Performance of a novel polyvinyl alcohol/polyethylene glycol hydrogel for heat sink

-

摘要:

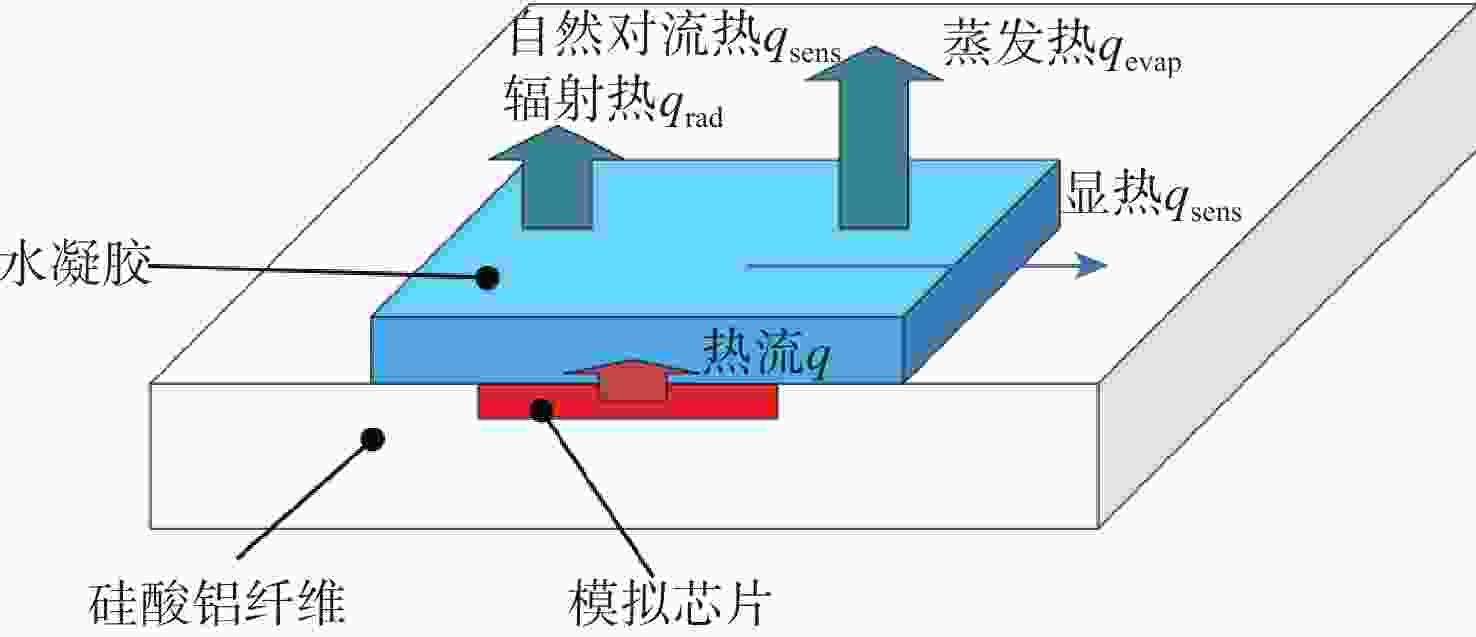

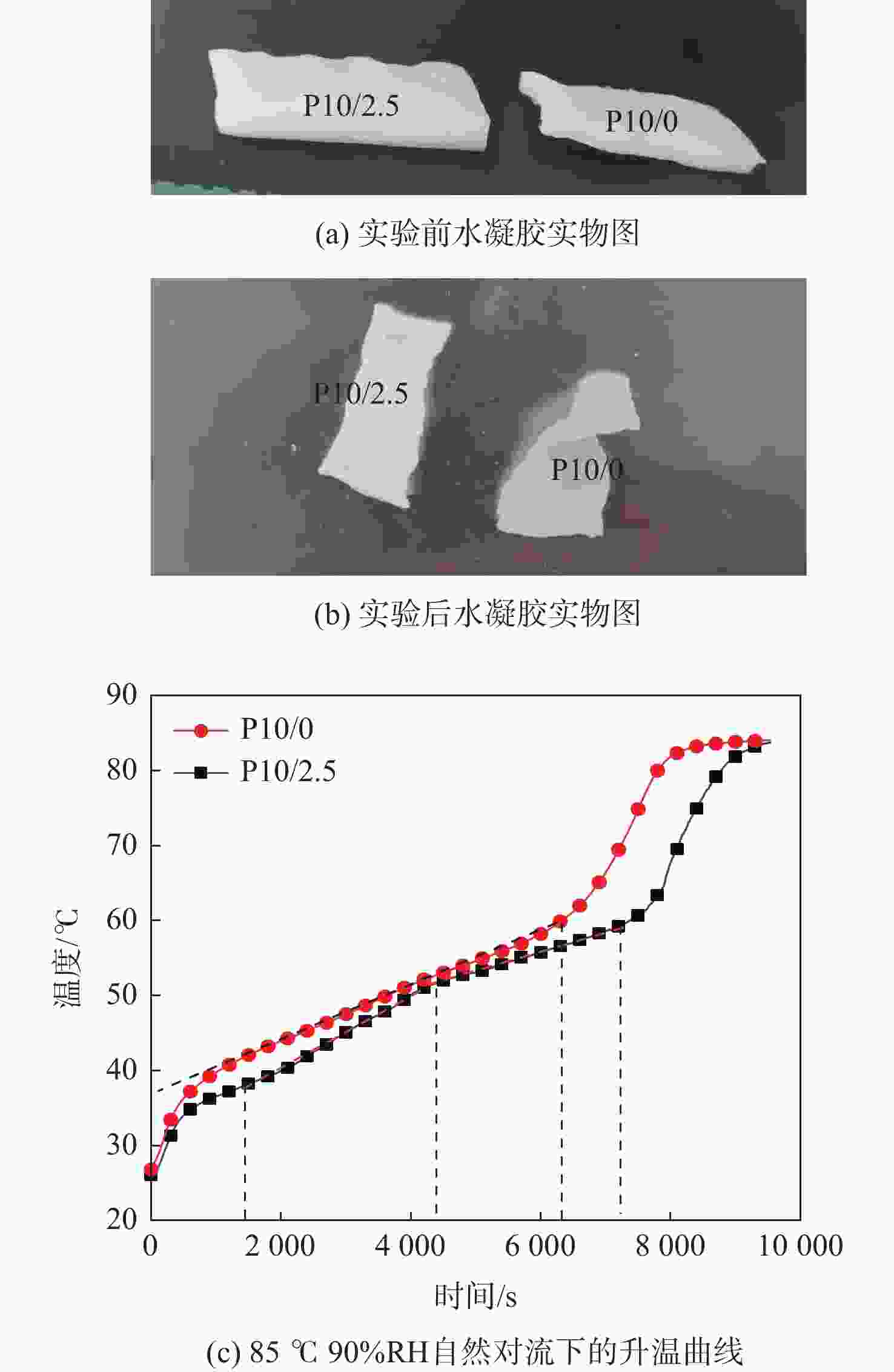

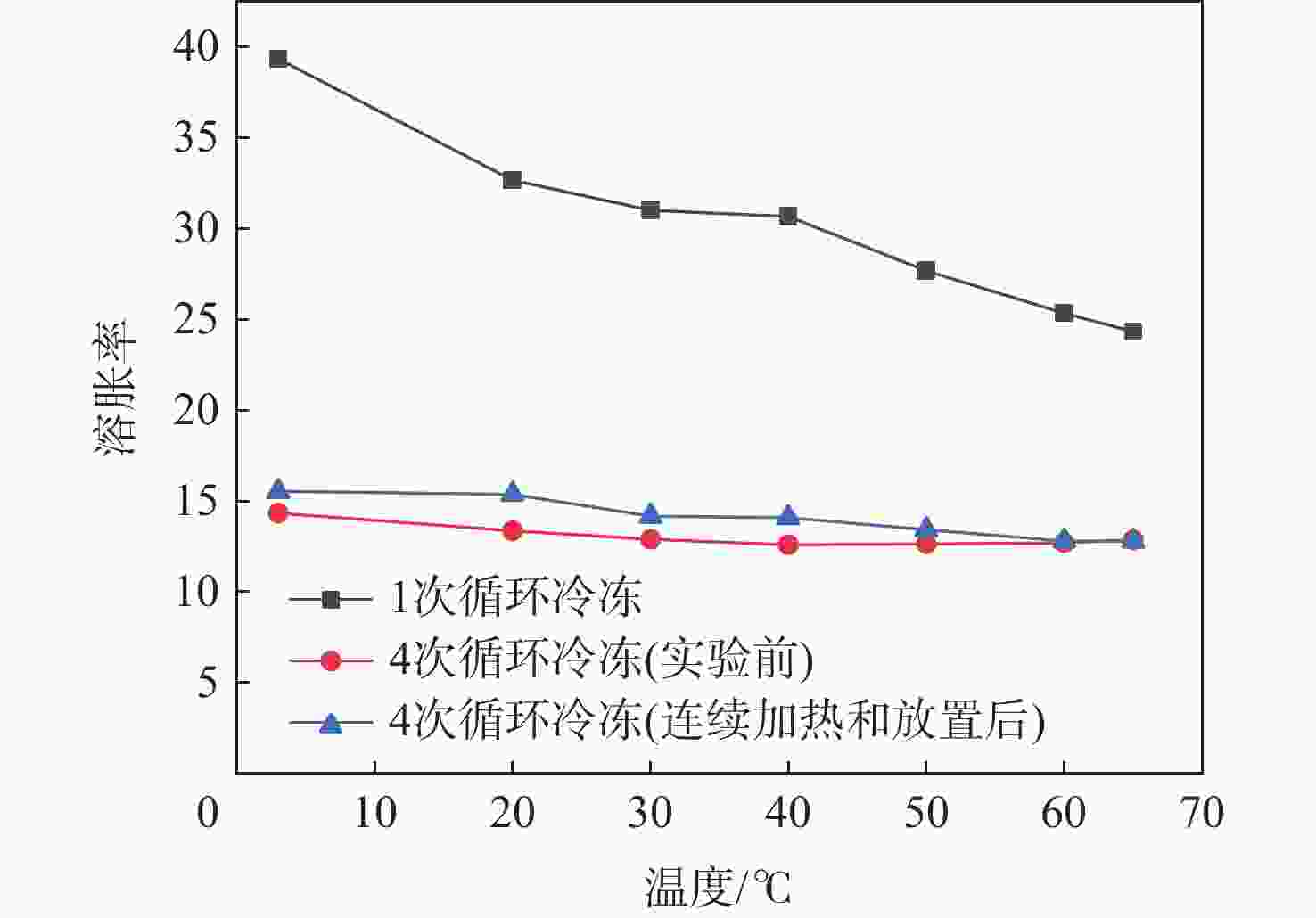

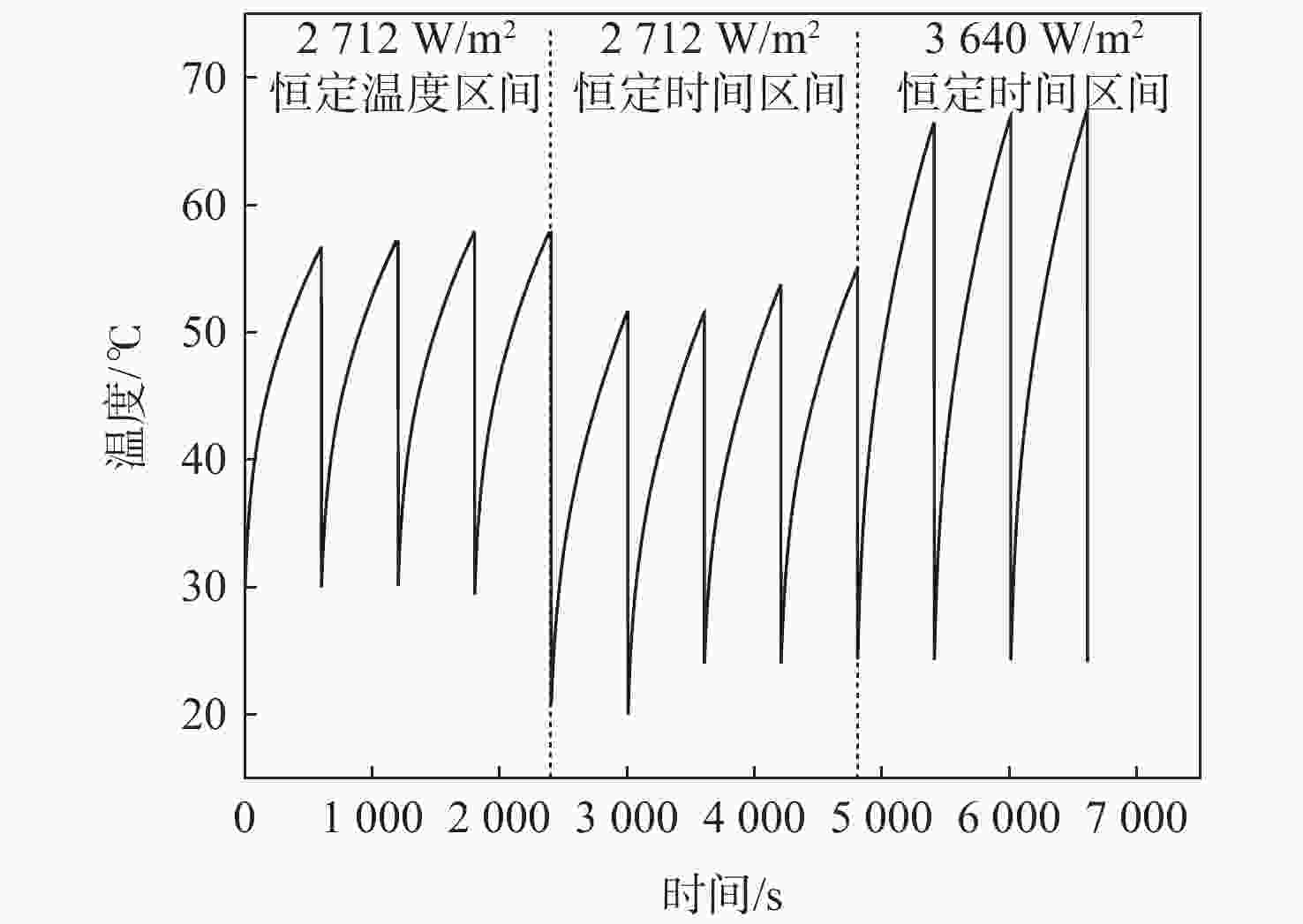

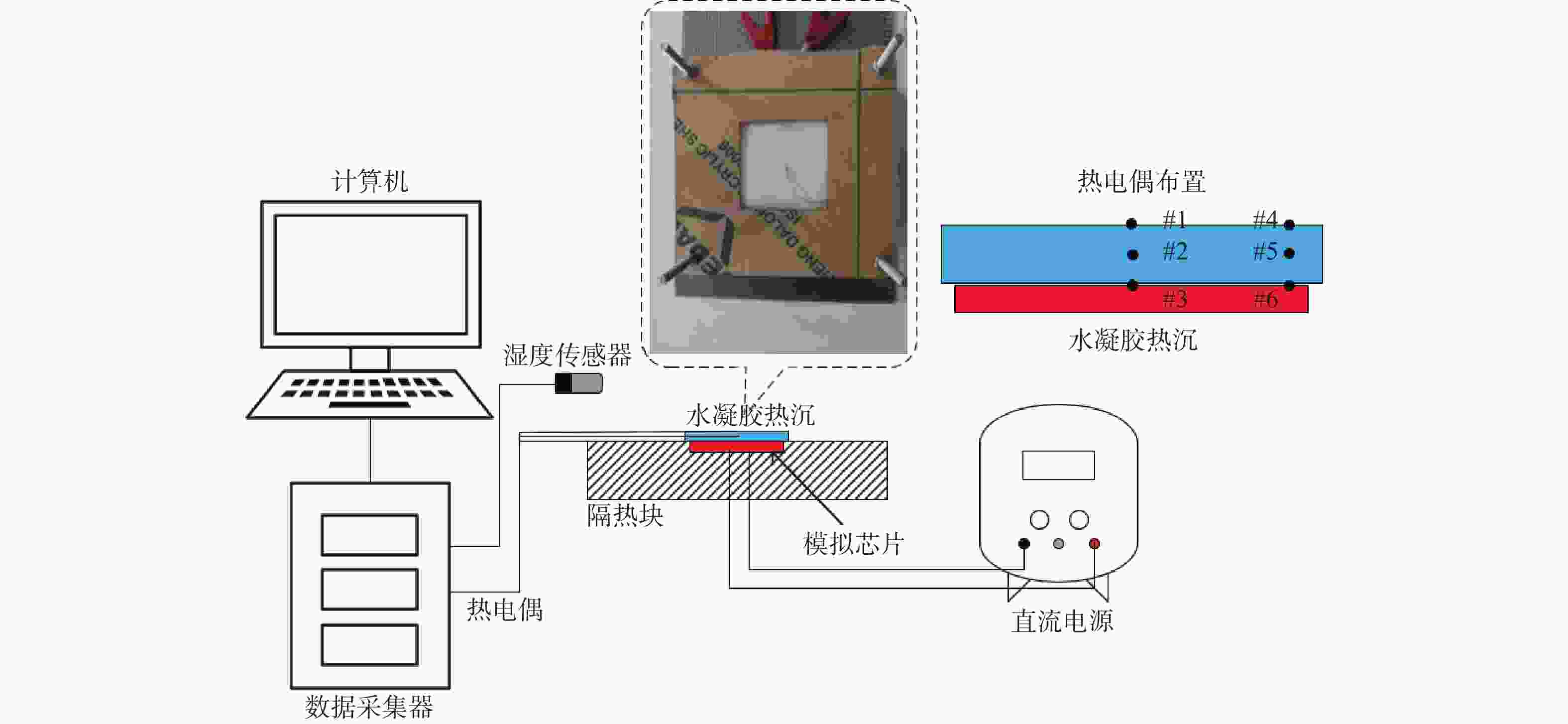

为研究水凝胶作为热管理技术的可行性和潜力,采用物理循环冷冻法制备一种力学和经济性良好的新型聚乙烯醇(PVA)/聚乙二醇(PEG)复合水凝胶热沉,热沉尺寸为60 mm×60 mm×2 mm,通过表面的水分蒸发来实现自冷。在2712 W/m2热流下进行散热性能探究实验,得到了升温特性、蒸发对流强度变化关系和溶胀变化规律。发现加入2.5%质量分数的PEG减小了随循环冷冻次数增加造成的制备变形,减小了75.53%的含水量衰减,同时使芯片表面控温下降7.53%。根据实验结果计算得到了蒸发换热系数,并研究了热流、厚度和湿度对蒸发散热的影响。通过对水凝胶不同温度和使用情况(4 h连续使用及120 d常温储存)下溶胀率的测定,证明水凝胶具备一定的短时使用可靠性,但对温度的敏感响应并不显著。

Abstract:To study the feasibility and potential of hydrogels for thermal management, a novel polyvinyl alcohol (PVA) /polyethylene glycol (PEG) composite hydrogel heat sink with good mechanics and economy was prepared by freezing-thaw method. The size of the sink is 60 mm×60 mm×2 mm, and self-cooling is realized by water evaporation on the surface. A heat dissipation experiment was carried out with a heat flow of 2712 W/m2, and the heating characteristics, the relationship of the evaporative convection intensity change and the swelling change law were obtained. It was found that the addition of 2.5% PEG reduced the preparation deformation caused by the increase in the number of freezing cycles, with the water content attenuation being decreased by 75.53%, and the chip surface temperature 7.53%. Based on the experimental results, the evaporation heat transfer coefficient was calculated, and the effects of heat flow, thickness, and humidity on evaporative heat dissipation were studied. The swelling rates of the hydrogel with different temperatures and usage conditions (4 h continuous use and 120-day storage at room temperature) were then measured, showing that the hydrogel has a certain short-term reliability in spite of the insignificant sensitive response to temperature.

-

Key words:

- polyvinyl alcohol hydrogel /

- heat sink /

- evaporative cooling /

- thermal management /

- electronic device

-

表 1 水凝胶制备材料

Table 1. Materials for hydrogel preparation

水凝胶 PVA/g PEG/g 去离子水/mL P10/0 10 0 90 P10/2.5 10 2.5 87.5 P5/2.5 5 2.5 92.5 表 2 不同参数下PVA/PEG复合水凝胶的蒸发换热系数及水凝胶的散热贡献率

Table 2. Evaporation heat transfer coefficient of PVA/PEG composite hydrogel with different parameters, and contribution of hydrogel to heat dissipation

热流密度/

( W·m−2)水凝胶

厚度/mm蒸发换热

系数he

/(W·(m2·K)−1)$\dfrac{q_{{\rm{sens}}}+q_{{\rm{evap}}}}{q}$/% 760 3 21.60 52.39 1280 3 25.57 50.85 2000 3 24.90 48.82 2712 3 30.21 58.32 3640 3 42.29 65.28 2712 2 43.01 62.30 2712 8 31.06 63.04 -

[1] 唐广笛, 张天昊, 章桐. 面向大功率芯片散热的电动汽车电机控制器结构优化[J]. 电机与控制应用, 2020, 47(10): 80-84.TANG G D, ZHANG T H, ZHANG T. Structural optimization of motor controller in electric vehicle aiming at high-power chips cooling[J]. Electric Machines and Control Application, 2020, 47(10): 80-84(in Chinese). [2] 侯煦, 邢玉明, 郝兆龙, 等. 高碳醇/膨胀石墨复合相变热沉多目标优化研究[J]. 北京航空航天大学学报, 2021, 47(9): 1866-1873.HOU X, XING Y M, HAO Z L, et al. Multi-objective geometric optimization of a high alcohol/expanded graphite composite PCM based heat sink[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(9): 1866-1873 (in Chinese). [3] 孙潇. 用于芯片散热的蒸发冷却技术[D]. 上海: 东华大学, 2011: 1-5.SUN X. Evaporative cooling technology used for chip cooling[D]. Shanghai: Donghua University, 2011: 1-5 (in Chinese). [4] HOLLOWAY J L, LOWMAN A M, PALMESE G R. The role of crystallization and phase separation in the formation of physically cross-linked PVA hydrogels[J]. Soft Matter, 2012, 9(3): 826-833. [5] LEE W F, CHIU R J. Investigation of charge effects on drug release behavior for ionic thermosensitive hydrogels[J]. Materials Science and Engineering:C, 2002, 20(1/2): 161-166. [6] ROTZETTER A C C, SCHUMACHER C M, BUBENHOFER S B, et al. Thermoresponsive polymers: Thermoresponsive polymer induced sweating surfaces as an efficient way to passively cool buildings[J]. Advanced Materials, 2012, 24(39): 5277-5277. doi: 10.1002/adma.201290239 [7] HUANG Z, ZHANG X, ZHOU M, et al. Bio-inspired passive skin cooling for handheld microelectronics devices[J]. Journal of Electronic Packaging, 2012, 134(1): 014501. doi: 10.1115/1.4005908 [8] CUI S, HU Y, HUANG Z, et al. Cooling performance of bio-mimic perspiration by temperature-sensitive hydrogel[J]. International Journal of Thermal Sciences, 2014, 79: 276-282. doi: 10.1016/j.ijthermalsci.2014.01.015 [9] PU S, SU J, LI L, et al. Bioinspired sweating with temperature sensitive hydrogel to passively dissipate heat from high-end wearable electronics[J]. Energy Conversion and Management, 2018, 180: 747-756. [10] YI G B, HUANG Y W, XIONG F H, et al. Preparation and swelling behaviors of rapid responsive semi-IPN NaCMC/PNIPAm hydrogels[J]. Journal of Wuhan University of Technology Materials Science Edition, 2011, 26(6): 1073-1078. doi: 10.1007/s11595-011-0365-3 [11] MENG H, LI G Q. Reversible switching transitions of stimuli-responsive shape changing polymers[J]. Journal of Materials Chemistry A, 2013, 1(27): 7838-7865. doi: 10.1039/c3ta10716g [12] HUBBARD A M, CUI W, HUANG Y, et al. Hydrogel/elastomer laminates bonded via fabric interphases for stimuli-responsive actuators[J]. Matter, 2019, 1(3): 674-689. doi: 10.1016/j.matt.2019.04.008 [13] 罗加祺. 过渡金属碳/氮化物(MXene)-聚合物纳米复合材料的制备及其性能研究[D]. 北京: 北京化工大学, 2020: 35-40.LUO J Q. Preparation and properties of transition metal carbide/nitride(MXene)-polymer nanocomposites[D]. Beijing: Beijing University of Chemical Technology, 2020: 35-40 (in Chinese). [14] 张林, 张娜, 曹秋枫. PVA水凝胶制备方法研究进展[J]. 化工时刊, 2018, 32(2): 29-32. doi: 10.16597/j.cnki.issn.1002-154x.2018.02.009ZHANG L, ZHANG N, CAO Q F. Research progress in preparation methods of PVA hydrogels[J]. Chemical Industry Times, 2018, 32(2): 29-32(in Chinese). doi: 10.16597/j.cnki.issn.1002-154x.2018.02.009 [15] 李东. 聚乙烯醇水凝胶薄膜的力学性能调控及应用[D]. 大连: 大连理工大学, 2020: 35-45.LI D. Mechanical property modulation and application of poly(vinyl alcohol) hydrogel membrane[D]. Dalian: Dalian University of Technology, 2020: 35-45(in Chinese). [16] PEPPAS N A, MERRILL E W. Differential scanning calorimetry of crystallized PVA hydrogels[J]. Journal of Applied Polymer Science, 1976, 20(6): 1457-1465. doi: 10.1002/app.1976.070200604 [17] ZAMENGO M, MORIKAWA J. Evaluation of cooling ability for a novel heat sink made of polyvinyl alcohol hydrogel[J]. International Journal of Heat and Mass Transfer, 2019, 143: 118523. doi: 10.1016/j.ijheatmasstransfer.2019.118523 [18] QIU M, CHEN D, SHEN C, et al. Platelet-rich plasma-loaded poly(D, L-lactide)-poly(ethylene glycol)-poly(D, L-lactide) hydrogel dressing promotes full-thickness skin wound healing in a rodent model[J]. International Journal of Molecular Sciences, 2016, 17(7): 1001. doi: 10.3390/ijms17071001 [19] CHANG C F, CHANG C Y, TSAI W T, et al. Adsorption equilibrium of polyethylene glycol in the copper electroplating solution on activated carbon[J]. Journal of Colloid and Interface, 2000, 232(1): 207-209. doi: 10.1006/jcis.2000.7180 [20] 杜倩雯, 陈琳, 钟春燕, 等. BC/PVA/PEG增强型复合水凝胶的制备及其表征[J]. 广东化工, 2014, 41(16): 17-18. doi: 10.3969/j.issn.1007-1865.2014.16.009DU Q W, CHEN L, ZHONG C Y, et al. Production and characterization of bacterial cellulose-poly (vinyl aicohol)-poly (ethylene glycol) enhanced nanocomposite hydrogel[J]. Guangdong Chemical Industry, 2014, 41(16): 17-18(in Chinese). doi: 10.3969/j.issn.1007-1865.2014.16.009 [21] 周学华. 高强度多孔PVA水凝胶的制备及其性能的研究[D]. 北京: 中国石油大学, 2016: 20-30.ZHOU X H. Preparation of polyvinyl alcohol porous hydrogel with high strength and well ciprofloxacin release efficiency[D]. Beijing: China University of Petroleum, 2016: 20-30 (in Chinese). [22] MA K X, ZHANG X Z, YANG Y Y, et al. Preparation and characterization of fast response macroporous poly(N-isopropylacrylamide) hydrogels[J]. Langmuir, 2001, 17(20): 6094-6099. doi: 10.1021/la010105v [23] 张梅, 那莹, 姜振华. 接枝共聚法制备聚乙二醇(PEG)/聚乙烯醇(PVA)高分子固-固相变材料性能研究[J]. 高等学校化学学报, 2005, 26(1): 181-185. doi: 10.3321/j.issn:0251-0790.2005.01.031ZHANG M, NA Y, JIANG Z H. Preparation and properties of polymeric solid-solid phase change materials of polyethylene glycol(PEG)/poly(vinyl alcohol)(PVA) copolymers by graft copolymerization[J]. Chemical Journal of Chinese Universities, 2005, 26(1): 181-185(in Chinese). doi: 10.3321/j.issn:0251-0790.2005.01.031 [24] 孙大辉, 崔艳, 疏官胜, 等. 聚乙二醇(PEG)/聚乙烯醇(PVA)温敏水凝胶的制备及温敏特性研究[C]//2009全国功能材料科技与产业高层论坛, 2009: 355-358.SUN D H, CUI Y, SHU G S, et al. Study on preparation and sensitive properties of polyethylene glycol (PEG)/polyvinyl alcohol (PVA) thermo-sensitive hydrogel[C]//Proceedings of 2009 China Functional Materials Technology and Industry Forum, 2009: 355-358 (in Chinese). [25] 徐天宇. 聚乙烯醇/聚乙二醇新型温敏水凝胶的制备及性能研究[D]. 长春: 吉林大学, 2012: 15-30.XU T Y. Study on preparation and sensitive properties of polyethylene glycol (PEG)/polyvinyl alcohol (PVA) thermo-sensitive hydrogel[D]. Changchun: Jilin University, 2012: 15-30 (in Chinese). [26] PEPPAS N A, MERRILL E W. Crosslinked poly(vinyl alcohol) hydrogels as swollen elastic networks[J]. Journal of Applied Polymer Science, 1977, 21(7): 1763-1770. doi: 10.1002/app.1977.070210704 [27] MORI Y, TOKURA H, YOSHIKAWA M. Properties of hydrogels synthesized by freezing and thawing aqueous polyvinyl alcohol solutions and their applications[J]. Journal of Materials Science, 1997, 32(2): 491-496. doi: 10.1023/A:1018586307534 [28] KOSKI A, YIM K, SHIVKUMAR S. Effect of molecular weight on fibrous PVA produced by electrospinning[J]. Materials Letters, 2004, 58(3-4): 493-497. doi: 10.1016/S0167-577X(03)00532-9 [29] AGU D L J D, BADANO J M, RINTOUL I. Kinetics and thermodynamics of swelling and dissolution of PVA gels obtained by freeze-thaw technique[J]. Materials Chemistry and Physics, 2018, 216: 14-16. doi: 10.1016/j.matchemphys.2018.05.038 [30] SIROUSAZAR M, YARI M. Dehydration kinetics of polyvinyl alcohol hydrogel wound dressings during wound healing process[J]. Chinese Journal of Polymer Science, 2010, 28(4): 121-128. [31] POTKONJAK B, JOVANOVIC J, STANKOVIC B, et al. Comparative analyses on isothermal kinetics of water evaporation and hydrogel dehydration by a novel nucleation kinetics model[J]. Chemical Engineering Research & Design Transactions of the Institution of Chemical Engineers, 2015, 100: 323-330. [32] THEODORE L, BERGMAN L, ADRIENNE S, et al. Fundamentals of heat and mass transfer[M]. 7th ed. Hoboken: Wiley Press, 2011: 594-625. [33] MACHIDA Y, KUROKI S, KANEKIYO M, et al. A structural study of water in a poly(vinyl alcohol) gel by 17O NMR spectroscopy[J]. Journal of Molecular Structure, 2000, 554(1): 81-90. doi: 10.1016/S0022-2860(00)00561-5 -

下载:

下载: