-

摘要:

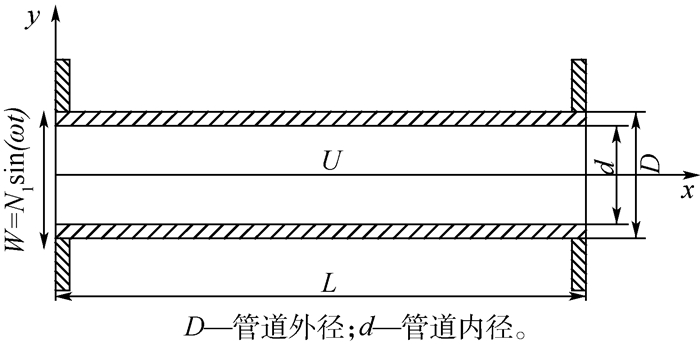

针对硬岩掘进机工作过程中产生的强烈振动影响管道的工作性能的问题,建立了基础振动下两端固定支撑输流管道横向振动的数学模型,运用Galerkin方法和等效弯矩法对管道最大应力进行了数值求解,并且用实验证实了数学模型的正确性。研究了基础振动参数对管道最大应力的影响规律,并根据最大应力判据条件得到了不同基础振动参数下管道工作的正常-失效区域,制定了以流量-压力-强振动参数为依据的管道抗振结构设计方法。结果表明:基础振动会引起液压管道应力剧增而导致其工作失效,新的设计方法能有效改善强振动环境下管道的工作性能。

Abstract:Against the problem that strong vibration has effect on the performance of hydraulic pipe during the working process of tunnel boring machine, the transverse vibration mathematical model of the clamped-clamped hydraulic pipe under the foundation vibration was built; The methods of Galerkin and equivalent bending moment were adopted to solve pipe's maximum stress, and the correctness of mathematical model was verified by experiments. The influence rule of foundation vibration parameters on pipe's maximum stress was researched and the normal-failure areas of pipe under different foundation vibration parameters were obtained on the basis of maximum stress criterion. The anti-vibration structural design method was developed based on flow-pressure-strong vibration parameters. The results indicate that foundation vibration causes dramatic increase of hydraulic pipe stress and thus leads to its performance failure, and the new design method can effectively improve the performance of pipe under the strong vibration environment.

-

Key words:

- foundation vibration /

- hydraulic pipe /

- stress analysis /

- anti-vibration structure /

- design method

-

表 1 系统参数设置

Table 1. System parameter setting

参数 数值 壁厚/m 0.004 管道内径/m 0.05 管道弹性模量/GPa 201 管道固支间距/m 2 管材密度/(kg·m-3) 7 985 管材泊松比 0.3 流体平均流速/(m·s-1) 3 流体密度/(kg·m-3) 890 -

[1] KOYAMA Y.Present status and technology of shield tunneling method in Japan[J].Tunnelling and Underground Space Technology, 2003, 18(2):145-159. http://www.ingentaconnect.com/content/els/08867798/2003/00000018/00000002/art00040 [2] LI X H, YU H B, YUAN M Z, et al.Study on the linear dynamic model of shield TBM cutterhead driving system[C]//IECON 2011-37th Annual Conference on IEEE Industrial Electronics Society.Piscataway, NJ:IEEE Press, 2011:3864-3871. [3] 吴晓南, 舒浩纹, 昝林峰, 等.试压工况下盾构隧道内输气管道应力分析[J].天然气工业, 2013, 33(3):73-77. http://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201303020.htmWU X N, SHU H W, ZAN L F, et al.Stress analysis of gas pipeline in tunnels on pressure testing condition[J].Natural Gas Industry, 2013, 33(3):73-77(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-TRQG201303020.htm [4] XIA L, HUANG K, HONG F L, et al.Stress analysis of suspended gas pipeline[J].Applied Mechanics and Materials, 2013, 448(1):1359-1362. https://www.researchgate.net/publication/269383367_Stress_Analysis_of_Suspended_Gas_Pipeline [5] XIAO N W, SHI J W, HONG F L, et al.Analysis of hot oil pipe-line stress influencing factors[J].Advanced Materials Research, 2014, 887(1):899-902. http://www.scientific.net/AMR.887-888.899 [6] 耿艳辉, 詹晨菲.生产线液压系统长大管道设计[J].流体传动与控制, 2012, 52(3):21-24. http://www.cnki.com.cn/Article/CJFDTOTAL-LTCD201203007.htmGENG Y H, ZHAN C F.Design of long and large pipeline of hydraulic system used in product line[J].Fluid Power Transmission and Control, 2012, 52(3):21-24(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-LTCD201203007.htm [7] 朱博.工程机械液压系统管路设计及装配原则[J].建筑机械, 2011(2):94-97. http://www.cnki.com.cn/Article/CJFDTOTAL-JZJX201103024.htmZHU B.Principle of pipeline design and assembly for hydraulic system of construction machinery[J].Construction Machinery, 2011(2):94-97(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JZJX201103024.htm [8] SVEDEMAN S J, ARNOLD K E.Criteria for sizing multiphase flowlines for erosive/corrosive service[J].SPE Production & Facilities, 1996, 9(1):74-80. https://www.researchgate.net/publication/250090044_Criteria_for_Sizing_Multiphase_Flowlines_for_ErosiveCorrosive_Service [9] NAYYAR M L.ASME code for pressure piping, B31:ASME B31.1b-2009[S].New York:ASME, 2009:6-10. [10] JIN J D, ZOU G S.Bifurcations and chaotic motions in the autonomous system of a restrained pipe conveying fluid[J].Journal of Sound and Vibration, 2003, 260(5):783-805. doi: 10.1016/S0022-460X(02)00982-3 [11] SEMLER C, LI G X, PAIDOUSSIS M P.The nonlinear equations of motion of pipes conveying fluid[J].Journal of Sound and Vibration, 1994, 169(5):577-599. doi: 10.1006/jsvi.1994.1035 [12] 邹光胜, 金基铎, 闻邦椿.Melnikov方法在输流管混沌运动研究中的应用[J].力学与实践, 2004, 26(2):29-32. http://www.cnki.com.cn/Article/CJFDTOTAL-LXYS200402007.htmZOU G S, JIN J D, WEN B C.Application of Melnikov method in the study of chaotic motions of pipe conveying fluid[J].Mechanics in Engineering, 2004, 26(2):29-32(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-LXYS200402007.htm [13] PAIDOUSSIS M P, LI G X, RAND R H.Chaotic motions of a constrained pipe conveying fluid:Comparison between simulation analysis and experiment[J].ASME Journal of Applied Mechanics, 1991, 58(2):559-565. doi: 10.1115/1.2897220 [14] STOSIAK M.Vibration insulation of hydraulic system control components[J].Archives of Civil and Mechanical Engineering, 2011, 11(1):237-248. doi: 10.1016/S1644-9665(12)60186-1 [15] 陈炳瑞, 冯夏庭, 曾雄辉, 等.深埋隧洞TBM掘进微震实时监测与特征分析[J].岩石力学与工程学报, 2011, 30(2):275-283. http://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201102009.htmCHEN B R, FENG X T, ZENG X H, et al.Real-time microseismic monitoring and its characteristic analysis during TBM tunneling in deep-buried tunnel[J].Chinese Journal of Rock Mechanics and Engineering, 2011, 30(2):275-283(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201102009.htm [16] 苏华友.双护盾TBM开挖深埋隧洞围岩稳定性研究[D].成都:西南交通大学, 2009:36-40.SU H Y.Surrounding rock stability study of double-shield TBM during tunneling in deep-buried tunnel[D].Chengdu:Southwest Jiaotong University, 2009:36-40(in Chinese). -

下载:

下载: