A new overreading model for wet gas vortex metering considering entrained droplet flow parameters

-

摘要:

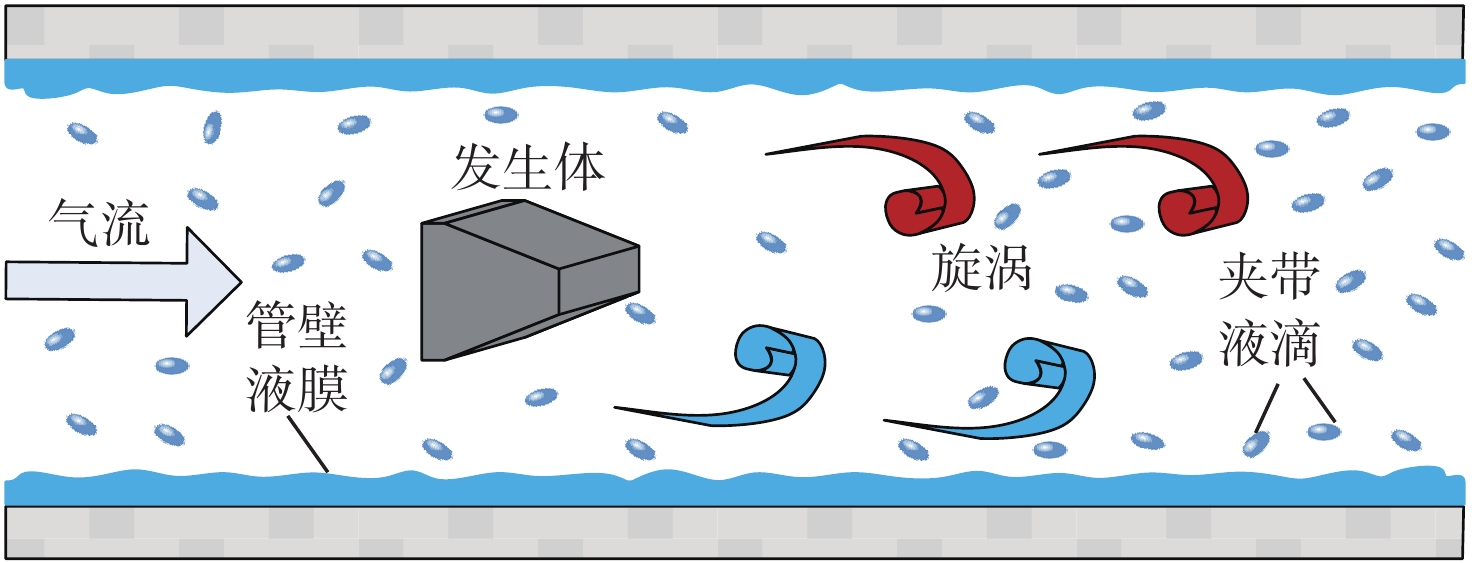

为提高两相涡街湿气测量精度,针对传统涡街过读公式预测精度差、适用范围受限问题,提出基于夹带液滴参数(夹带率和粒径)的涡街过读预测模型。为进行不同夹带液滴工况的实验研究,建立基于雾化混合的可调压环雾状流实验装置,并建立光学图像法测量系统,获得液滴直径及其分布信息。结合环雾状流型及涡街过读机制,考虑液滴-液膜传质和液滴-旋涡耦合作用,提出影响涡街过读的无量纲尺度参数。建立基于液相加载量、韦伯数和斯托克斯数的涡街过读预测模型,将夹带液滴参数和载气参数(密度和速度)的影响考虑在内,理论上可拓展公式适用范围。最后,评估现有过读关联式的预测性能,并结合实验和模型假设中夹带液滴参数的差异进行详细分析,进一步确认了夹带率和粒径对涡街过读特性的重要影响。结果表明:所提模型在不同液滴夹带条件下都给出了很好的预测,相对偏差在±1.0%以内,预测精度和可拓展性较其他公式有了较大提高。

Abstract:To improve the wet gas metering accuracy by using a vortex flowmeter, aiming at the problems of low prediction accuracy and narrow application scope of the traditional meter overreading correlations, a meter overreading model based on flow parameters of the entrained droplets (entrainment fraction and droplet size) was proposed. To conduct experimental studies on different entrained droplet conditions, the annular mist flow loop based on atomizing mixing was developed, and the optical imaging system was built to measure the droplet diameter and distribution. The dimensionless scaling parameters were discovered by combining the annular mist flow pattern with the vortex meter overreading mechanism and taking into account the droplet-liquid film mass transfer and the droplet-vortex coupling mechanism. The meter overreading model was developed with liquid mass loading, Weber number and Stokes number, taking the effects of the entrained droplet parameters and the carried gas parameters (density and velocity) into consideration, thus, its application scope is expanded. Finally, the performance of other overreading correlations was evaluated and analyzed by the differences of the entrained droplet parameters in their experimental conditions and the model assumptions. The results indicate that the proposed model provides a uniform prediction for the meter overreading, the relative deviations are within ±1.0% error band, both the predicted accuracy and the model extensibility are greatly improved compared with other overreading correlations.

-

Key words:

- wet gas flow /

- vortex flowmeter /

- annular mist flow /

- meter overreading /

- entrained droplet

-

表 1 环雾状流实验装置主要参数

Table 1. Main parameters of annular mist flow loop

参数 范围 操作压力/kPa 100~700 操作温度/℃ 0~80 气相标准表体积流量/(m3·h−1) 9~25 计量泵测量液相流量/(kg·h−1) 1.7~17 雾化喷嘴压力/MPa 0~9.5 注:参数项测量精度相对误差分别为0.1%,0.5%,1.0%,2.0%,1.0%。 表 2 测量系统主要参数

Table 2. Main parameters of measurement system

系统组成 参数 取值 相机 分辨率 1280×1024 像素/(μm×μm) 3.45 ×3.45 曝光时间/μs 1~10 帧率/fps 10 远心镜头 工作距离/cm 9.2~12 放大倍率 0.5~4.5 控制器 功率/W 50 输出电压/V 5 光源 波长/nm 532 (绿光) 注:fps为帧/s。 表 3 不同工况下的液滴粒径及过读特性 (PJ6)

Table 3. Droplet SMD and meter overreading under different conditions (PJ6)

载气

工况P/

kPaUsg/

(m·s−1)Ql/

(mL·s−1)dp/

μmfVS/

HzOR 250 kPa,

18 m3/h246.8 29.7 0.39 18.0 1714.7 1.0110 245.6 30.0 0.64 16.6 1744.7 1.0184 243.7 30.7 0.77 16.1 1793.4 1.0216 233.2 30.3 0.92 15.1 1779.6 1.0274 247.3 29.2 0.99 14.6 1719.0 1.0288 247.8 29.6 1.04 14.3 1740.8 1.0302 250 kPa,

24 m3/h249.4 40.4 0.36 17.5 2273.1 1.0105 250.6 40.2 0.61 16.3 2276.8 1.0181 252.2 40.0 0.79 15.8 2277.7 1.0233 252.7 39.7 0.93 14.8 2272.9 1.0276 255.7 39.6 1.01 14.5 2270.9 1.0299 255.4 39.5 1.07 14.0 2268.5 1.0317 350 kPa,

18 m3/h358.1 29.4 0.38 20.1 1696.9 1.0128 354.1 29.2 0.61 18.1 1697.1 1.0184 347.5 30.0 0.78 16.8 1754.4 1.0263 345.8 29.9 0.93 16.5 1761.4 1.0320 352.1 29.6 1.03 15.7 1748.1 1.0345 345.5 29.9 1.05 15.5 1767.1 1.0359 表 4 不同工况下的液滴粒径及过读特性 (PJ8)

Table 4. Droplet SMD and meter overreading under different conditions (PJ8)

载气

工况P/

kPaUsg/

(m·s−1)Ql/

(mL·s−1)dp/

μmfVS/

HzOR 250 kPa,

18 m3/h253.8 30.6 0.46 36.1 1761.7 1.0082 262.5 30.2 0.93 31.2 1754.5 1.0167 257.0 30.0 1.42 25.3 1759.9 1.0262 253.4 30.3 1.85 24.2 1790.6 1.0344 252.8 30.4 2.23 21.5 1809.2 1.0413 248.6 29.9 2.58 20.9 1794.9 1.0494 267.4 29.4 2.89 19.6 1770.2 1.0526 258.4 30.4 3.17 19.2 1836.6 1.0577 250 kPa,

24 m3/h255.6 40.6 0.53 30.9 2285.0 1.0103 259.6 40.4 1.01 22.9 2295.4 1.0200 261.4 39.9 1.46 21.6 2286.3 1.0288 257.2 40.3 1.87 20.9 2328.1 1.0374 262.9 40.4 2.23 20.6 2345.2 1.0434 256.3 40.6 2.57 19.9 2373.0 1.0512 260.2 40.7 2.84 19.3 2389.0 1.0558 250.3 40.7 3.13 19.0 2409.1 1.0639 350 kPa,

18 m3/h352.9 29.7 0.48 39.5 1708.9 1.0087 359.7 30.1 1.02 34.4 1746.2 1.0183 348.3 30.3 1.44 28.1 1771.3 1.0265 355.7 30.1 1.83 25.6 1773.3 1.0330 358.6 30.1 2.23 23.1 1785.7 1.0397 350.4 30.2 2.55 22.4 1801.7 1.0468 347.8 29.5 2.86 20.5 1771.1 1.0537 350.9 30.1 3.13 20.0 1815.7 1.0572 表 5 不同工况下的液滴粒径及过读特性 (PJ10)

Table 5. Droplet SMD and meter overreading under different conditions (PJ10)

载气

工况P/

kPaUsg/

(m·s−1)Ql/

(mL·s−1)dp/

μmfVS/

HzOR 250 kPa,

18 m3/h246.0 29.9 2.00 58.0 1772.5 1.0385 243.0 30.4 2.40 45.4 1818.7 1.0457 250.5 30.4 2.93 36.8 1830.6 1.0542 255.6 30.2 3.36 34.0 1832.7 1.0614 255.7 30.0 3.77 32.8 1833.8 1.0693 244.6 29.9 4.21 28.2 1848.1 1.0811 246.6 29.1 4.65 26.3 1818.2 1.0917 250 kPa,

24 m3/h254.7 40.8 2.01 46.5 2363.1 1.0416 255.5 39.9 2.46 38.4 2336.8 1.0519 258.5 40.1 2.96 31.2 2368.8 1.0617 247.1 40.5 3.87 27.9 2443.7 1.0838 249.8 39.9 4.33 24.8 2428.3 1.0939 350 kPa,

18 m3/h344.8 29.9 2.09 61.1 1763.7 1.0361 357.5 29.4 2.52 52.3 1749.1 1.0429 351.5 30.2 3.01 40.5 1810.2 1.0507 360.1 29.6 3.43 38.6 1783.4 1.0577 358.9 29.5 3.88 34.2 1791.4 1.0658 359.8 29.3 4.32 31.3 1794.9 1.0736 362.8 29.3 4.72 29.1 1802.1 1.0796 表 6 涡街流量计在湿气测量中的过读公式及实验条件

Table 6. Vortex meter overreading correlations in wet gas and their experimental conditions

公式来源 工况压力/MPa 介质 混合方式 管径/mm 液相加载量/% 过读公式 校正精度/% Hussein和Owen [16] 0.4

0.6过热蒸汽、水 雾化喷嘴 50 0 ~ 19 $ {\left( {1{\text{ + }}\phi } \right)^{0.5}} $ 2 Hall和Steven [18] 1.2

4.8

7.8天然气、

癸烷引射器 100 0 ~ 56 $1{\text{ + 1} }{\text{.14} }X_{ {\text{LM} } } ^{0.84}$ 2 贾云飞和孔德仁[19] 0.1 空气、水 引射器 50 0 ~ 75 $1 + \dfrac{1}{3}{\beta _{\rm{l}}}\dfrac{ { {\rho _{\rm{l}}} } }{ { {\rho _{\rm{g}}} } }$ 10 Stewart等 [20] 1.5

3.0

6.0氮、煤油 引射器 100 0 ~ 60 $\left\{ \begin{array}{l} 1\text{+}2.59{X}_{\text{LM} },P=1.5\;\text{MP}\text{a}\\ 1\text{+}1.68{X}_{\text{LM} },P=3.0\;\text{MPa}\\ 1\text{+}1.22{X}_{\text{LM} },P=6.0\;\text{MPa}\end{array} \right.$ 5 本文所提

公式0.25

0.35空气、水 雾化喷嘴 15 0 ~ 30 $1 + 0.003\;9We_{\rm{g}}^{0.540\;7}{\phi ^{0.839\;8} }{\kern 1pt} {S t_L}^{ - 0.057\;1}$ 1 -

[1] 盛碧霞, 冀海峰, 王保良, 等. 基于新型C4D的小管道气液两相流流型辨识方法[J]. 北京航空航天大学学报, 2017, 43(11): 2273-2279. doi: 10.13700/j.bh.1001-5965.2017.0063SHENG B X, JI H F, WANG B L, et al. Flow pattern identification method of gas-liquid two-phase flow in ductule based on new C4D[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(11): 2273-2279(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0063 [2] 宋军辉, 宋保银, 张钊, 等. 逆载对管道内汽水两相流临界热流密度的影响[J]. 北京航空航天大学学报, 2017, 43(4): 842-848. doi: 10.13700/j.bh.1001-5965.2016.0331SONG J H, SONG B Y, ZHANG Z, et al. Effect of inverse load on critical heat flux of steam-water two-phase flow in a tube[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(4): 842-848(in Chinese). doi: 10.13700/j.bh.1001-5965.2016.0331 [3] BRIL J P, ARIRACHAKARAN S J. State of the art in multiphase flow[J]. Journal of Petroleum Technology, 1992, 44(5): 538-541. doi: 10.2118/23835-PA [4] OSHINOWO T, CHARLES M E. Vertical two-phase flow: Part I. Flow pattern correlations[J]. The Canadian Journal of Chemical Engineering, 1974, 52(1): 25-35. doi: 10.1002/cjce.5450520105 [5] MEHDIZADEH P, MARRELLI J, TING V C. Wet gas metering: Trends in applications and technical developments[C]//SPE Annual Technical Conference and Exhibition. San Antordo: Society of Petroleum Engineers, 2002: 1-14. [6] STEVEN R. Wet gas metering[D]. Scotland: University of Strathclyde, 2001. [7] LI J X, WANG C, DING H B, et al. Online measurement of wet gas by modelling frequency and amplitude characteristics of a vortex flowmeter[J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(6): 3666-3678. [8] LI J X, WANG C, DING H B, et al. EMD and spectrum-centrobaric-correction-based analysis of vortex street characteristics in mist annular flow of wet gas[J]. IEEE Transactions on Instrumentation and Measurement, 2018, 67(5): 1150-1160. doi: 10.1109/TIM.2018.2790598 [9] LI J X, WANG C, DING H B. Characteristics of vortex flowmeter in vapor-liquid mist flow[C]//International Instrumentation and Measurement Technology Conference. Houston: IEEE Instrumentation and Measurement Society, 2018: 1-6. [10] WANG C, ZHANG Z X, DING H B, et al. Measurement property of vortex flowmeter in wet gas flow using mist flow apparat[C]// International Instrumentation and Measurement Technology Conference. Houston: IEEE Instrumentation and Measurement Society, 2018: 1-6. [11] SUN H J, LUO Y K, DING H B, et al. Experimental investigation on atomization properties of impaction-pin nozzle using imaging method analysis[J]. Experimental Thermal and Fluid Science, 2021, 122: 110322. doi: 10.1016/j.expthermflusci.2020.110322 [12] WANG C, DING H B, WANG H. Thermodynamic model and dynamic temperature compensation positive-pressure-based sonic nozzle gas flow standard[J]. IEEE Transactions on Instrumentation and Measurement, 2013, 62(5): 1154-1165. doi: 10.1109/TIM.2012.2234599 [13] YANG Y, CHUNG J N, TROUTT T R, et al. The effects of particles on the stability of a two-phase wake flow[J]. International Journal of Multiphase Flow, 1993, 19(1): 137-149. doi: 10.1016/0301-9322(93)90029-T [14] SAWANT P, ISHIII M, MORI M. Droplet entrainment correlation in vertical upward co-current annular two-phase flow[J]. Nuclear Engineering and Design, 2008, 238(6): 1342-1352. doi: 10.1016/j.nucengdes.2007.10.005 [15] LI J X, WANG C, DING H B, et al. A new overreading model for wet gas vortex metering based on vorticity transport mechanism[J]. Measurement, 2020, 162: 107884. doi: 10.1016/j.measurement.2020.107884 [16] HUSSEIN I B, OWEN I. Calibration of flowmeters in superheated and wet steam[J]. Flow Measurement and Instrumentation, 1991, 2(4): 209-215. doi: 10.1016/0955-5986(91)90003-A [17] PAN L, HANRATTY T J. Correlation of entrainment for annular flow in vertical pipes[J]. International Journal of Multiphase Flow, 2002, 28(3): 363-384. doi: 10.1016/S0301-9322(01)00073-8 [18] HALL A, STEVEN R. A discussion on vortex meter technologies with wet gas flows[C]// Proceedings of 7th South East Asia Hydrocarbon Flow Measurement Workshop. Kuala Lumpur: TUV National Engineering Laboratory, 2008: 1-20. [19] 贾云飞, 孔德仁. 基于波理论的涡街流量计雾状流测量模型[J]. 化工学报, 2009, 60(3): 601-607. doi: 10.3321/j.issn:0438-1157.2009.03.010JIA Y F, KONG D R. Fog two-phase flow correlation for vortex flow meter based on theory of vortex street wave[J]. CIESC Journal, 2009, 60(3): 601-607(in Chinese). doi: 10.3321/j.issn:0438-1157.2009.03.010 [20] STEWART D G, HODGES D, BROWN G J. Recent research results in wet gas flow[C]//Proceedings of South East Asia Hydrocarbon Flow Measurement Workshop. Kuala Lumpur: TUV National Engineering Laboratory, 2004: 1-13. [21] BURGER M, SCHMEHL R, KOCH R, et al. DNS of droplet-vortex interaction with a Karman vortex street[J]. International Journal of Heat and Fluid Flow, 2006, 27(2): 81-191. -

下载:

下载: