Influence of one side facesheet crack damage on flexural properties of titanium honeycomb sandwich structures

-

摘要:

钛合金蜂窝夹层结构在制备或使用过程中可能会产生面板裂纹损伤。采用试验和有限元结合的方法研究了单侧面板裂纹损伤对钛合金蜂窝夹层结构弯曲性能的影响。结果显示:单侧面板裂纹损伤会明显降低钛合金蜂窝夹层结构面板弯曲强度,弯曲强度近似随裂纹长度的增加而线性降低;有限元模型能够准确预测结构的破坏模式和破坏强度,预测得到的面板弯曲强度与试验结果最大偏差仅为6%。采用的有限元方法可用于含面板裂纹损伤的钛合金蜂窝壁板结构弯曲性能的工程预估。

Abstract:During the manufacturing process and service period, the crack damage may occur in the facesheet of titanium honeycomb sandwich structure. The influence of one side facesheet crack damage on flexural properties of titanium honeycomb sandwich structures was studied experimentally and numerically. The research results show that the flexural strength of titanium honeycomb sandwich structure with one side facesheet crack damage is obviously lower than that of the structure without crack damage, and the flexural strength decreases linearly with the increase of the crack length; the finite element models can accurately predict the failure mode and fracture strength of the structures, and the maximum deviation between the predicted results and the test result is only 6%. The finite element analysis method can be used to predict the flexural strength of titanium honeycomb sandwich structure with facesheet crack damage in the engineering estimate.

-

表 1 试验件尺寸参数

Table 1. Dimension parameters of specimens

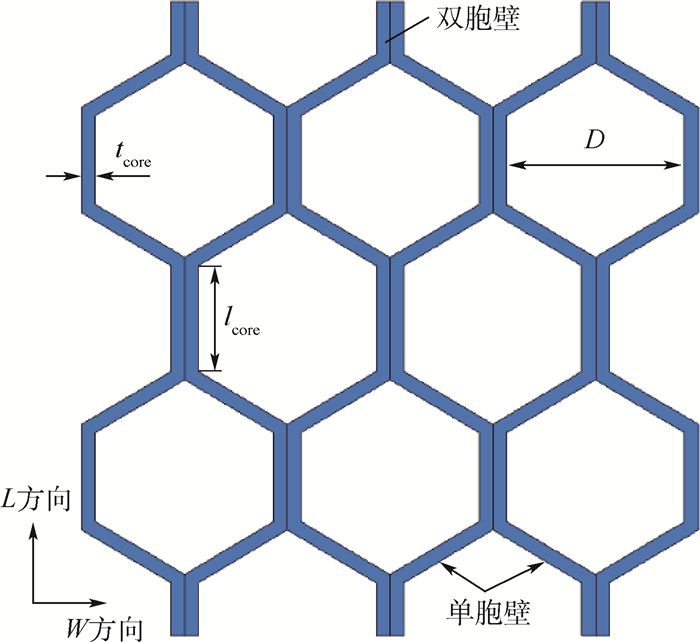

参数 数值 长度/mm 440 宽度/mm 50 芯体高度/mm 15 面板厚度/mm 0.8 芯格直径/mm 4.8 芯材厚度/mm 0.05 裂纹宽度/mm 0.1 裂纹长度/mm 0, 12.5, 19, 25 表 2 试验测试得到的钛合金蜂窝夹层结构面板弯曲强度

Table 2. Experimental facesheet flexural strength of titanium honeycomb sandwich structures

裂纹长度/mm 裂纹长度/面板宽度×100% 面板弯曲强度试验值 面板弯曲强度降低比例/% 最小值/MPa 最大值/MPa 平均值/MPa 标准差/MPa 离散系数/% 0 0 1 062 1 106 1 087 17.06 1.6 0 12.5 25 690 748 713 24.52 3.4 34 19 38 524 659 592 61.61 10.4 46 25 50 465 554 523 31.46 6.0 52 表 3 试验件采用的钛合金材料参数

Table 3. Material parameters of titanium used in specimen

材料 弹性模量/GPa 泊松比 屈服强度/MPa 破坏强度/MPa 断裂韧性/(MPa·m1/2) 临界能释放率/(MPa·m) TC1 120.47 0.358 635 689 TC4 108.48 0.30 861 967 83.3 64 000 表 4 钛合金蜂窝夹层结构面板弯曲强度对比

Table 4. Comparison of bending strength of titanium honeycomb sandwich structure

裂纹长度/mm 裂纹长度 /% 面板弯曲强度/MPa 偏差/% 面板宽度 有限元预测值 试验值 0 0 1 026 1 087 -6 12.5 25 688 713 -4 19 38 574 592 -3 25 50 550 523 5 -

[1] WOODWARD J R.Titanium honeycomb sandwich fabrication process[C]//Fifth National SAMPLE Technical Conference, 1973: 432-437. [2] 谢宗蕻, 岳喜山, 孙俊锋.钛合金蜂窝壁板隔热性能试验研究[J].南京航空航天大学学报, 2016, 48(1):16-20. http://www.cnki.com.cn/Article/CJFDTotal-NJHK201601003.htmXIE Z H, YUE X S, SUN J F.Experimental study on thermal insulation performance of titanium honeycomb sandwich panels[J].Journal of Nanjing University of Aeronautics & Astronautics, 2016, 48(1):16-20(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-NJHK201601003.htm [3] 岳喜山, 欧阳小龙, 侯金保, 等.钛合金蜂窝壁板结构钎焊工艺[J].航空制造技术, 2009(10):96-98. http://www.cnki.com.cn/Article/CJFDTotal-HKGJ200910024.htmYUE X S, OUYANG X L, HOU J B, et al.Brazing process of titanium alloy honeycomb sandwich panel structure[J].Aeronautical Manufacturing Technology, 2009(10):96-98(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-HKGJ200910024.htm [4] 静永娟, 李晓红, 岳喜山.TC1钛合金蜂窝夹层结构的钎焊工艺研究与分析[J].航空制造技术, 2012(13):137-139. http://www.cnki.com.cn/Article/CJFDTotal-HKGJ201213032.htmJING Y J, LI X H, YUE X S.Research and analysis of processing parameter for brazing honeycomb sandwich construction in titanium alloy[J].Aeronautical Manufacturing Technology, 2012(13):137-139(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-HKGJ201213032.htm [5] ZHAO W, XIE Z H, LI X, et al.Compression after impact behavior of titanium honeycomb sandwich structure[J].Journal of Sandwich Structures and Materials, 2018, 20(5):639-657. doi: 10.1177/1099636217707150 [6] XIE Z H, ZHAO W, HANG J T, et al.Low-velocity impact behavior of titanium honeycomb sandwich structures[J].Journal of Sandwich Structures and Materials, 2018, 20(8):1009-1027. doi: 10.1177/1099636217728421 [7] 刘晓宇.钛合金蜂窝夹层结构力学性能分析与试验验证[D].西安: 西北工业大学, 2014.LIU X Y.Mechanical properties of titanium honeycomb sandwich structures analysis and experimental validation[D].Xi'an: Northwestern Polytechnical University, 2014(in Chinese). [8] ZENKERT D.An introduction to sandwich construction[M].London:Engineering Materials Advisory Services Ltd., 1995. [9] SHENOI R A, GROVES A, RAJAPAKSE Y D S.Theory and applications of sandwich structures[M].Southampton:University of Southampton Press, 2005. [10] 王兴业.夹层结构复合材料设计原理及其应用[M].北京:化学工业出版社, 2007.WANG X Y.Design principle and application of sandwich structure composite materials[M].Beijing:Chemical Industry Press, 2007(in Chinese). [11] 杨凯, 刘立武, 于开平, 等.带有典型缺陷的金属蜂窝夹层结构的剩余强度研究[J].固体火箭技术, 2011, 34(5):652-654. http://www.cnki.com.cn/Article/CJFDTotal-GTHJ201105026.htmYANG K, LIU L W, YU K P, et al.Study on the residual strength of metal honeycomb sandwich structure with typical defects[J].Journal of Solid Rocket Technology, 2011, 34(5):652-654(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-GTHJ201105026.htm [12] 赵震波, 许希武, 郭树祥.梯度钛合金裂纹扩展速率测试及梯度对扩展寿命影响[J].复合材料学报, 2017, 34(1):168-174. http://www.cnki.com.cn/Article/CJFDTotal-FUHE201701022.htmZHAO Z B, XU X W, GUO S X.Fatigue crack growth rate determination of graded titanium alloys and the influence of gradient for propagation life[J].Acta Materiae Compositae Sinica, 2017, 34(1):168-174(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-FUHE201701022.htm [13] MAZEL V, DIARRA H, BUSIGNIES V, et al.Study of the validity of the three-point bending test for pharmaceutical round tablets using finite element method modeling[J].Journal of Pharmaceutical Sciences, 2014, 103(4):1305-1308. doi: 10.1002/jps.23898 [14] 孔祥皓, 赫晓东.带有典型缺陷的金属蜂窝夹层结构的共面力学性能研究[J].固体火箭技术, 2010, 33(6):684-689. http://www.cnki.com.cn/Article/CJFDTotal-GTHJ201006020.htmKONG X H, HE X D.Study on coplanar mechanical properties of metal honeycomb sandwich structures with typical defects[J].Journal of Solid Rocket Technology, 2010, 33(6):684-689(in Chinese). http://www.cnki.com.cn/Article/CJFDTotal-GTHJ201006020.htm [15] HUANG X, RICHARDS N L.Activated diffusion brazing technology for manufacture of titanium honeycomb structures-A statistical study[J].Welding Research, 2004, 83(3):73-81. [16] ALLEN H G.Analysis and design of structural sandwich panels[M].Oxford:Pergamon Press, 1969. [17] 杨宇.金属蜂窝夹层结构弯曲性能分析[J].科技视界, 2015(26):104-105.YANG Y.Bending property analysis of metal honeycomb sandwich structure[J].Science & Technology Vision, 2015(26):104-105(in Chinese). [18] 上海玻璃钢研究所, 北京航空材料研究院.夹层结构弯曲性能试验方法: GB/T 1456-2005[S].北京: 中国标准出版社, 2005.Shanghai FRP Research Institute, Bejing Institute of Aeronautical Materials.Test method for flexural properties of sandwich constructions: GB/T 1456-2005[S].Beijing: China Standard Press, 2005(in Chinese). [19] 郭玉瑛.飞机设计手册第三册:材料(上)[M].北京:航空工业出版社, 1997:405.GUO Y Y.Aircraft design manual three:Material(1)[M].Beijing:Aeronautical Industry Press, 1997:405(in Chinese). -

下载:

下载: