-

摘要:

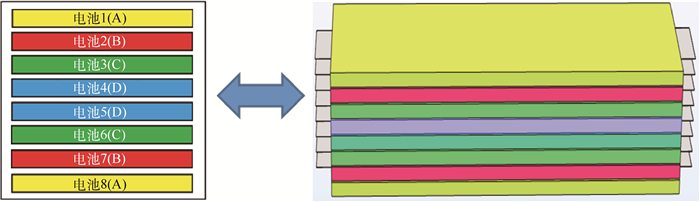

为了研究锂离子电池成组使用时遇到的不一致性和温度不均的问题,基于电化学-热耦合模型,以8块软包电池为例,通过多种串并联方式建立不同的电路模块,分析在1C和0.5C放电过程中电池的温度特征和不一致性。结果表明:电池模块的均温性和一致性与放电倍率有关。不管是先串后并还是先并后串,并联支路的增加或者是串联单元数量的减少都会使电池模块的平均温升和最大温差降低,还会影响温升速率和放电结束时的电压。并联支路数相同时,先串后并模块的一致性要比先并后串好。对于先并后串的模块,其并联支路中串联电池的数量越多,放电过程中电池之间的一致性越差。对于先串后并的模块,其并联的支路数越多,电池的一致性越差。

Abstract:In order to study the inconsistency and uneven behavior of temperature in lithium-ion batteries packing, based on the electrochemical-thermal coupling model, this paper takes eight pouch batteries as an example, establishes different circuit modules through different series and parallel connection modes, and analyzes the temperature characteristics and inconsistency of batteries at the discharge of 1C and 0.5C. The results show that the inconsistency and temperature difference of the battery module are related to the discharge rate. The increase of parallel branches or the decrease of the number of series units will not only reduce the average temperature rise and maximum temperature difference of battery module, but also affect the temperature rise rate and voltage at the end of discharge. When the number of parallel branches is the same, the consistency of the series-parallel modules is better than that of parallel-series modules. For the parallel-series modules, the more batteries are connected in series in the parallel branch, the worse the consistency of the batteries is. For the series-parallel modules, the more the number of parallel branches, the worse the battery consistency.

-

表 1 电池的部分参数

Table 1. Partial battery parameters

参数 正极 隔膜 负极 其余数据 描述 L/μm 90a 20a 60a 厚度 Rp/μm 3.5a 6a 活性颗粒粒子半径 ε1 0.56b 0.44b 固相体积分数 ε2 0.555 6b 0.4b 0.444 4b 液相体积分数 c1, max/(mol·m-3) 19 102b 36 100b 最大可嵌锂浓度 c2, 0/(mol·m-3) 1 200a 1 200a 1 200a 初始电解液锂浓度 k0/(m·s-1) 4.38×10-11c 1.63×10-11c 反应速率常数 H×W×Lb/mm 342×109.5×9.5a 电池长×宽×厚 Cpa/(J·(kg·K)-1) 1 299.4a 电芯平均比热容 Cpb/(J·(kg·K)-1) 900a 385a 极耳比热容 λa/(W·(m·K)-1) 1.282 7b 电芯平均导热系数 λb/(W·(m·K)-1) 238b 400b 极耳导热系数 注:上标a为厂家提供数据;上标b为计算所得数据;上标c为根据参考文献和基于文献调整所得。 表 2 控制方程和边界条件

Table 2. Governing equations and boundary conditions

控制方程 边界条件 质量守恒

电荷守恒

电化学反应速率

能量守恒

表 3 放电结束时的P0值

Table 3. P0 at the end of discharge

电路 P0值/10-5 0.5C 1C 电路a 7.488 9 22.843 3 电路b 88.537 5 179.948 6 电路c 54.487 5 89.021 1 电路d 10.012 9 20.278 2 电路e 88.706 9 180.002 8 电路f 155.269 4 296.066 4 -

[1] LI J, CHENG Y, AI L H, et al. 3D simulation on the internal distributed properties of lithiumion battery with planar tabbed configuration[J]. Journal of Power Sources, 2015, 293: 993-1005. doi: 10.1016/j.jpowsour.2015.06.034 [2] DU S L, LAI Y Q, AI L, et al. An investigation of irreversible heat generation in lithium-ion batteries based on a thermo-electrochemical coupling method[J]. Applied Thermal Engineering, 2017, 121: 501-510. doi: 10.1016/j.applthermaleng.2017.04.077 [3] APPIAH W A, PARK J, SONG S, et al. Design optimization of LiNiO6CoO2MnO2O2/graphite lithiumion cells based on simulation and experimental data[J]. Journal of Power Sources, 2016, 319: 147-158. doi: 10.1016/j.jpowsour.2016.04.052 [4] FENG X N, SUN J, OUYANG M G, et al. Characterization of penetration induced thermal runaway propagation process within a large format lithium-ion battery module[J]. Journal of Power Sources, 2015, 275: 261-273. doi: 10.1016/j.jpowsour.2014.11.017 [5] 李波, 张永生, 唐小晴. 电池组一致性影响因素分析[J]. 电池, 2019, 49(4): 312-315. https://www.cnki.com.cn/Article/CJFDTOTAL-DACI201904012.htmLI B, ZHANG Y S, TANG X Q. Analysis of factors affecting for battery pack consistency[J]. Battery Bimonthly, 2019, 49(4): 312-315(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-DACI201904012.htm [6] 杨彦涛, 张研, 范光辉. 电池性能参数相关性及发热特性[J]. 电池, 2018, 48(3): 191-194. https://www.cnki.com.cn/Article/CJFDTOTAL-DACI201803021.htmYANG Y T, ZHANG Y, FAN G H. Correlation of battery performance parameters and thermal characteristics[J]. Battery Bimonthly, 2018, 48(3): 191-194(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-DACI201803021.htm [7] LOVE C T, VIRJI M B V, ROCHELEAU R E, et al. State-of-health monitoring of 18650 4S packs with a single-point impedance diagnostic[J]. Journal of Power Sources, 2014, 266: 512-519. doi: 10.1016/j.jpowsour.2014.05.033 [8] LAMB J, ORENDORFF C J, STEELE L A M, et al. Failure propagation in multi-cell lithium ion batteries[J]. Journal of Power Sources, 2015, 283: 517-523. doi: 10.1016/j.jpowsour.2014.10.081 [9] 干年妃, 孙长乐, 刘东旭, 等. 变接触面液冷系统的电池模组温度一致性研究[J]. 湖南大学学报(自然科学版), 2020, 47(6): 34-42. https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX202006005.htmGAN N F, SUN C L, LIU D X, et al. Study on temperature consistency of battery module for liquid cooling system with variable contact surface[J]. Journal of Hunan University (Natural Sciences), 2020, 47(6): 34-42(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HNDX202006005.htm [10] WANG B, JI C W, WANG S F, et al. Study of non-uniform temperature and discharging distribution for lithium-ion battery modules in series and parallel connection[J]. Applied Thermal Engineering, 2020, 168: 114831. doi: 10.1016/j.applthermaleng.2019.114831 [11] 王帅, 尹忠东, 郑重, 等. 电池单体参数不一致对电池模组性能影响研究[J]. 电测与仪表, 2020, 57(10): 76-82. https://www.cnki.com.cn/Article/CJFDTOTAL-DCYQ202010012.htmWANG S, YI Z D, ZHEN Z, et al. The influence of cell parameters inconsistency on the performance of different topological battery modules[J]. Electrical Measurement & Instrumentation. 2020, 57(10): 76-82(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-DCYQ202010012.htm [12] 李腾, 林成涛, 陈全世. 磷酸铁锂电池组成组过程的不一致性分析[J]. 清华大学学报(自然科学版), 2012, 52(7): 1001-1006. https://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201207024.htmLI T, LIN C T, CHEN S Q. Inconsistency analysis of LiFePO4 battery packing[J]. Journal of Tsinghua University(Science and Technology), 2012, 52(7): 1001-1006(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-QHXB201207024.htm [13] BANDHAUER T M, GARIMELLA S, FULLER T F. A critical review of thermal issues in lithium-ion batteries[J]. Journal of the Electrochemical Society, 2011, 158(3): 1. doi: 10.1149/1.3515880 [14] YANG N X, ZHANG X W, SHANG B B, et al. Unbalanced discharging and aging due to temperature differences among the cells in a lithium-ion battery pack with parallel combination[J]. Journal of Power Sources, 2016, 306: 733-741. doi: 10.1016/j.jpowsour.2015.12.079 [15] 王震坡, 孙逢春, 林程. 不一致性对动力电池组使用寿命影响的分析[J]. 北京理工大学学报, 2006, 26(7): 577-580. doi: 10.3969/j.issn.1001-0645.2006.07.004WANG Z P, SUN F C, LIN C. An analysis on the influence of inconsistencies upon the service life of power battery packs[J]. Transactions of Beijing Institute of Technology, 2006, 26(7): 577-580(in Chinese). doi: 10.3969/j.issn.1001-0645.2006.07.004 [16] DU S L, LAI Y Q, AI L, et al. An investigation of irreversible heat generation in lithium-ion batteries based on a thermo-electrochemical coupling method[J]. Applied Thermal Engineering, 2017, 121: 501-510. doi: 10.1016/j.applthermaleng.2017.04.077 [17] 朱建功, 孙泽昌, 魏学哲, 等. 车用锂离子电池低温特性与加热方法研究进展[J]. 汽车工程, 2019, 41(5): 571-581. https://www.cnki.com.cn/Article/CJFDTOTAL-QCGC201905015.htmZHU J G, SUN Z C, WEI X Z, et al. Research progress on low-temperature characteristics and heating techniques of vehicle lithium-ion battery[J]. Automotive Engineering, 2019, 41(5): 571-581(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-QCGC201905015.htm [18] 郭健忠, 张华伟, 张麒麟, 等. 车载动力电池成组热不一致性研究[J]. 机械设计与制造, 2020(9): 35-39. doi: 10.3969/j.issn.1001-3997.2020.09.010GUO J Z, ZHANG H W, ZHANG Q L, et al. Reasearch on thermal un-uniformity of vehicle traction battery pack[J]. Machinery Design & Manufacture, 2020(9): 35-39(in Chinese). doi: 10.3969/j.issn.1001-3997.2020.09.010 [19] AN Z J, JIA L, WEI L T, et al. Investigation on lithium-ion battery electrochemical and thermal characteristic based on electrochemical-thermal coupled model[J]. Applied Thermal Engineering, 2018, 137: 792-807. doi: 10.1016/j.applthermaleng.2018.04.014 [20] 许仕源. 基于模型的锂离子电池SOC估算[D]. 长沙: 湖南大学, 2019: 22-25.XU S Y. Model-based SOC estimation of lithium-ion battery[D]. Changsha: Hunan University, 2019: 22-25(in Chinese). [21] 王丽君. 磷酸铁锂电池SOC估算方法的研究[D]. 淮南: 安徽理工大学, 2019: 9-10.WANG L J. Study on SOC estimation method of lithium-ion phosphate batteries[D]. Huainan: Anhui University of Science & Technology, 2019: 9-10(in Chinese). -

下载:

下载: