Method for output displacement solving of compliant micro-motion mechanism with multi-input forces

-

摘要:

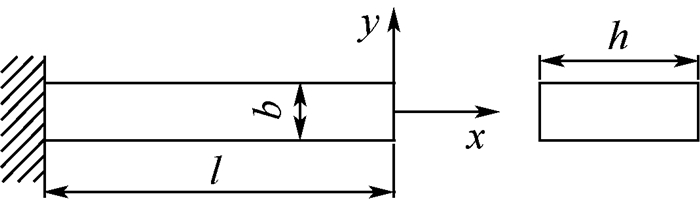

对于单个外力作用下的微动机构,柔度描述了外力与其输出位移之间的关系,是影响微动机构动态性能和精度的重要性能指标。对于多个外力作用下的情况,与之相对应的是微动机构输出位移与其多外力间的关系式。为求解该关系式,采用了柔度矩阵和刚体运动规律相结合的方法。首先,对整体进行单元划分,并求解结构中各柔性单元的端点位移与端点力之间的关系式;然后,根据各单元间的结构关系求解各不同单元端点力或端点位移间的叠加和协调关系式;最后,综合所有求得的关系式整理出输出位移与外力之间的关系式。运用该方法求解了一种微动夹持器的工作端位移,并与有限元分析软件的计算结果进行了对比。研究结果表明:该方法具有普遍适用性以及可靠的精度,能够用于一般微动机构的性能分析与优化。应用MATLAB软件对求得的关系式进行分析,获得了结构参数优化所需的理论依据。

Abstract:For the compliant micro-motion mechanism with one input force, compliance describes the relation between output displacement and input force, and is an important performance index for the dynamic performance and positioning precision. For the one with many input forces, the relation equation between output displacement and input forces has the same role with the compliance. For obtaining this equation, the method which combined the compliance matrix method and the motion raw of rigid body was proposed. Firstly, the whole structure is divided to elements, and the relation equation between displacement and force of element end is established. Secondly, the superposition or coordinate relation equation about displacements or forces of different element ends was solved according to their structural relation. Finally, the equation of relation between the output displacement and the input forces was worked out by synthesizing all the solved equations. The output displacement of a micro-motion gripper was worked out by this method and contrasted with the one from finite element analysis method. The results show that this method has the enough precision and a good adaptability for micro-motion mechanism performance analysis and optimization. The theory suggestion about dimension optimization was obtained by analyzing the equation by using MATLAB software.

-

表 1 位移uIx和uIy的理论值与有限元分析值结果对比

Table 1. Comparison of displacement uIx and uIy results between theoretical analysis and finit element analysis

外力 位移uIy 位移uIx F2/N F1/N 理论值/μm 有限元分析值/μm 相对误差/% 理论值/μm 有限元分析值/μm 相对误差/% 0 10 -1.31 -1.42 7.7 -0.122 -0.132 7.6 20 -2.62 -2.84 7.7 -0.245 -0.265 7.5 30 -3.93 -4.27 7.9 -0.367 -0.397 7.6 40 -5.24 -5.69 7.9 -0.490 -0.530 7.5 50 -6.56 -7.12 7.8 -0.612 -0.663 7.7 5 10 0.020 9 0.047 8 56 0.003 75 0.007 45 49 20 -1.29 -1.37 5.8 -0.119 -0.125 4.8 30 -2.60 -2.80 7.1 -0.241 -0.258 6.5 40 -3.91 -4.22 7.3 -0.364 -0.390 6.6 50 -5.22 -5.65 7.6 -0.486 -0.523 7.1 10 10 1.34 1.46 8.2 0.132 0.142 7.0 20 0.041 7 0.095 6 56 0.007 51 0.014 9 49 30 -1.27 -1.33 4.5 -0.115 -0.118 2.5 40 -2.58 -2.75 6.2 -0.237 -0.250 5.2 50 -3.89 -4.17 6.7 -0.360 -0.382 5.7 15 10 2.68 2.92 8.2 0.256 0.281 8.8 20 1.37 1.50 8.6 0.134 0.146 8.2 30 0.062 6 0.143 56 -0.011 3 -0.022 3 49 40 -1.25 -1.28 2.3 -0.111 -0.110 1.0 50 -2.56 -2.70 5.2 -0.234 -0.242 3.3 20 10 4.02 4.38 8.2 0.382 0.418 8.6 20 2.71 2.97 8.7 0.260 0.284 8.4 30 1.40 1.53 8.4 0.141 0.154 8.4 40 0.083 5 0.191 56 0.015 0.029 8 49 50 -1.23 -1.24 0.8 -0.107 -0.103 3.9 -

[1] SARAJILIC E, YAMAHATA C, CORDERO M, et al.Three-phase electrostatic rotary stepper micromotor with a flexural pivot bearing[J]. Journal of Microelectromechanical System, 2012, 19(2):338-394. http://cn.bing.com/academic/profile?id=929704ae51f627e6398606a95797dde1&encoded=0&v=paper_preview&mkt=zh-cn [2] 于靖军, 郝光波, 陈贵敏, 等.柔性机构及其应用[J].机械工程学报, 2015, 51(13):53-68. https://www.researchgate.net/profile/Guimin_Chen/publication/281066471_State-of-art_of_Compliant_Mechanisms_and_Their_Applications/links/55e664c308aede0b57376c70/State-of-art-of-Compliant-Mechanisms-and-Their-Applications.pdfYU J J, HAO G B, CHEN G M, et al.State-of-art of compliant mechanisms and their applications[J]. Journal of Mechanical Engineering, 2015, 51(13):53-68(in Chinese). https://www.researchgate.net/profile/Guimin_Chen/publication/281066471_State-of-art_of_Compliant_Mechanisms_and_Their_Applications/links/55e664c308aede0b57376c70/State-of-art-of-Compliant-Mechanisms-and-Their-Applications.pdf [3] 李静, 庞岩, 冯咬齐, 等.柔性航天器姿控执行机构微振动集中隔离与分散隔离对比研究[J].航天器环境工程, 2016, 33(1):58-64. doi: 10.3969/j.issn.1673-1379.2016.01.010LI J, PANG Y, FENG Y Q, et al.Comparison of concentrated and distributed isolations of micro vibrations in flexible spacecraft attitude actuators[J]. Spacecraft Environment Engineering, 2016, 33(1):58-64(in Chinese). doi: 10.3969/j.issn.1673-1379.2016.01.010 [4] LI Y, XU Q.A totally decoupled piezo-driven XYZ flexure parallel micropositioning stage for micro/nanomanipulation[J]. IEEE Transactions on Automation Science and Engineering, 2011, 8(2):265-279. doi: 10.1109/TASE.2010.2077675 [5] FUCHIWAKI O, AOYAMA H.Design and control of versatile micro robot for microscopic manipulation[M]. Livermore:American Society for Precision Engineering, 2001:22-29. [6] 郑洋洋, 宫金良, 张彦斐.基于传递矩阵法的柔性杠杆放大机构刚度分析[J].北京航空航天大学学报, 2017, 43(4):849-856. http://bhxb.buaa.edu.cn/CN/abstract/abstract13950.shtmlZHENG Y Y, GONG J L, ZHANG Y F.Rigidity analysis of a flexible lever magnifying mechanism based on transfer matrix method[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(4):849-856(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract13950.shtml [7] NI Y, DENG Z, WU X, et al.Modeling and analysis of an over-constrained flexure-based compliant mechanism[J]. Measurement, 2014, 50(1):270-278. https://www.sciencedirect.com/science/article/pii/S0263224114000268 [8] 于靖军, 毕树生, 宗光华, 等.基于伪刚体模型法的全性机构位置分析[J].机械工程学报, 2002, 38(2):75-78. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_jxgcxb200202017YU J J, BI S S, ZONG G H, et al.Kinematics analysis of fully compliant mechanisms using the pseudo-rigid-body model[J]. Journal of Mechanical Engineering, 2002, 38(2):75-78(in Chinese). http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_jxgcxb200202017 [9] HER I, CHANG J.A linear scheme for the displacement analysis of micropositioning stages with flexure hinges[J]. Journal of Mechanical Design, 1994, 116(3):770-776. doi: 10.1115/1.2919449 [10] 李育文, 张华, 杨建新, 等.6-UPS并联机床静刚度的有限元分析和实验研究[J].中国机械工程, 2004, 15(2):112-115. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_zgjxgc200402006LI Y W, ZHANG H, YANG J X, et al.Finite element analysis and experimental study for the stiffness of a 6-UPS parallel kinematic machine[J]. China Mechanical Engineering, 2004, 15(2):112-115(in Chinese). http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_zgjxgc200402006 [11] 栾玉亮, 荣伟彬, 孙立宁.基于有限元方法的3-PPSR大长径比柔性并联机器人刚度模型分析[J].机器人, 2014, 36(6):730-736. http://www.cnki.com.cn/Article/CJFDTotal-JQRR201406013.htmLUAN Y L, RONG W B, SUN L N.Analysis on stiffness model of 3-PPSR flexible parallel robot with high aspect based on finite element method[J]. Robot, 2014, 36(6):730-736(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-JQRR201406013.htm [12] 于靖军, 毕树生, 宗光华.空间全柔性机构位置分析的刚度矩阵法[J].北京航空航天大学学报, 2002, 28(3):323-326. http://bhxb.buaa.edu.cn/CN/abstract/abstract10852.shtmlYU J J, BI S S, ZONG G H.Stiffness matrix method for displacement analysis of full spatial compliant mechanisms[J]. Journal of Beijing University of Aeronautics and Astronautics, 2002, 28(3):323-326(in Chinese). http://bhxb.buaa.edu.cn/CN/abstract/abstract10852.shtml [13] 张德福, 赵磊.基于柔度矩阵法的整体式XY光学微调整机构研究[J].仪器仪表学报, 2014, 35(2):269-275. http://d.wanfangdata.com.cn/Periodical_yqyb201402005.aspxZHANG D F, ZHAO L.Research of monolithic XY micro-adjustment mechanism based on compliance matrix[J]. Chinese Journal of Scientific Instrument, 2014, 35(2):269-275(in Chinese). http://d.wanfangdata.com.cn/Periodical_yqyb201402005.aspx [14] 于靖军, 毕树生, 宗光华, 等.3自由度柔性微机器人的静刚度分析[J].机械工程学报, 2002, 38(4):7-10. http://d.wanfangdata.com.cn/Periodical_jxgcxb200204002.aspxYU J J, BI S S, ZONG G H, et al.Analysis for the static stiffness of a 3DOF parallel compliant micromanipulator[J]. Chinese Journal of Mechanical Engineering, 2002, 38(4):7-10(in Chinese). http://d.wanfangdata.com.cn/Periodical_jxgcxb200204002.aspx [15] 吴鹰飞, 周兆英.柔性铰链的设计计算[J].工程力学, 2002, 19(6):136-140. http://d.old.wanfangdata.com.cn/Periodical/gclx200206027WU Y F, ZHOU Z Y.Design of flexure hinges[J]. Engineering Mechanics, 2002, 19(6):136-140(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/gclx200206027 [16] KOSEKI Y, TANIKAWA T, KOYACHI N, et al. Kinematic analysis of a translational 3-d of micro-parallel mechanism using the matrix method[J]. Advanced Robotics, 2002, 16(3):251-264. doi: 10.1163/156855302760121927 -

下载:

下载: