Influence of penetration damage on in-plane compression properties of titanium honeycomb sandwich cover structure

-

摘要:

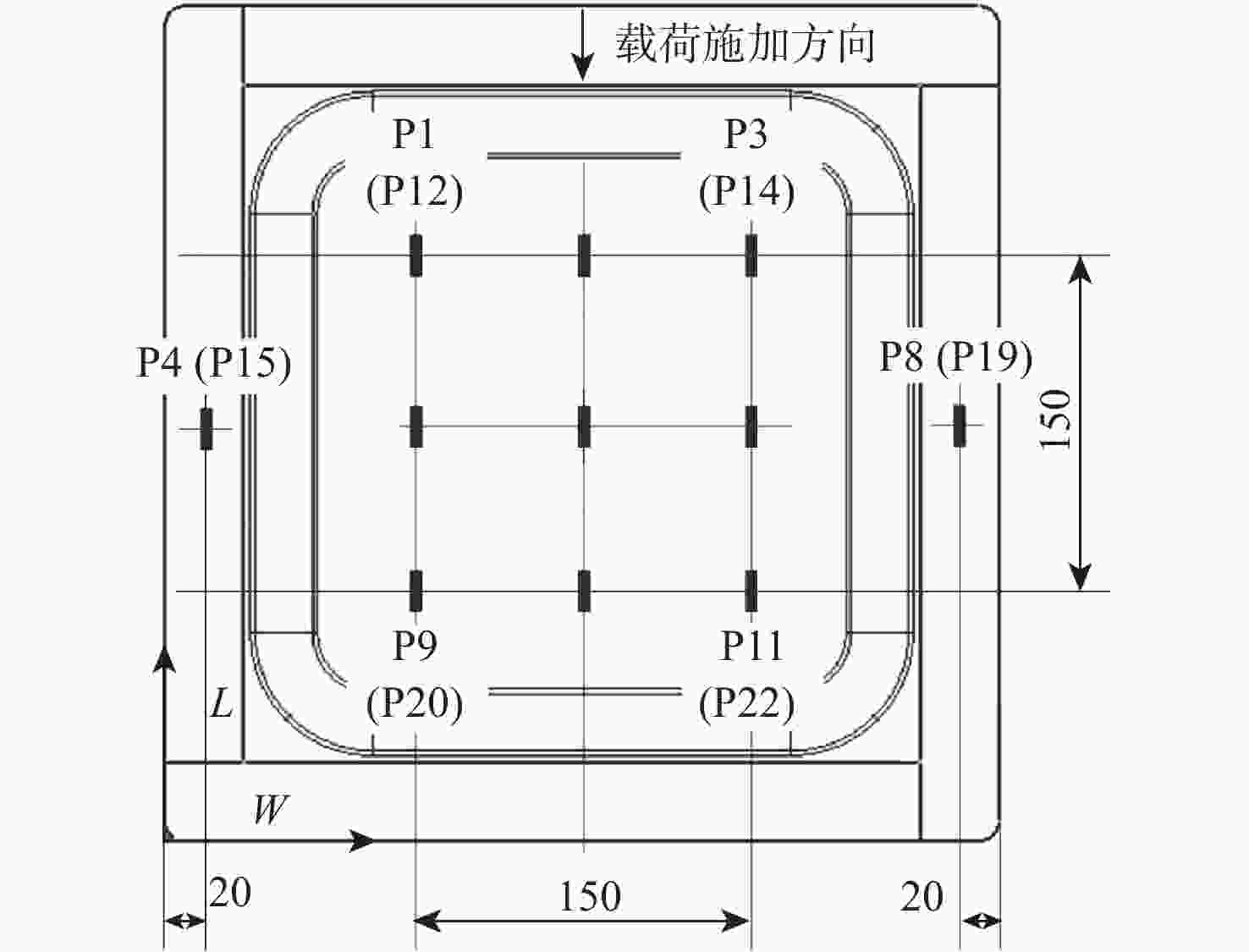

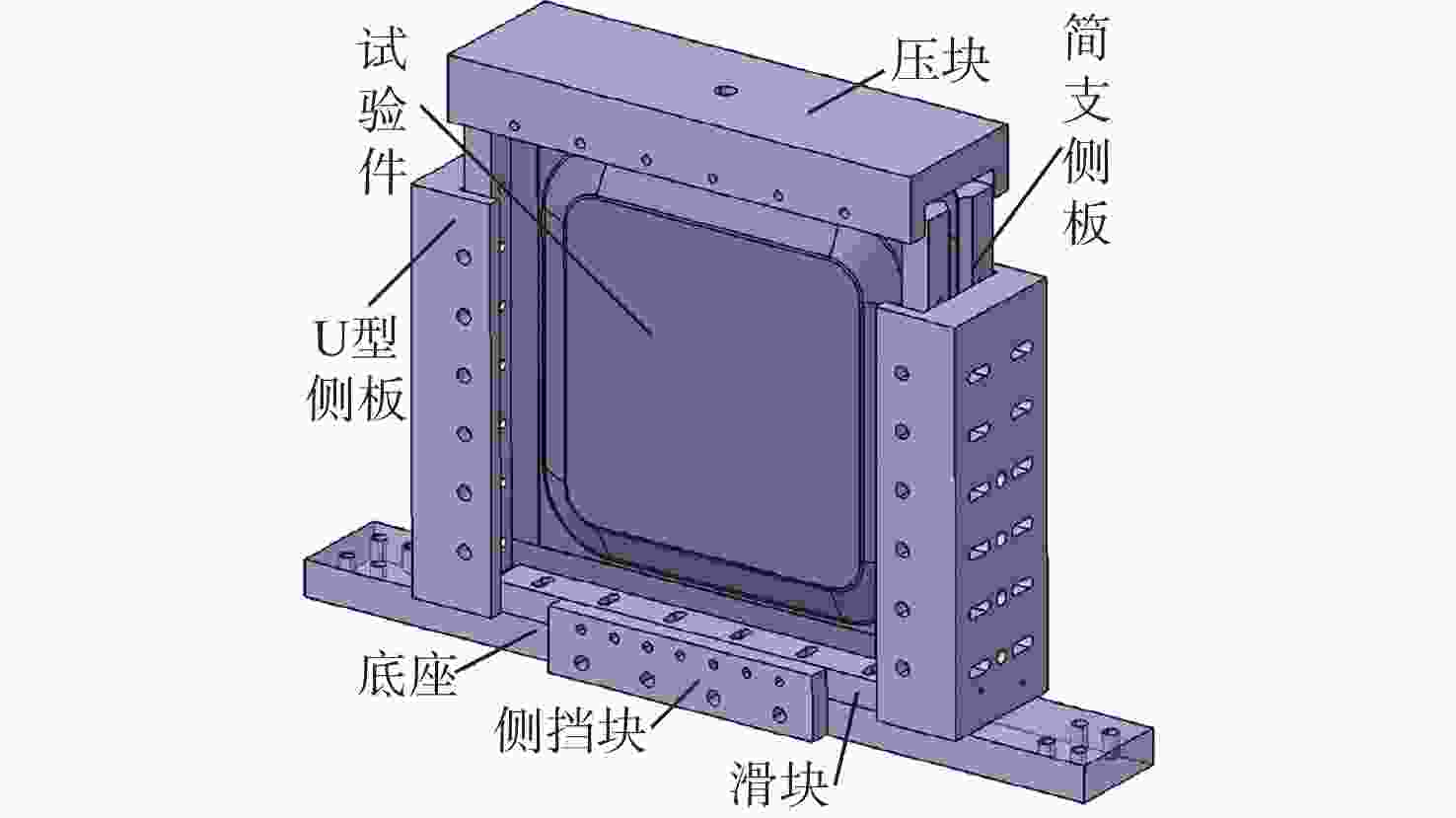

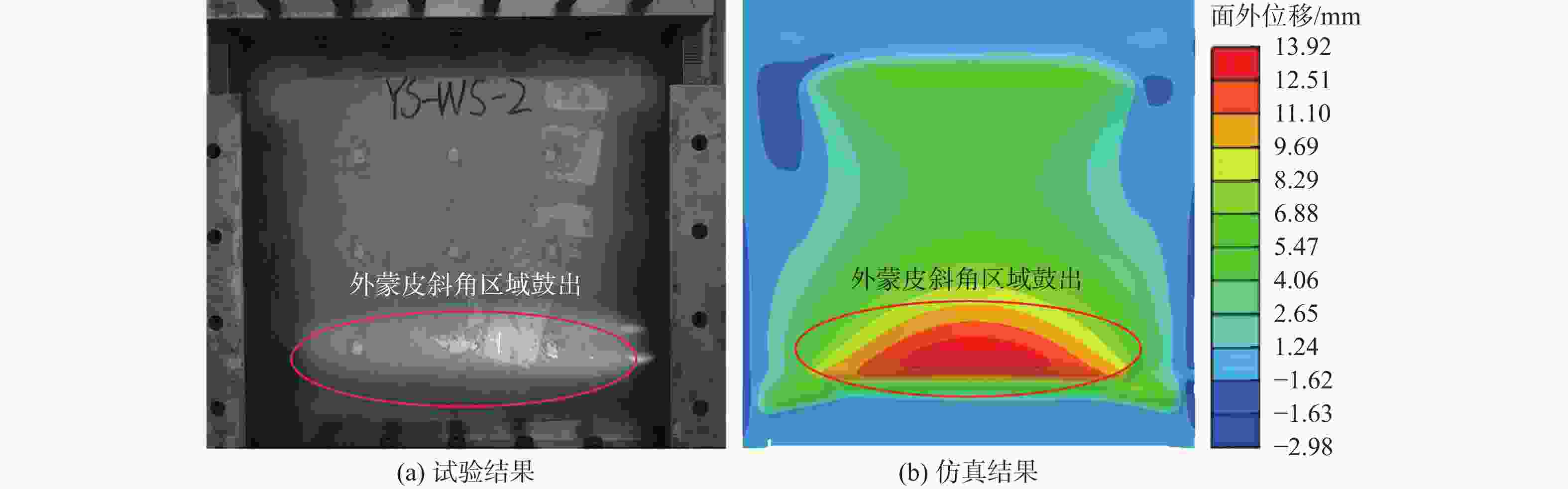

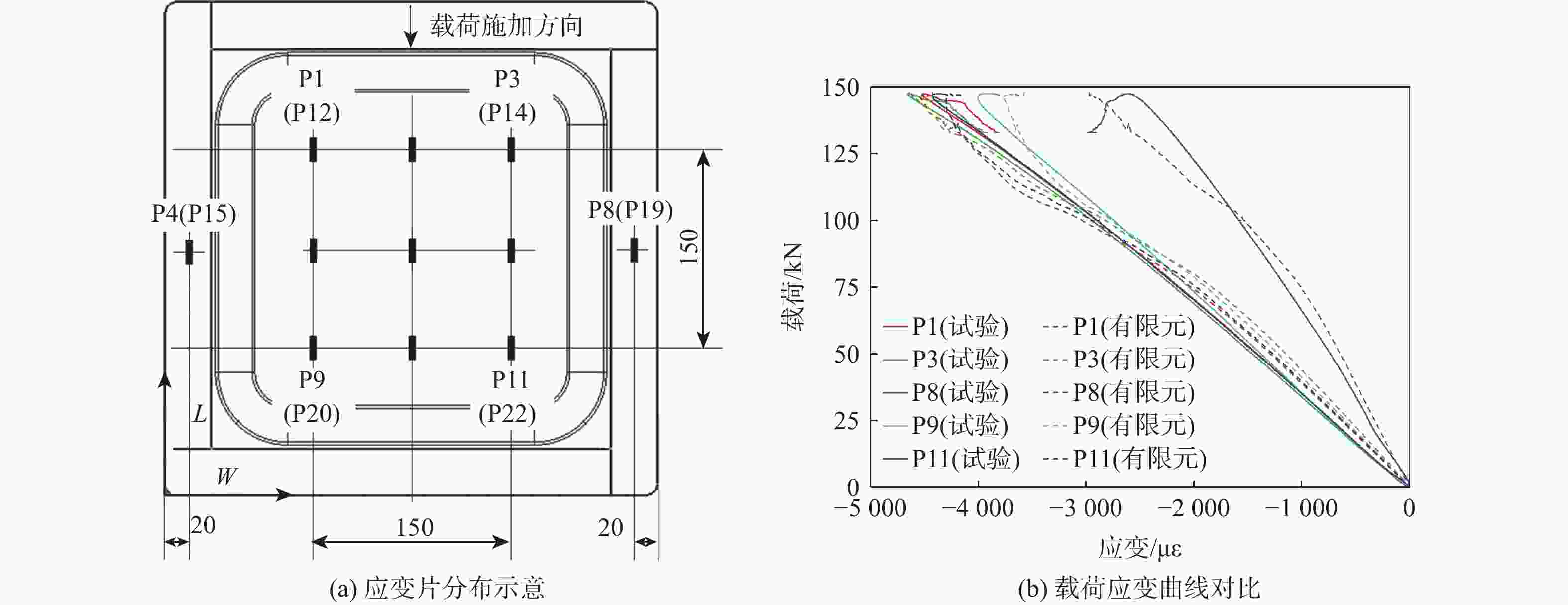

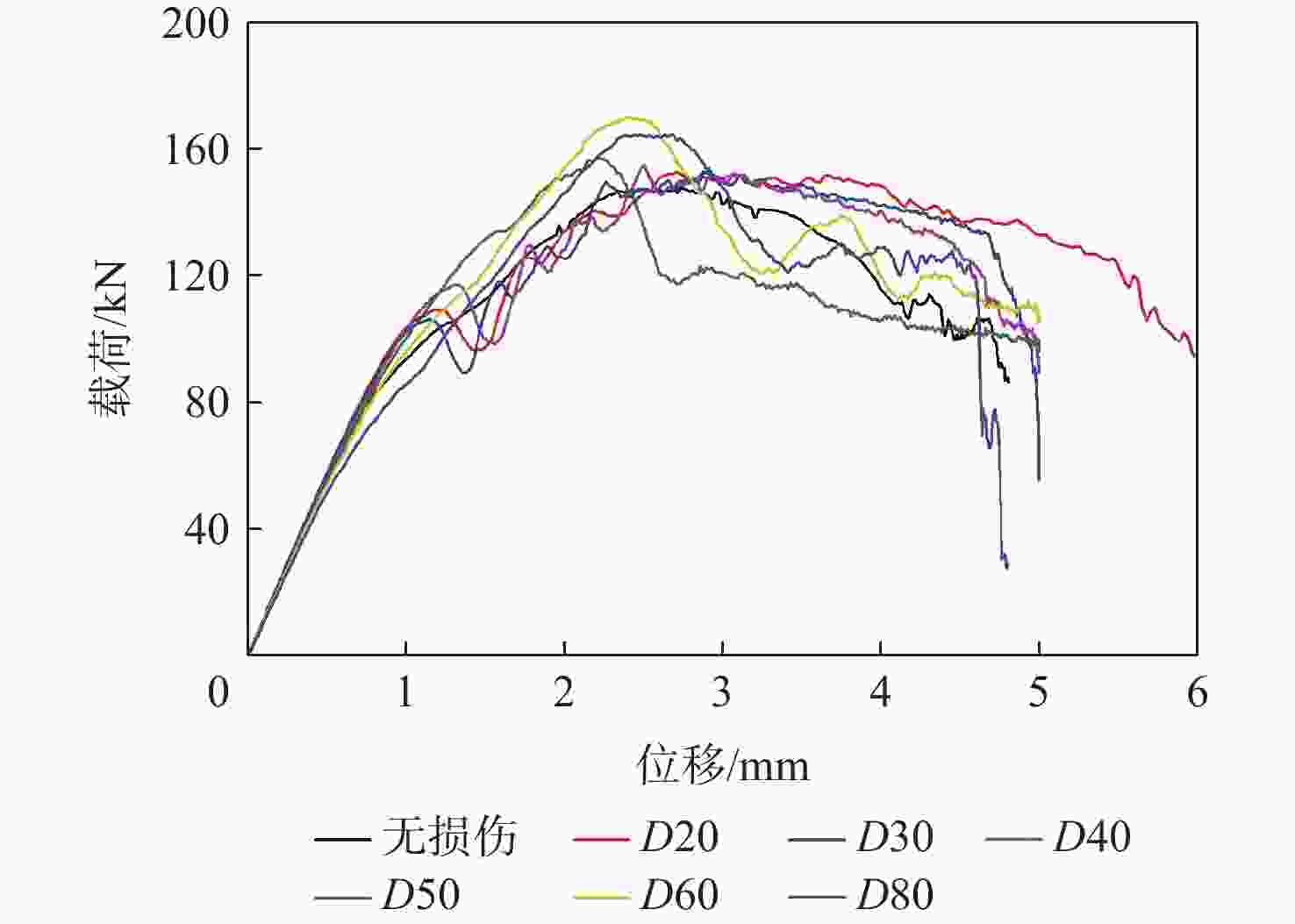

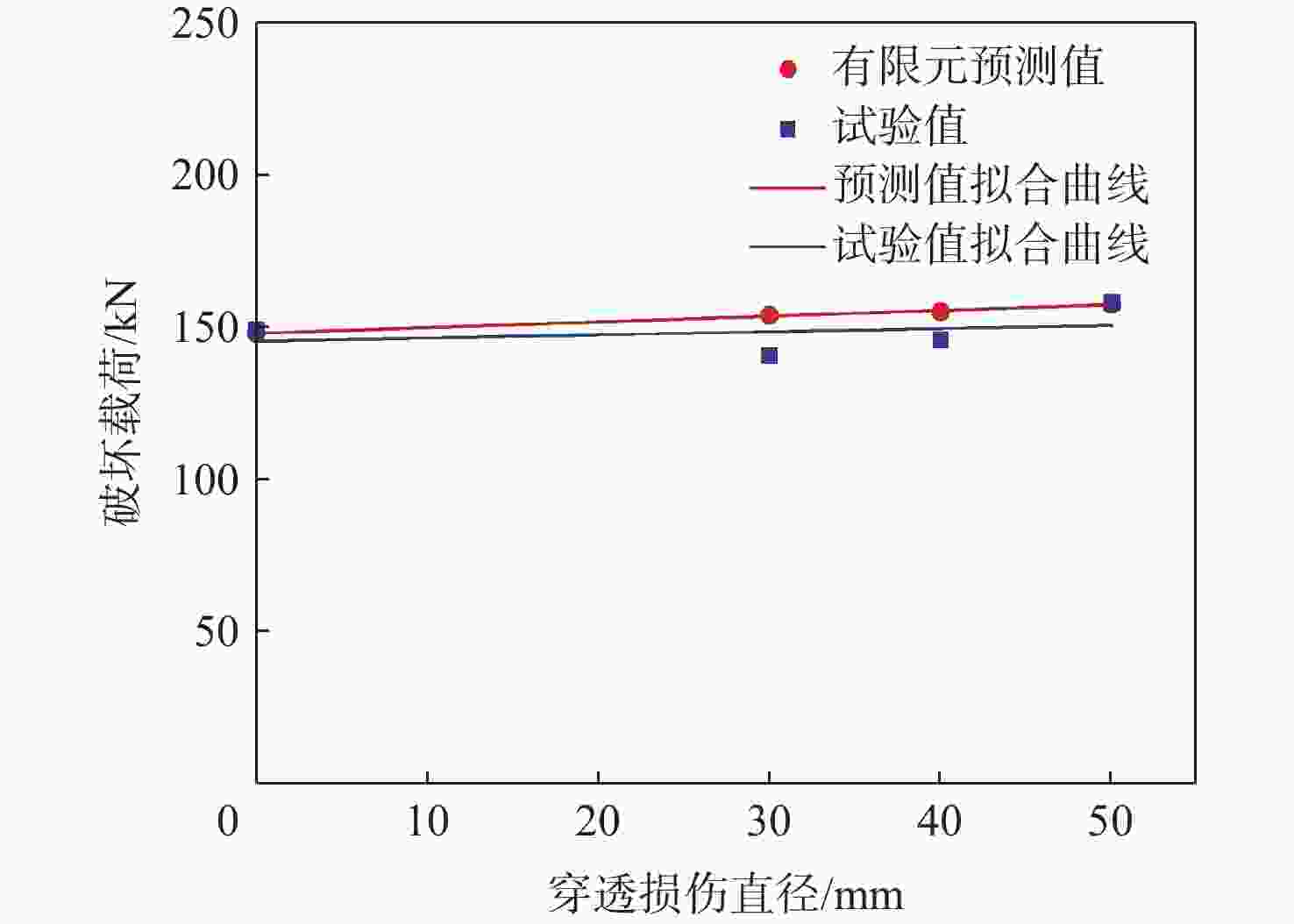

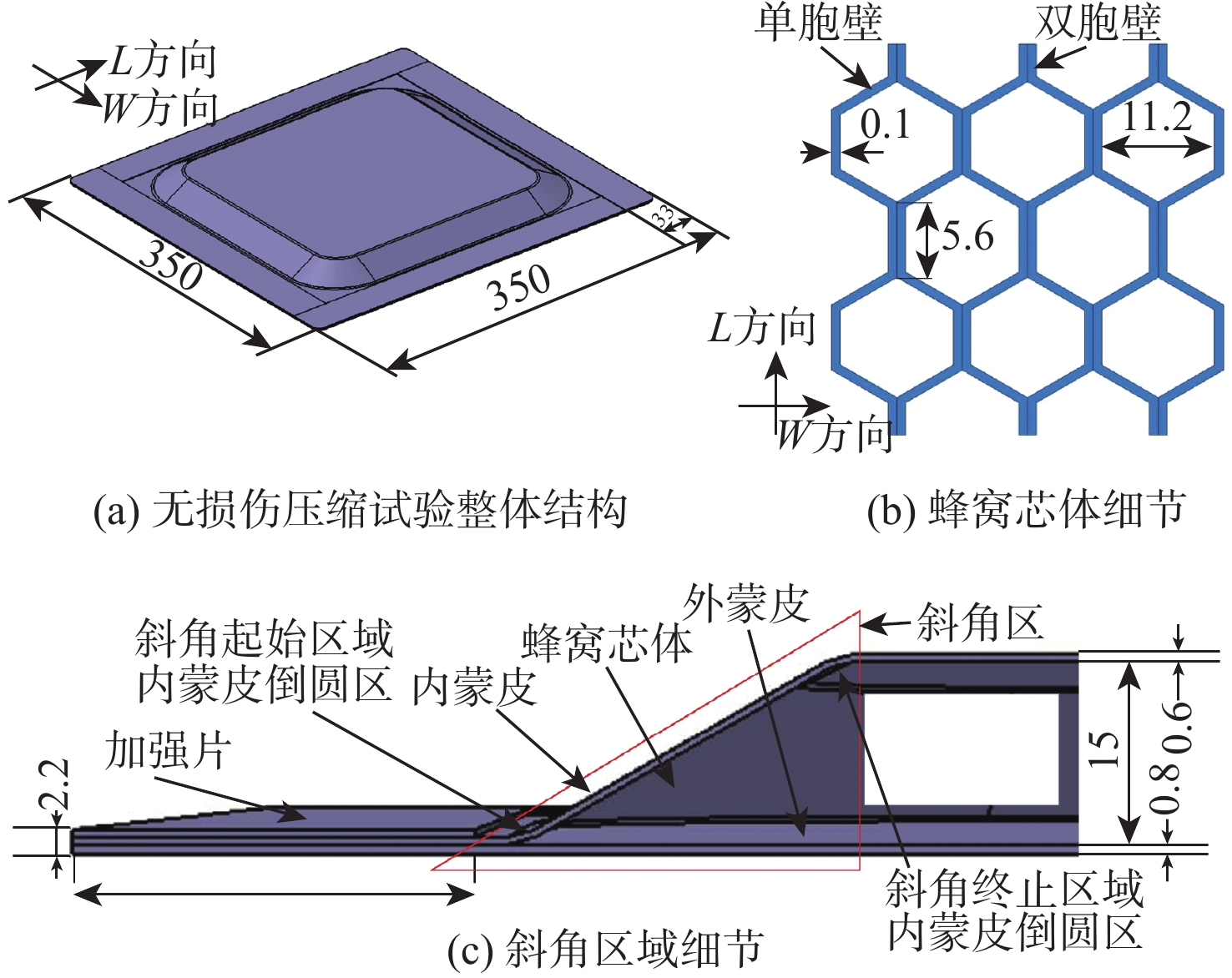

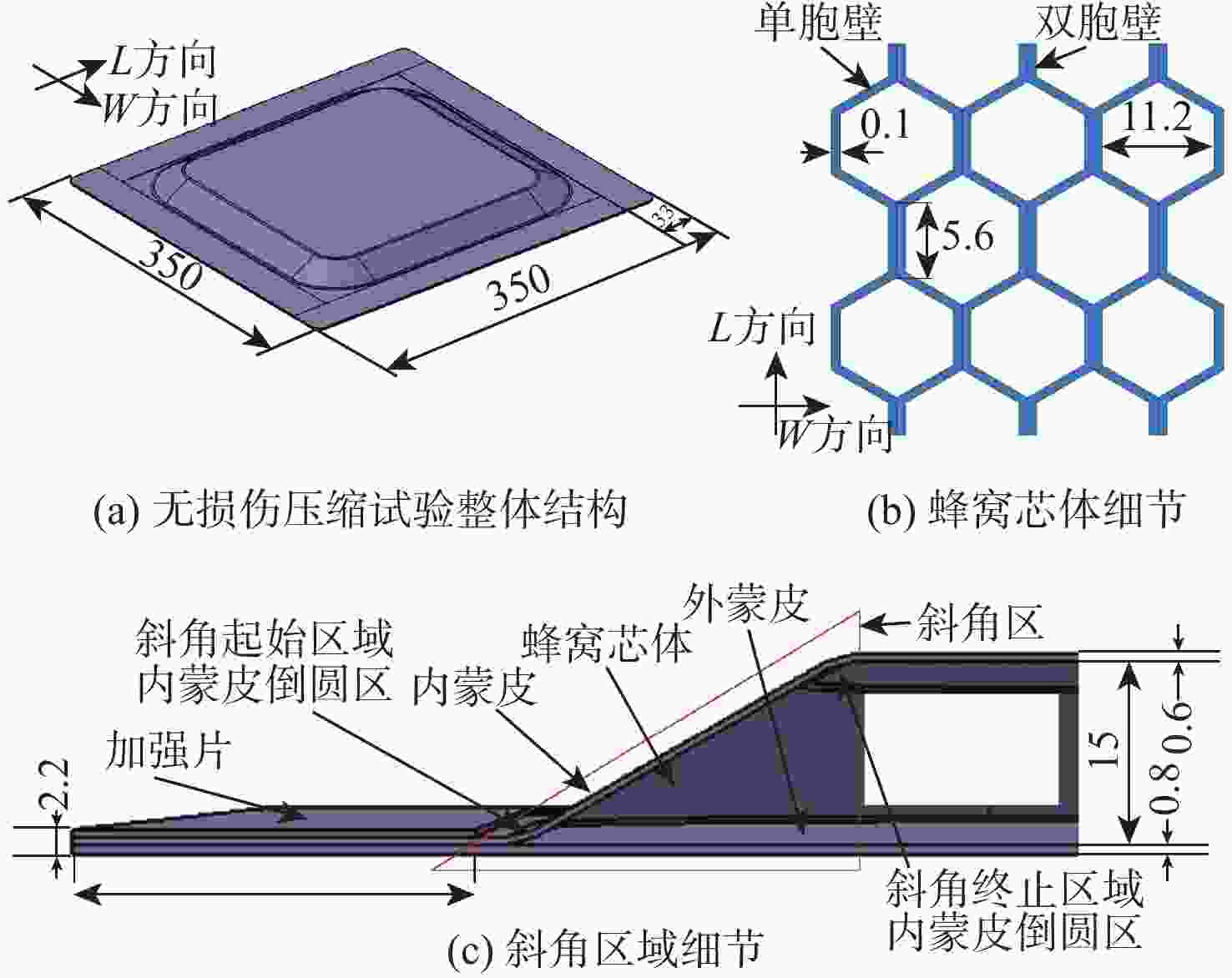

钛合金蜂窝口盖壁板在实际服役过程中可能会产生穿透性损伤,从而影响口盖壁板面内压缩性能。采用试验和有限元计算相结合的方法研究了穿透性损伤对钛合金蜂窝口盖壁板面内压缩性能的影响。结果显示:含穿透性损伤的钛合金蜂窝口盖壁板的面内压缩破坏载荷要略高于无损伤钛合金蜂窝口盖壁板,且面内压缩破坏载荷随穿透性损伤直径增大而增大;有限元模型预测的破坏模式与试验结果一致,预测的破坏载荷与试验结果的最大偏差为9.33%,两者吻合较好。研究结果可以为钛合金蜂窝口盖壁板的设计及面内压缩性能的预测提供数据支持和研究方法参考。

Abstract:During the service period, penetration damage may occur in the titanium honeycomb sandwich cover structure which will affect the in-plane compression properties of the sandwich cover structure. The influence of penetration damage on the in-plane compression properties of titanium honeycomb sandwich cover structure was studied by a combination of experiments and finite element methods. The results show that the in-plane compression failure load of the titanium honeycomb sandwich cover structure with penetration damage is slightly higher than that of the titanium honeycomb sandwich cover structure without damage. Moreover, the in-plane compression failure load increases with the increase of the diameter of penetration damage. The greatest variation is 9.33%, the maximum agreement between the failure load and test results is good, and the failure mode predicted by the finite element model is compatible with the test data.The finite element method can be used for engineering prediction of the in-plane compression properties of titanium honeycomb sandwich cover structure.

-

表 1 钛合金蜂窝口盖壁板面内压缩破坏载荷试验值

Table 1. Experimental compression failure loads of the titanium honeycomb sandwich cover structure

损伤直

径/mm破坏载荷平

均值/kN离散系

数/%面内压缩破坏载

荷降低比例/%0 149.40 7.85 30 140.80 1.86 6.11 40 158.17 11.39 2.33 50 157.53 9.57 −5.54 注:降低比例的负号表示提高。 表 2 TC4材料参数

Table 2. Material parameters of TC4

材料 弹性模量/GPa 泊松比 屈服强度/MPa 破坏强度/MPa TC4 108.48 0.30 861.59 967.12 表 3 TC4应力与塑性应变

Table 3. The true stress and the plastic strain of TC4

应力/MPa 塑性应变/με 830 0 861.7 0.002 960 0.01 1000 0.012 表 4 钛合金蜂窝口盖壁板破坏载荷对比

Table 4. Comparison of failure loads of the titanium honeycomb sandwich cover structure

损伤直径/mm 破坏载荷 偏差/% 有限元预测值/kN 试验值/kN 0 148.03 149.40 −0.92 30 153.93 140.80 9.33 40 155.07 146.00 6.21 50 157.53 158.17 −5.56 -

[1] ZHAO W, XIE Z H, LI X, et al. Compression after impact behavior of titanium honeycomb sandwich structures[J]. Journal of Sandwich Structures & Materials, 2018, 20(5): 639-657. [2] XIE Z H, ZHAO W, WANG X N, et al. Low-velocity impact behaviour of titanium honeycomb sandwich structures[J]. Journal of Sandwich Structures & Materials, 2018, 20(8): 1009-1027. [3] 杨海波, 江少华, 赵志远, 等. 钛合金蜂窝整体机身壁板技术应用研究[J]. 航空制造技术, 2013, 56(16): 126-128. doi: 10.3969/j.issn.1671-833X.2013.16.029YANG H B, JIANG S H, ZHAO Z Y, et al. Engineering application research of titanium honeycomb integral fuselage panel technology[J]. Aeronautical Manufacturing Technology, 2013, 56(16): 126-128(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.16.029 [4] 谢宗蕻, 岳喜山, 孙俊锋. 钛合金蜂窝壁板隔热性能试验研究[J]. 南京航空航天大学学报, 2016, 48(1): 16-20. doi: 10.16356/j.1005-2615.2016.01.003XIE Z H, YUE X S, SUN J F. Experimental study on thermal insulation performance of titanium honeycomb sandwich panels[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2016, 48(1): 16-20(in Chinese). doi: 10.16356/j.1005-2615.2016.01.003 [5] GIBSON L J, ASHBY M F. Cellular Solids[M]. Cambridge: Cambridge University Press, 1997: 93-108. [6] 王颖坚. 面外压力下蜂窝结构弹性屈曲临界载荷[J]. 固体力学学报, 1993, 14(1): 63-66. doi: 10.19636/j.cnki.cjsm42-1250/o3.1993.01.009WANG Y J. Elastic buckling critical load of honeycomb structure under out-of-plane pressure[J]. Acta Mechanica Solida Sinica, 1993, 14(1): 63-66(in Chinese). doi: 10.19636/j.cnki.cjsm42-1250/o3.1993.01.009 [7] 唐劼尧, 柏敏建. 轴压载荷下复合材料蜂窝夹芯板的稳定性研究[J]. 兵器装备工程学报, 2020, 41(9): 242-246. doi: 10.11809/bqzbgcxb2020.09.045TANG J Y, BAI M J. Stability evaluation on composite honeycomb sandwich panels subjected to compressive loadings[J]. Journal of Ordnance Equipment Engineering, 2020, 41(9): 242-246(in Chinese). doi: 10.11809/bqzbgcxb2020.09.045 [8] 潘松, 王新峰, 陈晓烽. 含面芯脱粘边缘闭合蜂窝壁板压缩稳定性研究[J]. 南京航空航天大学学报, 2019, 51(1): 35-40. doi: 10.16356/j.1005-2615.2019.01.006PAN S, WANG X F, CHEN X F. Stability research of edge closed honeycomb sandwich panels with face/core debond under compression[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2019, 51(1): 35-40(in Chinese). doi: 10.16356/j.1005-2615.2019.01.006 [9] 谢宗蕻, 苏霓, 张磊, 等. 复合材料蜂窝夹芯板低速冲击损伤扩展特性[J]. 南京航空航天大学学报, 2009, 41(1): 30-35. doi: 10.3969/j.issn.1005-2615.2009.01.007XIE Z H, SU N, ZHANG L, et al. Damage propagation behavior of composite honeycomb sandwich panels under low-velocity impact[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2009, 41(1): 30-35(in Chinese). doi: 10.3969/j.issn.1005-2615.2009.01.007 [10] 王琦, 童国权, 陈峰, 等. 缺陷对高温合金蜂窝板弯曲力学性能的影响[J]. 航空制造技术, 2017, 60(S1): 106-111. doi: 10.16080/j.issn1671-833x.2017.1/2.106WANG Q, TONG G Q, CHEN F, et al. Effect of defects on bending mechanical property of high temperature alloy honeycomb panels[J]. Aeronautical Manufacturing Technology, 2017, 60(S1): 106-111(in Chinese). doi: 10.16080/j.issn1671-833x.2017.1/2.106 [11] 孔祥皓, 赫晓东. 带有典型缺陷的金属蜂窝夹层结构的共面力学性能研究[J]. 固体火箭技术, 2010, 33(6): 684-689. doi: 10.3969/j.issn.1006-2793.2010.06.018KONG X H, HAO X D. Study on coplanar mechanical properties of metal honeycomb sandwich with typical defects[J]. Journal of Solid Rocket Technology, 2010, 33(6): 684-689(in Chinese). doi: 10.3969/j.issn.1006-2793.2010.06.018 [12] 杨凯, 刘立武, 于开平, 等. 带有典型缺陷的金属蜂窝夹层结构的剩余强度研究[J]. 固体火箭技术, 2011, 34(5): 652-654. doi: 10.3969/j.issn.1006-2793.2011.05.025YANG K, LIU L W, YU K P, et al. Study on the residual strength of metal honeycomb sandwich structure with typical defects[J]. Journal of Solid Rocket Technology, 2011, 34(5): 652-654(in Chinese). doi: 10.3969/j.issn.1006-2793.2011.05.025 [13] 岳喜山, 欧阳小龙, 侯金保, 等. 钛合金蜂窝壁板结构钎焊工艺[J]. 航空制造技术, 2009, 52(10): 96-98. doi: 10.3969/j.issn.1671-833X.2009.10.019YUE X S, OUYANG X L, HOU J B, et al. Brazing process of titanium alloy honeycomb sandwich panel structure[J]. Aeronautical Manufacturing Technology, 2009, 52(10): 96-98(in Chinese). doi: 10.3969/j.issn.1671-833X.2009.10.019 [14] 静永娟, 李晓红, 岳喜山. TC1钛合金蜂窝夹层结构的钎焊工艺研究与分析[J]. 航空制造技术, 2012, 55(13): 137-139. doi: 10.3969/j.issn.1671-833X.2012.13.029JING Y J, LI X H, YUE X S. Research and analysis of processing parameter for brazing honeycomb sandwich construction in titanium alloy[J]. Aeronautical Manufacturing Technology, 2012, 55(13): 137-139(in Chinese). doi: 10.3969/j.issn.1671-833X.2012.13.029 [15] 静永娟, 岳喜山, 李智渊, 等. 芯体缺失对钛合金蜂窝夹层结构强度的影响及规律研究[J]. 航空制造技术, 2013, 56(16): 143-145. doi: 10.3969/j.issn.1671-833X.2013.16.033JING Y J, YUE X S, LI Z Y, et al. Influence from honeycomb core deletion on Ti-alloy honeycomb sandwich construction[J]. Aeronautical Manufacturing Technology, 2013, 56(16): 143-145(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.16.033 [16] 刘晓宇. 钛合金蜂窝夹层结构力学性能分析与试验验证[D]. 西安: 西北工业大学, 2014: 13-30.LIU X Y. Mechanical properties of titanium honeycomb sandwich structures analysis and experimental validation[D]. Xi’an: Northwestern Polytechnical University, 2014: 13-30(in Chinese). [17] 岳喜山, 闫群, 赵伟, 等. 单侧面板裂纹损伤对钛合金蜂窝夹层结构弯曲性能影响[J]. 北京航空航天大学学报, 2020, 46(11): 2018-2025. doi: 10.13700/j.bh.1001-5965.2019.0587YUE X S, YAN Q, ZHAO W, et al. Influence of one side facesheet crack damage on flexural properties of titanium honeycomb sandwich structures[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(11): 2018-2025(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0587 [18] 中国航空研究院. 复合材料结构设计手册[M]. 北京: 航空工业出版社, 2001: 554.Chinese Aeronautical Establishment. Composite structure design manual[M]. Beijing: Aviation Industry Press, 2001: 554(in Chinese). [19] ASTMD7137. Standard test method for measuring the damage resistance of a fiber reinforced polymer matrix composite to a drop-weight impact event: ASTM D7137[S]. Philadelphia, PA: American Society for Testing and Materials, 2007: 16. [20] SYSTÈMES D. Abaqus 6.14 online documentation [EB/OL]. (2014-06-14)[2020-05-13]. http://130.149.89.49:2080/v6.14/index.html. -

下载:

下载: