Dual-linear-array TFM ultrasonic imaging method for weld defects of complex structure

-

摘要:

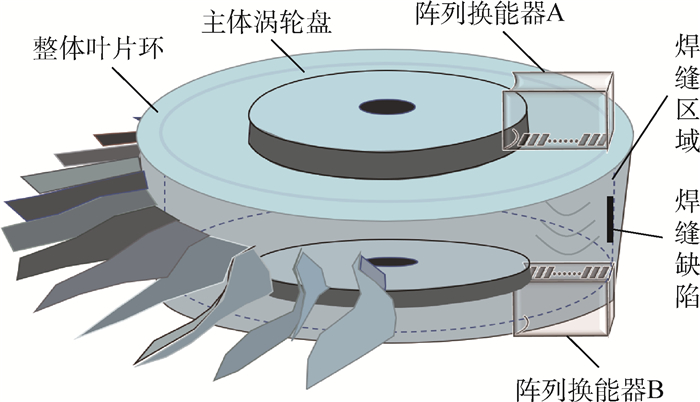

某型航空发动机高温合金盘由涡轮盘本体和外层整体叶片环焊接而成,采用常规单通道超声方法检测焊接面缺陷时,存在检测分辨率低、信噪比差等问题,为此,提出了一种采用两组线性阵列换能器的检测方案。利用全聚焦方法(TFM)对焊接面缺陷进行成像表征,与常规全聚焦方法不同,阵列孔径和波形模式均能随检测深度动态变化,其最优参数通过理论仿真确定。制备了含预埋缺陷的航空发动机高温合金盘试样,开展了检测实验。结果表明:提出的双线阵全聚焦超声成像方法能有效提高高温合金盘未焊合面积型缺陷的检测能力,是一种可行的检测方案。

-

关键词:

- 双线性阵列换能器 /

- 全聚焦(TFM)成像 /

- 高温合金盘 /

- 面积型缺陷 /

- 声学仿真

Abstract:A certain type of superalloy disk component of aero-engine is welded by the turbine disk and the outer integral blade ring, and when the conventional single-channel ultrasonic method is used to detect welding surface defects, there are problems such as low detection resolution and poor signal-to-noise ratio. For this reason, a detection scheme using dual-linear-array transducer is proposed. The Total Focusing Method (TFM) is used to image and characterize welding surface defects. Unlike the conventional TFM, the array aperture and waveform pattern can be dynamically changed with the detection depth, and the optimal parameters are determined by theoretical simulation. Samples of aero-engine superalloy disk with embedded defects were prepared, and testing experiments were carried out. The results show that the proposed dual-linear-array TFM ultrasonic imaging method can effectively improve the detection ability of unwelded area defects in superalloy disk and is a feasible detection scheme.

-

表 1 不同位置矩形缺陷在4种模式下的DSNR值统计

Table 1. DSNR values for rectangular defects of different positions in four modes

缺陷位置/mm DSNR/dB AL-BL AS-BS AS-BL AL-BS 8.3 34.41 34.63 52.47 28.11 18.3 36.90 39.60 35.05 30.35 28.3 33.81 37.17 37.17 48.77 -

[1] 曲伸, 李英, 倪建成, 等. 航空发动机先进焊接技术应用[J]. 航空制造技术, 2015(20): 53-55. https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201520008.htmQU S, LI Y, NI J C, et al. Application of advanced welding technology in aeroengine[J]. Aeronautical Manufacturing Technology, 2015(20): 53-55(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201520008.htm [2] RAUJOL S, PETTINARI F, LOCQ D, et al. Creep straining micro-mechanisms in a powder metallurgical nickel based superalloy[J]. Materials Science and Engineering: A, 2004, 387-389: 678-682. doi: 10.1016/j.msea.2004.02.091 [3] TERZI S, COUTURIER R, GUETAZ L, et al. Modelling the plastic deformation during high temperature creep of a powder metallurgy coarse grained superalloy[J]. Materials Science and Engineering: A, 2008, 483-484: 598-601. doi: 10.1016/j.msea.2006.10.186 [4] POLLOCK T M, TIN S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties [J]. Jornal of Propulsion and Power, 2006, 22(2): 361. doi: 10.2514/1.18239 [5] 张国庆, 张义文, 郑亮, 等. 航空发动机用粉末高温合金及制备技术研究进展[J]. 金属学报, 2019, 55(9): 1133-1144. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201909006.htmZHANG G Q, ZHANG Y W, ZHENG L, et al. Research progress in powder metallurgy superalloys and manufacturing technologies for aero-engine application[J]. Acta Metallurgica Sinica, 2019, 55(9): 1133-1144(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201909006.htm [6] RASISSON G. Evolution of PM nickel base superalloy processes and products[J]. Powder Metallurgy, 2008, 50(1): 10-13. http://www.zhangqiaokeyan.com/academic-journal-foreign_other_thesis/020414279995.html [7] CHEN J, DONG J, ZHANG M, et, al. Deformation mechanisms in a fine-grained Udimet 720LI nickel-base super alloy with high volume fractions of γ' phases[J]. Materials Science and Engineering: A, 2016, 673: 122-134. doi: 10.1016/j.msea.2016.07.068 [8] YANG P, CHENG B, SHI K R. A novel method to design sparse linear arrays for ultrasonic phased array[J]. Ultrasonics, 2006, 44: 717-721. doi: 10.1016/j.ultras.2006.05.131 [9] CHATILLON S, CARRIAUX G, SERRE M, et al. Ultrasonic non-destructive testing of pieces of complex geometry with a flexible array transducer[J]. Ultrasonic, 2000, 38: 131-134. doi: 10.1016/S0041-624X(99)00181-X [10] PUEL B, LESSELIER D, CHATILLON S, et al. Optimization of ultrasonic arrays design and setting using a differential evolution[J]. NDT & E International, 2011, 44: 797-803. http://www.sciencedirect.com/science/article/pii/S0963869511001204 [11] 杨平华, 林莉, 刘春伟, 等. 相控阵声束焦距及换能器孔径综合有现货的实验研究[J]. 无损检测, 2011, 35(3): 9-13.YANG P H, LIN L, LIU C W, et al. Experimental study on the integrated optimization of focus length and transducer aperture for phased array beam[J]. Nondestructive Testing, 2011, 35(3): 9-13(in Chinese). [12] 涂春磊, 邹建华, 强天鹏, 等. 对接焊缝相控阵超声检测可靠性的CIVA仿真与试验[J]. 无损检测, 2013, 35(11): 22-26. https://www.cnki.com.cn/Article/CJFDTOTAL-WSJC201311007.htmTU C L, ZOU J H, QIANG T P, et al. Reliability analysis of phased ultrasonic testing for butt weld by CIVA simulation and experiment[J]. Nondestructive Testing, 2013, 35(11): 22-26(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-WSJC201311007.htm [13] 李莹莹, 陈军, 林莉. 面积型缺陷相控阵超声检测可靠性的研究[J]. 无损探伤, 2014, 38(4): 6-9. doi: 10.3969/j.issn.1671-4423.2014.04.002LI Y Y, CHEN J, LIN L. Research on the reliability of phased array ultrasonic testing on planar defects[J]. Nondestructive Testing Technology, 2014, 38(4): 6-9(in Chinese). doi: 10.3969/j.issn.1671-4423.2014.04.002 [14] HUNTER A J, DRINKWATER B W, WILCOX P D. The wave number algorithm for full matrix imaging using an ultrasonic array[J]. IEEE Transaction on Ultrasonics, Ferroelectrics, and Frequency Control, 2008, 55(11): 2450-2462. doi: 10.1109/TUFFC.952 [15] VELICHKO A, WILCOX P D. Reversible back-propagation imaging algorithm for post processing of ultrasonic array data[J]. IEEE Transaction on Ultrasonics, Ferroelectrics, and Frequency Control, 2009, 56(11): 2492-2503. doi: 10.1109/TUFFC.2009.1336 -

下载:

下载: