-

摘要:

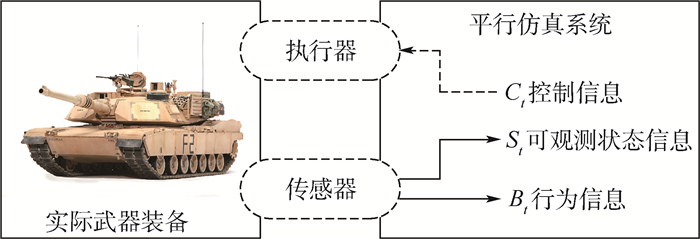

装备平行仿真是系统建模与仿真领域的新兴仿真技术,已经成为研究热点。在装备维修保障领域中,分析了装备剩余寿命(RUL)预测存在的突出问题,即模型参数固定、不具备自适应演化能力,成为阻碍实现装备剩余寿命自适应预测的首要因素。结合装备平行仿真理论,在建模分析的基础上提出了面向装备剩余寿命预测的平行仿真框架,该框架以Wiener状态空间模型为基础仿真模型,在动态注入的装备退化观测数据驱动下,利用期望最大化(EM)算法在线更新模型参数,并利用卡尔曼滤波(KF)算法实现仿真输出数据与观测数据的同化(DA),从而实现仿真模型动态演化,使得仿真输出不断逼近装备真实退化状态,为准确预测剩余寿命提供高逼真度仿真模型和数据输出。以某轴承性能退化数据为数据驱动源,对该框架进行了验证,仿真结果表明平行仿真方法能准确仿真装备性能退化过程,在提高预测精度的基础上实现了装备剩余寿命的自适应预测,有力证明了平行仿真方法的可行性和有效性。

Abstract:As an emerging simulation technology in the field of system modeling & simulation, equipment parallel simulation has become research emphasis. In the field of equipment maintenance support, the outstanding problem of equipment remaining useful life(RUL) prediction is analyzed, i.e., the stable model parameters without self-evolution ability, which has become the primary factor that hinders adaptive prediction of equipment remaining useful life. Combined with parallel systems theory, equipment remaining useful life prediction oriented parallel simulation framework is proposed on the basis of modeling analysis and Wiener state space model is taken as the basic simulation model in the framework. Driven by the dynamic implanted equipment degradation observation data, the model parameters are updated online by using expectation maximum(EM) algorithm and the data assimilation (DA) between simulation outputs and observation data is executed by using Kalman filter(KF), so as to realize dynamic evolution of the simulation model. The simulation model evolution which makes the simulation outputs close to equipment real degradation state provides high fidelity model and data for equipment remaining useful life prediction accurately. The framework is verified by the performance degradation data of a bearing. The simulation results show that the parallel simulation method can accurately simulate the equipment performance degradation process and the adaptive prediction of equipment remaining useful life is realized on the basis of the improved prediction accuracy, proving the feasibility and effectiveness of parallel simulation method.

-

[1] 李伟, 李宗毅, 翟中敏.嵌入式仿真技术及其在军事上的应用[J].系统仿真学报, 2009, 21(21):6968-6971. http://d.wanfangdata.com.cn/Periodical_xtfzxb200921062.aspxLI W, LI Z Y, ZHAI Z M.Embedded simulation and its application in military[J].Journal of System Simulation, 2009, 21(21):6968-6971(in Chinese). http://d.wanfangdata.com.cn/Periodical_xtfzxb200921062.aspx [2] DAVIS W J. On-line simulation: Need and evolving research requirements[M]//BANKS J. Handbook of simulation: Principles, methodology, advances, applications and practices. Hoboken: Wiley, 1998: 465-516. [3] AYDT H, TURNER S J, CAI W T, et al. Research issues in symbiotic simulation[C]//Proceedings of the 2010 Winter Simulation Conference. Piscataway, NJ: IEEE Press, 2010: 1213-1222. [4] CHEN B.KD-ACP:A software framework for social computing in emergency management[J].Mathematical Problems in Engineering, 2014, 21(3):35-38. https://www.hindawi.com/journals/mpe/aa/915429/ [5] 邱晓刚, 胡艮胜.面向辅助决策的平行系统思考[J].指挥与控制学报, 2016, 2(3):230-233. http://www.cqvip.com/QK/72033X/201603/670607863.htmlQIU X G, HU G S.The consideration of parallel system for decision support[J].Journal of Command and Control, 2016, 2(3):230-233(in Chinese). http://www.cqvip.com/QK/72033X/201603/670607863.html [6] GEBRAEEL N, ELWANY A, PAN J.Residual life predictions in the absence of prior degradation knowledge[J].IEEE Transactions on Reliability, 2009, 58(1):106-117. doi: 10.1109/TR.2008.2011659 [7] SI X S, WANG W B, HU C H, et al.Remaining useful life estimation-A review on the statistical data driven approaches[J].European Journal of Operational Research, 2011, 213(1):1-14. doi: 10.1016/j.ejor.2010.11.018 [8] 葛承垄, 朱元昌, 邸彦强, 等.装备平行仿真技术的基础理论问题[J].系统工程与电子技术, 2017, 39(5):1169-1177. doi: 10.3969/j.issn.1001-506X.2017.05.33GE C L, ZHU Y C, DI Y Q, et al.Basic theoretical issues of equipment parallel simulation technology[J].System Engineering and Electronics, 2017, 39(5):1169-1177(in Chinese). doi: 10.3969/j.issn.1001-506X.2017.05.33 [9] 王飞跃.平行系统方法与复杂系统的管理和控制[J].控制与决策, 2004, 19(5):485-489. https://www.wenkuxiazai.com/doc/930657fb700abb68a982fb09-4.htmlWANG F Y.Parallel system methods for management and control of complex systems[J].Control & Decision, 2004, 19(5):485-489(in Chinese). https://www.wenkuxiazai.com/doc/930657fb700abb68a982fb09-4.html [10] WANG F Y.Parallel control and management for intelligent transportation systems:Concepts, architectures, and applications[J].IEEE Transactions on Intelligent Transportation Systems, 2010, 11(3):630-638. doi: 10.1109/TITS.2010.2060218 [11] DAREMA F. Dynamic data driven application systems[EB/OL]. [2016-07-01]. http://www.cise.nsf.gov/dddas. [12] HUANG Y, VERBRAECK A. A dynamic data-driven approach for rail transport system simulation[C]//Proceedings of the 2009 Winter Simulation Conference. Piscataway, NJ: IEEE Press, 2009: 2553-2562. [13] GU F. Dynamic data driven application system for wildfire spread simulation[D]. Atlanta: Georgia State University, 2010. [14] FUJIMOTO R, LUNCEFORD D, PAGE E, et al. Grand challenges for modeling and simulation: 350[R]. Schloss Dagstuhl: Parallel/Distributed Simulation Working Group, 2002. [15] 葛承垄, 朱元昌, 邸彦强, 等.装备平行仿真理论框架研究[J].指挥与控制学报, 2017, 3(1):48-56. http://www.cqvip.com/QK/72033X/201701/7000158970.htmlGE C L, ZHU Y C, DI Y Q, et al.Theoretical framework for equipment parallel simulation[J].Journal of Command and Control, 2017, 3(1):48-56(in Chinese). http://www.cqvip.com/QK/72033X/201701/7000158970.html [16] 陈淼, 孙强, 王东科.平行系统在反导指挥控制中的应用[J].指挥控制与仿真, 2017, 39(1):70-72. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qbzhkzxtyfzjs201701016CHEN M, SUN Q, WANG D K.Application of parallel system method in command and control for anti-missile system[J].Command Control & Simulation, 2017, 39(1):70-72(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qbzhkzxtyfzjs201701016 [17] 葛承垄, 朱元昌, 邸彦强, 等.装备精确维修平行仿真系统及关键技术研究[J].现代防御技术, 2016, 44(6):162-168. http://www.doc88.com/p-4495693142022.htmlGE C L, ZHU Y C, DI Y Q, et al.Research on parallel simulation system and essential technology for equipment precision maintenance[J].Modern Defence Technology, 2016, 44(6):162-168(in Chinese). http://www.doc88.com/p-4495693142022.html [18] 毛少杰, 周芳, 楚威, 等.面向指挥决策支持的平行仿真系统研究[J].指挥与控制学报, 2016, 2(4):315-321. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zhykzxb201604010MAO S J, ZHOU F, CHU W, et al.Parallel simulation systems for command and decision support[J].Journal of Command and Control, 2016, 2(4):315-321(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zhykzxb201604010 [19] 孙黎阳, 楚威, 毛少杰, 等.面向C4ISR系统决策支持的平行仿真框架[J].指挥信息系统与技术, 2015, 6(3):56-61. http://newoa.scnu.edu.cn/scnu/component/attachmentAction.do?action=downloadFile&id=1314404SUN L Y, CHU W, MAO S J, et al.Parallel simulation framework for C4ISR system command decision support[J].Command Information System and Technology, 2015, 6(3):56-61(in Chinese). http://newoa.scnu.edu.cn/scnu/component/attachmentAction.do?action=downloadFile&id=1314404 [20] 窦林涛, 初阳, 周玉芳, 等.平行仿真技术在指控系统中的应用构想[J].指挥控制与仿真, 2017, 39(1):62-69. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qbzhkzxtyfzjs201701015DOU L T, CHU Y, ZHOU Y F, et al.Conception of the application of parallel simulation technology in command and control system[J].Command Control & Simulation, 2017, 39(1):62-69(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qbzhkzxtyfzjs201701015 [21] 王会霞.平行仿真技术研究[J].航天控制, 2016, 34(6):64-67. http://www.cqvip.com/QK/90122X/201606/671033086.htmlWANG H X.Research on parallel simulation technology[J].Aerospace Control, 2016, 34(6):64-67(in Chinese). http://www.cqvip.com/QK/90122X/201606/671033086.html [22] KALMAN R E.A new approach to linear filtering and prediction problems[J].Transactions of the ASME-Journal of Basic Engineering, 1960, 82(1):35-45. doi: 10.1115/1.3662552 [23] MORTADA M.Diagnosis of rotor bearings using logical analysis of data[J].Journal of Quality in Maintenance Engineering, 2011, 17(4):371-397. doi: 10.1108/13552511111180186 -

下载:

下载: