Application of pulse compression technique in steel plate corrosion detection with SH guided wave EMATs

-

摘要:

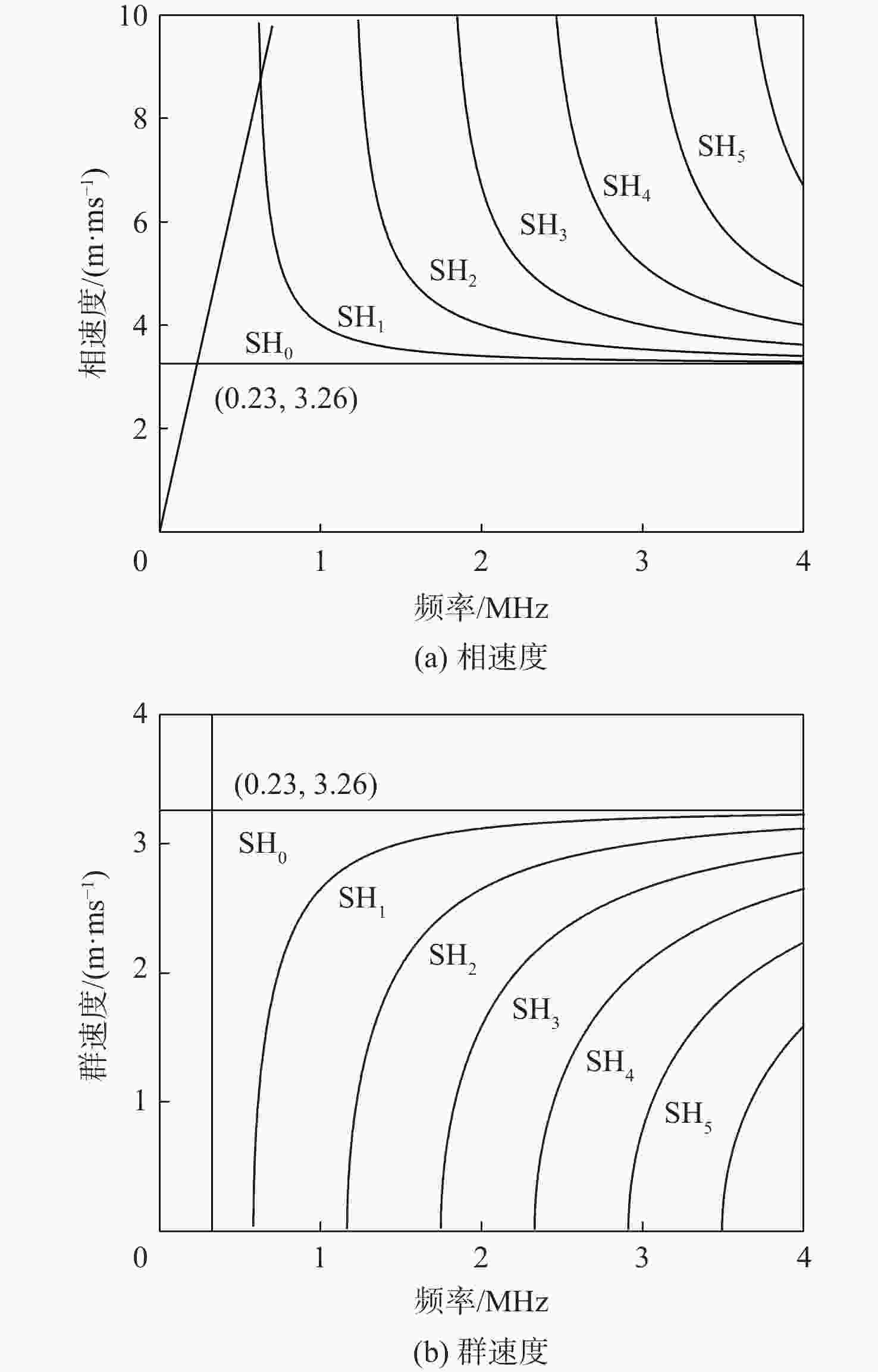

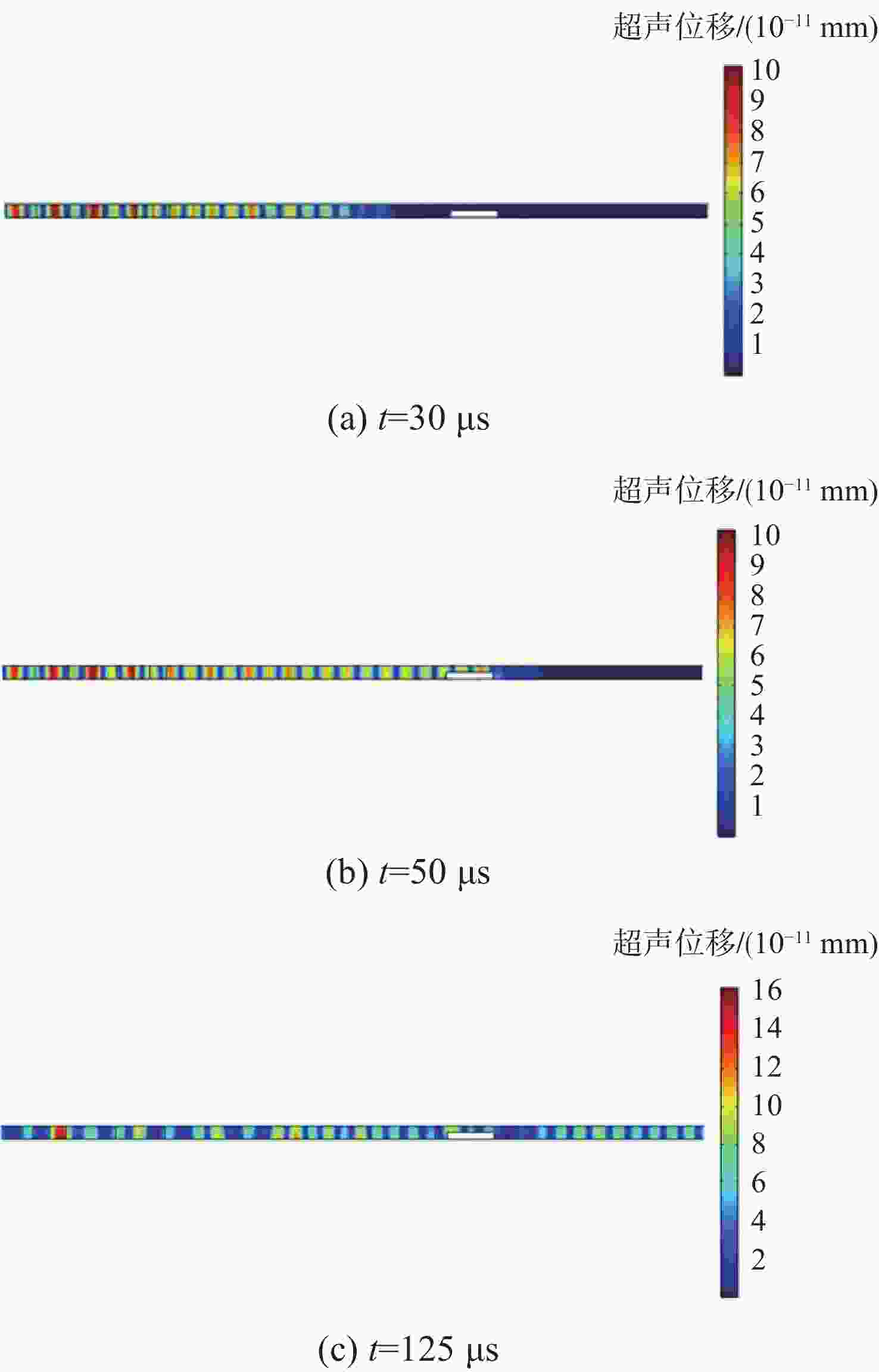

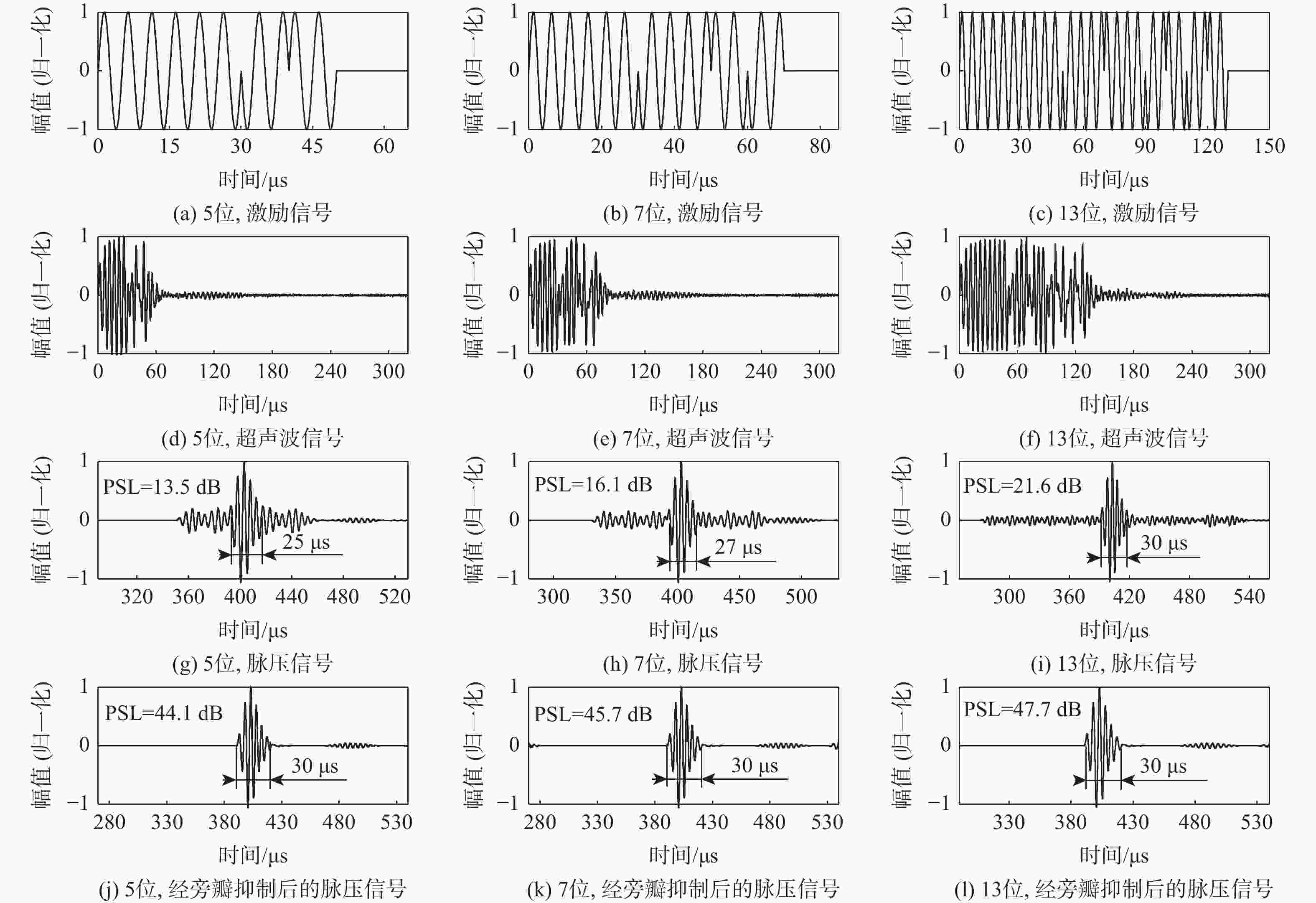

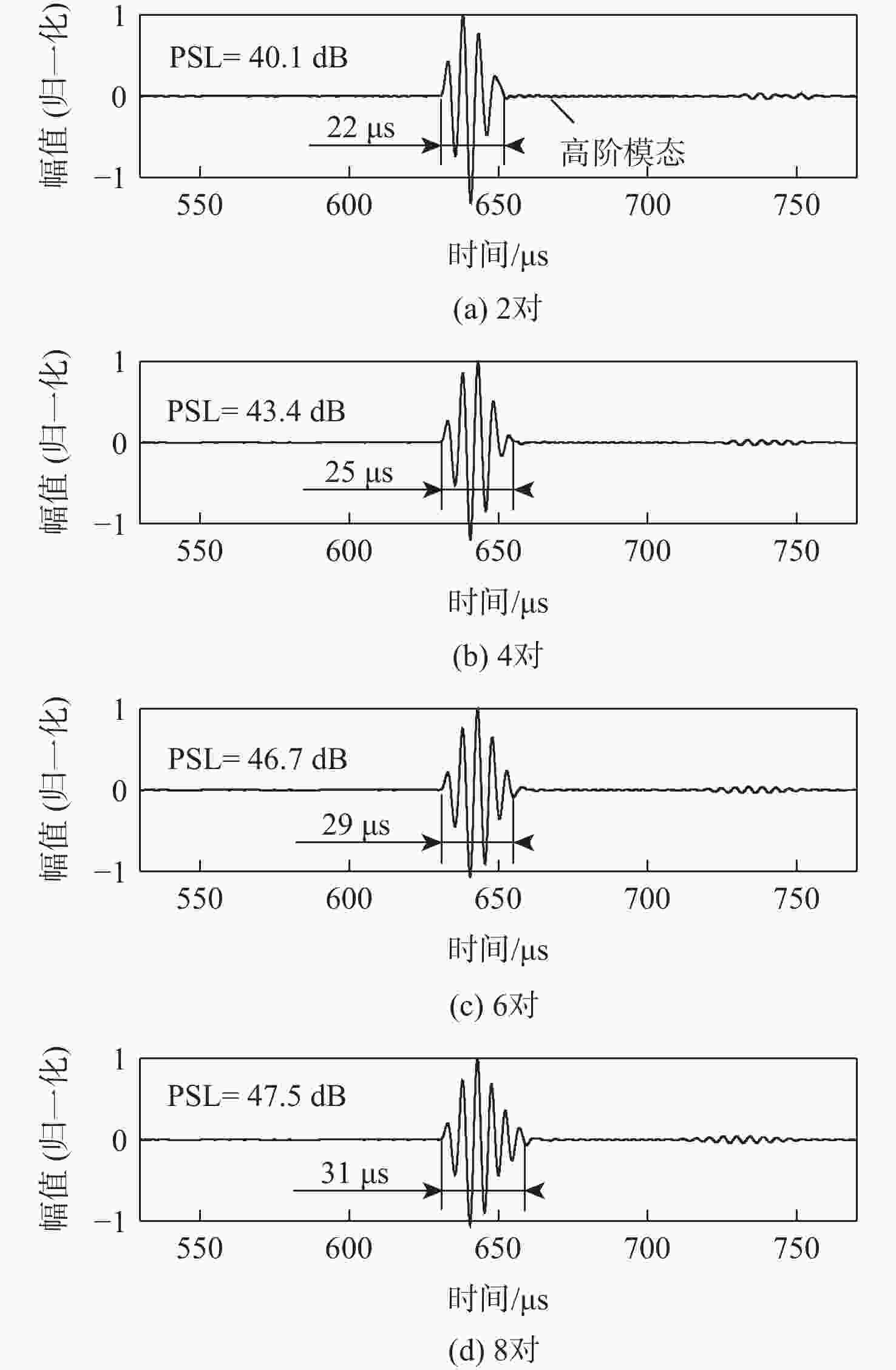

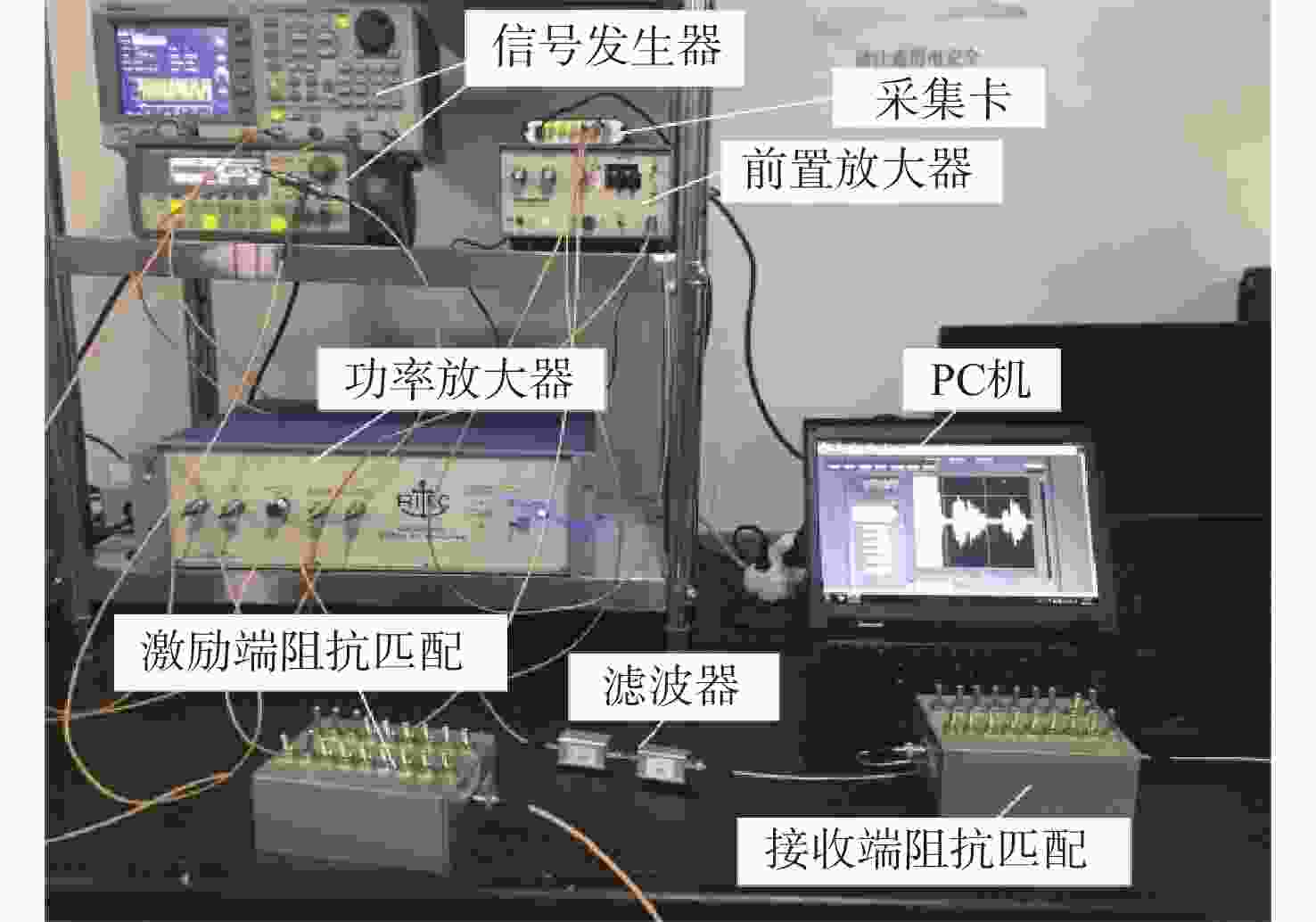

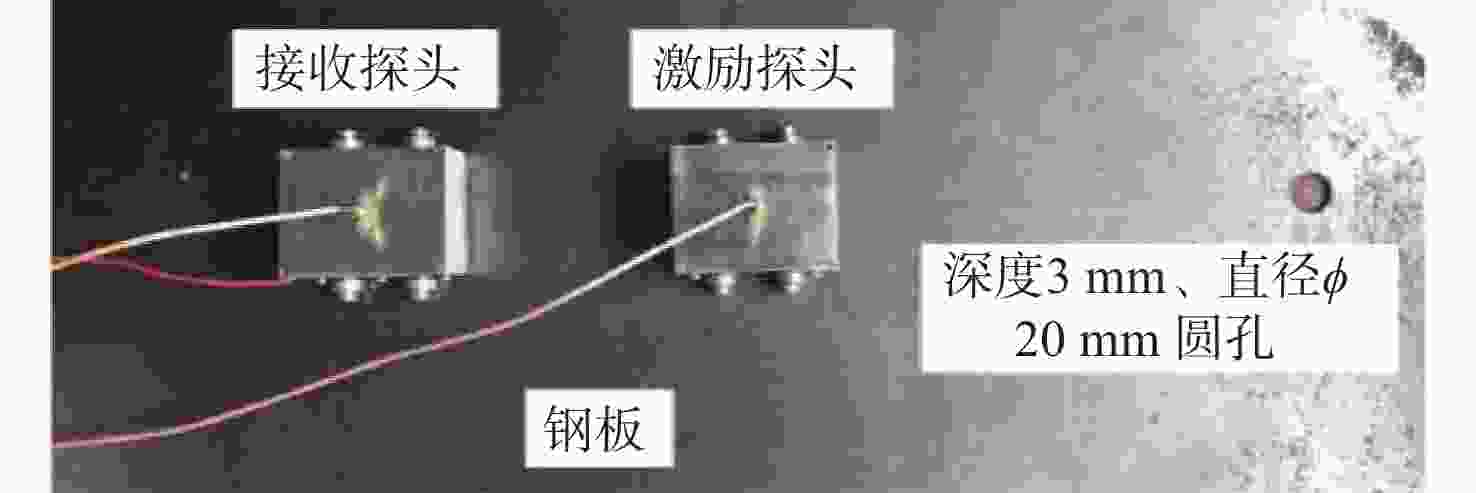

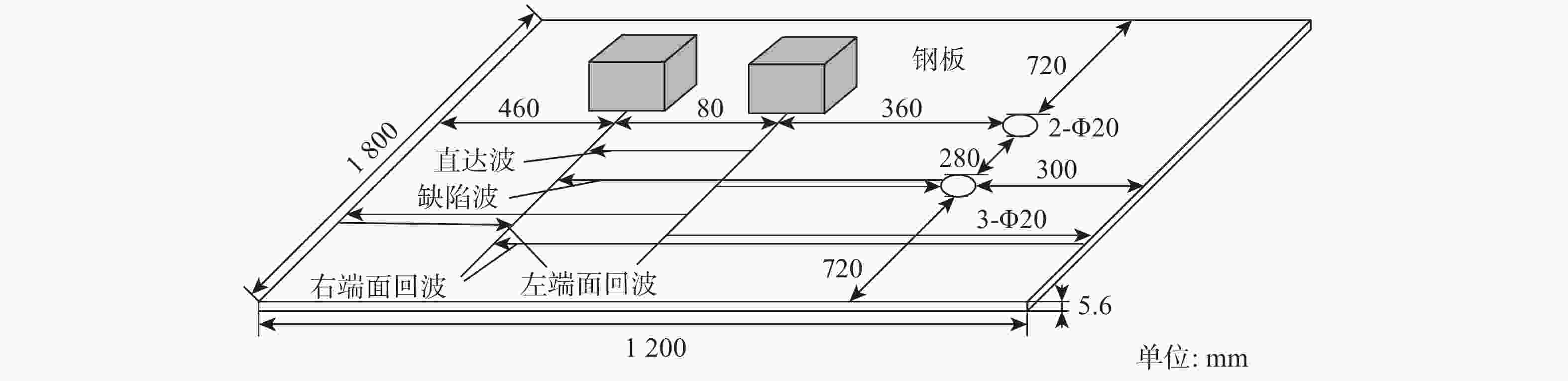

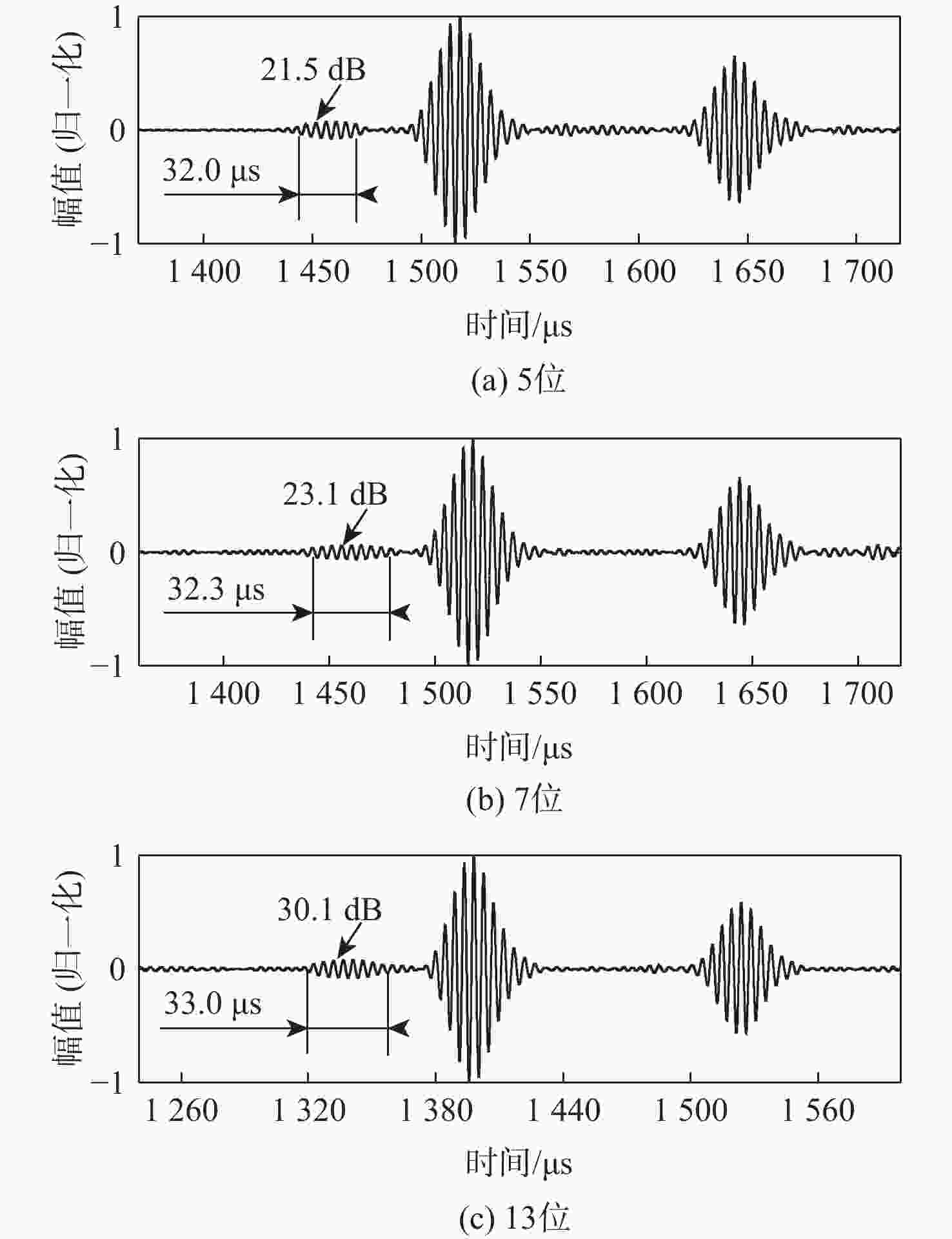

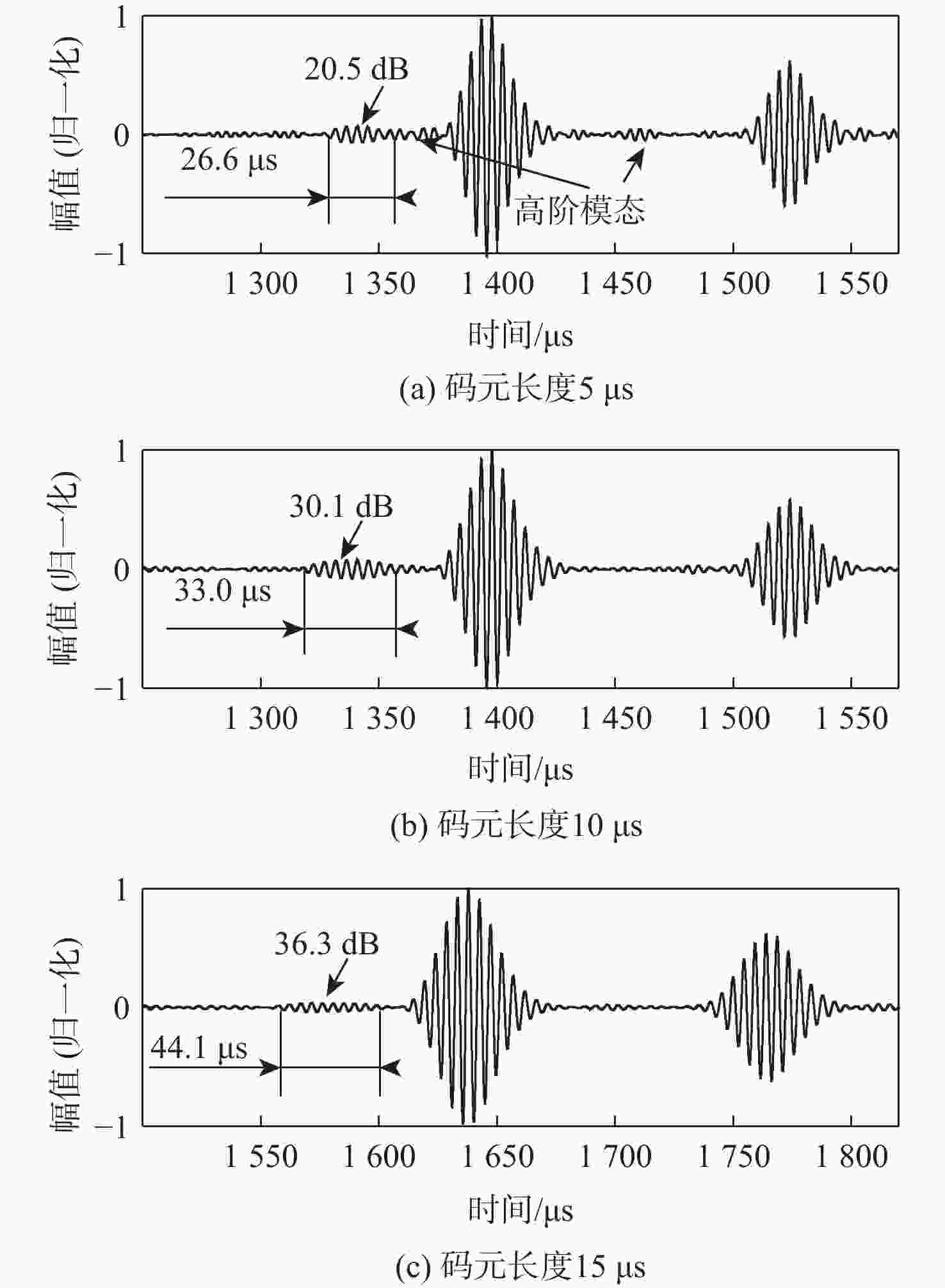

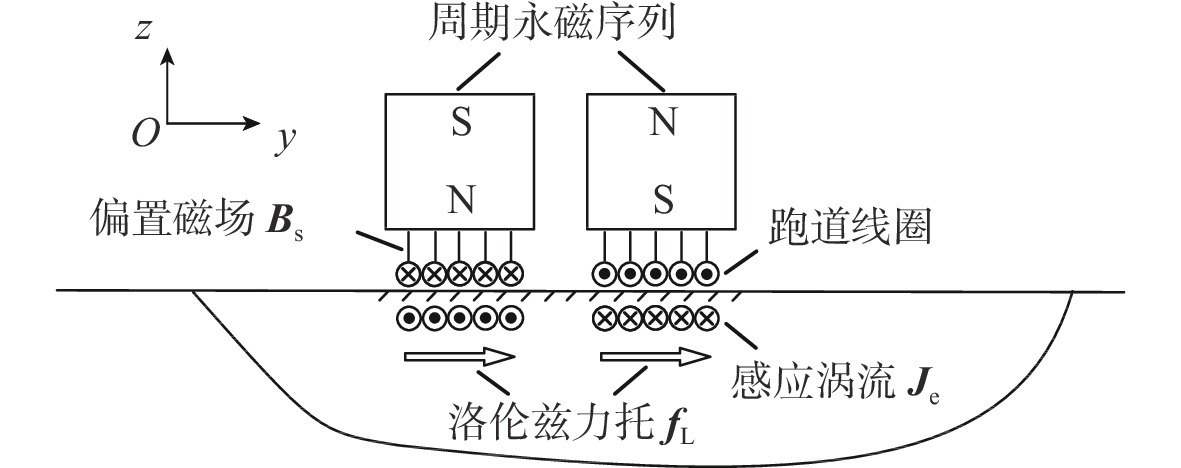

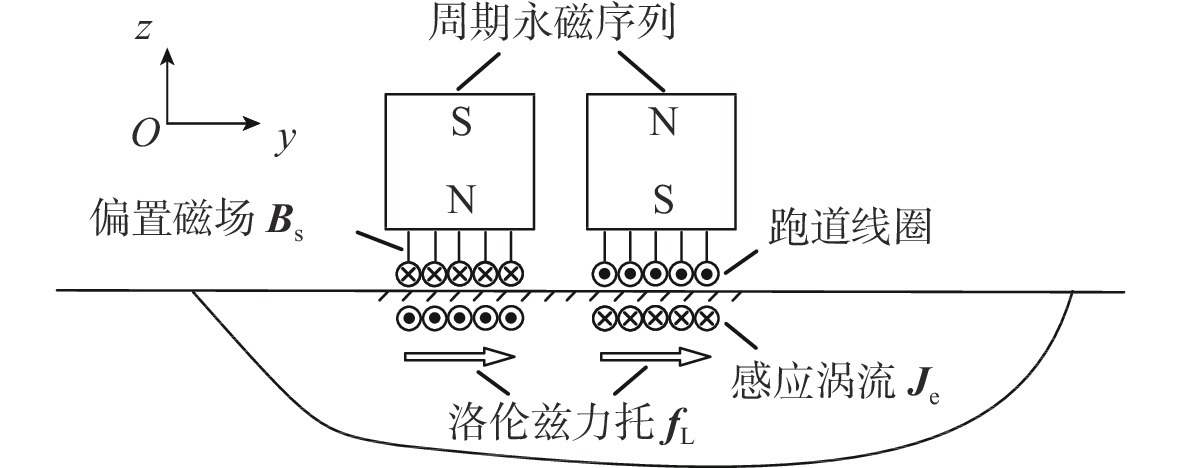

将Barker码脉冲压缩技术应用于水平剪切(SH)导波电磁超声换能器( EMAT),对提高在役钢板腐蚀检测回波的信噪比(SNR)和空间分辨率,以及实现大范围在线快速扫查具有重要的工程应用价值。建立基于Barker码信号激励的钢板SH导波传播有限元模型,结合实验分析与数值计算,分析了Barker码序列长度、码元长度、EMAT设计参数、提离等因素对脉冲压缩后缺陷回波的信噪比和波包宽度的影响,并与传统单一频率脉冲串激励方式进行对比实验。结果表明:与单一频率脉冲串激励方式相比,采用Barker码脉冲压缩技术,可以将缺陷波的SNR提高5.8 dB;当EMAT提离为3.0 mm时,经过脉冲压缩后的缺陷回波SNR>8.7 dB,而采用单一频率脉冲串激励方式对应的SNR接近于0 dB;当Barker码信号序列长度为13位、码元长度为15 μs时,能检测深度为1 mm、直径为20 mm的圆孔,且SNR>25.4 dB。

Abstract:The application of Barker code pulse compression technique in a shear horizontal (SH) guided wave electromagnetic acoustic transducer (EMAT) has significant value in engineering application as it enhances the signal-to-noise ratio (SNR) and spatial resolution of the corrosion echo detected in in-service steel plates, and helps to realize large-scale and rapid on-line scanning. In this paper, a finite element model of SH-guided wave propagation in a steel plate excited by Barker code signals is established. Then, combined with experimental analysis and numerical calculations, the effects of Barker code sequence length, subpulse length, EMAT design parameters, and lift-off on the SNR and wave packet width of the pulse-compressed echoes are analyzed and compared with those of the traditional tone-burst excitation method. The results show that the SNR of the defect echo processed with the Barker code pulse compression technique is 5.8 dB higher than that with the tone-burst excitation method. When the EMAT liftoff is 3.0 mm, the SNR of the defect echo after Barker code pulse compression is greater than 8.7 dB, while that with the tone-burst excitation method is approximately 0 dB. When the sequence length and subpulse of the Barker code signals are respectively 13 and 15 μs, a circular hole with a depth of 1 mm and a diameter of 20 mm can be detected, the SNR of which is greater than 25.4 dB.

-

表 1 有限元建模参数

Table 1. Parameters in finite element model

变量 数值 变量 数值 钢板长度ws/mm 300 纵波波速/(m·s−1) 5960 钢板宽度ls/mm 100 横波波速/(m·s−1) 3260 钢板高度hs/mm 5.6 钢板密度/(kg·m−3) 7932 永磁体间距d/mm 7 圆孔直径/mm 20 永磁体长度wm/mm 20 圆孔深度/mm 3 表 2 采用不同Barker码激励信号和无同步平均时,2 mm深度圆孔对应的缺陷波SNR

Table 2. SNR of the defect echo from 2 mm deep circular hole with different Barker code signals and without synchronous average

Barker激励信号 缺陷波SNR/dB 序列长度/位 码元长度/μs 5 10 17.7 7 10 20.7 13 5 16.3 13 10 26.5 13 15 31.4 -

[1] HU X W, NG C T, KOTOUSOV A. Scattering characteristics of quasi-Scholte waves at blind holes in metallic plates with one side exposed to water[J]. NDT & E International, 2020, 117: 102379. [2] SUNGGO C, HWANJEONG C, CLIFF J L. Nondestructive inspection of spent nuclear fuel storage canisters using shear horizontal guided waves[J]. Nuclear Engineering and Technology, 2018, 50(6): 890-898. doi: 10.1016/j.net.2018.04.011 [3] ALAN C K, MIGUEL A F, JEAN PIERRE V D W, et al. Interaction of SH guided waves with wall thinning[J]. NDT & E International, 2019, 101: 94-103. [4] WEI X, LI G, XIAO L, et al. Shear strength reduction of trapezoidal corrugated steel plates with artificial corrosion pits[J]. Journal of Constructional Steel Research, 2021, 180: 106583. doi: 10.1016/j.jcsr.2021.106583 [5] RATHOD V T, ROY M D. Ultrasonic Lamb wave based monitoring of corrosion type of damage in plate using a circular array of piezoelectric transducers[J]. NDT & E International, 2011, 44(7): 628-636. [6] SAIT S, ABBAS Y, BOUBENIDER F. Estimation of thin metal sheets thickness using piezoelectric generated ultrasound[J]. Applied Acoustics, 2015, 99: 85-91. doi: 10.1016/j.apacoust.2015.05.011 [7] WEI X Y, YANG Y, YAO W Q, et al. Design of full bridge high voltage pulser for sandwiched piezoelectric ultrasonic transducers used in long rail detection[J]. Applied Acoustics, 2019, 149: 15-24. doi: 10.1016/j.apacoust.2019.01.012 [8] LEE J H, LEE S J. Application of laser-generated guided wave for evaluation of corrosion in carbon steel pipe[J]. NDT & E International, 2008, 42(3): 222-227. [9] GAO T F, SUN H, HONG Y Q, et al. Hidden corrosion detection using laser ultrasonic guided waves with multi-frequency local wavenumber estimation[J]. Ultrasonic, 2020, 108: 106182. doi: 10.1016/j.ultras.2020.106182 [10] 唐志峰, 孙兴涛, 张鹏飞, 等. 集测厚与导波检测于一体的复合式电磁超声换能器研究[J]. 仪器仪表学报, 2020, 41(9): 98-109. doi: 10.19650/j.cnki.cjsi.J2006440TANG Z F, SUN X T, ZHANG P F, et al. Research on composite electromagnetic ultrasonic transducer integrating thickness measurement and guided wave detection[J]. Chinese Journal of Scientific Instrument, 2020, 41(9): 98-109(in Chinese). doi: 10.19650/j.cnki.cjsi.J2006440 [11] 王晓娟, 赵锴, 郑毅. 管道纵向超声导波的对称模态转换特性分析[J]. 仪器仪表学报, 2020, 41(9): 151-160. doi: 10.19650/j.cnki.cjsi.J2006453WANG X J, ZHAO K, ZHENG Y. Characteristics of symmetric mode conversion of longitudinal guided-wave modes in pipeline[J]. Chinese Journal of Scientific Instrument, 2020, 41(9): 151-160(in Chinese). doi: 10.19650/j.cnki.cjsi.J2006453 [12] 唐琴, 石文泽, 卢超, 等. 多层螺旋线圈电磁超声换能器优化设计及其实验研究[J]. 中南大学学报(自然科学版), 2020, 51(7): 1792-1803.TANG Q, SHI W Z, LU C, et al. Optimization design and experimental study of multi-layer spiral coils electromagnetic acoustic transducer[J]. Journal of Central South University(Science and Technology), 2020, 51(7): 1792-1803(in Chinese). [13] 杨理践, 吕瑞宏, 高松巍, 等. 基于SH导波的防腐层能量密度检测机理研究[J]. 仪器仪表学报, 2016, 37(5): 1101-1109. doi: 10.19650/j.cnki.cjsi.2016.05.018YANG L J, LYU R H, GAO S W, et al. Research on the detection mechanism of energy density in pipeline coating based on SH wave[J]. Chinese Journal of Scientific Instrument, 2016, 37(5): 1101-1109(in Chinese). doi: 10.19650/j.cnki.cjsi.2016.05.018 [14] ANDRUSCHAK N, SALETES I, FILLETER T, et al. An NDT guided wave technique for the identification of corrosion defects at support locations[J]. NDT & E International, 2015(75): 72-79. [15] 周琛, 何建, 胡暮平, 等. 基于L(0, 2)超声导波的管段结构损伤定位研究[J]. 仪器仪表学报, 2020, 41(12): 181-191.ZHOU C, HE J, HU M P, et al. Research on damage location of pipe section based on L ( 0, 2) ultrasonic guided wave[J]. Chinese Journal of Scientific Instrument, 2020, 41(12): 181-191(in Chinese). [16] RICCI M, SENNI L, BURRASCANO P, et al. Pulse-compression ultrasonic technique for the inspection of forged steel with high attenuation[J]. Insight-Non-Destructive Testing and Condition Monitoring, 2012, 54(2): 91-95. [17] 石文泽, 陈巍巍, 陈尧, 等. 基于脉冲压缩技术的高温连铸坯壳厚度测量EMAT设计及应用[J]. 仪器仪表学报, 2019, 40(8): 119-130. doi: 10.19650/j.cnki.cjsi.J1905323SHI W Z, CHEN W W, CHEN Y, et al. Design and application of an EMAT for solidification shell thickness detection in continuous casting slab based on the pulse compression technique[J]. Chinese Journal of Scientific Instrument, 2019, 40(8): 119-130(in Chinese). doi: 10.19650/j.cnki.cjsi.J1905323 [18] ZHU W, WU H Z. Characterization and analysis of coded excitation ultrasound parameters for rock properties[J]. Chinese Journal of Acoustics, 2017, 36(1): 29-42. [19] AN Y, WANG X C, YUE B, et al. A novel method for natural gas pipeline safety online monitoring based on acoustic pulse compression[J]. Process Safety and Environmental Protection, 2019(130): 174-181. [20] FU J, WEI G, HUANG Q H, et al. Barker coded excitation with linear frequency modulated carrier for ultrasonic imaging[J]. Biomedical Signal Processing & Control, 2014(13): 306-312. [21] ZHOU Z Z, MA B Q, JIANG J T, et al. Application of wavelet filtering and Barker-coded pulse compression hybrid method to air-coupled ultrasonic testing[J]. Nondestructive Testing & Evaluation, 2014, 29(4): 297-314. [22] 张慧琳, 宋小军. Barker码激励超声导波在长骨检测中的应用[J]. 声学学报, 2014, 39(2): 257-263. doi: 10.15949/j.cnki.0371-0025.2014.02.013ZHANG H L, SONG X J. Application of Barker code excited ultrasonic guided waves to long bone detection[J]. Chinese Journal of Acoustics, 2014, 39(2): 257-263(in Chinese). doi: 10.15949/j.cnki.0371-0025.2014.02.013 [23] 宋寿鹏, 乔梦丽. 基于NLFM Barker编码的板材焊缝缺陷超声检测方法研究[J]. 仪器仪表学报, 2020, 41(4): 246-254.SONG S P, QIAO M L. Research on ultrasonic testing of plate weld flaw based on NLFM Barker coded excitation method[J]. Chinese Journal of Scientific Instrument, 2020, 41(4): 246-254(in Chinese). [24] ISLA J, CEGLA F. Coded excitation for pulse-echo systems[J]. IEEE Transactions on Ultrasonics Ferroelectrics and Frequency Control, 2017, 64(4): 736-748. [25] 王强, 毛捷, 李威, 等. 橡胶-钢粘接结构的谐振超声编码检测方法[J]. 机械工程学报, 2020, 56(20): 22-27. doi: 10.3901/JME.2020.20.022WANG Q, MAO J, LI W, et al. Resonant ultrasonic coded method for rubber-steel bonded structure[J]. Chinese Journal of Mechanical Engineering, 2020, 56(20): 22-27(in Chinese). doi: 10.3901/JME.2020.20.022 [26] 赵晓群. 11位Barker码性能研究[J]. 系统工程与电子技术, 1997, 19(6): 56-58. doi: 10.3321/j.issn:1001-506X.1997.06.014ZHAO X Q. Study on 11 bits Barker code performances[J]. Journal of Systems Engineering and Electronics, 1997, 19(6): 56-58(in Chinese). doi: 10.3321/j.issn:1001-506X.1997.06.014 [27] 李汛江, 苏凡凡, 赵正予. 电离层探测仪回波能量积累算法[J]. 中南大学学报(自然科学版), 2011, 42(12): 3777-3783.LI X J, SU F F, ZHAO Z Y. Energy accumulation algorithms for ionosonde[J]. Journal of Central South University(Science and Technology), 2011, 42(12): 3777-3783(in Chinese). [28] 王强, 毛捷, 丁晓东, 等. 衰减匹配的超声Barker码激励方法[J]. 声学学报, 2020, 45(2): 227-234. doi: 10.15949/j.cnki.0371-0025.2020.02.009WANG Q, MAO J, DING X D, et al. Ultrasonic Barker-code excitation method with attenuation matching[J]. Chinese Journal of Acoustics, 2020, 45(2): 227-234(in Chinese). doi: 10.15949/j.cnki.0371-0025.2020.02.009 [29] RIHACZEK A W, GOLDEN R M. Range sidelobe suppression for Barker codes[J]. IEEE Transactions on Aerospace & Electronic Systems, 1971(6): 1087-1092. [30] POUYAN K, PETER C. The choice of ultrasonic inspection method for the detection of corrosion at inaccessible locations[J]. NDT & E International, 2018, 99: 80-92. [31] HUANG S L, ZHAO W, ZHANG Y S, et al. Study on the lift-off effect of EMAT[J]. Sensors and Actuators A:Physical, 2009, 153(2): 218-221. doi: 10.1016/j.sna.2009.05.014 -

下载:

下载: