-

摘要:

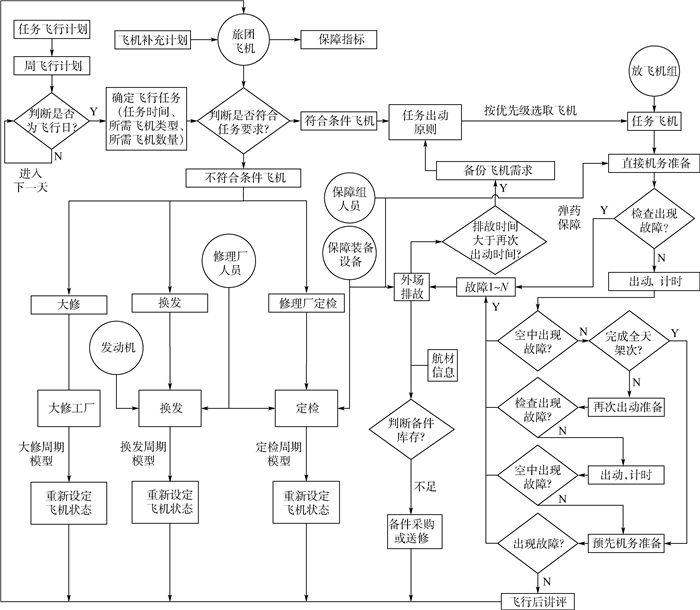

针对航空装备体系结构复杂、要素繁多、耦合性强的特点,对其保障流程进行了研究。采用多Agent建模技术开展航空装备体系保障性仿真建模,并进行分析评估;考虑到保障过程中大量存在的主客观不确定性因素,分别采用模糊变量和随机分布2种变量形式予以描述;为符合客观变量动态时变的特点,将基于交叉熵的最大似然估计和哈密顿蒙特卡罗方法相结合,实现基于信息更新的仿真参数描述,优化航空装备体系保障仿真模型。以一个典型战训任务为例,验证了所提方法的可行性和准确性。

Abstract:Aimed at the characteristics of complex structure, various elements, and strong coupling of aviation equipment system, based on the analysis of its support process, the multi-Agent modeling technology is used to carry out the supportability modeling of the aviation equipment system, and analysis and evaluation are performed. Taking into account the large amount of subjective and objective uncertainty factors in the support process, the uncertainty factors are described in the forms of random distribution and fuzzy variables. In order to conform to the characteristics of dynamic time-varying objective variables, the maximum likelihood estimation based on cross-entropy and the Hamilton Monte Carlo method are combined to realize simulation parameter description based on information update and optimize aviation equipment system support simulation model. Finally, a typical combat training task is taken as an example to verify the feasibility and accuracy of the proposed method.

-

Key words:

- aviation equipment system /

- support /

- multi-Agent model /

- uncertainty /

- information update /

- simulation evaluation

-

表 1 航空装备体系保障流程参数描述

Table 1. Aviation equipment system support process parameter description

类别 参数 战训任务参数 飞行日安排 单日飞行批次 每批飞行架次 每日参训任务持续时间 年总计划飞行时间 装备可靠性参数 MTBF 飞机初始飞行时间 维修性参数 定检时间 大修时间 检查时间 保障性参数 航材备件申领时间 车辆申领延误时间 大修厂维修能力 修理厂定检能力 工具数量 航材备件初始数量 保障设备数量 表 2 主要仿真参数

Table 2. Main simulation parameters

参数 数值 飞行日安排

单日飞行批次 3 每批飞行架次 4 每日参训任务持续时间/h 1.5 年总计划飞行时间/h 4 500 分系统1 MTBF/h 60 分系统2 MTBF/h 100 分系统3 MTBF/h 69 分系统4 MTBF/h 94 分系统5 MTBF/h 126 分系统6 MTBF/h 50 分系统7 MTBF/h 83 分系统8 MTBF/h 94 分系统9 MTBF/h 78 分系统10 MTBF/h 80 分系统11 MTBF/h 132 分系统12 MTBF/h 106 大修时间/d 300 定检时间/d 14 检查时间/min 22.5 航材备件申领时间/d 1 车辆申领延误时间/min 3 大修厂维修能力 2 修理厂定检能力 4 工具数量 24 航材备件初始数量 5 保障设备数量 24 表 3 客观不确定变量分布参数

Table 3. Objective uncertain variable distribution parameters

分系统序号 a b k 1 0.010 1 0.006 1 0.869 5 2 0.006 2 0.004 1.113 7 3 0.008 9 0.005 1 0.869 4 4 0.005 0.005 0.631 3 5 0.003 8 0.003 6 0.623 7 6 0.011 7 0.007 5 0.860 5 7 0.005 9 0.005 1 0.589 9 8 0.005 7 0.003 7 0.565 3 9 0.008 4 0.003 5 0.769 8 10 0.006 3 0.005 3 0.628 5 11 0.004 4 0.002 6 0.698 12 0.009 4 0.001 5 37.380 2 表 4 主观不确定变量分布参数

Table 4. Subjective uncertain variable distribution parameters

主观不确定性变量 三角模糊数 大修时间/d (280,300,320) 定检时间/d (7,14,21) 检查时间/min (10,22.5,25) 航材备件申领时间/d (0.5,1,1.5) 车辆申领延误时间/min (2,3,4) -

[1] 丁刚, 张琳, 崔利杰, 等. 基于任务的航空装备保障体系概念建模研究[J]. 军事运筹与系统工程, 2020, 34(1): 39-46. doi: 10.3969/j.issn.1672-8211.2020.01.008DING G, ZHANG L, CUI L J, et al. Research on concept modeling of mission-based aviation equipment support system of systems[J]. Military Operations Research and Systems Engineering, 2020, 34(1): 39-46(in Chinese). doi: 10.3969/j.issn.1672-8211.2020.01.008 [2] 邢彪, 曹军海, 宋太亮, 等. 基于Agent的维修保障仿真系统设计与实现[J]. 系统仿真学报, 2017, 29(1): 129-135. https://www.cnki.com.cn/Article/CJFDTOTAL-XTFZ201701018.htmXING B, CAO J H, SONG T L, et al. Design and implementation for maintenance support simulation system based on Agent[J]. Journal of System Simulation, 2017, 29(1): 129-135(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-XTFZ201701018.htm [3] 冯强, 曾声奎, 康锐. 基于多主体的舰载机综合保障过程建模方法[J]. 系统工程与电子技术, 2010, 32(1): 211-216. https://www.cnki.com.cn/Article/CJFDTOTAL-XTYD201001047.htmFENG Q, ZENG S K, KANG R. Multiagent-based modeling method for integrated logistic support of the carrier aircraft[J]. Systems Engineering and Electronics, 2010, 32(1): 211-216(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-XTYD201001047.htm [4] 郭霖瀚, 康锐, 康晓明. 装备群保障规模预测方法研究[J]. 系统工程与电子技术, 2009, 31(5): 1262-1265. doi: 10.3321/j.issn:1001-506X.2009.05.058GUO L H, KANG R, KANG X M. Equipments support footprint forecast method research[J]. Systems Engineering and Electronics, 2009, 31(5): 1262-1265(in Chinese). doi: 10.3321/j.issn:1001-506X.2009.05.058 [5] MEHDIFAR F, BECHLIOULIS C P, HASHEMZADEH F, et al. Prescribed performance distance-based formation control of multi-agent systems[J]. Automatica, 2020, 119: 109086. doi: 10.1016/j.automatica.2020.109086 [6] FLOREZ L J, CARAFFINI F, PARRA C, et al. Cooperative and distributed decision-making in a multi-agent perception system for improvised land mines detection[J]. Information Fusion, 2020, 64: 32-49. doi: 10.1016/j.inffus.2020.06.009 [7] 赵星贺, 周斌, 封会娟, 等. 基于蒙特卡罗仿真评价车辆装备预防性维修间隔期方法[J]. 兵工自动化, 2019, 38(11): 92-96. https://www.cnki.com.cn/Article/CJFDTOTAL-BGZD201911022.htmZHAO X H, ZHOU B, FENG H J, et al. Evaluation method of preventive maintenance interval of vehicle equipment based on Monte Carlo simulation[J]. Ordnance Industry Automation, 2019, 38(11): 92-96(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-BGZD201911022.htm [8] AMIN M, MOHAMMAD R F, DAVOOD D, et al. Grey-fuzzy solution for multi-objective linear programming with interval coefficients[J]. Grey Systems: Theory and Application, 2018, 8(3): 312-327. doi: 10.1108/GS-01-2018-0007 [9] SURADEI D, JESSADA K, WAREE K. State-of-charge estimation based on theory of evidence and interval analysis with differential evolution optimization[J]. Annals of Operations Research, 2019, 300: 399-414. doi: 10.1007/s10479-019-03390-0 [10] AVRILIA K, NIKOS M, BASIL P. Fuzzy reasoning in the investigation of seismic behavior[J]. Mathematical Methods in the Applied Sciences, 2020, 43(13): 7747-7757. doi: 10.1002/mma.6184 [11] YOUSEFI N, COIT D W, SONG S. Reliability analysis of systems considering clusters of dependent degrading components[J]. Reliability Engineering & System Safety, 2020, 202: 107005. http://www.sciencedirect.com/science/article/pii/S0951832020305068 [12] SHI Y, ZHU W, XIANG Y, et al. Condition-based maintenance optimization for multi-component systems subject to a system reliability requirement[J]. Reliability Engineering & System Safety, 2020, 202: 107042. http://www.sciencedirect.com/science/article/pii/S0951832020305433 [13] PETCHROMPO S, LI H, ERGUIDO A, et al. A value-based approach to optimizing long-term maintenance plans for a multi-asset k-out-of-N system[J]. Reliability Engineering & System Safety, 2020, 200: 106924. http://www.sciencedirect.com/science/article/pii/S0951832019311470 [14] GAHLOT M, SINGH V V, AYAGI H I, et al. Stochastic analysis of a two units' complex repairable system with switch and human failure using copula approach[J]. Life Cycle Reliability and Safety Engineering, 2019, 9: 1-11. http://www.researchgate.net/publication/337805079_Stochastic_analysis_of_a_two_units'_complex_repairable_system_with_switch_and_human_failure_using_copula_approach [15] THACH T T, BRIS R, VOLF P, et al. Non-linear failure rate: A Bayes study using Hamiltonian Monte Carlo simulation[J]. International Journal of Approximate Reasoning, 2020, 123: 55-76. doi: 10.1016/j.ijar.2020.04.007 [16] ZHU T. Reliability estimation for two-parameter Weibull distribution under block censoring[J]. Reliability Engineering & System Safety, 2020, 203: 107071. http://www.sciencedirect.com/science/article/pii/S095183202030572X [17] ALMALKI S J, YUAN J. A new modified Weibull distribution[J]. Reliability Engineering & System Safety, 2013, 111: 164-170. http://uksacb.org/sites/default/files/webform/Research%20Paper1_A%20new%20modified%20Weibull%20distribution_0.pdf [18] 丛继平, 崔利杰, 丁刚, 等. 基于目标驱动的航空维修保障体系仿真研究[J]. 系统仿真学报, 2021, 33(9): 2157-2165. https://www.cnki.com.cn/Article/CJFDTOTAL-XTFZ202109018.htmCONG J P, CUI L J, DING G, et al. Simulation on aviation maintenance support system based on goal-driven[J]. Journal of System Simulation, 2021, 33(9): 2157-2165(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-XTFZ202109018.htm [19] 孙璐璐, 滕曰, 黄锐. 飞机完好率预测仿真研究[J]. 兵器装备工程学报, 2017, 38(8): 71-75. doi: 10.11809/scbgxb2017.08.017SUN L L, TENG Y, HUANG R. Simulation of aircraft readiness rate prediction[J]. Journal of Ordnance Equipment Engineering, 2017, 38(8): 71-75(in Chinese). doi: 10.11809/scbgxb2017.08.017 [20] DAMIAN D N, AJAY B C. NetLogo agent-based models as tools for understanding the self-organization of cell fate, morphogenesis and collective migration of the zebrafish posterior lateral line primordium[J]. Seminars in Cell & Developmental Biology, 2020, 100: 186-198. http://www.sciencedirect.com/science/article/pii/S1084952119300497 [21] KROESE D P, POROTSKY S, RUBINSTEIN R Y. The cross-entropy method for continuous multi-extremal optimization[J]. Methodology and Computing in Applied Probability, 2006, 8(3): 383-407. doi: 10.1007/s11009-006-9753-0 [22] BRAIBANT V, OUDSHOOM A, BOYER C, et al. Nondeterministic "possibilistic" approaches for structural analysis and optimal design[J]. AIAA Journal, 1999, 37(10): 1298-1303. doi: 10.2514/2.599 [23] LI Z, ZHANG T, CHENG S, et al. Stochastic gradient Hamiltonian Monte Carlo with variance reduction for Bayesian inference[J]. Machine Learning, 2019, 108(8-9): 1701-1727. doi: 10.1007/s10994-019-05825-y [24] STARCZEWSKI J T, GOETZEN P, NAPOLI C. Triangular fuzzy-rough set based fuzzification of fuzzy rule-based systems[J]. Journal of Artificial Intelligence and Soft Computing Research, 2020, 10(4): 271-285. doi: 10.2478/jaiscr-2020-0018 [25] CHENG K, LU Z Z, ZHOU Y C. Global sensitivity analysis using support vector regression[J]. Applied Mathematical Modelling, 2017, 49: 587-598. doi: 10.1016/j.apm.2017.05.026 [26] QUETZERI-SANTIAGO M A, CASTREJÓN-PITA J R, CAS-TREJÓN-PITA A A. On the analysis of the contact angle for impacting droplets using a polynomial fitting approach[J]. Experiments in Fluids, 2020, 61(6): 143. doi: 10.1007/s00348-020-02971-1 [27] FARAVELLI L. Response-surface approach for reliability analysis[J]. Journal of Engineering Mechanics, 1989, 115(12): 2763-2781. doi: 10.1061/(ASCE)0733-9399(1989)115:12(2763) [28] LI H S, LU Z Z, YUE Z F. Support vector machine for structural reliability analysis[J]. Applied Mathematics and Mechanics, 2006, 27(10): 1295-1303. doi: 10.1007/s10483-006-1001-z [29] HURTADO J E, ALVAREZ D A. Neural-network-based reliability analysis: A comparative study[J]. Computer Methods in Applied Mechanics and Engineering, 2001, 191(1-2): 113-132. doi: 10.1016/S0045-7825(01)00248-1 -

下载:

下载: