Influence analysis and suppression of random error on cavity transient heat transfer test

-

摘要:

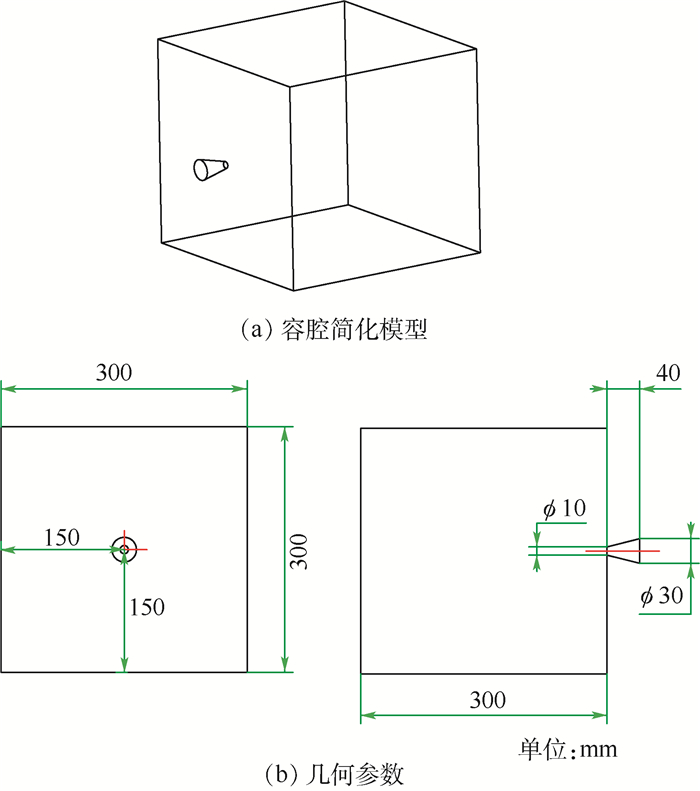

针对容腔瞬态换热试验中测试数据的随机误差被数据处理的差分过程放大的问题,定量分析了随机测试误差对换热特性的影响,并提出抑制方法。结果表明:容腔内壁面对流换热特性误差对瞬态温度随机误差最为敏感,导致换热特性试验结果不确定度高。将改进经验模态分解(EMD)算法应用于数据差分处理过程中可以有效抑制测试随机误差对换热特性的影响。在容腔充气过程中,采用误差抑制方法后,容腔壁面换热特性的最大误差从129.07%降到63.62%,时均误差从25.24%降到8.12%。

Abstract:To solve the problem that the random error of the measurement data in the cavity transient heat transfer test is amplified by the differential process of data processing, the influence of random measurement error on the heat transfer characteristics is quantitatively analyzed, and the suppression method is proposed. The results show that the error of the convective heat transfer characteristic of the inner wall of the cavity is most sensitive to the random error of the transient temperature, resulting in high uncertainty of the test results of the heat transfer characteristics. The improved empirical mode decomposition (EMD) algorithm can be used in data differential process to effectively suppress the influence of random errors on the heat transfer characteristics. In the cavity inflation process, the maximum error of the heat transfer characteristics of the cavity wall surface decreases from 129.07% to 63.62% and the time average error decreases from 25.24% to 8.12% with the usage of error suppression method.

-

Key words:

- air system /

- cavity /

- random error /

- error analysis /

- empirical mode decomposition

-

表 1 理想气体物性参数

Table 1. Physical property parameters of ideal gas

参数 cP/(J·(kg·K)-1) λ/(W·(m·K)-1) μ/(10-5kg·(m·s)-1) Rg/(J·(kg·K)-1) 数值 1 004.4 0.026 1 1.831 287 表 2 试验随机误差

Table 2. Random error in experiment

δL/mm δTin/K δTw/K δP(t)/Pa δT(t)/K 0.1 0.3 0.3 N(0, 152) N(0, 0.22) -

[1] 王华阁, 陈光, 张恩和, 等.航空发动机设计手册:第16册空气系统及传热分析[M].北京:航空工业出版社, 2001.WANG H G, CHEN G, ZHANG E H, et al.Aero engine design manual:Volume 16 air system and heat transfer analysis[M].Beijing:Aviation Industry Press, 2001(in Chinese). [2] CROSS H.Analysis of flow in networks of conduits or conductors No.22[R].Urbana: University of Illinois, Engineering Experiment Station, 1936. [3] 蔡瑞忠, 谢茂清.热工流体网络的实时仿真模型及其算法[J].系统仿真学报, 1992, 4(4):13-18. http://cdmd.cnki.com.cn/Article/CDMD-10217-1017243044.htmCAI R Z, XIE M Q.Real-time simulation model and algorithm of thermal fluid network[J].Journal of System Simulation, 1992, 4(4):13-18(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10217-1017243044.htm [4] 吴丁毅.内流系统的网络计算法[J].航空学报, 1996, 17(6):653-657. doi: 10.3321/j.issn:1000-6893.1996.06.006WU D Y.Network computing method for inflow system[J].Acta Aeronautica et Astronautica Sinica, 1996, 17(6):653-657(in Chinese). doi: 10.3321/j.issn:1000-6893.1996.06.006 [5] 陶智, 侯升平, 丁水汀, 等.流体网络法在发动机空气冷却系统设计中的应用[J].航空动力学报, 2009, 24(1):1-6. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb200901001TAO Z, HOU S P, DING S T, et al.Application of fluid network method in engine air cooling system design[J].Journal of Aeronautical Power, 2009, 24(1):1-6(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hkdlxb200901001 [6] KUTZ K J, SPEER T M.Simulation of the secondary air system of aero engines[C]//ASME 37th International Gas Turbine and Aeroengine Congress and Exposition.New York: ASME, 1992: 1-12. https://www.mendeley.com/catalogue/simulation-secondary-air-system-aero-engines/ [7] ALEXIOU A, MATHIOUDAKIS K.Secondary air system component modeling for engine performance simulations[C]//ASME Turbo Expo 2008: Power for Land, Sea and Air.New York: ASME, 2009: 1-9. [8] 刘传凯, 刘海明, 丁水汀, 等.强瞬变空气系统的模块化仿真建模[J].航空动力学报, 2015, 30(8):1826-1833. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201508005LIU C K, LIU H M, DING S T, et al.Modularized simulation modeling of air system with fast transients[J].Journal of Aeronautical Power, 2015, 30(8):1826-1833(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201508005 [9] 侯升平, 陶智, 丁水汀, 等.非稳态流体网络模拟新方法及其应用[J].航空动力学报, 2009, 24(6):1253-1257. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb200906009HOU S P, TAO Z, DING S T, et al.New simulation approach to the unsteady fluid network and the application[J].Journal of Aeronautical Power, 2009, 24(6):1253-1257(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hkdlxb200906009 [10] 丁水汀, 车巍巍, 刘传凯.空气系统双腔模型的压力动态特性分析[J].北京航空航天大学学报, 2016, 42(4):654-660. https://bhxb.buaa.edu.cn/CN/abstract/abstract13858.shtmlDING S T, CHE W W, LIU C K.Analysis of pressure dynamic characteristics of air system double cavity model[J].Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(4):654-660(in Chinese). https://bhxb.buaa.edu.cn/CN/abstract/abstract13858.shtml [11] CALCAGIN C, GALLAR L, PACHIDIS V.Development of a one dimensional dynamic gas turbine secondary air system model-PartⅡ: Assembly and validation of a complete network[C]//ASME Turbo Expo 2009: Power for Land, Sea and Air.New York: ASME, 2009: 466-474. [12] GALLAR L, CALCAGIN C, LLORENS C, et al.Time accurate modelling of the secondary air system response to rapid transients[J].Aerospace Engineering, 2011, 225(G):946-958. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=9260b1c2d48485326eb265e7c891b46b [13] DUTTON J C, ROBERT E C.Experiments to study the gaseous discharge and filling of vessels[J].International Journal of Engineering Education, 1997, 13(2):123-134. [14] THORNCROFT G, PATTON J S, GOROON R.Modeling compressible air flow in a charging or discharging vessel and assessment of polytropic exponent: AC 2007-2695[R].Chantilly, VA: American Society for Engineering Education, 2007. [15] 李世武, 熊莉芳.封闭方腔自然对流换热的研究[J].工业加热, 2007, 36(3):10-13. doi: 10.3969/j.issn.1002-1639.2007.03.004LI S W, XIONG L F.Study of natural convection in a closed square cavity[J].Industrial Heating, 2007, 36(3):10-13(in Chinese). doi: 10.3969/j.issn.1002-1639.2007.03.004 [16] 马崇扬, 王长茂, 张东辉.单侧部分开口方腔自然对流数值模拟[J].原子能科学技术, 2016, 50(9):1612-1617. http://d.old.wanfangdata.com.cn/Periodical/yznkxjs201609012MA C Y, WANG C M, ZHANG D H.Numerical simulation of natural convection in one side partial open square cavity[J].Atomic Energy Science and Technology, 2016, 50(9):1612-1617(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/yznkxjs201609012 [17] 杨丽红.容器放气过程的数值模拟及热力学模型研究[D].上海: 上海交通大学, 2007. http://cdmd.cnki.com.cn/article/cdmd-10248-2007153615.htmYANG L H.Study on the numerical and the thermodynamic model of the tank discharge process[D].Shanghai: Shanghai Jiaotong University, 2007(in Chinese). http://cdmd.cnki.com.cn/article/cdmd-10248-2007153615.htm [18] 郭钟华, 李小宁, 香川利春.考虑热传递的真空容腔压力响应研究[J].真空科学与技术学报, 2015, 35(1):74-78. http://d.old.wanfangdata.com.cn/Periodical/zkkx201501014GUO Z H, LI X N, KAGAWA T.Impact of heat transfer on pressure response in vacuum chamber of pneumatic vacuum system[J].Chinese Journal of Vacuum Science and Technology, 2015, 35(1):74-78(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/zkkx201501014 [19] 丁水汀, 于航, 邱天.非绝热单孔容腔瞬态响应的零维建模[J].北京航空航天大学学报, 2018, 44(2):215-222. https://bhxb.buaa.edu.cn/CN/abstract/abstract14357.shtmlDING S T, YU H, QIU T.Zero-dimensional modeling of transient response of non-adiabatic single-hole cavity[J].Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(2):215-222(in Chinese). https://bhxb.buaa.edu.cn/CN/abstract/abstract14357.shtml [20] DING S T, YU H, QIU T, et al.Modeling of the cavity response to rapid transient considering the effect of heat transfer[C]//Proceedings of ASME Turbo Expo.New York: ASME, 2018. [21] 王婷.EMD算法研究及其在信号去噪中的应用[D].哈尔滨: 哈尔滨工程大学, 2010. http://cdmd.cnki.com.cn/Article/CDMD-10217-1011020271.htmWANG T.Research on EMD algorithm and its application in signal denoising[D].Harbin: Harbin Engineering University, 2010(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10217-1011020271.htm [22] 盛柯芳.基于EMD的离散数字曲线光顺方法[D].杭州: 浙江工业大学, 2008.SHENG K F.EMD based smoothing algorithm research for digital curves and surfaces[D].Hangzhou: Zhejiang University of Technology, 2008(in Chinese). [23] 王学敏, 黄方林.EMD端点效应抑制的一种实用方法[J].振动、测试与诊断, 2012, 32(3):493-497. doi: 10.3969/j.issn.1004-6801.2012.03.027WANG X M, GUANG F L.A practical method for EMD endpoint effect suppression[J].Journal of Vibration, Measurement & Diagnosis, 2012, 32(3):493-497(in Chinese). doi: 10.3969/j.issn.1004-6801.2012.03.027 [24] 陈光, 洪杰, 马艳红.航空燃气涡轮发动机结构[M].北京:北京航空航天大学出版社, 2010:107.CHEN G, HONG J, MA Y H.Aviation gas turbine engine structure[M].Beijing:Beihang University Press, 2010:107(in Chinese). [25] 吕鹏飞, 裴东兴, 沈大伟.基于K型热电偶的瞬态测温技术的研究[J].传感技术学报, 2014, 27(6):775-780. doi: 10.3969/j.issn.1004-1699.2014.06.013LV P F, PEI D X, SHEN D W.The research of transient thermometry technology based on K-style thermocouple[J].Chinese Journal of Sensors and Actuators, 2014, 27(6):775-780(in Chinese). doi: 10.3969/j.issn.1004-1699.2014.06.013 [26] 王瑞, 张志杰, 李岩峰, 等.基于热电偶的爆炸场温度补偿方法及其LabVIEW实现[J].爆破器材, 2016, 45(1):60-64. doi: 10.3969/j.issn.1001-8352.2016.01.014WANG R, ZHANG Z J, LI Y F, et al.Thermocouple based explosion field temperature compensation method and its LabVIEW implementation[J].Explosive Materials, 2016, 45(1):60-64(in Chinese). doi: 10.3969/j.issn.1001-8352.2016.01.014 [27] 赵化彬, 张志杰.爆炸瞬态温度测试中热电偶传感器实时补偿技术[J].火工品, 2017(1):49-53. doi: 10.3969/j.issn.1003-1480.2017.01.014ZHAO H B, ZHANG Z J.The technology of thermocouple sensor real-time compensation in explosive transient temperature test[J].Initiators & Pyrotechnics, 2017(1):49-53(in Chinese). doi: 10.3969/j.issn.1003-1480.2017.01.014 [28] 赵伟国.热式气体质量流量测量方法与工程学系及系统研究[D].杭州: 浙江大学, 2009. http://cdmd.cnki.com.cn/Article/CDMD-10335-2010067777.htmZHAO W G.Measurement technology and system design of the thermal gas flow[D].Hangzhou: Zhejiang University, 2009(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10335-2010067777.htm [29] 轩春青, 轩志伟, 赖富文.压力传感器测试系统的动态校准及特性分析[J].传感技术学报, 2015, 28(7):982-986. doi: 10.3969/j.issn.1004-1699.2015.07.007XUAN C Q, XUAN Z W, LAI F W.The dynamic calibration of pressure sensor test system and sensitivity analysis[J].Chinese Journal of Sensors and Actuators, 2015, 28(7):982-986(in Chinese). doi: 10.3969/j.issn.1004-1699.2015.07.007 [30] 杨文杰, 张志杰, 王代华, 等.压力传感器动态误差修正方法的FPGA实现[J].传感技术学报, 2017, 30(3):402-406. doi: 10.3969/j.issn.1004-1699.2017.03.012YANG W J, ZHANG Z J, WANG D H, et al.Realization of dynamic error correction method of pressure sensor by FPGA[J].Chinese Journal of Sensors and Actuators, 2017, 30(3):402-406(in Chinese). doi: 10.3969/j.issn.1004-1699.2017.03.012 [31] 郑敬超.车铣数控加工精度分布规律的研究[D].沈阳: 东北大学, 2008. http://cdmd.cnki.com.cn/Article/CDMD-10145-2010256667.htmZHENG J C.Research on the distribution rule of the numerical control turning and milling precision[D].Shenyang: Northeastern University, 2008(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10145-2010256667.htm [32] 卞金洪, 王吉林, 周锋.高精度压力传感器中温度补偿技术研究[J].哈尔滨理工大学学报, 2011, 16(6):55-57. doi: 10.3969/j.issn.1007-2683.2011.06.011BIAN J H, WANG J L, ZHOU F.Research of temperature compensation on high accuracy pressure sensors[J].Journal of Harbin University of Science and Technology, 2011, 16(6):55-57(in Chinese). doi: 10.3969/j.issn.1007-2683.2011.06.011 [33] 付新菊, 关威.卫星用高精度压力传感器研究[J].仪表技术与传感器, 2018(2):151-153. doi: 10.3969/j.issn.1002-1841.2018.02.036FU X J, GUAN W.Research on high precision pressure sensor used in satellite[J].Instrument Technique and Sensor, 2018(2):151-153(in Chinese). doi: 10.3969/j.issn.1002-1841.2018.02.036 [34] 聂绍忠.硅压阻式压力传感器的高精度补偿算法及其实现[J].自动化仪表, 2018, 39(6):49-53. http://d.old.wanfangdata.com.cn/Periodical/zdhyb201806013NIE S Z.High accurate compensation algorithm of silicon piezoresistive pressure sensor and its implementation[J].Process Automation Instrumentation, 2018, 39(6):49-53(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/zdhyb201806013 [35] 唐兆廷.航天器用热电偶测温仪的设计[D].西安: 西安电子科技大学, 2011. http://cdmd.cnki.com.cn/Article/CDMD-10701-1013114509.htmTANG Z T.The design of spacecraft thermocouple thermometer[D].Xi'an: Xidian University, 2011(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10701-1013114509.htm [36] 赵勇, 伍先达.高精度温度快速测量系统设计[J].自动化与仪器仪表, 2008(6):21-23. doi: 10.3969/j.issn.1001-9227.2008.06.008ZHAO Y, WU X D.The design of high precision temperature rapid measurement system[J].Automation and Instrumentation, 2008(6):21-23(in Chinese). doi: 10.3969/j.issn.1001-9227.2008.06.008 [37] 刘武发, 李素艳, 张才吉, 等.网络接口高精度热电偶设计与误差分析[J].仪表技术与传感器, 2008(11):75-78. doi: 10.3969/j.issn.1002-1841.2008.11.026LIU W F, LI S Y, ZHANG C J, et al.Design and error analysis of high accurate thermocouple with network interface[J].Instrument Technique and Sensor, 2008(11):75-78(in Chinese). doi: 10.3969/j.issn.1002-1841.2008.11.026 [38] 张鹏, 伍宇烨, 许煜雄, 等.低温热电偶的标定及标定过程中的非线性现象的研究[J].低温物理学报, 2003, 25(1):51-55. doi: 10.3969/j.issn.1000-3258.2003.01.010ZHANG P, WU Y Y, XU Y X, et al.Calibration of low-temperature thermocouples and research on related non-linear phenomena[J].Chinese Journal of Low Temperature Physics, 2003, 25(1):51-55(in Chinese). doi: 10.3969/j.issn.1000-3258.2003.01.010 [39] 任成, 李聪新, 杨星团.高温气冷堆环境模拟装置热电偶信号波动问题研究[J].原子能科学技术, 2014, 48(增刊):588-593. http://d.old.wanfangdata.com.cn/Periodical/yznkxjs2014Z1109REN C, LI C X, YANG X T.Investigation on thermocouple signal fluctuation phenomenon in environment simulation facility of high temperature gas-cooled reactor[J].Atomic Energy Science and Technology, 2014, 48(Supplement):588-593(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/yznkxjs2014Z1109 [40] 丁振良.误差理论与数据处理[M].哈尔滨:哈尔滨工业大学出版社, 2014:17-18.DING Z L.Error theory and data processing[M].Harbin:Harbin Institute of Technology Press, 2014:17-18(in Chinese). -

下载:

下载: