Hydrodynamic lubrication characteristics of piston ring gap under high pressure and high shear rate

-

摘要:

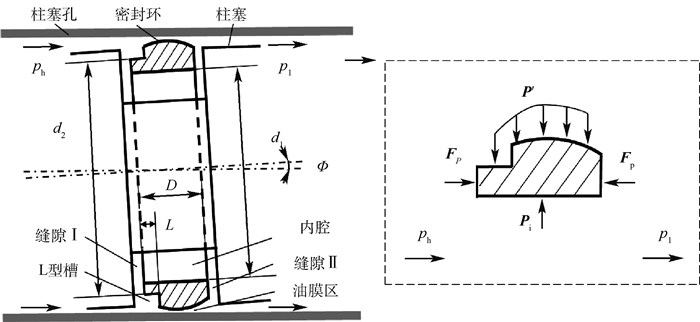

为减少高压高剪切率下热效应对密封环缝隙流体润滑性能的影响,以密封环缝隙流体剪切速度梯度、壁面剪切应力和油膜温升表征摩擦副润滑性能,采用RNG

k-ε 湍流模型,通过Workbench建立流-固-热多场模型,计算得到不同主轴转角下缝隙流动形态变化规律和温升前后油膜厚度变化量、不同L型槽内外径比及长径比下流速流型分布规律、壁面剪切应力、温度分布和热变形量。研究结果表明:密封环L型槽黏性底层随剪切速度增大而增厚,油膜厚度随运动周期增加而变薄;当L型槽内外径比小于1.07时,随比值减小密封环壁面剪切应力不断增大,最大变化率为7%;密封环L型槽长径比在0.19时平均壁面剪切应力达到最大,当长径比继续增大时,油膜区剪切速度梯度逐渐减小,油膜温升和热变形亦随之减小。研究结果可为马达优化以减少能量损失和改善密封环润滑条件提供理论指导和依据。Abstract:In order to reduce the thermal effect on the lubrication performance of piston ring under high pressure and high shear rate, the friction pair lubrication performance is characterized by the shear velocity gradient, the wall shear stress and the oil film temperature rise. RNG

k-ε turbulence model is used and the fluid-solid-thermal multi-physics model is established through Workbench to calculate the change rule of gap flow pattern, the film thickness change before and after temperature rise, the flow velocity and pattern distribution rule, wall shear stress, temperature distribution and thermal deformation under different L-shaped groove internal and external diameter ratio and length-to-diameter ratio. The results show that the L-groove viscous bottom layer thickens with the increase of shear speed, and the oil film thickness becomes thinner with the increase of motion period.When the ratio of the internal diameter to the external diameter of the L-groove is less than 1.07, the shear stress increases as the ratio decreases, and the maximum change rate is 7%.The average shear stress of the piston ring reaches the maximum when the length-to-diameter ratio is 0.19. If the ratio continues to increase, the oil film temperature rise and thermal deformation decrease as the velocity gradient decreases. The research results can provide theoretical guidance and basis for the optimization of motor to reduce energy loss and improve the lubrication condition of piston ring. -

表 1 密封环参数设定

Table 1. Parameter setting of piston ring

参数 取值范围 L型槽长L/密封环宽度D 0.13~0.27 L型槽外径d2/密封环内径d1 1.03~1.08 密封环密度ρm/(kg·m-3) 7 801 弹性模量E/MPa 2.07×105 泊松比ε 0.29 表 2 密封环工况条件

Table 2. Working condition of piston ring

环境参数 数值 初始缝隙高度δ0/μm 10 工作压差Δ P/MPa 35 剪切速度vx/(m·s-1) 6 负载/(N·m) 889 进油温度Ti/℃ 45 Fe热膨胀系数/℃ 1.0×10-5 初始润滑油黏度μ0/(mm2·s-1) 68 表 3 不同长径比下密封环的变形量与润滑特性

Table 3. Deformation and lubrication characteristics of piston ring under different length-to-diameter ratio

L/D 三维模型 最大变形/μm 最大应力/MPa 最小油膜厚度/μm 0.13

2.62 159 0.8 0.16

2.69 164 0.75 0.19

2.76 169 0.70 0.22

2.71 165 0.73 0.25

2.65 159 0.76 0.27

2.59 154 0.79 -

[1] 汤何胜, 訚耀保, 李晶, 等. 计及表面变形的轴向柱塞泵滑靴副热流体动力润滑分析[J]. 机械工程学报, 2017, 53(4): 168-176. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201704023.htmTANG H S, YIN Y B, LI J, et al. Thermo-hydrodynamic lubrication analysis of slipper pair in axial piston pump considering surface deformation[J]. Journal of Mechanical Engineering, 2017, 53(4): 168-176(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201704023.htm [2] 尹延国, 邢大淼, 尤涛, 等. 基于有限元法的面接触摩擦热流分配系数反推研究[J]. 摩擦学学报, 2012, 32(6): 592-598. https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201206011.htmYIN Y G, XING D M, YOU T, et al. Back-calculation of heat transfer coefficient of surface contact friction surface based on finite element method[J]. Journal of Tribology, 2012, 32(6): 592-598(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201206011.htm [3] HOUG G R. Drag characteristics of V-groove and transverse curvature riblets[J]. AIAA, 1980, 72(3): 168-184. doi: 10.2514/5.9781600865466.0168.0184 [4] 马纪明, 申亚勇, 李齐林. 基于CFD的斜盘/滑靴副油膜特性分析[J]. 北京航空航天大学学报, 2016, 42(2): 265-272. doi: 10.13700/j.bh.1001-5965.2015.0107MA J M, SHEN Y Y, LI Q L. Analysis of oil film characteristics of swash plate/slipper pair based on CFD[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(2): 265-272(in Chinese). doi: 10.13700/j.bh.1001-5965.2015.0107 [5] 刘赵淼, 王国斌, 申峰. 基于Navier滑移的油膜缝隙微流动特性数值分析[J]. 机械工程学报, 2011, 47(21): 104-110. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201121017.htmLIU Z M, WANG G B, SHEN F. Numerical analysis of oil film flow in micro gap with Navier slip boundary conditions[J]. Journal of Mechanical Engineering, 2011, 47(21): 104-110(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201121017.htm [6] 吴承伟, 胡令臣. 界面滑移和油膜破裂[J]. 大连理工大学学报, 1993, 33(2): 172-178. https://www.cnki.com.cn/Article/CJFDTOTAL-DLLG199302008.htmWU C W, HU L C. Wall slippage and oil film collapse[J]. Journal of Dalian University of Technology, 1993, 33(2): 172-178(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-DLLG199302008.htm [7] BERGADA J M, KUMAR S, DAVIES D L, et al. A complete analysis of axial piston pump leakage and output flow ripples[J]. Applied Mathematical Modelling, 2012, 36(4): 1731-1751. doi: 10.1016/j.apm.2011.09.016 [8] AKSOY S, AKSIT M F. A fully coupled 3D thermo-elasto-hydrodynamics model for a bump type compliant foil journal bearing[J]. Tribology International, 2015(82): 110-122. http://www.sciencedirect.com/science/article/pii/S0301679X14003491 [9] IVANTYSYNOVA M, HUANG C H, BEHR R. Measurements of elasto-hydrodynamic pressure field in the gap between piston and cylinder[C]//Bath Workshop on Power Transmission and Motion Control, 2005: 451-465. [10] IVANTYSYNOVA M, PELOSI M. The impact of axial piston machines mechanical parts constraint conditions on the thermo-elasto hydrodynamic lubrication analysis of the fluid film interfaces[J]. International Journal of Fluid Power, 2013, 14(3): 35-51. doi: 10.1080/14399776.2013.10801412 [11] PELOSI M, IVANTYSYNOVA M. A novel fluid structure interaction model for lubricating gaps of piston machines[J]. Fluid Structure Interaction, 2009, 105(5): 13-23. http://www.researchgate.net/publication/271423639_A_novel_fluid-structure_interaction_model_for_lubricating_gaps_of_piston_machines [12] PELOSI M, IVANTYSYNOVA M. Heat transfer and thermal elastic deformation analysis on the piston/cylinder interface of axial piston machines[J]. Journal of Tribology, 2012, 134(10): 1-15. http://scitation.aip.org/getabs/servlet/GetabsServlet?prog=normal&id=JOTRE9000134000004041101000001&idtype=cvips&gifs=Yes [13] 朱自强, 鞠胜军, 吴宗成. 层流流动主/被动控制技术[J]. 航空学报, 2016, 37(7): 2065-2090. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201607003.htmZHU Z Q, JU S J, WU Z C. Laminar flow active/passive control technology[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(7): 2065-2090(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201607003.htm [14] 吴波, 丛茜, 杨利, 等. 具有仿生条纹结构的内燃机活塞疲劳特性回归分析[J]. 农业工程学报, 2016, 32(4): 48-55. https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201604007.htmWU B, CONG Q, YANG L, et al. Regression analysis of fatigue property of internal combustion engine piston with bionic stripe structure[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(4): 48-55(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201604007.htm [15] CHOI K S. Near-wall structure of a turbulent boundary layer with riblets[J]. Journal of Fluid Mechanics, 1989, 208: 417-458. doi: 10.1017/S0022112089002892 [16] LIU Z H, DONG W C, XIONG Y, et al. Analysis on factors and mechanism of drag reduction by grooved surface[J]. Journal of Ship Mechanics, 2007, 11(6): 820-831. http://en.cnki.com.cn/Article_en/CJFDTOTAL-CBLX200706001.htm [17] 童宝宏, 杨文, 刘庆运. 柱塞泵螺旋沟槽式柱塞-铜套副缝隙流场流动与均压特性[J]. 农业工程学报, 2018, 34(2): 55-63. https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201802008.htmTONG B H, YANG W, LIU Q Y. Flowing and pressure-balancing characteristics of clearance field in helical grooved piston-copper sleeve pair of piston pump[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(2): 55-63(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-NYGU201802008.htm [18] CHO I S, BEAK I H, JO J C, et al. Lubrication characteristics of dual piston ring in bent-axis type piston pumps[J]. Journal of Mechanical Science and Technology, 2010, 24(6): 1363-1368. doi: 10.1007/s12206-010-0342-3 -

下载:

下载: