Damage mechanics-based fatigue life prediction for additive manufacturing metal materials

-

摘要:

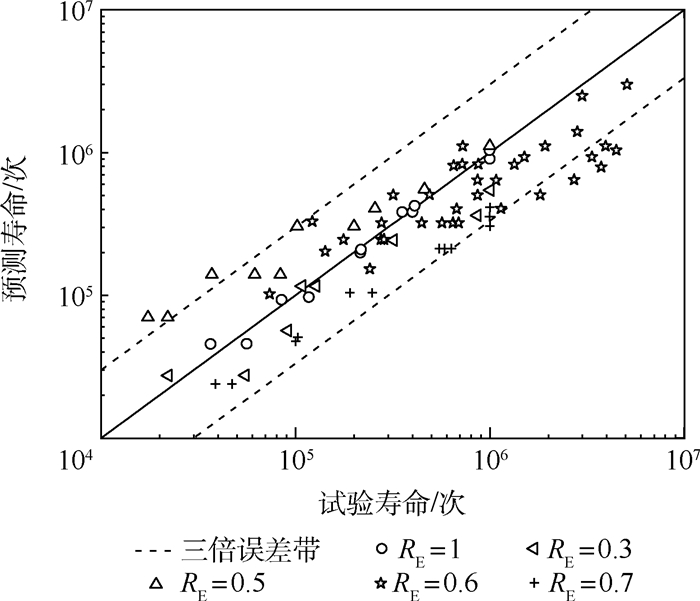

增材制造(AM)技术发展迅速,广泛应用于航空航天领域合金构件的加工制造,而很多增材制造合金构件承受循环载荷,疲劳失效破坏十分普遍。通过建立考虑增材制造过程影响的疲劳损伤模型,计算了增材制造金属材料的疲劳寿命。给出了弹塑性本构模型和考虑增材制造过程参数的疲劳损伤模型,进而给出了疲劳寿命计算的有限元数值方法;对增材制造金属材料进行了疲劳寿命预测,预测值与试验值基本吻合,并从疲劳数据的分散性及增材制造金属材料内部的孔隙率2个方面分析了计算误差;讨论了体积能量密度比对增材制造金属材料疲劳性能的影响,并对结果进行了分析,为增材制造金属材料的疲劳损伤评定提供一种有效的方法。

Abstract:The additive manufacturing (AM) technology develops rapidly and it is widely employed in the fabrication of aerospace alloy components.Many additive manufacturing alloy components bear cyclic loadings, and the fatigue failure is very common. The fatigue damage model considering the influence of additive manufacturing process is established and the fatigue lives of additive manufacturing alloy materials are predicted. The elastic-plastic constitutive model and the fatigue damage model considering the additive manufacturing process parameters are presented, and the finite element numerical method is presented for the fatigue life computation. The fatigue lives of additive manufacturing metal materials are predicted, which are basically consistent with the experimental results, and the computed errors are analyzed from two aspects including the scatter of fatigue data and the porosity in the additive manufacturing materials. The influence of the volume energy density ratio on the fatigue properties of additive manufacturing metal materials is discussed, and the results are analyzed. This research provides an effective method for the fatigue damage evaluation of additive manufacturing metal materials.

-

表 1 标定的2种材料参数

Table 1. Two kinds of calibrated material parameters

材料 α β m n SS316L 0.84 2.46 52 164 0.001 8 Ti6Al4V 0.9 2.89 70 405 0.004 26 -

[1] NGO T D, KASHANI A, IMBALZANO G, et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges[J]. Composites Part B: Engineering, 2018, 143: 172-196. doi: 10.1016/j.compositesb.2018.02.012 [2] BLAKEY-MILNER B, GRADL P, SNEDDEN G, et al. Metal additive manufacturing in aerospace: A review[J]. Materials & Design, 2021, 209: 110008. [3] ZHANG M, SUN C N, ZHANG X, et al. Fatigue and fracture behaviour of laser powder bed fusion stainless steel 316L: Influence of processing parameters[J]. Materials Science and Engineering A, 2017, 703(4): 251-261. [4] ZHANG M, SUN C N, ZHANG X, et al. Elucidating the relations between monotonic and fatigue properties of laser powder bed fusion stainless steel 316L[J]. The Journal of the Minerals, Metals & Materials Society, 2018, 70(3): 390-395. [5] ZHANG M, SUN C N, ZHANG X, et al. Predictive models for fatigue property of laser powder bed fusion stainless steel 316L[J]. Materials & Design, 2018, 145: 42-54. [6] SPIERINGS A B, STARR T L, WEGENER K. Fatigue performance of additive manufactured metallic parts[J]. Rapid Prototyping Journal, 2013, 19(2): 88-94. doi: 10.1108/13552541311302932 [7] KAHLIN M, ANSELL H, MOVERARE J J. Fatigue behaviour of notched additive manufactured Ti6Al4V with as-built surfaces[J]. International Journal of Fatigue, 2017, 101: 51-60. doi: 10.1016/j.ijfatigue.2017.04.009 [8] AKITA M, UEMATSU Y, KAKIUCHI T, et al. Defect-dominated fatigue behavior in type 630 stainless steel fabricated by selective laser melting[J]. Materials Science and Engineering A, 2016, 666(6): 19-26. [9] EDWARDS P, RAMULU M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V[J]. Materials Science and Engineering A, 2014, 598(3): 327-337. [10] SANAEI N, FATEMI A. Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review[J]. Progress in Materials Science, 2020, 117(4): 100724. [11] KASPEROVICH G, HAUBRICH J, GUSSONE J, et al. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting[J]. Materials & Design, 2016, 105: 160-170. [12] ZHANG B, LI Y, BAI Q. Defect formation mechanisms in selective laser melting: A review[J]. Chinese Journal of Mechanical Engineering, 2017, 30(3): 515-527. doi: 10.1007/s10033-017-0121-5 [13] 陈迪, 王燎, 高海燕, 等. 3D打印钛合金内部孔洞的研究进展[J]. 应用激光, 2019, 39(1): 72-78. https://www.cnki.com.cn/Article/CJFDTOTAL-YYJG201901011.htmCHEN D, WANG L, GAO H Y, et al. Research progress on 3D printing internal cavity of titanium alloy[J]. Applied Laser, 2019, 39(1): 72-78(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-YYJG201901011.htm [14] TONELLI L, LIVERANI E, VALLI G, et al. Effects of powders and process parameters on density and hardness of A357 aluminum alloy fabricated by selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2020, 106(1-2): 371-383. doi: 10.1007/s00170-019-04641-x [15] YAN W, GE W, QIAN Y, et al. Multi-physics modeling of single/multiple-track defect mechanisms in electron beam selective melting[J]. Acta Materialia, 2017, 134(8): 324-333. [16] 姚卫星. 结构疲劳寿命分析[M]. 北京: 国防工业出版社. 2003: 20-25.YAO W X. Fatigue life analysis of structures[M]. Beijing: National Defense Industry Press, 2003: 20-25(in Chinese). [17] ZHU S P, LIAO D, LIU Q, et al. Nonlinear fatigue damage accumulation: Isodamage curve-based model and life prediction aspects[J]. International Journal of Fatigue, 2019, 128: 105185. doi: 10.1016/j.ijfatigue.2019.105185 [18] BENKABOUCHE S, GUECHICHI H, AMROUCHE A, et al. A modified nonlinear fatigue damage accumulation model under multiaxial variable amplitude loading[J]. International Journal of Mechanical Sciences, 2015, 100: 180-194. doi: 10.1016/j.ijmecsci.2015.06.016 [19] YUAN H, ZHANG L, MA S. Damage evolution and characterization for sintered powder metals with the varying porosity[J]. Engineering Fracture Mechanics, 2019, 207: 86-98. doi: 10.1016/j.engfracmech.2018.12.014 [20] 郑战光, 蔡敢为, 李兆军. 一种新的疲劳损伤演化模型[J]. 工程力学, 2010, 27(2): 37-40. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201002008.htmZHENG Z G, CAI G W, LI Z J. A new model of fatigue damage evolution[J]. Engineering Mechanics, 2010, 27(2): 37-40(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201002008.htm [21] CHABOCHE J L, GALLERNEAU F. An overview of the damage approach of durability modelling at elevated temperature[J]. Fatigue & Fracture of Engineering Materials & Structures, 2001, 24(6): 405-418. [22] LEMAITRE J. A course on damage mechanics[M]. Berlin: Springer, 2012: 1-20. [23] SHEN F, HU W, MENG Q. A non-local approach based on the hypothesis of damage dissipation potential equivalence to the effect of stress gradient in fretting fatigue[J]. International Journal of Fatigue, 2016, 90: 125-138. doi: 10.1016/j.ijfatigue.2016.04.028 [24] LI P, WARNER D H, FATEMI A, et al. Critical assessment of the fatigue performance of additively manufactured Ti-6Al-4V and perspective for future research[J]. International Journal of Fatigue, 2016, 85: 130-143. doi: 10.1016/j.ijfatigue.2015.12.003 [25] LIU Q C, ELAMBASSERIL J, SUN S J, et al. The effect of manufacturing defects on the fatigue behaviour of Ti-6Al-4V specimens fabricated using selective laser melting[J]. Advanced Materials Research, 2014, 891(3): 1519-1524. [26] VAN HOOREWEDER B, BOONEN R, MOENS D, et al. On the determination of fatigue properties of Ti6Al4V produced by selective laser melting: AIAA 2012-1733[R]. Reston: AIAA, 2012. -

下载:

下载: