Hygrothermal property of domestic carbon fiber/bismaleimide resin composites for aeronautic application

-

摘要:

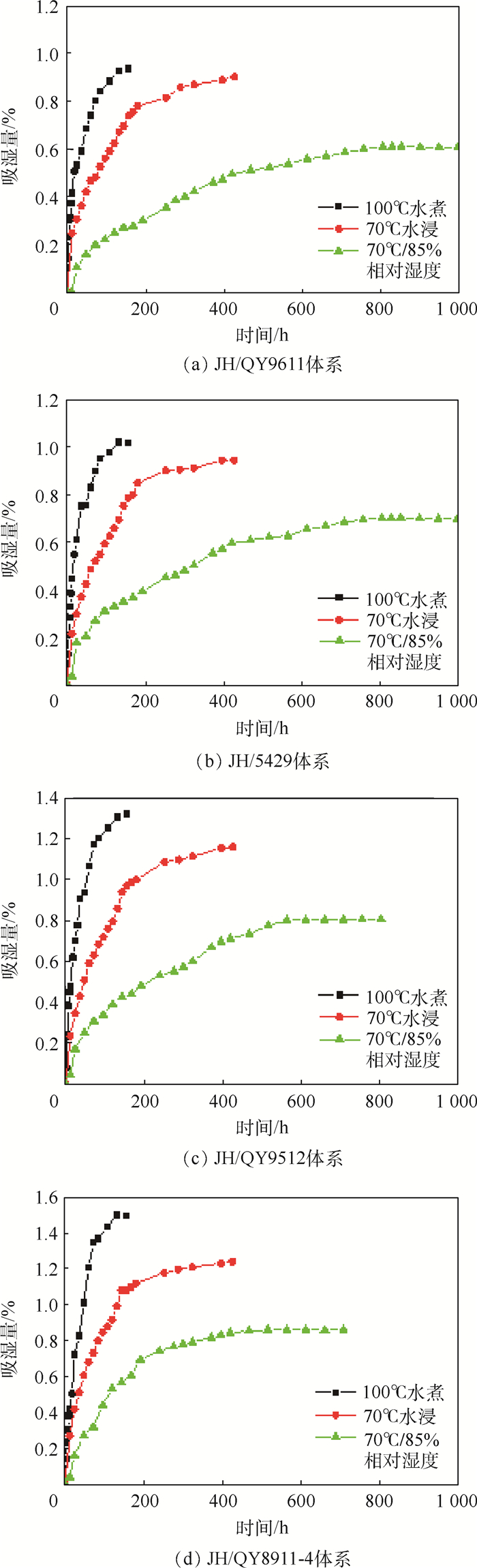

针对1种航空用国产T700级碳纤维和4种双马树脂(QY9611、5429、QY9512、QY8911-4),采用3种湿热条件(100℃水煮、70℃水浸、70℃/85%相对湿度)对其复合材料单向层板进行湿热处理,通过研究吸湿量、扩散系数、显微结构、化学成分、耐热温度及力学性能,分析了复合材料的湿热特性。结果表明,4种复合材料在3种湿热条件下的吸湿行为均符合Fick第二扩散定律,100℃水煮时平衡吸湿量和扩散系数最大,70℃/85%相对湿度时两者最小。4种复合材料吸湿速度有明显区别,这与其原材料形式和成型工艺不同有关。湿热处理未导致复合材料内部产生损伤和化学变化,主要引起增塑效应,导致玻璃化转变温度降低。复合材料的90°拉伸性能测试结果表明,高温和吸湿耦合作用下复合材料力学性能衰减更为明显,破坏模式由基体开裂转变为界面脱黏和开裂。

Abstract:For a kind of domestic T700-grade carbon fiber and four types of bismaleimide resin (QY9611, 5429, QY9512, QY8911-4) used in aeronautic field, three hydrothermal conditions, including 100℃ boiling water, 70℃ water immersion and 70℃/85% relative humidity, were adopted to treat these unidirectional composite laminates. Moisture absorption content, diffusion coefficient, microstructure, chemical groups, resistance to temperature and mechanical property were studied to evaluate hydrothermal property of composite. The results show that the moisture absorption of the four types of composites under the three conditions all follows Fick's second law. Moisture equilibrium content and diffusion coefficient are the largest under boiling water condition, while they are the least under the condition of 70℃/85% relative humidity. Obvious differences on the speeds of moisture absorption among the four bismaleimide composites have the relationship with material type and molding method. Hydrothermal treatment does not result in damage inside composite and chemical change, and the resulting plasticization effect results in decrease in glass transition temperature. The test results of 90° tensile properties of the composites show that the coupling of elevated temperature and moisture absorption causes more serious degradation in composite's mechanical property, and its failure mode transforms from matrix cracking to debonding and fracture at interface region.

-

Key words:

- composite /

- carbon fiber /

- bismaleimide resin /

- hydrothermal treatment /

- moisture absorption

-

表 1 碳纤维/双马树脂复合材料单向层板基本信息

Table 1. Basic information of carbon fiber/bismaleimide resin composite unidirectional laminates

规格种类 成型工艺 材料形式 生产厂家 T700级JH碳纤维/QY9611树脂 热压罐 单向预浸料 中航复合材料有限责任公司 T700级JH碳纤维/5429树脂 热压罐 单向预浸料 T700级JH碳纤维/QY9512树脂 RFI(树脂膜熔渗) 单向织物+树脂膜 T700级JH碳纤维/QY8911-4树脂 RTM(树脂传递模塑) 单向织物+树脂 表 2 不同湿热条件下4种T700级JH碳纤维/双马树脂复合材料平衡吸湿量和平衡时间

Table 2. Equilibrium moisture absorption content and balance time of four kinds of T700-grade JH carbon fiber/bismaleimide resin composite under different hygrothermal conditions

处理方式 平衡吸湿量/% 平衡时间/h JH/QY8911-4 JH/QY9512 JH/5429 JH/QY9611 100℃水煮 1.50 1.32 1.02 0.94 130 70℃水浸 1.24 1.16 0.95 0.90 390 70℃/85%相对湿度 0.86 0.81 0.70 0.61 ≤850 表 3 不同湿热条件下4种T700级JH碳纤维/双马树脂复合材料扩散系数

Table 3. Diffusion coefficient of four kinds of T700-grade JH carbon fiber/bismaleimide resin composite under different hygrothermal conditions

材料体系 处理方式 Dz/(mm2·s-1) JH/QY9611 100℃水煮 1.68×10-6 70℃水浸 8.86×10-7 70℃/85%相对湿度 1.79×10-7 JH/5429 100℃水煮 2.19×10-6 70℃水浸 1.01×10-6 70℃/85%相对湿度 3.15×10-7 JH/QY9512 100℃水煮 2.23×10-6 70℃水浸 9.78×10-7 70℃/85%相对湿度 4.04×10-7 JH/QY8911-4 100℃水煮 2.36×10-6 70℃水浸 1.19×10-6 70℃/85%相对湿度 2.03×10-7 表 4 复合材料层板纤维体积分数和孔隙率

Table 4. Fiber volume fraction and porosity of composite laminate

材料体系 纤维体积分数/% 孔隙率/% JH/QY8911-4 60.49 0.11 JH/QY9512 60.54 0.12 JH/5429 64.93 0.11 JH/QY9611 64.27 0.12 表 5 70℃水浸390 h前后4种T700级JH碳纤维/双马树脂复合材料玻璃化转变温度

Table 5. Glass transition temperature of four kinds of T700-grade JH carbon fiber/bismaleimide resin composite before and after 70℃ water immersion for 390 h

材料体系 玻璃化转变温度/℃ 变化率/% 干态 湿态 JH/QY9611 236 184 28.3 JH/5429 234 182 28.6 JH/QY9512 235 202 16.3 JH/QY8911-4 258 218 18.3 -

[1] 益小苏.复合材料手册[M].北京:化学工业出版社, 2009:424-430.YI X S.Composite materials handbook[M].Beijing:Chemical Industry Press, 2009:424-430(in Chinese). [2] 詹博文, 孙凌玉, 黄彬城, 等.车用复合材料螺旋弹簧的设计与优化[J].北京航空航天大学学报, 2018, 44(7):1520-1527. doi: 10.13700/j.bh.1001-5965.2017.0548ZHAN B W, SUN L Y, HUANG B C, et al.Design and optimization of automotive composite helical spring[J].Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(7):1520-1527(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0548 [3] PEI S, YAN Z, LUO Y, et al.Effect of temperature and cyclic hygrothermal aging on the interlaminar shear strength of carbon fiber/bismaleimide (BMI) composite[J].Materials & Design, 2011, 32(8):4341-4347. http://www.sciencedirect.com/science/article/pii/S0261306911002627 [4] JEDIDI J, JACQUEMIN F, VAUTRIN A.Design of accelerated hygrothermal cycles on polymer matrix composites in the case of a supersonic aircraft[J].Composite Structures, 2005, 68(4):429-437. doi: 10.1016/j.compstruct.2004.04.009 [5] YUICHIRO A, KEN Y, TAKASHI I.Effect of hygrothermal condition on compression after impact strength of CFRP laminates[J].Composites Science and Technology, 2008, 68(6):1376-1383. doi: 10.1016/j.compscitech.2007.11.015 [6] JOLIFF Y, BELEC L, HEMAN M B, et al.Experimental analytical and numerical study of water diffusion in unidirectional composite materials-Interphase impact[J].Computational Materials Science, 2012, 64(4):141-145. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=14f58900410af35bd194f0928839da19 [7] BAO L R, YEE A F.Effect of temperature on moisture absorption in a bismaleimide resin and its carbon fiber composites[J].Polymer, 2002, 43(14):3987-3997. doi: 10.1016/S0032-3861(02)00189-1 [8] BAO L R, YEE A F.Moisture diffusion and hygrothermal aging in bismaleimide matrix carbon fiber composites-Part Ⅰ:Uni-weave composites[J].Composites Science and Technology, 2002, 62(16):2099-2110. doi: 10.1016/S0266-3538(02)00161-6 [9] BAO L R, YEE A F.Moisture diffusion and hygrothermal aging in bismaleimide matrix carbon fiber composites-Part Ⅱ:Woven and hybrid composites[J].Composites Science and Technology, 2002, 62(16):2111-2119. doi: 10.1016/S0266-3538(02)00162-8 [10] 冯青, 李敏, 顾轶卓, 等.不同湿热条件下碳纤维/环氧复合材料湿热性能实验研究[J].复合材料学报, 2010, 27(6):16-20. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fhclxb201006003FENG Q, LI M, GU Y Z, et al.Experimental research on hygrothermal properties of carbon fiber/epoxy resin composite under different hygrothermal conditions[J].Acta Materiae Compositae Sinica, 2010, 27(6):16-20(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fhclxb201006003 [11] 齐磊, 李敏, 顾轶卓, 等.双马树脂复合材料湿热特性实验研究[J].航空学报, 2009, 30(12):2476-2480. doi: 10.3321/j.issn:1000-6893.2009.12.034QI L, LI M, GU Y Z, et al.Experimental study on hygrothermal properties of several kinds of carbon fiber/BMI resin composites[J].Acta Aeronautica et Astronautica Sinica, 2009, 30(12):2476-2480(in Chinese). doi: 10.3321/j.issn:1000-6893.2009.12.034 [12] 王迎芬, 彭公秋, 谢富原.国产T700级碳纤维/BMI复合材料湿热性能[J].材料科学与工艺, 2018, 26(3):16-22. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=clkxygy201803003WANG Y F, PENG G Q, XIE F Y.Hygrothermal properties of domestic T700 carbon fiber/bismaleimide composites[J].Materials Science and Technology, 2018, 26(3):16-22(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=clkxygy201803003 [13] 封彤波, 肇研, 罗云烽, 等.循环湿热环境下碳纤维复合材料的界面性能[J].北京航空航天大学学报, 2010, 36(12):1427-1431. https://bhxb.buaa.edu.cn/CN/Y2010/V36/I12/1427FENG T B, ZHAO Y, LUO Y F, et al.Effect of cyclic hygrothermal environment on interfacial property of CCF300/BMI composites[J].Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(12):1427-1431(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2010/V36/I12/1427 [14] 齐忠新, 燕瑛, 刘玉佳, 等.T300/QY8911单向板湿热性能模拟与损伤分析[J].北京航空航天大学学报, 2012, 38(7):947-952. https://bhxb.buaa.edu.cn/CN/Y2012/V/I7/947QI Z X, YAN Y, LIU Y J, et al.Hygrothermal properties simulation and damage analysis of T300/QY8911 unidirectional laminates[J].Journal of Beijing University of Aeronautics and Astronautics, 2012, 38(7):947-952(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2012/V/I7/947 [15] ANA P B, ANA P P, ERICK S G, et al.Accelerated aging effects on carbon fiber/epoxy composites[J].Composites Part B:Engineering, 2017, 110:298-306. doi: 10.1016/j.compositesb.2016.11.004 [16] CHOI H S, AHN K J, NAM J D, et al.Hygroscopic aspects of epoxy/carbon fiber composite laminates in aircraft environments[J].Composites Part A:Applied Science and Manufacturing, 2001, 32(5):709-720. doi: 10.1016/S1359-835X(00)00145-7 [17] 中国航空工业总公司第六二三研究所.树脂基复合材料层合板湿热环境吸湿试验方法:HB 7401-96[S].北京:中国航空工业总公司, 1996:1-4. [18] ARNOLD J C, ALSTON S M, KORKEES F.An assessment of methods to determine the directional moisture diffusion coefficients of composite materials[J].Composites Part A:Applied Science and Manufacturing, 2013, 55:120-128. doi: 10.1016/j.compositesa.2013.08.012 [19] ASTM Committee D30.Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM D5229/D5229M-14[S].[S.l]: ASTM, 2014: 1-19. [20] ASTM Committee D30.Standard test method for tensile properties of polymer matrix composite materials: ASTM D 3039-2008[S].[S.l]: ASTM, 2008: 1-13. -

下载:

下载: