Sensitive parameters affecting performance of three-petal high-speed floating-ring seal

-

摘要:

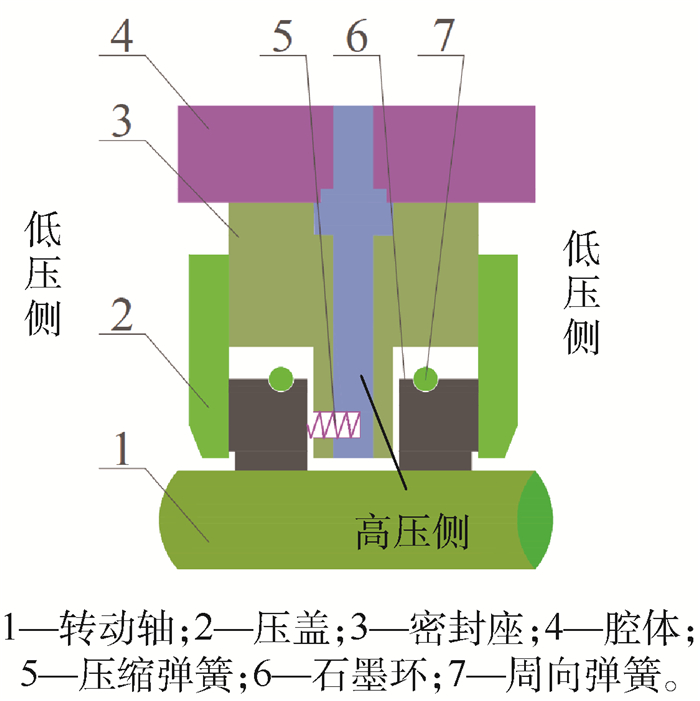

针对应用在液体火箭发动机上的三瓣式高速浮环密封(TFRS),揭示密封在复杂多变工况下的泄漏特性和磨损特性,得到影响密封特性的敏感参数,促进高速密封技术的发展。针对压力、转速和密封周向弹簧比压等关键敏感参数,数值模拟了密封的泄漏率变化规律,试验测量了密封环的泄漏率和磨损率。研究结果表明:泄漏率和磨损率都随压力增大而增大;转速对三瓣式高速浮环密封磨损率敏感,对密封泄漏率不敏感,随着转速的增加,磨损率增大较快,泄漏率减小较慢;随着密封周向弹簧比压的增大,前期密封周向弹簧比压对泄漏率敏感,此时泄漏率变化幅度较大,磨损率变化幅度较小,后期密封周向弹簧比压对磨损率敏感,此时磨损率变化幅度较大,泄漏率变化幅度较小,密封周向弹簧比压在适当范围内时,泄漏率和磨损率都较小。研究结果为液体火箭发动机三瓣式高速浮环密封的设计、实际应用和深入研究提供了基础。

Abstract:In view of the three-petal high-speed floating-ring seal (TFRS) applied in liquid rocket engine, the leakage and wear characteristics of the seal under complex and changeable conditions are revealed, and the sensitive parameters affecting the sealing characteristics are obtained, which promotes the development of high-speed seal technology. According to the key parameters of pressure, rotational speed and circumferential spring specific pressure of the seal, the leakage rate of TFRS was simulated numerically, and the leakage rate and wear rate of TFRS were measured experimentally. The analysis results show that the leakage rate and wear rate increase with the increase of pressure. Speed is sensitive to TFRS wear rate and insensitive to TFRS leakage rate. With the increase of speed, wear rate increases rapidly and leakage rate decreases slowly. With the increase of spring specific pressure of the seal, the earlier spring specific pressure of the seal are the sensitive parameters affecting the leakage rate. At this time, the leakage rate changes greatly and the wear rate changes slightly. The later spring specific pressure of the seal are the sensitive parameters affecting the wear rate. At this time, the wear rate changes greatly and the leakage rate changes slightly. The leakage rate and wear rate are smaller in the appropriate range of spring specific pressure of the seal. The research results provide a basis for the design, application and in-depth study of TFRS for liquid rocket engines.

-

Key words:

- engine /

- floating-ring seal /

- leakage /

- wear /

- numerical simulation /

- experiment analysis

-

表 1 结构参数

Table 1. Structure parameters

结构参数 数值 周向弹簧槽径/mm 35 瓣环内径/mm 23 瓣环外径/mm 37 瓣环宽度/mm 6 单瓣角度/(°) 118 分瓣数量 3 注:内槽类型为正弦曲线环形沟槽;连接方式为榫形搭接。 表 2 操作参数

Table 2. Operation parameters

操作参数 数值 进口压力pi/MPa 0~0.4 出口压力po/MPa 0 介质温度/K 295 密度/(kg·m-3) 1.197 黏度/(Pa·s) 1.82×10-5 转速n/(r·min-1) 0~27 000 注:介质为空气。 -

[1] OIKE M, NOSAKA M, KIKUCHI M, et al.Performance of a shaft seal system for the LE-7 rocket engine oxidizer turbopump[C]//International Symposium on Space Technology and Science.Kagoshima: Space Technology and Science, 1992: 143-154. [2] NOSAKA M, OIKE M.Shaft seals of turbopumps for rockets[J].Journal of Tribology, 1990, 35(4):411-421. [3] OIKE M, NOSAKA M, KIKUCHI M, et al.Performance of a segmented circumferential seal for a liquid oxygen turbopump[J].Journal of Tribology, 1992, 37(4):511-523. [4] OIKE M, NOSAKA M, WATANABE Y, et al.Experimental study on high-pressure gas seals for a liquid oxygen turbopump[J].ASLE Transactions, 1988, 31(1):91-97. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1080/10402008808981803 [5] OIKE M, WATANABE Y, KIKUCTI M, et al.Sealing characteristics of a carbon segmented circumferential seal for a liquid oxygen turbopump[J].Technical Report of National Aerospace Laboratory, 1992, 1155:1-15. http://adsabs.harvard.edu/abs/1991STIN...9312364O [6] TRAN H, HASELBACHER P.High-performance lift augmentation dynamic seals for turbine bearing compartments[J].Sealing Technology, 2004, 2004(1):5-10. doi: 10.1016/S1350-4789(04)00187-4 [7] DUAN W B, CHU F L, KIM C H, et al.A bulk-flow analysis of static and dynamic characteristics of floating ring seals[J].Tribology International, 2007, 40(3):470-478. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=9e65712e25498fa5ee236f992bfcb113 [8] BALAKH L Y, NIKIFOROV A N.The reduction of the vibration level in high-speed rotor systems by means of floating seal rings[J].Journal of Machinery Manufacture and Reliability, 2013, 42(4):276-280. doi: 10.3103/S105261881304002X [9] MEL'NIK V.Calculation of the characteristics of seals with floating rings[J].Chemical and Petroleum Engineering, 2013, 49(7-8):542-548. doi: 10.1007/s10556-013-9790-9 [10] ARGHIR M, MARIOT A.Theoretical analysis of the static characteristics of the carbon segmented seal[J].Journal of Tribology, 2016, 139(6):42-56. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bb9bfa97b4838e4882a2db8800c9fc2a [11] 王飞, 刘向锋, 刘莹.浅槽环瓣型浮动环密封的性能分析[J].润滑与密封, 2005(6):74-76. doi: 10.3969/j.issn.0254-0150.2005.06.024WANG F, LIU X F, LIU Y.Performance analysis of the shallow slot split floating ring seal[J].Lubrication Engineering, 2005(6):74-76(in Chinese). doi: 10.3969/j.issn.0254-0150.2005.06.024 [12] 王飞, 刘向锋, 刘莹.浅槽环瓣型浮动环密封的参数优化[J].润滑与密封, 2006(2):105-107. doi: 10.3969/j.issn.0254-0150.2006.02.033WANG F, LIU X F, LIU Y.Parameters optimization of the shallow-slot split floating ring seal[J].Lubrication Engineering, 2006(2):105-107(in Chinese). doi: 10.3969/j.issn.0254-0150.2006.02.033 [13] 苏令.新型浅槽环瓣型浮动环密封综合性能分析及软件开发[D].北京: 清华大学, 2006.SU L.Performance analysis and software development of a new shallow-slot split floating ring seal[D].Beijing: Tsinghua University, 2006(in Chinese). [14] 苏令, 刘向锋, 刘莹.浅槽环瓣型浮动环密封的动态特性分析[J].润滑与密封, 2007, 32(1):105-107. doi: 10.3969/j.issn.0254-0150.2007.01.032SU L, LIU X F, LIU Y.Dynamic characteristic analysis of the shallow slot-split floating ring seal[J].Lubrication Engineering, 2007, 32(1):105-107(in Chinese). doi: 10.3969/j.issn.0254-0150.2007.01.032 [15] 丁少鹏, 白少先.气体润滑环瓣式浮动环密封高速特性[J].润滑与密封, 2016, 41(7):43-47. doi: 10.3969/j.issn.0254-0150.2016.07.007DING S P, BAI S X.Behavior of a gas lubricated split floating ring seal operating at high speed[J].Lubrication Engineering, 2016, 41(7):43-47(in Chinese). doi: 10.3969/j.issn.0254-0150.2016.07.007 [16] 夏鹏, 刘占生.浮环密封结构弹性对间隙泄漏量和动力学系数的影响[J].推进技术, 2017, 38(12):2815-2821. http://d.old.wanfangdata.com.cn/Periodical/tjjs201712021XIA P, LIU Z S.Effects of structure elasticity on leakage and rotor dynamic coefficients of floating ring seals[J].Journal of Propulsion Technology, 2017, 38(12):2815-2821(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/tjjs201712021 [17] 夏鹏, 王祥和, 刘占生, 等.CFD优化火箭涡轮泵间隙密封静动态特性计算模型[J].推进技术, 2017, 38(7):1603-1609. http://d.old.wanfangdata.com.cn/Periodical/tjjs201707021XIA P, WANG X H, LIU Z S, et al.CFD optimized calculation of static and dynamic characteristics for annular seals in rocket turbo pumps[J].Propulsion Technology, 2017, 38(7):1603-1609(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/tjjs201707021 [18] 刘占生, 夏鹏, 张广辉, 等.浮环密封运动机理及对轴系稳定性的影响[J].振动与冲击, 2016, 35(9):110-116. http://d.old.wanfangdata.com.cn/Periodical/zdycj201609017LIU Z S, XIA P, ZHANG G H, et al.Floating ring seals movement mechanism and its influence on stability of a rotor system[J].Journal of Vibration and Shock, 2016, 35(9):110-116(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/zdycj201609017 [19] 沈文金, 叶小强.深度变推发动机浮动环工作适应性研究[J].火箭推进, 2017, 43(5):28-33. doi: 10.3969/j.issn.1672-9374.2017.05.005SHEN W J, YE X Q.Investigation for working adaptability of floating ring seals in deep throttling engines[J].Journal of Rocket Propulsion, 2017, 43(5):28-33(in Chinese). doi: 10.3969/j.issn.1672-9374.2017.05.005 [20] 马利军, 李双喜, 蔡纪宁, 等.高温镶装式浮环密封的径向间隙研究[J].润滑与密封, 2018, 43(6):90-95. doi: 10.3969/j.issn.0254-0150.2018.06.017MA L J, LI S X, CAI J N, et al.Research on radial clearance of high temperature mounted floating ring seal[J].Lubrication Engineering, 2018, 43(6):90-95(in Chinese). doi: 10.3969/j.issn.0254-0150.2018.06.017 [21] 邓强国, 宋鹏云, 毛文元, 等.气体黏度与温度和压力关系的拟合表达式[J].排灌机械工程学报, 2017, 35(2):144-151. http://d.old.wanfangdata.com.cn/Periodical/pgjx201702010DENG Q G, SONG P Y, MAO W Y, et al.Fitting expression of relationship between gas viscosity and temperature and/or pressure[J].Journal of Drainage and Irrigation Machinery Engineering, 2017, 35(2):144-151(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/pgjx201702010 -

下载:

下载: