Kinematics analysis and multi-objective optimization of a novel parallel perfusion robot

-

摘要:

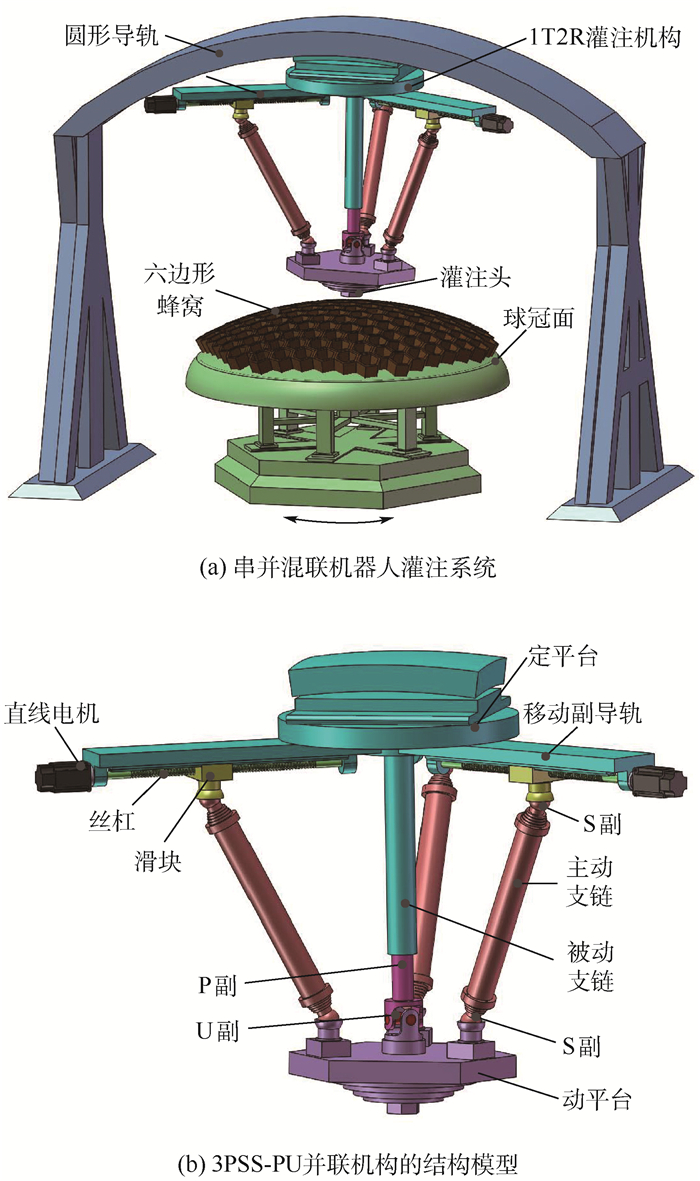

针对大型航天器蜂窝结构灌注需求,提出一种新型串并混联灌注机器人机构,主要对并联机构进行分析研究。首先,对3PSS-PU并联机构进行了运动学分析,建立了运动学反解数学模型和雅可比矩阵;其次,确定了影响机构工作空间主要因素的约束条件,求解出了机构的工作空间;然后,建立了机构的刚度模型,求得机构在运动过程中的刚度变化分布;最后,利用遗传算法,以工作空间和全局刚度为目标对机构结构参数进行优化分析,确定了最终的机构尺寸参数,为蜂窝灌注机器人应用奠定基础。

Abstract:In order to meet the demand of honeycomb structure perfusion of large spacecraft, a novel hybrid perfusion robot is proposed. This article mainly focuses on the analysis of the parallel mechanism. First, the kinematics analysis of 3PSS-PU parallel mechanism is conducted, and the inverse kinematic model and Jacobian matrix of 3PSS-PU mechanism are established. Then, the constraints of the main factors influencing workspace of the mechanism are given, and the reachable workspace is obtained. Next, stiffness model of the mechanism is established, and stiffness distribution of the mechanism in the process of movement is displayed. Finally, aimed at workspace volume and global stiffness, multi-objective optimization analysis of structure parameters is performed based on genetic algorithm, and final dimension parameters of the mechanism are obtained. This work would lay the foundation for the application of the honeycomb perfusion robot.

-

Key words:

- parallel perfusion robot /

- kinematics analysis /

- workspace /

- stiffness /

- multi-objective optimization

-

表 1 3PSS-PU并联机构结构参数

Table 1. Structural parameters of 3PSS-PU parallel mechanism

参数 数值 Rm/mm 250 li/mm 220 φ1/(°) 60 ϕ1/(°) 60 simin/mm 0 simax/mm 450 αimin/(°) 50 αimax/(°) 120 βimin/(°) 50 βimax/(°) 120 表 2 3PSS-PU并联机构优化设计参数

Table 2. Optimum design parameters of 3PSS-PU parallel mechanism

组数 机构设计参数 Rm/mm li/mm φ1/rad ϕ1/rad 1 266.608 0 237.058 5 0.676 7 0.687 6 2 269.573 9 237.284 5 0.634 9 0.733 3 3 270.356 9 236.858 3 0.634 9 0.733 3 4 267.452 5 237.519 3 0.676 7 0.687 6 5 269.551 9 237.284 3 0.634 9 0.733 3 6 269.551 9 237.284 3 0.676 7 0.687 6 7 267.452 5 237.519 3 0.676 7 0.687 6 8 267.199 7 237.557 2 0.634 9 0.733 3 9 266.526 2 237.056 6 0.634 9 0.733 3 10 269.573 4 237.284 4 0.634 9 0.733 3 11 270.347 2 236.971 9 0.676 7 0.687 6 12 267.452 5 237.519 3 0.634 9 0.733 3 13 269.551 7 237.284 3 0.634 9 0.733 3 14 269.329 7 237.303 0 0.676 7 0.687 6 15 270.355 1 236.848 2 0.634 9 0.733 3 16 269.562 5 237.280 2 0.634 9 0.733 3 17 269.414 6 237.272 3 0.676 7 0.687 6 18 267.473 7 237.515 3 0.676 7 0.687 6 19 270.339 5 236.969 1 0.634 9 0.733 3 20 267.452 5 237.519 3 0.634 9 0.733 3 表 3 3PSS-PU并联机构优化前后结构参数对比

Table 3. Comparison of initial and optimized structure parameters for 3PSS-PU parallel mechanism

设计参数 初始值 优化值 Rm/mm 250 267 li/mm 220 237 φ1/rad π/3 0.63 ϕ1/rad π/3 0.73 表 4 3PSS-PU并联机构优化前后刚度参数对比

Table 4. Comparison of initial and optimized stiffness parameters for 3PSS-PU parallel mechanism

刚度参数 初始值 优化值 倍数 k11 1 272.95 4 023.15 3.160 k22 6.244 17×107 1.102 13×108 1.765 k33 9.851 90×105 9.015 62×106 9.151 E 6.342 81×107 1.192 33×108 1.880 S 929 775 1 069 132 1.150 -

[1] ACKERMAN P K, BAKER A L, NEWQUIST C W. Thermal protection system: US 5322725[P]. 1994-06-21. [2] WU D F, ZHOU A F, ZHENG L M, et al.Study on the thermal protection performance of superalloy honeycomb panels in high-speed thermal shock environments[J].Theoretical & Applied Mechanics Letters, 2014, 4(2):19-26. [3] 程文礼, 袁超, 邱启艳, 等.航空用蜂窝夹层结构及制造工艺[J].航空制造技术, 2015, 476(7):94-98.CHENG W L, YUAN C, QIU Q Y, et al.Honeycomb sandwich structure and manufacturing process in aviation industry[J]. Aeronautical Manufacturing Technology, 2015, 476(7):94-98(in Chinese). [4] 张纪奎, 马志阳, 李学梅, 等.带防热层复合材料锥壳热固化变形的数值模拟[J].北京航空航天大学学报, 2013, 39(8):1037-1041.ZHANG J K, MA Z Y, LI X M, et al.Numerical simulation of cure deformation of composite taper shell with thermal protection layer[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(8):1037-1041(in Chinese). [5] 郑力铭, 吴大方, 王岳武, 等.金属蜂窝板高温环境下的隔热性能试验与计算[J].北京航空航天大学学报, 2012, 38(6):731-735.ZHENG L M, WU D F, WANG Y W, et al.Experiment and numerical simulation on heat-shielding properties of metallic honeycomb panel in high temperature environment[J].Journal of Beijing University of Aeronautics and Astronautics, 2012, 38(6):731-735(in Chinese). [6] LEE C S G, ZIEGLER M.Geometric approach in solving inverse kinematics of PUMA robots[J]. IEEE Transactions on Aerospace & Electronic Systems, 1984, 20(6):695-706. [7] OMODEI A, LEGNANI G, ADAMINI R.Three methodologies for the calibration of industrial manipulators:Experimental results on a SCARA robot[J].Journal of Robotic Systems, 2000, 17(6):291-307. doi: 10.1002/(ISSN)1097-4563 [8] NUBIOLA A, BONEV I A.Absolute calibration of an ABB IRB 1600 robot using a laser tracker[J].Robotics and Computer-Integrated Manufacturing, 2013, 29(1):236-245. doi: 10.1016/j.rcim.2012.06.004 [9] FANG Y F, TSAI L W.Structure synthesis of a class of 4-DoF and 5-DoF parallel manipulators with identical limb structures[J].International Journal of Robotics Research, 2002, 21(9):799-810. doi: 10.1177/0278364902021009314 [10] 房海蓉, 方跃法, 郭胜.四自由度对称并联机器人结构综合方法[J].北京航空航天大学学报, 2005, 31(3):346-350.FANG H R, FANG Y F, GUO S.Structural synthesis method for 4-degrees-of-freedom symmetrical parallel manipulators[J]. Journal of Beijing University of Aeronautics and Astronautics, 2005, 31(3):346-350(in Chinese). [11] 张克涛, 方跃法, 房海蓉.基于变胞原理的一种探测车机构设计与分析[J].北京航空航天大学学报, 2007, 33(7):838-841.ZHANG K T, FANG Y F, FANG H R.Design and analysis of a rover mechanism based on the metamorphic principle[J].Journal of Beijing University of Aeronautics and Astronautics, 2007, 33(7):838-841(in Chinese). [12] PASHKEVICH A, CHABLAT D, WENGER P.Stiffness analysis of over-constrained parallel manipulators[J].Mechanism & Machine Theory, 2009, 44(5):966-982. [13] GAO Z, ZHANG D.Performance analysis, mapping, and multi-objective optimization of a hybrid robotic machine tool[J]. IEEE Transactions on Industrial Electronics, 2015, 62(1):423-433. doi: 10.1109/TIE.2014.2327008 [14] GAO F, PENG B, ZHAO H, et al.A novel 5-DOF fully parallel kinematic machine tool[J].The International Journal of Advanced Manufacturing Technology, 2006, 31(1):201-207. doi: 10.1007/s00170-005-0171-1 [15] 陈友东, 季旭东, 汤伟.管道喷涂机器人:结构与位姿调整[J].北京航空航天大学学报, 2015, 41(2):209-215.CHEN Y D, JI X D, TANG W.Pipeline spraying robot:Structure and pose adjustment[J].Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(2):209-215(in Chinese). [16] 于靖军, 毕树生, 宗光华, 等.面向生物工程的微操作机器人机构型综合研究[J].北京航空航天大学学报, 2001, 27(3):356-360.YU J J, BI S S, ZONG G H, et al.Research on type synthesis of micromanipulation mechanisms for bioengineering[J].Journal of Beijing University of Aeronautics and Astronautics, 2001, 27(3):356-360(in Chinese). [17] KIM G S, SHIN H J, YOON J.Development of 6-axis force/moment sensor for a humanoid robot's intelligent foot[J].Sensors & Actuators A Physical, 2008, 2(3):122-133. [18] CHI Z, ZHANG D, XIA L, et al.Multi-objective optimization of stiffness and workspace for a parallel kinematic machine[J]. International Journal of Mechanics and Materials in Design, 2013, 9(3):281-293. doi: 10.1007/s10999-013-9219-9 [19] KONAK A, COIT D W, SMITH A E.Multi-objective optimization using genetic algorithms:A tutorial[J].Reliability Engineering & System Safety, 2006, 91(9):992-1007. [20] HUANG H Z, QU N J, ZUO N M J. A new method of system reliability multi-objective optimization using genetic algorithms[C]//Proceedings of Reliability and Maintainability Symposium. Piscataway, NJ: IEEE Press, 2006: 278-283. -

下载:

下载: