilling (CD), the rotary ultrasonic-assisted drilling (RUAD) technology is introduced. Firstly, based on the analysis of the types and forming mechanism of CFRP hole defects in CD and the characteristics of RUAD, the defect suppression mechanism of CFRP hole in RUAD is proposed. Then, the experimental platform including a self-designed contactless energy transfer and a vibration system for RUAD, vertical machining center platform and force measurement system is built. Finally, the cutting force and torque, hole defects and quality of hole wall obtained in both CD and RUAD are compared at the same process parameters, respectively. The experimental results indicate that compared with CD, the cutting force and torque produced in RUAD decrease by 41.46% to 46.32% and 41.61% to 48.94%, respectively. And the delamination, tearing and fiber losing of the CFRP hole are effectively suppressed and the hole quality is greatly improved. The forming mechanism of hole defects in CD and the defect suppression mechanism of CFRP hole in RUAD are verified to be correct by the experimental results. The research in this paper indicates that the RUAD process can be used for machining of CFRP hole with lowdamage.

-

表 1 CFRP工件材料属性

Table 1. Material properties of CFRP workpiece

属性 数值 CFRP密度/(kg·m-3) 1 520 铺层厚度/mm 0.2 碳纤维硬度HRC 53~65 碳纤维密度/(kg·m-3) 1 760 碳纤维的弹性模量/GPa 230 碳纤维的拉伸强度/GPa 4 850 碳纤维的泊松比 0.3 环氧树脂基体密度/(kg·m-3) 1 190 环氧树脂基体弹性模量/GPa 2.7 环氧树脂基体抗拉强度/MPa 80~85 环氧树脂基体泊松比 0.35 表 2 刀具几何参数

Table 2. Tool geometric parameters

参数 数值 直径/mm 7.5 总长度/mm 98 顶角/(°) 118 刃前角/(°) 10 刃后角/(°) 10 螺旋角/(°) 20 横刃宽度/mm 0.2 主切削刃宽度/mm 1 表 3 实验条件和工艺参数

Table 3. Experimental conditions and process parameters

条件与参数 CD RUAD 刀具材料 硬质合金 硬质合金 刀具涂层 无 无 冷却 无 无 钻孔直径/mm 7.5 7.5 钻孔深度/mm 5.0 5.0 主轴转速/(r·min-1) 1 500,2 000,2 500, 3 000 1 500,2 000,2 500, 3 000 每转进给量/(mm·r-1) 0.01 0.01 频率/kHz 0 18.687 振幅/μm 0 10.0 -

[1] 冉治国, 燕瑛, 李剑峰, 等.复合材料板件热分层分析及实验验证[J].北京航空航天大学学报, 2014, 40(6):819-823. http://www.cqvip.com/QK/90750X/201406/661695485.htmlRAN Z G, YAN Y, LI J F, et al.Thermal stress induced composite laminate delamination analysis and experiment verification[J].Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(6):819-823(in Chinese). http://www.cqvip.com/QK/90750X/201406/661695485.html [2] 南成根, 吴丹, 马信国, 等.碳纤维复合材料/钛合金叠层钻孔质量研究[J].机械工程学报, 2016, 52(11):177-185. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxgcxb201611023NAN C G, WU D, MA X G, et al.Study on the drilling quality of carbon fiber reinforced plastic and titanium stacks[J].Journal of Mechanical Engineering, 2016, 52(11):177-185(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxgcxb201611023 [3] XU J, MANSORI M E.Experimental study on drilling mechanisms and strategies of hybrid CFRP/Ti stacks[J].Composite Structures, 2016, 157:461-482. doi: 10.1016/j.compstruct.2016.07.025 [4] PARK K Y, CHOI J H, LEE D G.Delamination-free and high efficiency drilling of carbon fiber reinforced plastics[J].Journal of Composite Materials, 1995, 29(15):1988-2002. doi: 10.1177/002199839502901503 [5] SLOAN J.Skinning the F-35 fighter[J].High Performance Composites, 2009, 17(6):30. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Open J-Gate000002122493 [6] 王巍.CFRP加工工具研制及加工工艺研究[D].南京: 南京航空航天大学, 2012: 25-30. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=D281251WANG W.Development of the cutting tools for CFRP and research on machining technology[D].Nanjing: Nanjing University of Aeronautics and Astronautics, 2012: 25-30(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=D281251 [7] LIU D F, TANG Y J, CONG W L.A review of mechanical drilling for composite laminates[J].Composite Structures, 2012, 94(4):1265-1279. doi: 10.1016/j.compstruct.2011.11.024 [8] DAVIM J P, RUBIO J C, ABRAO A M.A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates[J].Composites Science & Technology, 2007, 67(9):1939-1945. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=01799e8cb52f46237f530920cda591c3 [9] GENG D, ZHANG D, LI Z, et al.Feasibility study of ultrasonic elliptical vibration-assisted reaming of carbon fiber reinforced plastics/titanium alloy stacks[J].Ultrasonics, 2017, 75:80-90. doi: 10.1016/j.ultras.2016.11.011 [10] GENG D, ZHANG D, XU Y, et al.Rotary ultrasonic elliptical machining for side milling of CFRP:Tool performance and surface integrity[J].Ultrasonics, 2015, 59(4):128-137. http://cn.bing.com/academic/profile?id=6109d6eeb7338c07b9d6f4bbeda1f5e5&encoded=0&v=paper_preview&mkt=zh-cn [11] GENG D, ZHANG D, XU Y, et al.Effect of speed ratio in edge routing of CFRP by rotary ultrasonic elliptical machining[J].Journal of Reinforced Plastics and Composites, 2015, 34(21):1779-1790. doi: 10.1177/0731684415597483 [12] 康仁科, 马付建, 董志刚, 等.难加工材料超声辅助切削加工技术[J].航空制造技术, 2012(16):44-49. doi: 10.3969/j.issn.1671-833X.2012.16.006KANG R K, MA F J, DONG Z G, et al.Ultrasonic assisted machining of difficult-to-cut material[J].Aeronautical Manufacturing Technology, 2012(16):44-49(in Chinese). doi: 10.3969/j.issn.1671-833X.2012.16.006 [13] GAITONDE V N, KARNIK S R, RUBIO J C, et al.Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites[J].Journal of Materials Processing Technology, 2008, 203(1):431-438. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5f590016904cc12706ec12e62c7475a4 [14] 张厚江, 陈五一, 陈鼎昌.碳纤维复合材料(CFRP)钻孔出口缺陷的研究[J].机械工程学报, 2004, 40(7):150-155. doi: 10.3321/j.issn:0577-6686.2004.07.031ZHANG H J, CHEN W Y, CHEN D C.Investigation of the exit defects in drilling CFRP[J].Journal of Mechanical Engineering, 2004, 40(7):150-155(in Chinese). doi: 10.3321/j.issn:0577-6686.2004.07.031 [15] PUJANA J, RIVERO A, CELAYA A.Analysis of ultrasonic-assisted drilling of Ti6Al4V[J].International Journal of Machine Tools and Manufacture, 2009, 49(6):500-508. doi: 10.1016/j.ijmachtools.2008.12.014 [16] CHEN W C.Some experimental investigations in the drilling of carbon fiber reinforced plastic (CFRP) composite laminates[J].International Journal of Machine Tools and Manufacture, 1997, 37:1097-1108. doi: 10.1016/S0890-6955(96)00095-8 [17] ZHANG D Y, WANG L J.Investigation of chip in vibration drilling[J].International Journal of Machine Tools and Manufacture, 1998, 38(3):165-176. doi: 10.1016/S0890-6955(97)00047-3 [18] AZARHOUSHANG B, AKBARI J.Ultrasonic-assisted drilling of inconel 738-LC[J].International Journal of Machine Tools and Manufacture, 2007, 47(7-8):1027-1033. doi: 10.1016/j.ijmachtools.2006.10.007 [19] ZHANG D Y, FENG X J, WANG L J, et al.Study on the drill skidding motion in ultrasonic vibration microdrilling[J].International Journal of Machine Tools and Manufacture, 1994, 34(6):847-857. doi: 10.1016/0890-6955(94)90064-7 [20] BAGHLANI V, MEHBUDI P, AKBARI J, et al.Ultrasonic assisted deep drilling of inconel 738LC superalloy[J].Procedia CIRP, 2013, 6:571-576. doi: 10.1016/j.procir.2013.03.096 [21] MAKHDUM, PHADNIS V A, ROY A, et al.Effect of ultrasonically-assisted drilling on carbon-fibre-reinforced plastics[J].Journal of Sound and Vibration, 2014, 333(23):5939-5952. doi: 10.1016/j.jsv.2014.05.042 [22] PHADNIS V A, MAKHDUM F, ROY A, et al.Experimental and numerical investigations in conventional and ultrasonically assisted drilling of CFRP laminate[J].Procedia CIRP, 2012, 1(7):455-459. http://cn.bing.com/academic/profile?id=db8771a94eefbdbeccb4ca98c8b67b4e&encoded=0&v=paper_preview&mkt=zh-cn [23] 余婷.CFRP材料的超声振动辅助铣削和钻孔实验研究[D].南昌: 南昌航空大学, 2018. http://cdmd.cnki.com.cn/Article/CDMD-10406-1018816826.htmYU T.Ultrasonic vibration-aided milling and drilling of CFRP materials[D].Nanchang: Nanchang Hangkong University, 2018(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10406-1018816826.htm [24] LI Z, ZHANG D Y, QIN W, et al.Removal analyses of chip and rod in rotary ultrasonic-assisted drilling of carbon fiber-reinforced plastics using core drill[J].Journal of Reinforced Plastics and Composites, 2016, 35(15):1173-1190. doi: 10.1177/0731684416644510 [25] 邵振宇, 李哲, 张德远, 等.钛合金旋转超声辅助钻削的钻削力和切屑研究[J].机械工程学报, 2017, 53(19):66-72. http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201719008SHAO Z Y, LI Z, ZHANG D Y, et al.Study on the thrust force and chip in rotary ultrasonic-assisted drilling of titanium alloys (Ti6Al4V)[J].Journal of Mechanical Engineering, 2017, 53(19):66-72(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201719008 [26] 李哲, 张德远, 姜兴刚.钛合金旋转超声辅助钻削的出口毛刺[J].北京航空航天大学学报, 2017, 43(7):1380-1386. http://d.old.wanfangdata.com.cn/Periodical/bjhkhtdxxb201707013LI Z, ZHANG D Y, JIANG X G.Exit burr in rotary ultrasonic-assisted drilling of titanium alloys[J].Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(7):1380-1386(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/bjhkhtdxxb201707013 -

下载:

下载: