-

摘要:

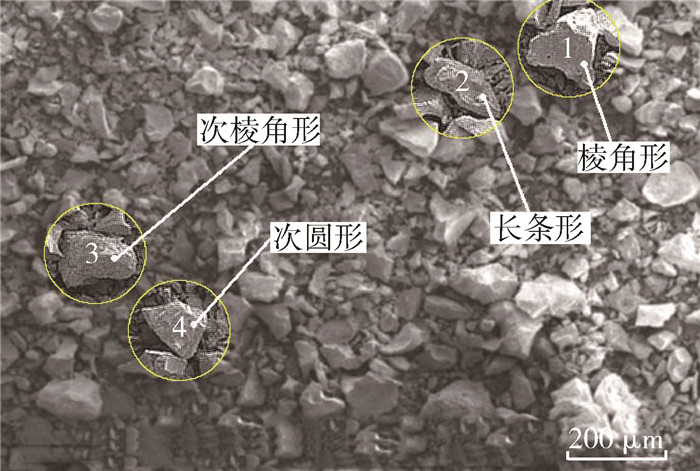

空基激光选区熔化(SLM)技术与原位资源利用(ISRU)概念结合,有望解决地外大规模基地建设的工程难题。SLM铺粉过程对成形件性能和质量有重要影响。基于非球形粒子叠加球模型方法,建立模拟月壤颗粒几何模型;基于线性弹簧-阻尼接触作用模型、Hamaker理论及牛顿运动定律,建立颗粒动力学模型;采用三维离散单元方法(DEM)及软球模型,进行不同工况下模拟月壤在铺粉过程中的流变特性研究。结果显示:所提模型和方法能开展指定工况和环境参数的模拟月壤颗粒系统流动性和堆积行为数值仿真研究;月面低重力环境导致粉床表面粗糙度变大、堆积密度和平均配位数变小;通过降低铺粉速度和优化刮刀型面,可以有效改善月基铺粉的粉床质量,获得更密实和均匀的粉床结构。

-

关键词:

- 月球探测 /

- 模拟月壤 /

- 增材制造 /

- 离散单元方法(DEM) /

- 叠加球模型

Abstract:Spaced-based Selective Laser Melting (SLM) technique in combination with In-Situ Resource Utilization (ISRU) concept can be an off-world manufacturing solution to the significant engineering challenge on the large-scale construction for extra-terrestrial bases. Powder spreading process in SLM has a major impact on the characteristics and quality of final part. The geometric shape of the lunar regolith simulant particles was modeled by means of a non-spherical particle superposition model method. The particle's dynamic model was established based on linear spring-damping contact model, Hamaker theory and Newton's laws of motion. A three-dimensional Discrete Elemeat Method (DEM) technique with soft-sphere approach was employed to investigate the rheological behavior of the lunar regolith simulant powder during spreading process under various conditions. The results show that the proposed model and method can be used to study the flowability and packing behavior of lunar regolith simulant powder system as a function of process and environmental condition parameters. Lunar reduced gravity leads to larger values of surface roughness and smaller values of packing density and averaged coordination number of powder bed; the quality of lunar regolith simulant powder bed during spreading process under lunar gravity can be improved by reducing spreading speed and geometrically optimizing blade type spreader profile, resulting in a denser and more uniform powder bed.

-

表 1 模拟月壤DEM模型参数

Table 1. DEM model parameters for lunar regolith simulant

参数 数值 颗粒密度ρp/(kg·m-3) 2770 法向弹簧刚度kn/(N·m-1) 1×105 切向弹簧刚度ks/(N·m-1) 1×105 法向阻尼系数cn 0.7 切向阻尼系数cs 0.7 摩擦系数μp 0.3 -

[1] SANDERS G B, LARSON W E, PICARD M.Development and demonstration of sustainable surface infrastructure for Moon/Mars exploration[C]//62nd International Astronautical Congress, 2011: JSC-CN-24659. [2] FATERI M, GEBHARDT A.Experimental investigation of selective laser melting of lunar regolith for in-situ applications[C]//International Mechanical Engineering Congress and Exposition.New York: ASME, 2013: IMECE2013-64334. [3] HAFLEY R A.Electron beam free-form fabrication in the space environment[C]//Aerospace Sciences Meeting and Exhibit.Reston: AIAA, 2007: 8-11. [4] PRATER T, WERKHEISER N, LEDBETTER F.3D printing in zero G technology demonstration mission:Complete experimental results and summary of related material modeling efforts[J].International Journal of Advanced Manufacturing Technology, 2019, 101(1-4):391-417. doi: 10.1007/s00170-018-2827-7 [5] WERKHEISER N.In-space manufacturing: 3D printing in space technology demonstration[C]//National Space & Missile Materials Symposium, 2015: M15-4685. [6] CECCANTI F, DINI E, KESTELIER X D, et al.3D printing technology for a Moon outpost exploiting lunar soil[C]//61st International Astronautical Congress, 2010: 8812-8820. [7] CESARETTI G, DINI E, DE KESTELIER X, et al.Building components for an outpost on the lunar soil by means of a novel 3D printing technology[J].Acta Astronautica, 2014, 93:430-450. doi: 10.1016/j.actaastro.2013.07.034 [8] BALLA V K, ROBERSON L B, OCONNOR G W, et al.First demonstration on direct laser fabrication of lunar regolith parts[J].Rapid Prototyping Journal, 2012, 18(6):451-457. doi: 10.1108/13552541211271992 [9] FATERI M, GEBHARDT A.Process parameters development of selective laser melting of lunar regolith for on-site manufacturing applications[J].International Journal of Applied Ceramic Technology, 2015, 12(1):46-52. doi: 10.1111/ijac.12326 [10] GOULAS A, BINNER J G P, HARRIS R A, et al.Assessing extraterrestrial regolith material simulants for in-situ resource utilization based 3D printing[J].Applied Materials Today, 2017, 6:54-61. doi: 10.1016/j.apmt.2016.11.004 [11] GERDESL N, FOKKEN G, LINKE S, et al.Selective laser melting for processing of regolith in support of a lunar base[J].Journal of Laser Applications, 2018, 30(3):032018. doi: 10.2351/1.5018576 [12] GU D, MEINERS W, WISSENBACH K, et al.Laser additive manufacturing of metallic components:Materials, processes and mechanisms[J].International Materials Reviews, 2012, 57(3):133-164. doi: 10.1179/1743280411Y.0000000014 [13] ZIEGELMEIER S, CHRISTOU P, WOLLECKE F, et al.An experimental study into the effects of bulk and flow behaviour of laser sintering polymer powders on resulting part properties[J].Journal of Materials Processing Technology, 2015, 215(1):239-250. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ce183528b4274bcf3edafc50d5197fc7 [14] ZOHDI T I.Rapid simulation of laser processing of discrete particulate materials[J].Archives of Computational Methods in Engineering, 2013, 20(4):309-325. doi: 10.1007/s11831-013-9092-6 [15] XIANG Z W, YIN M, DENG Z, et al.Simulation of forming process of powder bed for additive manufacturing[J].Journal of Manufacturing Science and Engineering, 2016, 138(8):081002-1-081002-9. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fe46e3c239e7125b2434a6c71afea2cd [16] CHEN H, WEI Q, WEN S, et al.Flow behavior of powder particles in layering process of selective laser melting:Numerical modeling and experimental verification based on discrete element method[J].International Journal of Machine Tools and Manufacture, 2017, 123:146-159. doi: 10.1016/j.ijmachtools.2017.08.004 [17] PARTELI E J, POSCHEL T.Particle-based simulation of powder application in additive manufacturing[J].Powder Technology, 2016, 288:96-102. doi: 10.1016/j.powtec.2015.10.035 [18] HAERI S, WANG Y, GHITA O, et al.Discrete element simulation and experimental study of powder spreading process in additive manufacturing[J].Powder Technology, 2017, 306:45-54. doi: 10.1016/j.powtec.2016.11.002 [19] HAERI S.Optimisation of blade type spreaders for powder bed preparation in additive manufacturing using DEM simulations[J].Powder Technology, 2017, 321:94-104. doi: 10.1016/j.powtec.2017.08.011 [20] LI W, HUANG Y, CUI Y, et al.Trafficability analysis of lunar mare terrain by means of the discrete element method for wheeled rover locomotion[J].Journal of Terramechanics, 2010, 47(3):161-172. doi: 10.1016/j.jterra.2009.09.002 [21] HUANG Y, LU X, ZHAO R, et al.Three dimensional simulation of lunar dust levitation under the effect of simulated sphere body[J].Journal of Terramechanics, 2011, 48(4):297-306. doi: 10.1016/j.jterra.2011.06.005 [22] HUANG Y, ZHAO R, LI W, et al.Radiative characteristics of nonspherical particles based on a particle superposition model[J].Journal of Geophysical Research, 2013, 118(20):762-769. http://adsabs.harvard.edu/abs/2013JGRD..11811762H [23] RENZO A D, MAIO F P.Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes[J].Chemical Engineering Science, 2004, 59(3):525-541. doi: 10.1016/j.ces.2003.09.037 [24] JOHNSON K L, GREENWOOD J A.An adhesion map for the contact of elastic spheres[J].Journal of Colloid and Interface Science, 1997, 192(2):326-333. doi: 10.1006/jcis.1997.4984 [25] GOTZINGER M, PEUKERT W.Dispersive forces of particle-surface interactions:Direct AFM measurements and modelling[J].Powder Technology, 2003, 130(1-3):102-109. doi: 10.1016/S0032-5910(02)00234-6 [26] ISRAELACHVILI J N.Intermolecular and surface forces[M].2nd ed.Salt Lake City:Academic Press, 1992. [27] POPEL S I, ZELENYI L M, GOLUB A P, et al.Lunar dust and dusty plasmas:Recent developments, advances, and unsolved problems[J].Planetary and Space Science, 2018, 156:71-84. doi: 10.1016/j.pss.2018.02.010 -

下载:

下载: