-

摘要:

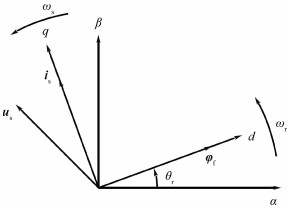

针对无位置传感器永磁同步电机(PMSM)在高速运行时无法准确观测转子位置,导致三相电流波动畸变的问题,提出了一种改进型滑模观测器(SMO)来预估转子位置和速度的新方法。该改进型滑模观测器采用S型切换函数来估算反电动势,并通过软件锁相环(SPLL)算法计算转子位置角,降低了传统滑模观测器抖振对转子位置角的影响,实现了PMSM在高速运行状态下转子位置角的准确观测。开发出一套高速永磁同步电机控制器,实现了电机在超高速高功率状态稳定运行。

-

关键词:

- 永磁同步电机(PMSM) /

- 无位置传感器 /

- 滑模观测器(SMO) /

- S型切换函数 /

- 软件锁相环(SPLL)

Abstract:Due to the problem that the rotor position of sensorless Permanent Magnet Synchronous Motor (PMSM) cannot be accurately observed at high speed, which causes distortion of three-phase current fluctuation, an improved Sliding Mode Observer (SMO) is proposed to estimate the rotor position and speed more precisely. A function is adopted to be the switching function of the SMO to eliminate the fluctuation in the calculation of the back-EMF. Furthermore, a Software Phase Locked Loop (SPLL) algorithm is introduced to decrease the influence of chatting of traditional sliding mode observer on rotor position. The combined method significantly improves the observation accuracy of the rotor position angle at high speed. A controller of high speed PMSM is successfully developed and can works steadily under ultra-high speed and high power condition.

-

表 1 实验用空气压缩机电机参数

Table 1. Air compressor motor parameters for experiment

电机参数 数值 额定功率/kW 18 额定转速/(r·min-1) 100 000 极对数 1 线电感/μH 312 线电阻/Ω 0.114 额定电流/A 80 电池电压/V 250~400 -

[1] 徐艳平, 钟彦儒, 杨惠.永磁同步电机矢量控制和直接转矩控制的研究[J].电力电子技术, 2008, 42(1):60-62.XU Y P, ZHONG Y R, YANG H.Research on vector control and direct torque control for permanent magnet synchronous motors[J].Power Electronics, 2008, 42(1):60-62(in Chinese). [2] DAI Y, SONG L, CUI S M.Development of PMSM drives for hybrid electric car applications[J].IEEE Transactions on Magnetics, 2007, 43(1):434-437. [3] 刘英培, 栗然.一种永磁同步电机直接转矩控制无传感器运行优化方法[J].中国电机工程学报, 2014, 34(30):5368-5377.LIU Y P, LI R.An optimization method of direct torque control and sensorless operation for permanent magnet synchronous motors[J].Proceedings of the CSEE, 2014, 34(30):5368-5377(in Chinese). [4] 鲁家栋, 刘景林.内置式永磁同步电机低速无位置传感器控制[J].电机与控制学报, 2018, 22(3):88-94.LU J D, LIU J L.Low-speed position sensorless control of IPMSM based on high frequency signal injection[J].Electric Machines and Control, 2018, 22(3):88-94(in Chinese). [5] WANG G, YANG R, XU D.DSP-based control of sensorless IPMSM drives for wide-speed-range operation[J].IEEE Transactions on Industrial Electronics, 2013, 60(2):720-727. http://ieeexplore.ieee.org/document/6221988 [6] GENDUSO F, MICELI R, RANDO C, et al.Back EMF sensorless-control algorithm for high-dynamic performance PMSM[J].IEEE Transactions on Industrial Applications, 2010, 57(6):2092-2100. http://ieeexplore.ieee.org/document/5289997/ [7] LEE G B, PARK J S, LEE S H, et al.High-performance sensorless-control of PMSM using back-EMF and reactive power[C]//ICCAS-SICE International Joint Conference.Piscataway: IEEE Press, 2009: 407-411. [8] 岳岩, 王惠民, 葛兴来.基于锁频环的内置式永磁同步电机无传感器控制[J].中国电机工程学报, 2019, 39(10):3075-3085. http://www.cnki.com.cn/Article/CJFDTotal-ZGDC201910028.htmYUE Y, WANG H M, GE X L.Frequency-locked loop based sensorless control for interior permanent magnet synchronous motor[J].Proceedings of the CSEE, 2019, 39(10):3075-3085(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-ZGDC201910028.htm [9] 尹忠刚, 刘静, 钟彦儒, 等.基于双参数模型参考自适应的感应电机无速度传感器矢量控制低速性能[J].电工技术学报, 2012, 27(7):124-131.YIN Z G, LIU J, ZHONG Y R, et al.Low-speed performance for induction motor sensorless vector control based on two-parameter model reference adaptation[J].Transactions of China Electrotechnical Society, 2012, 27(7):124-131(in Chinese). [10] 刘英培, 万健如, 沈虹, 等.基于EKF PMSM定子磁链和转速观测直接转矩控制[J].电工技术学报, 2009, 24(12):57-62.LIU Y P, WAN J R, SHEN H, et al.Stator flux linkage and rotor speed observation for PMSM DTC based on EKF[J].Transactions of China Electrotechnical Society, 2009, 24(12):57-62(in Chinese). [11] 李冉, 赵光宙, 徐绍娟.基于扩展滑模观测器的永磁同步电动机无传感器控制[J].电工技术学报, 2012, 27(3):79-85.LI R, ZHAO G Z, XU S J.Sensorless control of permanent magnet synchronous motor based on extended sliding mode observer[J].Transactions of China Electrotechnical Society, 2012, 27(3):79-85(in Chinese). [12] KIM H, SON J, LEE J.A high-speed sliding-mode observer for the sensorless speed control of a PMSM[J].IEEE Transactions on Industrial Electronics, 2011, 58(9):4069-4077. http://ieeexplore.ieee.org/document/5661838/ [13] BARAMBONES'O, ALKORTA P.Position control of the induction motor using an adaptive sliding-mode controller and observers[J].IEEE Transactions on Industrial Electronics, 2014, 61(12):6556-6565. http://ieeexplore.ieee.org/document/6786033 [14] 刘艳莉, 张烨, 吕继考, 等.PMSM改进型滑模观测器无传感器参数辨识[J].电力系统及其自动化学报, 2014, 26(4):30-34. http://www.cqvip.com/QK/98064X/201404/49523653.htmlLIU Y L, ZHANG Y, LÜ J K, et al.Sensorless parameters identification of permanent magnet synchronous motor by employing hyperbolic tangent function[J].Proceedings of the CSU-EPSA, 2014, 26(4):30-34(in Chinese). http://www.cqvip.com/QK/98064X/201404/49523653.html [15] 陆婋泉, 林鹤云, 冯奕, 等.永磁同步电机无传感器控制的软开关滑模观测器[J].电工技术学报, 2015, 30(2):106-113. http://d.wanfangdata.com.cn/Periodical/dgjsxb201502014LU X Q, LIN H Y, FENG Y, et al.Soft switching sliding mode observer for PMSM sensorless control[J].Transactions of China Electrotechnical Society, 2015, 30(2):106-113(in Chinese). http://d.wanfangdata.com.cn/Periodical/dgjsxb201502014 [16] 肖烨然, 刘刚, 宋欣达, 等.基于改进滑模观测器的永磁同步电机无位置传感器I/F起动方法[J].电力自动化设备, 2015, 35(8):95-102.XIAO Y R, LIU G, SONG X D, et al.Sensorless I/F startup based on modified sliding mode observer for PMSM[J].Electric Power Automation Equipment, 2015, 35(8):95-102(in Chinese). [17] DENG Y T, WANG J L, LI H W, et al.Adaptive sliding mode current control with sliding mode disturbance observer for PMSM drives[J].ISA Transactions, 2019, 88:113-126. http://www.sciencedirect.com/science/article/pii/S0019057818304816 -

下载:

下载: