Experiment on cavitation flow in critical cavitation condition of water-jet propulsion pump

-

摘要:

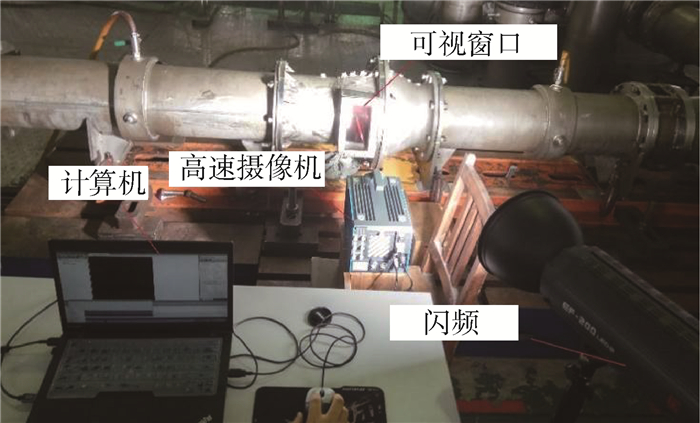

在舰艇空间尺寸的限制下,提高推进器的综合性能是舰船设计的关键。空化是喷水推进泵的主要噪声源和重要设计参数。为降低舰艇的噪声,提高喷水推进泵的空化性能,十分有必要研究空化流动结构演变规律及其对喷水推进泵性能的影响。以某型喷水推进泵为研究对象,采用高速摄像技术开展了喷水推进泵临界空化工况空化流动结构演变规律试验研究。在空化发生和发展过程中,喷水推进泵空化流动结构包括片状空化、云状空化、叶顶间隙空化、叶顶泄漏涡空化和垂直空化涡。试验捕捉了空化演变的物理过程,分析了各空化流动结构对喷水推进泵性能下降的影响。结合数值模拟和前人研究,阐述了空化流动结构形成机理及其对喷水推进泵性能的影响。研究结果为喷水推进泵内的空化现象提供了新的认识,也为空化性能预测方法的研究给予了借鉴和指导。

Abstract:Under the limiation of ship space, it is the key of ship design to improve the comprehensive performance of propeller. Cavitation is the main noise source of water-jet propulsion pump, so it is an important design parameter of water-jet propulsion pump. In order to reduce the noise of the ship and improve the cavitation performance of the water-jet propulsion pump, it is necessary to study the evolution law of the cavitation flow structure and its influence on the pump performance. In this paper, the evolution mechanism of cavitation flow structures in the critical cavitation conditions of water-jet propulsion pump is captured by high-speed photography. The cavitation flow structures of the water-jet propulsion pump during the occurrence and development of cavitation include sheet cavitation, cloud cavitation, tip leakage cavitation, tip vortex cavitation and vertical cavitation vortex. The experiment captures the physical process of cavitation evolution and the effect of each cavitation flow structure on pump performance degradation is analyzed. Combined with simulation and previous research, this paper further expounds the formation mechanism of cavitation flow structure and its influence on the pump performance.The research results not only provide new understanding of the cavitation phenomenon in the water-jet propulsion pump, but also provide reference and guiding significance for the study of cavitation performance prediction methods.

-

-

[1] 季斌, 罗先武, 吴玉林, 等.考虑热力学效应的高温水空化模拟[J].清华大学学报(自然科学版), 2010, 50(2):262-265. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qhdxxb201002024JI B, LUO X W, WU Y L, et al.Cavitating flow simulation for high temperature water based on thermodynamic effects[J].Journal of Tsinghua University(Science and Technology), 2010, 50(2):262-265(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qhdxxb201002024 [2] 熊英华, 刘影, 李述林, 等.基于替代燃料的航空燃油泵内部空化特性[J].航空动力学报, 2015, 30(11):2607-2615. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201511007XIONG Y H, LIU Y, LI S L, et al.Cavitation characteristic in aviation fuel pump based on surrogate fuel[J].Journal of Aerospace Power, 2015, 30(11):2607-2615(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201511007 [3] KATZ J.Cavitation phenomena within regions of flow separation[J].Journal of Fluid Mechanics, 1984, 140:397-436. doi: 10.1017/S0022112084000665 [4] LABERTEAUX K R, CECCIO S L, MASTROCOLA V J, et al.High speed digital imaging of cavitating vortices[J].Experiments in Fluids, 1998, 24(5):489-498. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=949b2536a0206e54581bbfa56242956c [5] PARK W G, JANG J H, CHUN H H, et al.Numerical flow and performance analysis of waterjet propulsion system[J].Ocean Engineering, 2005, 32(14-15):1740-1761. doi: 10.1016/j.oceaneng.2005.02.004 [6] 王勇, 刘厚林, 袁寿其, 等.离心泵非设计工况空化振动噪声的试验测试[J].农业工程学报, 2012, 28(2):35-38. doi: 10.3969/j.issn.1002-6819.2012.02.007WANG Y, LIU H L, YUAN S Q, et al.Experimental testing on cavitation vibration and noise of centrifugal pumps under off-design conditions[J].Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(2):35-38(in Chinese). doi: 10.3969/j.issn.1002-6819.2012.02.007 [7] 邵春雷, 顾伯勤, 周剑锋, 等.离心泵内部流动高速摄像测量及误差分析[J].农业工程学报, 2015, 31(24):52-58. doi: 10.11975/j.issn.1002-6819.2015.24.008SHAO C L, GU B Q, ZHOU J F, et al.Internal flow measurement in centrifugal pump by high speed photography and error analysis[J].Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(24):52-58(in Chinese). doi: 10.11975/j.issn.1002-6819.2015.24.008 [8] MINAMI S, KAWAGUCHI K, HONMA T.Experimental study on cavitation in centrifugal pump impellers[J].Journal of the Japan Society of Mechanical Engineers, 2008, 62(9):19-29. [9] ZHU B, CHEN H, WEI Q.Numerical and experimental investigation of cavitating characteristics in centrifugal pump with gap impeller[J].International Journal of Turbo & Jet-Engines, 2014, 31(2):187-196. http://cn.bing.com/academic/profile?id=27c5788e740779e3cf1594064a4089fc&encoded=0&v=paper_preview&mkt=zh-cn [10] 邓育轩, 李仁年, 韩伟, 等.螺旋离心泵内回流涡空化特性[J].农业工程学报, 2015, 31(1):86-90. doi: 10.3969/j.issn.1002-6819.2015.01.013DENG Y X, LI R N, HAN W, et al.Characteristics of backflow vortex cavitation in screw centrifugal pump[J].Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(1):86-90(in Chinese). doi: 10.3969/j.issn.1002-6819.2015.01.013 [11] 付强, 袁寿其, 朱荣生, 等.离心泵气液固多相流动数值模拟与试验[J].农业工程学报, 2012, 28(14):52-57. doi: 10.3969/j.issn.1002-6819.2012.14.009FU Q, YUAN S Q, ZHU R S, et al.Numerical simulation and experiment on gas-liquid-solid multiphase flow in centrifugal pump[J].Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(14):52-57(in Chinese). doi: 10.3969/j.issn.1002-6819.2012.14.009 [12] 高波, 杨敏官, 李忠, 等.空化流动诱导离心泵低频振动的实验研究[J].工程热物理学报, 2012, 33(6):965-968. http://www.cnki.com.cn/Article/CJFDTotal-GCRB201206016.htmGAO B, YANG M G, LI Z, et al.Experimental study on cavitation induced low frequency vibration in a centrifugal pump[J].Journal of Engineering Thermophysics, 2012, 33(6):965-968(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-GCRB201206016.htm [13] 赖鸣, 兰山, 黄广炎, 等.数字式高速摄像测试技术及其应用[J].实验技术与管理, 2012, 29(6):51-54. doi: 10.3969/j.issn.1002-4956.2012.06.015LAI M, LAN S, HUANG G Y, et al.Metrical technique of digital high speed photography and its application[J].Experimental Technology and Management, 2012, 29(6):51-54(in Chinese). doi: 10.3969/j.issn.1002-4956.2012.06.015 [14] 李世煌, 许建中.离心泵蜗壳内流动的高速摄影测试[J].北京农业工程大学学报, 1990, 10(1):55-60. http://www.cnki.com.cn/Article/CJFDTotal-BJGN199001008.htmLI S H, XU J Z.Measure fluid flowing in volute of centrifugal pump[J].Journal of Beijing Agricultural Engineering University, 1990, 10(1):55-60(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-BJGN199001008.htm [15] 王静, 廖庆喜, 田波平, 等.高速摄像技术在我国农业机械领域的应用[J].农机化研究, 2007(1):184-186. doi: 10.3969/j.issn.1003-188X.2007.01.061WANG J, LIAO Q X, TIAN B P, et al.The present and development tendency of high-speed photography applied on agricultural machinery[J].Journal of Agricultural Mechanization Research, 2007(1):184-186(in Chinese). doi: 10.3969/j.issn.1003-188X.2007.01.061 [16] 杨敦敏.离心泵内两相流流动特性的图像测量[D].西安: 西安理工大学, 2004.YANG D M.Image measurement of two-phase flow characteristic in centrifugal pump impeller[D].Xi'an: Xi'an University of Technology, 2004(in Chinese). [17] 袁寿其, 梁赟, 袁建平, 等.离心泵进口回流流场特性的数值模拟及试验[J].排灌机械工程学报, 2011, 29(6):461-465. doi: 10.3969/j.issn.1674-8530.2011.06.001YUAN S Q, LIANG Y, YUAN J P, et al.Numerical simulation and experiment on characteristics of centrifugal pump inlet recirculation[J].Journal of Drainage and Irrigation Machinery Engineering, 2011, 29(6):461-465(in Chinese). doi: 10.3969/j.issn.1674-8530.2011.06.001 [18] 朱兵.缝隙引流叶片提高低比转速离心泵性能的机理研究[D].上海: 上海大学, 2014.ZHU B.Research on the mechanism of performance improving in low specific speed centrifugal pump with gap drainage blades[D].Shanghai: Shanghai University, 2014(in Chinese). [19] PEARSALL I S.Design of pump impellers for optimum cavitation performance[J].Proceedings of the Institution of Mechanical Engineers, 1973, 187(1):667-678. doi: 10.1243/PIME_PROC_1973_187_060_02 [20] 潘中永, 袁寿其.泵空化基础[M].镇江:江苏大学出版社, 2013.PAN Z Y, YUAN S Q.Fundamentals of cavitation in pumps[M].Zhenjiang:Jiangsu University Press, 2013(in Chinese). [21] 石磊.三维水翼和轴流泵叶顶泄漏涡结构及其空化机理研究[D].镇江: 江苏大学, 2016.SHI L.Research on tip leakage vortex structure and cavitation mechanism in three-dimensional hydrofoil and axial flow pump[D].Zhenjiang: Jiangsu University, 2016(in Chinese). [22] LUO X, JI B, TSUJIMOTO Y.A review of cavitation in hydraulic machinery[J].Journal of Hydrodynamics, 2016, 28(3):335-358. doi: 10.1016/S1001-6058(16)60638-8 [23] TAN D, LI Y, WILKES I, et al.Experimental investigation of the role of large scale cavitating vortical structures in performance breakdown of an axial waterjet pump[J].Journal of Fluids Engineering, 2015, 137(11):317-320. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bcfb76651a18b4bc15eb87fb76c62a73 -

下载:

下载: