-

摘要:

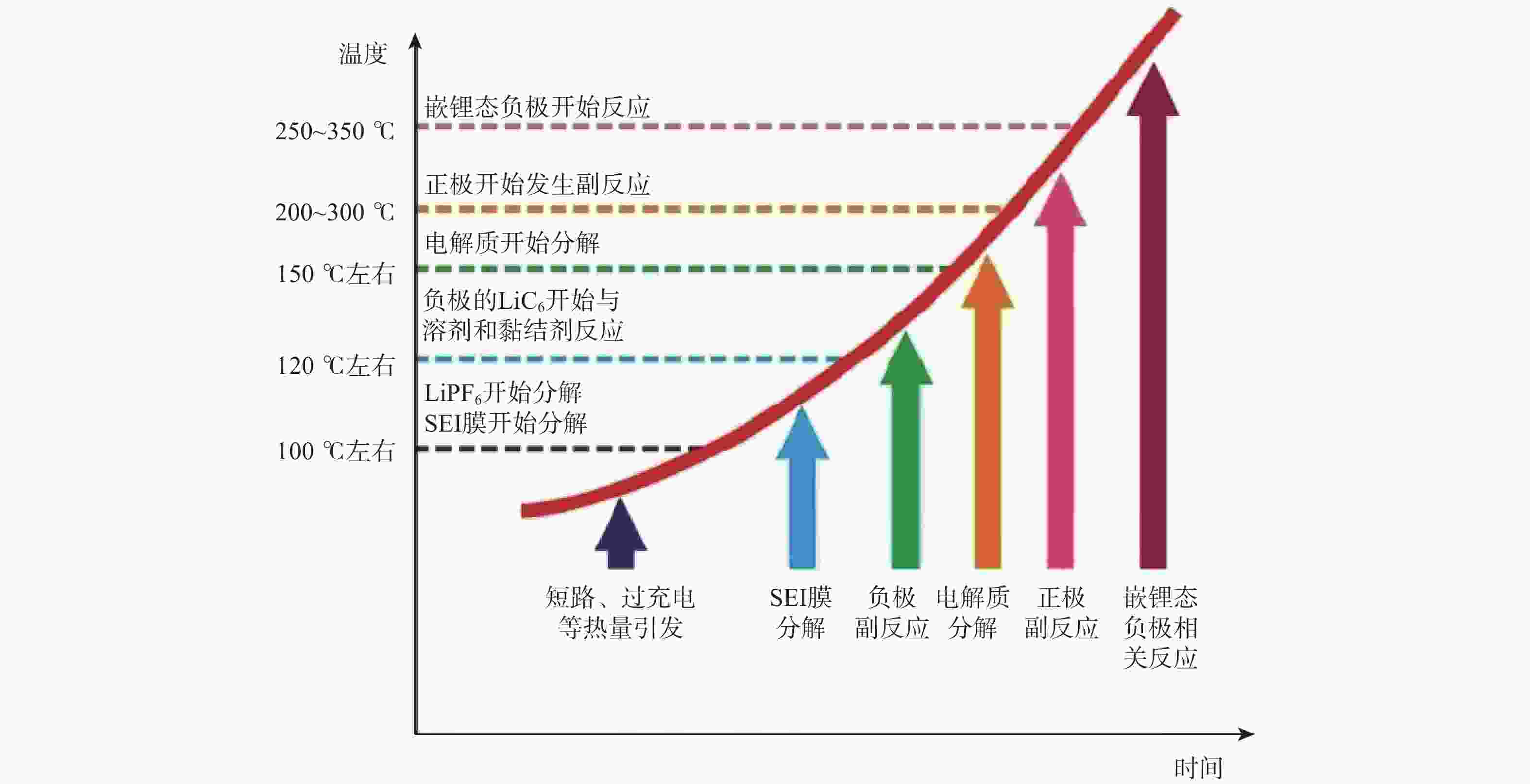

锂离子动力电池系统作为电动汽车最重要的核心部件,其动力性能和安全可靠性的提升是中国电动汽车进一步规模化发展的重大需求。锂离子动力电池的热安全问题贯穿于电池系统的整个生命周期,且在单体-模组-系统不同空间尺度下的表现形式不同。针对锂离子动力电池系统多空间尺度热安全问题,分别从单体电池生热、模组温度均一性、电池系统安全可靠性3个方面归纳总结了目前动力电池热安全设计的最新进展,并对一些重要研究成果进行了着重介绍,总结了锂离子动力电池系统热安全设计亟待解决的关键问题,提出了可行的解决方案,对今后的研究方向进行了展望,旨在为电池系统动力性能和安全可靠性提升提供有益的借鉴和参考。

Abstract:As the most important core component of electric vehicles, the lithium-ion power battery system requires improvement in power performance, safety, and reliability for further large-scale development of electric vehicles in China. Thermal safety issues of lithium-ion power batteries may occur throughout the whole life cycle of the battery system, and manifest differently in different spatial scales of monomers, modules, and systems. To address the multi-spatial scale thermal safety problems of the lithium-ion power battery system, the latest progress of thermal safety design of power batteries is reviewed from three aspects: heat generation of a single battery, temperature uniformity of a module, and safety and reliability of a battery system. Some important research results are introduced, and the key problems to be solved in the thermal safety design of a lithium-ion power battery system are summarized. Feasible solutions to the problems are put forward, and the future research direction is suggested, providing insight into increase in power performance, safety and reliability of battery systems.

-

-

[1] SATO N. Thermal behavior analysis of lithium-ion batteries for electric and hybrid vehicles[J]. Journal of Power Sources, 2001, 99(1-2): 70-77. doi: 10.1016/S0378-7753(01)00478-5 [2] BERNARDI D, PAWLIKOWS K, NEWMAN J. A general energy balance for battery systems[J]. Journal of the Electrochemical Society, 1985, 132(1): 5-12. [3] WANG J, LIU S Q, LIN C J, et al. Experimental study on the internal resistance and heat generation characteristics of lithium-ion power battery with NCM/C material system[J]. International Journal of Passenger Cars-Electronic and Electrical Systems, 2018, 11(2): 131-138. doi: 10.4271/07-11-02-0012 [4] 宋文吉, 陈明彪, 白帆飞, 等. 基于电-热耦合模型的锂离子电池热特性与优化[J]. 电池, 2018, 48(5): 309-312. doi: 10.19535/j.1001-1579.2018.05.004SONG W J, CHEN M B, BAI F F, et al. Thermal characteristics and optimization of lithium ion battery based on electric thermal coupling model[J]. Battery, 2018, 48(5): 309-312(in Chinese). doi: 10.19535/j.1001-1579.2018.05.004 [5] 姜水生, 何志坚, 文华. 基于电-热耦合模型的锂离子电池组热管理系统设计与优化[J]. 中国机械工程, 2018, 29(15): 1847-1853. doi: 10.3969/j.issn.1004-132X.2018.15.012JIANG S S, HE Z J, WEN H. Design and optimization of thermal management system for lithium ion battery pack based on electrical thermal coupling model[J]. China Mechanical Engineering, 2018, 29(15): 1847-1853(in Chinese). doi: 10.3969/j.issn.1004-132X.2018.15.012 [6] BARCELLONA S, PIEGARI L. Integrated electro-thermal model for pouch lithium-ion batteries[J]. Mathematics and Computers in Simulation, 2021, 183: 5-19. doi: 10.1016/j.matcom.2020.03.010 [7] PAN Y W, HUA Y, ZHOU S D, et al. A computational multi-node electro-thermal model for large prismatic lithium-ion batteries-Science Direct[J]. Journal of Power Sources, 2020, 459: 228070. [8] XIE Y, HE X, LI W, et al. A novel electro-thermal coupled model of lithium-on pouch battery covering heat generation distribution and tab thermal behaviors[J]. International Journal of Energy Research, 2020, 44(14): 11725-11741. [9] 崔灿. 锂离子动力蓄电池安全性的研究与应用[D]. 北京: 清华大学, 2014: 39-42.CUI C. Research and application on safety of lithium ion power battery[D]. Beijing: Tsinghua University, 2014: 39-42(in Chinese). [10] LAI X, JIN C Y, YI W, et al. Mechanism, modeling, detection, and prevention of the internal short circuit in lithium-ion batteries: Recent advances and perspectives[J]. Energy Storage Materials, 2021, 35: 470-499. doi: 10.1016/j.ensm.2020.11.026 [11] YUAN C C, WANG Q S, WANG Y, et al. Inhibition effect of different interstitial materials on thermal runaway propagation in the cylindrical lithium-ion battery module[J]. Applied Thermal Engineering, 2019, 153: 39-50. doi: 10.1016/j.applthermaleng.2019.02.127 [12] FENG X N, ZHENG S Q, REN D S, et al. Key characteristics for thermal runaway of li-ion batteries[J]. Energy Procedia, 2019, 158: 4684-4689. doi: 10.1016/j.egypro.2019.01.736 [13] LI H, DUAN Q L, ZHAO C P, et al. Experimental investigation on the thermal runaway and its propagation in the large format battery module with Li(Ni1/3Co1/3Mn1/3)O2 as cathode[J]. Journal of Hazardous Materials, 2019, 375: 241-254. doi: 10.1016/j.jhazmat.2019.03.116 [14] LAI X, WANG S N, WANG H B, et al. Investigation of thermal runaway propagation characteristics of lithium-ion battery modules under different trigger modes[J]. International Journal of Heat and Mass Transfer, 2021, 171: 121080. [15] REN D S, FENG X N, LU L G, et al. Overcharge behaviors and failure mechanism of lithium-ion batteries under different test conditions[J]. Applied Energy, 2019, 250: 323-332. doi: 10.1016/j.apenergy.2019.05.015 [16] HUANG Z, LI X, WANG Q, et al. Experimental investigation on thermal runaway propagation of large format lithium ion battery modules with two cathodes[J]. International Journal of Heat and Mass Transfer, 2021, 172: 121077. [17] 宋丽, 魏学哲, 戴海峰, 等. 锂离子电池单体热模型研究动态[J]. 汽车工程, 2013, 35(3): 285-291. doi: 10.3969/j.issn.1000-680X.2013.03.017SONG L, WEI X Z, DAI H F, et al. Research progress on thermal model of lithium-ion battery[J]. Automotive Engineering, 2013, 35(3): 285-291(in Chinese). doi: 10.3969/j.issn.1000-680X.2013.03.017 [18] DOYLE M, NEWMAN J. The use of mathematical modeling in the design of lithium/polymer battery systems[J]. Electrochemica Acta, 1995, 40(13): 2191-2196. [19] 庞辉. 基于电化学模型的锂离子电池多尺度建模及其简化方法[J]. 物理学报, 2017, 66(23): 312-322. doi: 10.7498/aps.66.238801PANG H. Multi scale modeling and simplification of lithium ion battery based on electrochemical model[J]. Acta Physica Sinica, 2017, 66(23): 312-322(in Chinese). doi: 10.7498/aps.66.238801 [20] HAN X F, HUANG Y X, LAI H X, et al. Electrochemical-thermal coupled investigation of lithium iron phosphate cell performances under air-cooled conditions[J]. Applied Thermal Engineering, 2019, 147: 908-916. doi: 10.1016/j.applthermaleng.2018.11.010 [21] LIU Y, TANG S, LI L X, et al. Simulation and parameter identification based on electrochemical-thermal coupling model of power lithium-ion battery[J]. Journal of Alloys and Compounds, 2021, 844:156003. [22] LIN C J, WEN H R, LIU L, et al. Heat generation quantification of high-specific-energy 21700 battery cell using average and variable specific heat capacities[J]. Applied Thermal Engineering, 2021, 184:116215. [23] CHEN L, JIANG L H, YE S L, et al. Comprehensive analysis on dynamic heat generation of LiNi1/3Co1/3Mn1/3O2 coin cell under overcharge[J]. Journal of the Electrochemical Society, 2019, 166(14): A3369-A3376. [24] CHEN L, JIANG L H, WANG Q S, et al. Dynamic heat generation of LiNi0.5Co0.2Mn0.3O2 half-cell under cycling based on an in situ micro-calorimetry[J]. Fire Technology, 2020, 56(6): 1-18. [25] 刘力硕, 张明轩, 卢兰光, 等. 锂离子电池内短路机理与检测研究进展[J]. 储能科学与技术, 2018, 7(6): 1003-1015. doi: 10.12028/j.issn.2095-4239.2018.0163LIU L S, ZHANG M X, LU L G, et al. Recent progress on mechanism and detection of internal short circuit in lithium-ion batteries[J]. Energy Storage Science and Technology, 2018, 7(6): 1003-1015(in Chinese). doi: 10.12028/j.issn.2095-4239.2018.0163 [26] NEWMAN J, DOYLE M. Modeling of galvanic static charge and discharge of the lithium/polymer/insertion cell[J]. Journal of the Electrochemical Society, 1993, 140(6): 1526-1526. doi: 10.1149/1.2221597 [27] 邵丹, 骆相宜, 钟灿鸣, 等. 动力锂离子电池安全性研究的进展[J]. 电池, 2020, 50(1): 83-86. doi: 10.19535/j.1001-1579.2020.01.020SHAO D, LUO X Y, ZHONG C M, et al. Progress in safety research of power lithium ion battery[J]. Battery, 2020, 50(1): 83-86(in Chinese). doi: 10.19535/j.1001-1579.2020.01.020 [28] WU X K, SONG K F, ZHANG X Y, et al. Safety issues in lithium ion batteries: Materials and cell design[J]. Frontiers in Energy Research, 2019, 7: 65. doi: 10.3389/fenrg.2019.00065 [29] 劳力. 高比能锂离子动力电池系统充电策略及热失控安全研究[D]. 合肥: 中国科学技术大学, 2020: 49-61.LAO L. Research on charging strategy and thermal runaway safety of high specific energy li-ion power battery system[D]. Hefei: University of Science and Technology of China, 2020: 49-61(in Chinese). [30] ZHAI P, LIU K S, WANG Z Y, et al. Multifunctional separators for high-performance lithium ion batteries[J]. Journal of Power Sources, 2021, 499: 229973. [31] TANIGUCHI S, SHIRONITA S, KONAKAWA K, et al. Thermal characteristics of 80°C storage-degraded 18650-type lithium-ion secondary cells[J]. Journal of Power Sourses, 2019, 416: 148-154. doi: 10.1016/j.jpowsour.2019.01.087 [32] WU Y, LIU X, WANG L, et al. Development of cathode electrolyte interphase for safer lithium batteries[J]. Energy Storage Materials, 2021, 37: 77-86. doi: 10.1016/j.ensm.2021.02.001 [33] CHEN M Y, OUYANG D X, WENG J W, et al. Environmental pressure effects on thermal runaway and fire behaviors of lithium-ion battery with different cathodes and state of charge[J]. Process Safety and Environmental Protection, 2019, 130: 250-256. doi: 10.1016/j.psep.2019.08.023 [34] SONG X, REN L, YANG X, et al. Influence of cycling aging and ambient pressure on the thermal safety features of lithium-ion battery[J]. Journal of Power Sources, 2020, 448: 227425. [35] 汪宜秀, 魏学哲, 房乔华, 等. 面向整组寿命最大化的电动汽车电池一致性变化规律及其均衡策[J]. 机械工程学报, 2020, 56(22): 176-183. doi: 10.3901/JME.2020.22.176WANG Y X, WEI X Z, FANG Q H, et al. Consistency change law and equilibrium strategy of electric vehicle battery for the whole group life maximization[J]. Journal of Mechanical Engineering, 2020, 56(22): 176-183(in Chinese). doi: 10.3901/JME.2020.22.176 [36] ALASTAIR H, MOHAMED W M, LAURA B D, et al. The surface cell cooling coefficient: A standard to define heat rejection from liithium ion battery pouch cells[J]. Journal of the Electrochemical Society, 2020, 167(2): 020524. [37] 任东生, 冯旭宁, 韩雪冰, 等. 锂离子电池全生命周期安全性演变研究进展[J]. 储能科学与技术, 2018, 7(6): 957-966. doi: 10.12028/j.issn.2095-4239.2018.0165REN D S, FENG X N, HAN X B, et al. Research progress on life cycle safety evolution of lithium-ion batteries[J]. Energy Storage Science and Technology, 2018, 7(6): 957-966(in Chinese). doi: 10.12028/j.issn.2095-4239.2018.0165 [38] XU Y, WU J, XU W, et al. Performance matrix analysis method of power battery system based on multi-parameters’ model[J]. Journal of Electrochemical Energy Conversion and Storage, 2021, 18(2): 020902. [39] AL-ZAREER M, DINCER I, ROSEN M A. A novel approach for performance improvement of liquid to vapor based battery cooling systems[J]. Energy Convers Manage, 2019, 187: 191-204. [40] FAN Y Q, YUN B, CHEN L, et al. Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium-ion batteries[J]. Applied Thermal Engineering, 2019, 155: 96-109. doi: 10.1016/j.applthermaleng.2019.03.157 [41] CHEN K, HOU J S, WU X L, et al. Design of flow pattern in air-cooled battery thermal management system[J]. International Journal of Energy Research, 2021, 45(6): 9541-9554. doi: 10.1002/er.6480 [42] LIU T, TAO C F, WANG X S. Cooling control effect of water mist on thermal runaway propagation in lithium ion battery modules[J]. Applied Energy, 2020, 267:115087. [43] CHEN J H, ZHAO X B, WANG B, et al. Multiobjective optimization of air-cooled battery thermal management system based on heat dissipation model[J]. Ionics, 2021, 27(3): 1307-1322. doi: 10.1007/s11581-020-03853-6 [44] KARIMI G, LI X. Thermal management of lithium-ion batteries for electric vehicles[J]. International Journal of Energy Research, 2013, 37(1): 13-24. doi: 10.1002/er.1956 [45] PESARAN A A. Battery thermal management in EVs and HEVs: Issues and solutions[C]//Advanced Automotive Battery Conference, 2001. [46] 罗玉涛, 罗卜尔思, 郎春艳. 锂离子动力电池组的直接接触液体冷却方法研究[J]. 汽车工程, 2016, 38(7): 909-914.LUO Y T, LUO B E S, LANG C Y. A research on the direct contact liquid cooling method of Lithium-ion battery pack[J]. Automotive Engineering 2016, 38(7): 909-914(in Chinese). [47] WANG C, ZHANG G Q, LI X X, et al. Experimental examination of large capacity LiFePO4 battery pack at high temperature and rapid discharge using novel liquid cooling strategy[J]. International Journal of Energy Research, 2018, 42(3): 1172-1182. doi: 10.1002/er.3916 [48] QIAN Z, LI Y M, RAO Z H. Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling[J]. Energy Convers Manage, 2016, 126: 622-631. [49] 苟飘, 徐俊, 刘晓艳, 等. 电动汽车锂电池模块化热管理系统的设计及实验研究[J]. 西安交通大学学报, 2019, 53(12): 104-110. doi: 10.7652/xjtuxb201912014GOU P, XU J, LIU X Y, et al. Design and experimental study of modular thermal management system for lithium battery of electric vehicle[J]. Journal of Xi’an Jiaotong University, 2019, 53(12): 104-110(in Chinese). doi: 10.7652/xjtuxb201912014 [50] ZHAO C R, JIANG F M. Minimization of thermal non-uniformity in lithium-ion battery pack cooled by channeled liquid flow[J]. International Journal of Heat and Mass Transfer, 2019, 129: 660-670. doi: 10.1016/j.ijheatmasstransfer.2018.10.017 [51] DENG T, ZHANG G D, RAN Y. Study on thermal management of rectangular Li-ion battery with serpentine-channel cold plate[J]. International Journal of Heat and Mass Transfer, 2018, 125: 143-152. [52] RAO Z H, QIAN Z, YONG G, et al. Thermal performance of liquid cooling based thermal management system for cylindrical lithium-ion battery module with variable contact surface[J]. Applied Thermal Engineering, 2017, 123: 1514-1522. doi: 10.1016/j.applthermaleng.2017.06.059 [53] SAW L H, POON H M, THIAM H S, et al. Novel thermal management system using mist cooling for lithium-ion battery packs[J]. Applied Energy, 2018, 223: 146-158. doi: 10.1016/j.apenergy.2018.04.042 [54] YAO C N, DAN D, ZHANG Y J, et al. Thermal performance of a micro heat pipe array for battery thermal management under special vehicle-operating conditions[J]. Automotive Innovation, 2020(4): 317-327. [55] YE X, ZHAO Y H, QUAN Z H, et al. Thermal management system of lithium-ion battery module based on micro heat pipe array[J]. International Journal of Energy Research, 2018, 42(2): 648-655. doi: 10.1002/er.3847 [56] ZHANG C W, XIA Z, WANG B, et al. A Li-ion battery thermal management system combining a heat pipe and thermoelectric cooler[J]. Energies, 2020, 13(4): 841. [57] OUYANG D X, WENG J W, HU J Y, et al. Effect of high temperature circumstance on lithium-ion battery and the application of phase change material[J]. Journal of the Electrochemical Society, 2019, 166(4): A559-A567. doi: 10.1149/2.0441904jes [58] ZOU D Q, LIU X S, HE R J, et al. Preparation of a novel composite phase change material (PCM) and its locally enhanced heat transfer for power battery module[J]. Energy Conversion and Management, 2019, 180(1): 1196-1202. [59] ZHANG W C, QIU J Y, YIN X X, et al. A novel heat pipe assisted separation type battery thermal management system based on phase change material[J]. Applied Thermal Engineering, 2020, 165: 114571. doi: 10.1016/j.applthermaleng.2019.114571 [60] JILTE R, ALFZAL A, PANCHAL S. A novel battery thermal management system using nano-enhanced phase change materials[J]. Energy, 2021, 219: 119564. [61] ZHANG J Y, LI X X, ZHANG G Q, et al. Experimental investigation of the flame retardant and form-stable composite phase change materials for a power battery thermal management system[J]. Journal of Power Sources, 2020, 480: 229116. [62] CHEN F F, HUANG R, WANG C M, et al. Air and PCM cooling for battery thermal management considering battery cycle life[J]. Applied Thermal Engineering, 2020, 173:115154. [63] LYU Y, SIDDIQUE A R M, MAJID S H, et al. Electric vehicle battery thermal management system with thermo electric cooling[J]. Energy Reports, 2019, 5: 822-827. doi: 10.1016/j.egyr.2019.06.016 [64] TANG W, XU X M, DING H, et al. Sensitivity analysis of the battery thermal management system with a reciprocating cooling strategy combined with a flat heat pipe[J]. ACS Omega, 2020, 5(14): 8258-8267. doi: 10.1021/acsomega.0c00552 [65] 王亮, 王荻楠, 王秀春. 冷却和蓄热结合的动力电池组热管理系统模型[J]. 电源技术, 2019, 43(4): 662-665. doi: 10.3969/j.issn.1002-087X.2019.04.035WANG L, WANG D N, WANG X C. Thermal management system model of power battery pack combined with cooling and heat storage[J]. Power Technology, 2019, 43(4): 662-665(in Chinese). doi: 10.3969/j.issn.1002-087X.2019.04.035 [66] HUANG Q Q, LI X X, ZHANG G Q, et al. Experimental investigation of the thermal performance of heat pipe assisted phase change material for battery thermal management system[J]. Applied Thermal Engineering, 2018, 141: 1092-1100. doi: 10.1016/j.applthermaleng.2018.06.048 [67] CHEN K, HOU J S, CHEN K, et al. Design of battery thermal management system based on phase change material and heat pipe[J]. Applied Thermal Engineering, 2021, 188: 116665. doi: 10.1016/j.applthermaleng.2021.116665 [68] PUTRA N, SANDI A F, ARIANTARA B, et al. Performance of beeswax phase change material (PCM) and heat pipe as passive battery cooling system for electric vehicles[J]. Case Studies in Thermal Engineering, 2020, 21: 100655. [69] KONG D P, PENG R Q, PING P, et al. A novel battery thermal management system coupling with PCM and optimized controllable liquid cooling for different ambient temperatures[J]. Energy Conversion and Management, 2020, 204: 112280. [70] YUAN Q Q, XU X M, TONG G Y, et al. Effect of coupling phase change materials and heat pipe on performance enhancement of Li-ion battery thermal management system[J]. International Journal of Energy Research, 2021, 45(4): 5399-5411. [71] ZHANG W C, LIANG Z C, YIN X X, et al. Avoiding thermal runaway propagation of lithium-ion battery modules by using hybrid phase change material and liquid cooling[J]. Applied Thermal Engineering, 2021, 184: 116380. [72] 朱波, 杜如海, 姚明尧, 等. 基于相变材料的纯电动汽车电池热管理研究[J]. 电源技术, 2020, 44(11): 1666-1670. doi: 10.3969/j.issn.1002-087X.2020.11.027ZHU B, DU R H, YAO M Y, et al. Research on thermal management of pure electric vehicle battery based on phase change materials[J]. Power Technology, 2020, 44(11): 1666-1670(in Chinese). doi: 10.3969/j.issn.1002-087X.2020.11.027 [73] 黄伟男, 宋永丰, 张维戈, 等. 基于温度修正的锂离子电池协同热仿真构架[J]. 中国电机工程学报, 2020, 40(12): 4013-4024. doi: 10.13334/J.0258-8013.PCSEE.190979HUANG W N, SONG Y F, ZHANG W G, et al. Collaborative thermal simulation framework for lithium ion battery based on temperature correction[J]. Chinese Journal of Electrical Engineering, 2020, 40(12): 4013-4024(in Chinese). doi: 10.13334/J.0258-8013.PCSEE.190979 [74] 王屹航, 杨元凯, 刘通, 等. 基于孔隙网络模型的电池热管理系统跨尺度分析[J]. 清华大学学报(自然科学版), 2021, 61(2): 170-176. doi: 10.16511/j.cnki.qhdxxb.2020.22.018WANG Y H, LIU Y K, LIU T, et al. Cross scale analysis of battery thermal management system based on pore network model[J]. Journal of Tsinghua University (Natural Science Edition), 2021, 61(2): 170-176(in Chinese). doi: 10.16511/j.cnki.qhdxxb.2020.22.018 [75] 王莉, 谢乐琼, 田光宇, 等. 锂离子电池安全事故: 安全性问题, 还是可靠性问题[J]. 储能科学与技术, 2021, 10(1): 1-6.WANG L, XIE L Q, TIAN G Y, et al. Lithium ion battery safety accident: Safety or reliability[J]. Energy Storage Science and Technology, 2021, 10(1): 1-6(in Chinese). [76] 高菲, 肖阳, 张文华, 等. 高温和荷电状态对锂离子电池单体力学响应的耦合影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1574-1583. doi: 10.13229/j.cnki.jdxbgxb20190458GAO F, XIAO Y, ZHANG W H, et al. Coupling effects of high temperature and state of charge on mechanical response of lithium ion battery[J]. Journal of Jilin University (Engineering Edition), 2020, 50(5): 1574-1583(in Chinese). doi: 10.13229/j.cnki.jdxbgxb20190458 [77] ZHANG Y, MEI W X, QIN P, et al. Numerical modeling on thermal runaway triggered by local overheating for lithium iron phosphate battery[J]. Applied Thermal Engineering, 2021, 192: 116928. [78] HU T, XU X M, SUN X, et al. Numerical study on the inhibition control of lithium-ion battery thermal runaway[J]. ACS Omega, 2020, 5(29): 18254-18261. doi: 10.1021/acsomega.0c01862 [79] LI Y, QI F, GUO H, et al. Numerical investigation of thermal runaway propagation in a Li-ion battery module using the heat pipe cooling system[J]. Numerical Heat Transfer, Part A:Applications, 2019, 75(3): 183-199. doi: 10.1080/10407782.2019.1580956 [80] CHOMBO P V, LAOONUAL Y. A review of safety strategies of a Li-ion battery[J]. Journal of Power Sources, 2020, 478: 228649. [81] TAKAHASHI F. Fire blanket and intumescent coating materials for failure resistance[J]. MRS Bulletin, 2021, 46(5): 429-434. doi: 10.1557/s43577-021-00102-7 [82] COMAN P T, DARCY E C, VEJE C T, et al. Numerical analysis of heat propagation in a battery pack using a novel technology for triggering thermal runaway[J]. Applied Energy, 2017, 203: 189-200. doi: 10.1016/j.apenergy.2017.06.033 [83] LIN K S, CHEN Y X, LIU Y S, et al. Reliability prediction of battery management system for electric vehicles based on accelerated degradation test: A semi-parametric approach[J]. IEEE Transactions on Vehicular Technology, 2020, 69(11): 12694-12704. doi: 10.1109/TVT.2020.3012197 [84] 黄培鑫, 兰凤崇, 陈吉清. 随机振动与冲击条件下电动车电池包结构响应分析[J]. 汽车工程, 2017, 39(9): 1087-1093. doi: 10.19562/j.chinasae.qcgc.2017.09.017HUANG P X, LAN F C, CHEN J Q. Structural response analysis of electric vehicle battery pack under random vibration and impact[J]. Automotive Engineering, 2017, 39(9): 1087-1093(in Chinese). doi: 10.19562/j.chinasae.qcgc.2017.09.017 [85] 兰凤崇, 黄培鑫, 陈吉清, 等. 车用电池包结构动力学建模及分析方法研究[J]. 机械工程学报, 2018, 54(8): 157-164. doi: 10.3901/JME.2018.08.157LAN F C, HUANG P X, CHEN J Q, et al. Study on structural dynamic modeling and analysis method of vehicle battery pack[J]. Journal of Mechanical Engineering, 2018, 54(8): 157-164(in Chinese). doi: 10.3901/JME.2018.08.157 [86] WANG L Z, SUN Y S, WANG X H, et al. Reliability modeling method for lithium-ion battery packs considering the dependency of cell degradations based on a regression model and copulas[J]. Materials, 2019, 12(7): 1054. doi: 10.3390/ma12071054 [87] LIU M J, LI W Y, WANG C S, et al. Reliability evaluation of large scale battery energy storage systems[J]. IEEE Transactions on Smart Grid, 2017, 8(6): 2733-2743. doi: 10.1109/TSG.2016.2536688 [88] LI H, LIU B H, ZHOU D, et al. Coupled mechanical-electrochemical-thermal study on the short-circuit mechanism of lithium-ion batteries under mechanical abuse[J]. Journal of the Electrochemical Society, 2020, 167(12): 120501. [89] LEE D C, KIM C W. Two way nonlinear mechanical electrochemical thermal coupled analysis method to predict thermal runaway of lithium-ion battery cells caused by quasi-static indentation[J]. Journal of Power Sources, 2020, 475: 228678. [90] ZHANG J, LV D, SIMEONE A, et al. Artificial neural network-based multi sensor monitoring system for collision damage assessment of lithium-ion battery cells[J]. Energy Technology, 2020, 8(5): 2000031. [91] 葛文韬, 黄晖, 段龙杨, 等. 基于实测道路谱的纯电动轻卡电池包支架动态载荷仿真及疲劳分析[J]. 振动与冲击, 2020, 39(9): 267-273. doi: 10.13465/j.cnki.jvs.2020.09.038GE W T, HUANG H, DUAN L Y, et al. Dynamic load simulation and fatigue analysis of battery pack bracket for pure electric light truck based on measured road spectrum[J]. Vibration and Impact, 2020, 39(9): 267-273(in Chinese). doi: 10.13465/j.cnki.jvs.2020.09.038 [92] 李潇. 多物理场下动力电池包结构的可靠性设计优化[D]. 长沙: 中南林业科技大学, 2020: 13-20.LI X. Reliability design optimization of power battery pack structure under multi physical field[D]. Changsha: Central South University of Forestry Science and Technology, 2020: 13-20(in Chinese). [93] SHUI L, CHEN F Y, GARG A, et al. Design optimization of battery pack enclosure for electric vehicle[J]. Structural and Multidisciplinary Optimization, 2018, 58(1): 331-347. doi: 10.1007/s00158-018-1901-y [94] 兰凤崇, 陈元, 周云郊, 等. 轻质多材料动力电池包箱体选材与优化[J]. 吉林大学学报(工学版), 2020, 50(4): 1227-1234. doi: 10.13229/j.cnki.jdxbgxb20190280LAN F C, CHEN Y, ZHOU Y J, et al. Material selection and optimization of light multi material power battery case[J]. Journal of Jilin University (Engineering Edition), 2020, 50(4): 1227-1234(in Chinese). doi: 10.13229/j.cnki.jdxbgxb20190280 [95] LI L, CHEN X P, HU R F, et al. Aging mechanisms and thermal characteristics of commercial 18650 lithium-ion battery induced by minor mechanical deformation[J]. Journal of Electrochemical Energy Conversion and Storage, 2021, 18(2): 021010. [96] NIU X D, GARG A, GOYAL A, et al. A coupled electrochemical-mechanical performance evaluation for safety design of lithium-ion batteries in electric vehicle: An integrated cell and system level approach[J]. Journal of Cleaner Production, 2019, 222: 633-645. doi: 10.1016/j.jclepro.2019.03.065 [97] 陈天雨. 大容量锂离子电池热失控蔓延建模与仿真研究[D]. 北京: 清华大学, 2019: 56-73.CHEN T Y. Modeling and simulation of thermal runaway spread of large capacity lithium-ion batteries[D]. Beijing: Tsinghua University, 2019: 56 -73(in Chinese). [98] 陈天雨, 冯旭宁, 欧阳明高, 等. 基于模型的动力电池系统多尺度热安全设计[J]. 中国机械工程, 2018, 29(15): 1840-1846. doi: 10.3969/j.issn.1004-132X.2018.15.011CHEN T Y, FENG X N, OUYANG M G, et al. Multi scale thermal safety design of power battery system based on model[J]. China Mechanical Engineering, 2018, 29(15): 1840-1846(in Chinese). doi: 10.3969/j.issn.1004-132X.2018.15.011 -

下载:

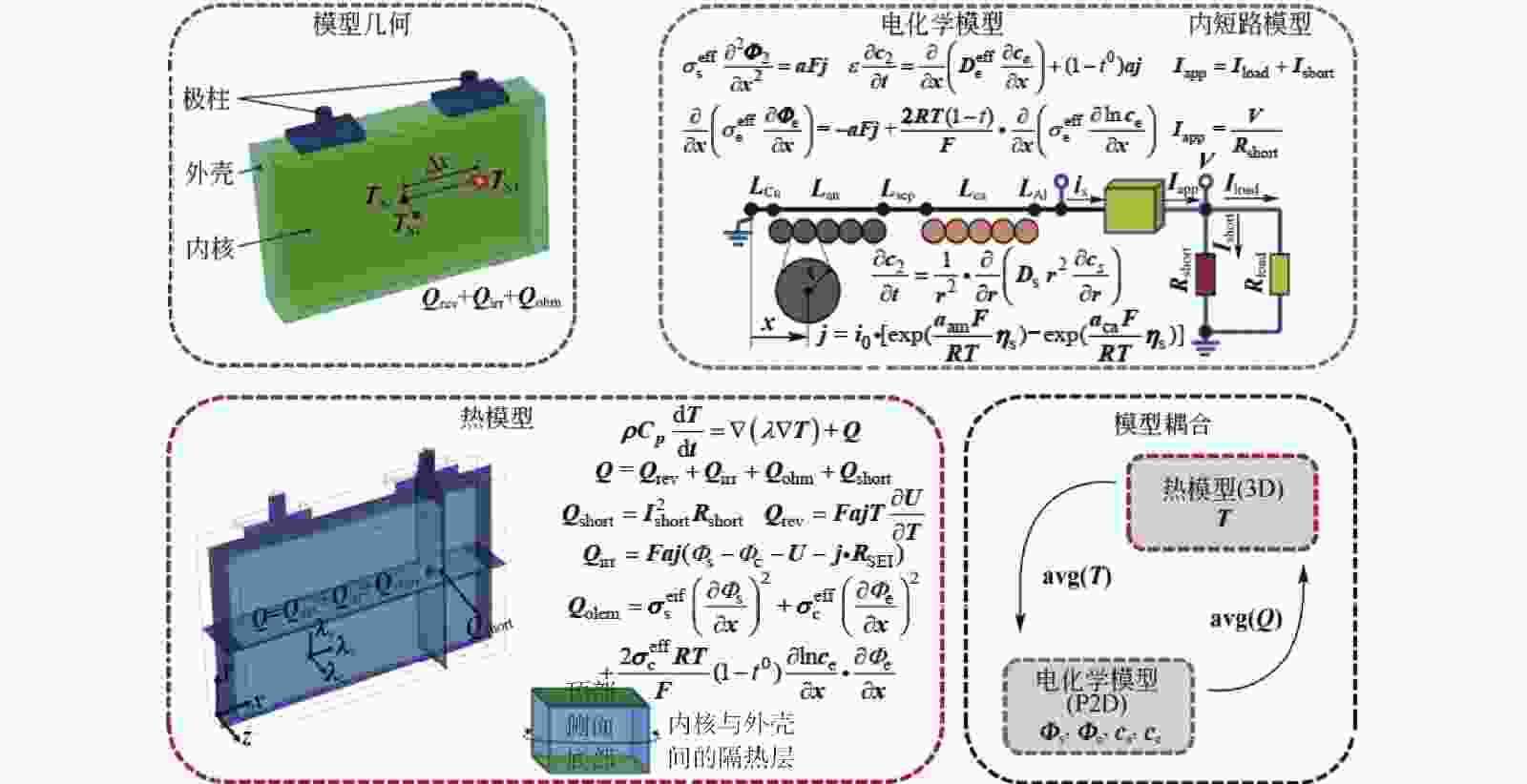

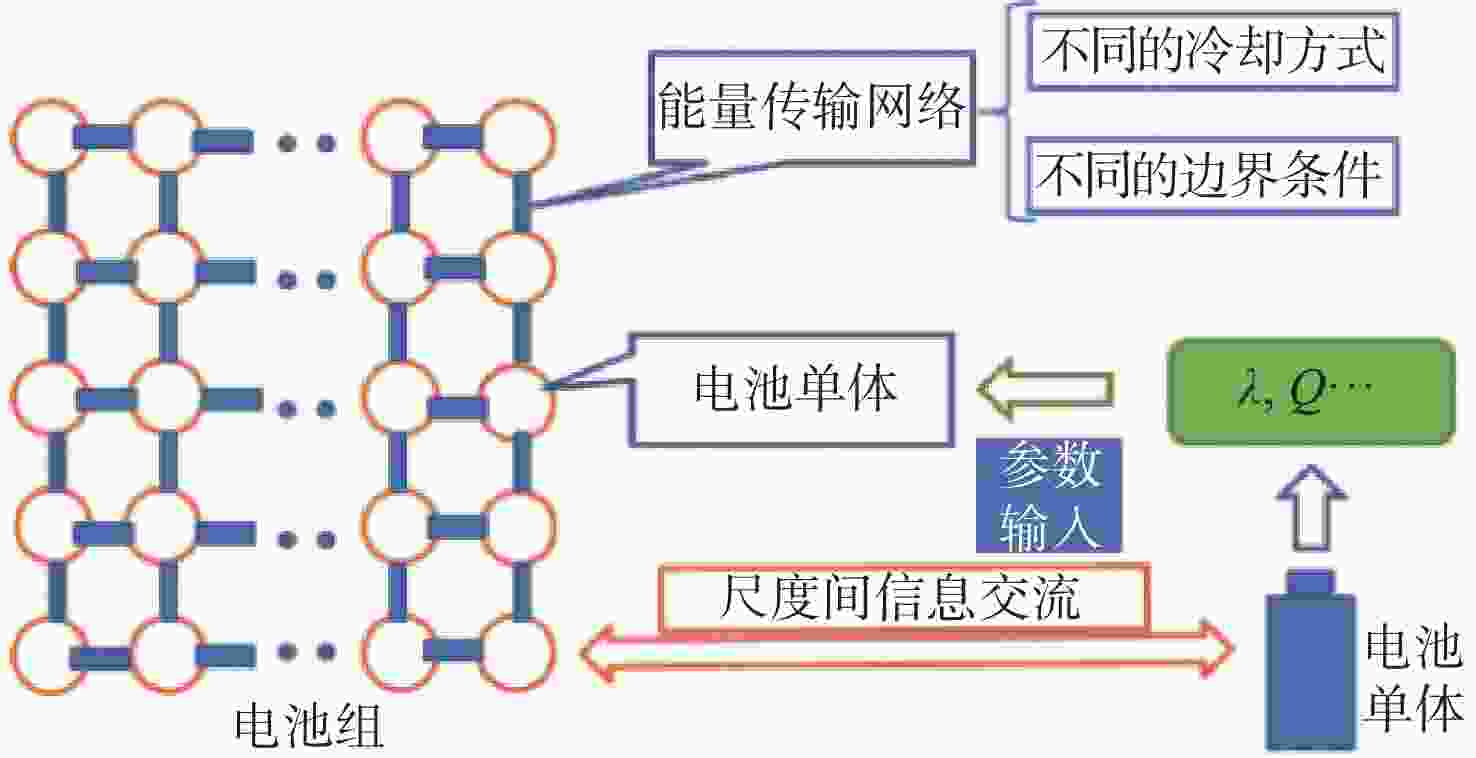

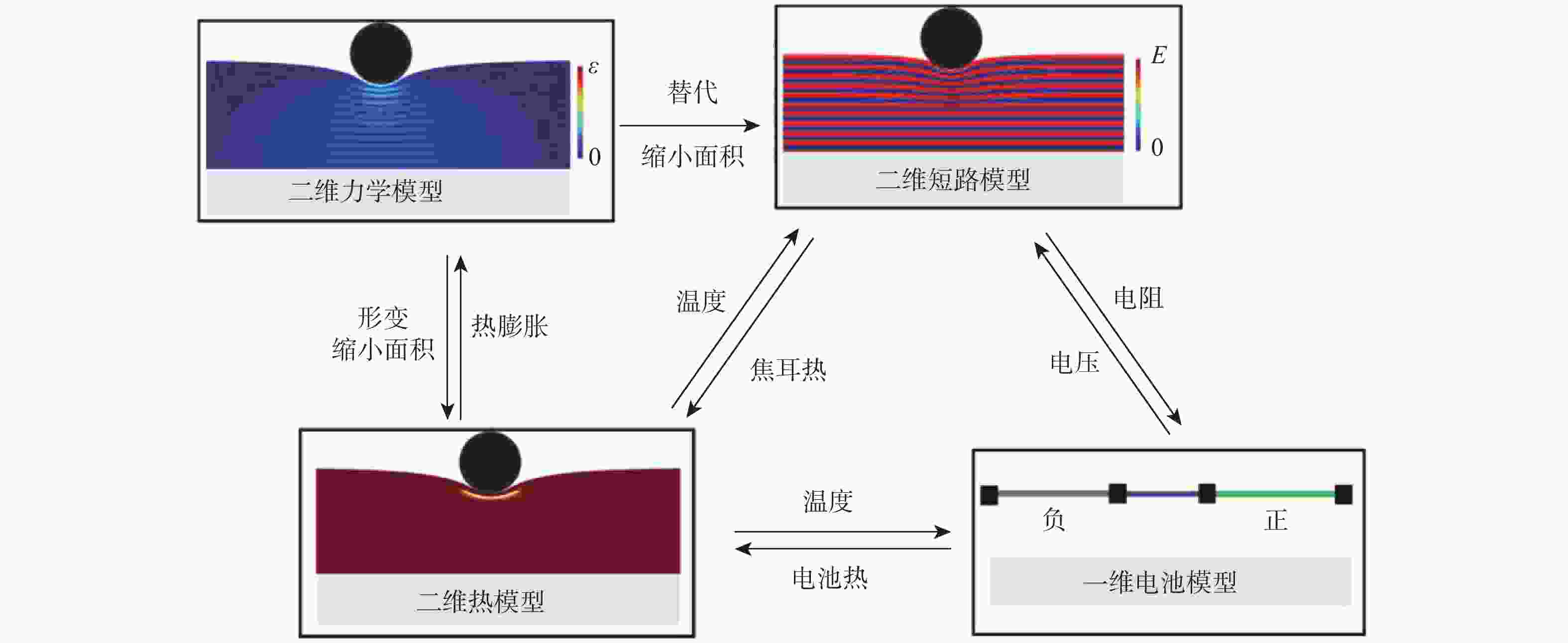

下载: