-

摘要:

使用自行开发的非定常流固耦合数值模拟程序,研究了上游叶排影响转子叶片颤振特性的机理,采用影响系数法分析轴向间距影响转子气动弹性稳定性的规律。结果表明:在协调叶栅中,叶片吸力面相邻的叶片振动对转子叶片气动阻尼的大小起决定性作用,其影响甚至超过振动叶片本身的影响;多排环境中,导叶(IGV)对转子叶片气动阻尼最小值的影响最大,并使其对应的节径增大;相邻叶片振动引起的通道变化抑制了导叶对非定常压力波的反射作用;随着轴向间距的减小,导叶对非定常压力波的反射作用减弱了非定常压力波的周向衰减,从而增大了叶片振动的非定常影响范围;在多排环境中使用影响系数法需要测量更多的叶片才能得到较为准确的气动阻尼。

Abstract:The mechanism of the upstream blade row affecting the flutter characteristics of the rotor blade is studied, using the self-developed unsteady fluid-solid coupling numerical simulation program. The influence coefficient method is used to analyze the effect of axial spacing on the aeroelastic stability of rotor. The results show that the neighboring blade vibration, which adjacent to the certain blade's suction side, determines the value of rotor aerodynamic damping in the tuned cascade, and its effect is even larger than the certain blade vibration itself; in the multi-row environment, inlet guide vanes(IGV) mainly affects the minimum aerodynamic damping of rotor blade, and IGV increases the nodal diameter value of the most unstable point of aeroelasticity; the channel change caused by blade vibration restrains the reflection of IGV on unsteady pressure wave; with the decrease of axial spacing, the range of unsteady influence of blade vibration is obviously increased, since the effect of IGV on the unsteady pressure wave attenuates the circumferential attenuation of unsteady pressure wave; the influence coefficient method needs to measure more blades to obtain more accurate aerodynamic damping in the multi-row environment.

-

Key words:

- axial spacing /

- influence coefficient method /

- aeroelastic stability /

- flutter /

- aerodynamic damping

-

表 1 叶片几何和实验参数

Table 1. Blade geometry and experimental parameters

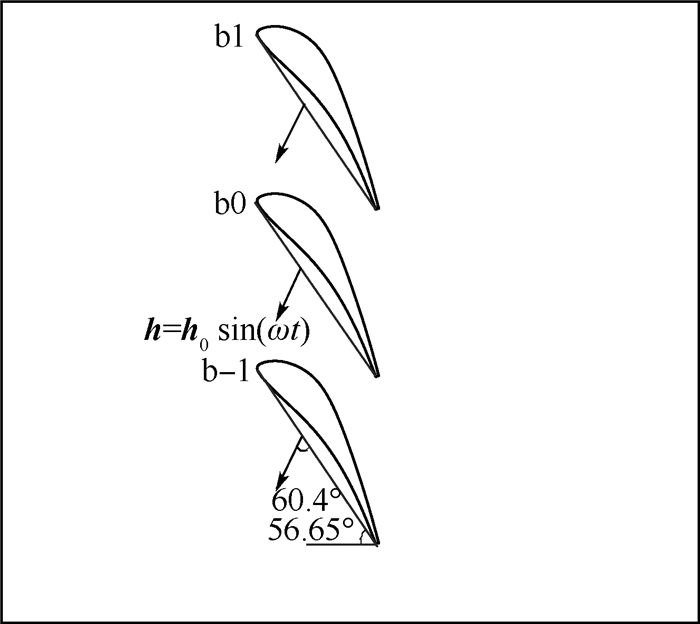

参数 数值 弦长/mm 72 栅距/mm 56.25 安装角/(°) 56.65 振幅/(10-4m) 3 振动方向/(°) 60.4 振动频率/Hz 149 折合频率 0.118 7 表 2 边界条件

Table 2. Boundary conditions

参数 数值 进口总压/kPa 160.9 进口总温/K 317.8 出口静压/kPa 101.3 出口气流角/(°) -71.5 出口等熵马赫数 0.85 表 3 不同叶片数下气动阻尼系数相对误差

Table 3. Relative error of aerodynamic damping coefficients with different blade numbers

% 叶片编号 Δx/c=10% Δx/c=15% Δx/c=30% Δx/c=50% Δx/c=70% Δx/c=90% Δx/c=150% 单转子 b-1~b0 14.58 18.50 23.31 19.25 13.24 8.40 2.21 0.77 b-1~b1 12.27 13.84 15.77 11.08 6.39 3.09 0.37 0.76 b-2~b2 4.08 5.64 7.42 5.10 2.51 0.81 0.13 2.30 b-3~b3 2.57 1.99 1.44 1.76 1.97 1.84 0.63 0.24 b-5~b5 0.44 0.34 0.03 0.09 0.01 0.11 0.34 0.02 -

[1] 陈懋章.风扇/压气机技术发展和对今后工作的建议[J].航空动力学报, 2002, 17(1):1-15. http://d.wanfangdata.com.cn/Periodical_hkdlxb200201001.aspxCHEN M Z.Development of fan/compressor techniques and suggestions on further researches[J].Journal of Aerospace Power, 2002, 17(1):1-15(in Chinese). http://d.wanfangdata.com.cn/Periodical_hkdlxb200201001.aspx [2] LANE F.System mode shapes in the flutter of compressor blade rows[J].Journal of the Aeronautical Sciences, 1956, 23(1):54-66. doi: 10.2514/8.3502 [3] CARTA F O, ST HILAIRE A O.Experimentally determined stability parameters of a subsonic cascade oscillating near stall[J].Journal of Engineering for Power, 1978, 100(1):111-120. doi: 10.1115/1.3446301 [4] CARTA F O, ST HILAIRE A O.Effect of inter-blade phase angle and incidence angle on cascade pitching stability[J].Journal of Engineering for Power, 1980, 102(2):391-396. doi: 10.1115/1.3230268 [5] 张小伟, 王延荣, 徐可宁.叶轮机械叶片颤振的影响参数[J].航空动力学报, 2011, 26(7):1558-1562. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_hkdlxb201107018ZHANG X W, WANG Y R, XU K N.Effects of parameters on blade flutter in turbomachinery[J].Journal of Aerospace Power, 2011, 26(7):1558-1562(in Chinese). http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_hkdlxb201107018 [6] BELL D L, HE L. Three dimensional unstea-dy flow for an oscillating turbine blade and the influence of tip leakage[C]//ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition. New York: ASME, 1998: V005T14A049. [7] ISOMURA K, GILES M B.A numerical study of flutter in a transonic fan[J].Journal of Turbomachinery, 1998, 120(3):500-507. doi: 10.1115/1.2841746 [8] HSU K, HOYNIAK D, ANAND M S. Full annulus multi-row flutter analyses[C]//ASME Turbo Expo 2012: Turbine Technical Conference and Exposition. New York: ASME, 2012: 1453-1462. [9] CULVER R, LIU F. Mixing-plane method for flutter computation in multi-stage turbomachines: AIAA-2009-862[R]. Reston: AIAA, 2009. [10] HUANG X Q, HE L, BELL D L.Influence of upstream stator on rotor flutter stability in a low pressure steam turbine stage[J].Proceedings of the Institution of Mechanical Engineers, Part A:Journal of Power and Energy, 2006, 220(1):25-35. doi: 10.1243/095765005X69170 [11] 杨慧, 李振鹏.转静干涉对转子叶片颤振特性的影响[J].北京航空航天大学学报, 2016, 42(2):258-264. http://bhxb.buaa.edu.cn/CN/abstract/abstract13773.shtmlYANG H, LI Z P.Influence of rotor-stator interaction on rotor blade flutter characteristics[J].Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(2):258-264(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract13773.shtml [12] LI H D, HE L.Blade aerodynamic damping variation with rotor-stator gap:A computational study using single-passage approach[J].Journal of Turbomachinery, 2005, 127(3):573-579. doi: 10.1115/1.1928932 [13] 杨慧, 沈真.上下游干涉对转子叶片颤振特性的影响[J].航空动力学报, 2016, 31(5):1170-1177. doi: 10.13224/j.cnki.jasp.2016.05.019.htmlYANG H, SHEN Z.Influence of up-and downstream blade rows on the rotor blade flutter characteristics[J].Journal of Aerospace Power, 2016, 31(5):1170-1177(in Chinese). doi: 10.13224/j.cnki.jasp.2016.05.019.html [14] HANAMURA Y, TANAKA H, YAMAGUCHI K.A simplified method to measure unsteady forces acting on the vibrating blades in cascade[J].Bulletin of the JSME, 1980, 23(180):880-887. doi: 10.1299/jsme1958.23.880 [15] 杨慧, 何力, 王延荣.压气机线性振荡叶栅气弹试验研究(二):叶尖间隙的影响[J].航空学报, 2008, 24(4):804-810. http://www.cnki.com.cn/Article/CJFDTotal-HKXB200804007.htmYANG H, HE L, WANG Y R.Experimental study on aeroelasticity in linear oscillating compressor cascade.PartⅡ:Tip-clearance effect[J].Journal of Turbomachinery, 2008, 24(4):804-810(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-HKXB200804007.htm [16] 郑赟.基于非结构网格的气动弹性数值方法研究[J].航空动力学报, 2009, 24(9):2069-2077. http://d.wanfangdata.com.cn/Periodical_hkdlxb200909025.aspxZHENG Y.Computationalaeroelasticity with an unstructured grid method[J].Journal of Turbomachinery, 2009, 24(9):2069-2077(in Chinese). http://d.wanfangdata.com.cn/Periodical_hkdlxb200909025.aspx [17] 杨慧, 郑赟.测量叶轮机振动叶片表面非定常气动响应的实验技术-影响系数法[J].实验流体力学, 2011, 25(3):71-77. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ltlxsyycl201103016YANG H, ZHENG Y.Experimental technique for measuring unsteady aerodynamics of vibrating blade in turbomachinery influence coefficient method[J].Journal of Experiments in Fluid Mechanics, 2011, 25(3):71-77(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ltlxsyycl201103016 [18] BLCS A, FRANSSON T H. Aeroelasticity in turbomachines: Comparison of theoretical and experimental cascade results: LTT-CONF-1986-001[R]. Lausanne: Éole Polytechnique Fédérale de Lausanne, 1986. [19] FRANSSON T H, VERDON J M. Updated report on standard configurations for unsteady flow through vibrating axial flow turbomachine cascades: LTT-CONF-1991-005[R]. Lausanne: Éole Polytechnique Fédérale de Lausanne, 1991. -

下载:

下载: