-

摘要:

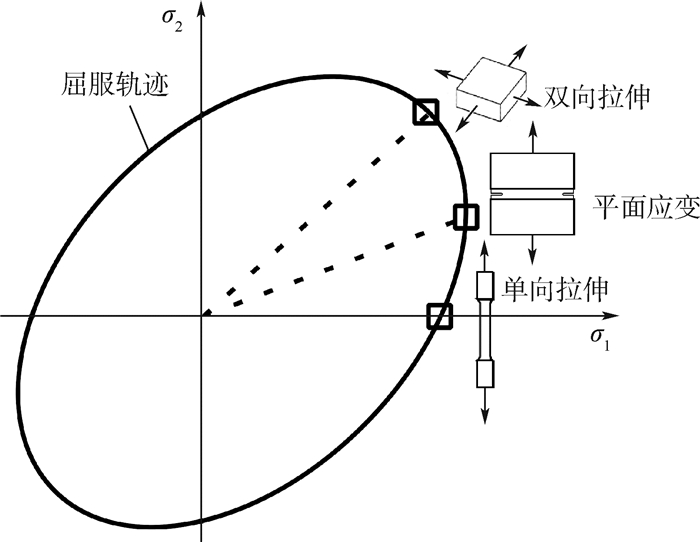

针对目前微细成形中材料屈服、强化行为实验研究的不足,提出通过建立多轴同步控制的微尺度双向加载实验系统,实现超薄板在复杂加载路径下的性能表征测试。双向加载实验系统基于四轴独立驱动的硬件组成和上、下位机分布式控制策略,采用数字散斑测量(DIC)计算实验过程的应变。通过建立交流永磁同步电机(PMSM)控制模型,辨识了速度闭环控制参数。在非线性PID控制方法实现单轴位置闭环控制的基础上,基于虚拟主轴法实现了不同位移/载荷比例条件下的四轴同步运动。双向加载实验结果表明:同步控制精度满足位移小于等于0.02 mm、载荷小于等于0.05 kN的要求,可用于超薄板微尺度屈服和强化行为的实验研究。

Abstract:Aimed at the currently insufficient experimental condition for the research on yielding and hardening behavior in microforming of ultrathin sheets, a micro-scaled biaxial loading test system was presented, which can achieve complex loading paths. The system is characterized with four independent driving axes in hardware, coupled with separated upper computer and lower computer in software structure. The digital image correlation (DIC) method is adopted to capture deformation strain in the biaxial tension process. The control model of permanent magnet synchronous motor (PMSM) was first established, and the control parameters of speed closed loop were identified. The control accuracy of single-axis position closed-loop is significantly improved by using the nonlinear PID control method, and the four-axis synchronous control under diverse displacement/load ratios is realized on the basis of virtual axis method. The biaxial loading experiment reveals that the system satisfies the requirements of displacement synchronization error within 0.02 mm and load synchronization error within 0.05 kN. The developed system can thus be used for experimental research on yielding and hardening behavior of ultrathin sheet.

-

表 1 双向加载实验系统技术指标

Table 1. Technical indicators of biaxial loading test system

指标 位移分辨率/μm 力传感器准确度等级 位移同步精度/mm 载荷同步精度/kN 数值 5 0.02~0.03 0.02 0.05 -

[1] SCHROERS J, PHAM Q, DESAI A.Thermoplastic forming of bulk metallic glass-A technology for MEMS and microstructure fabrication[J].Journal of Microelectromechanical Systems, 2007, 16(2):240-247. doi: 10.1109/JMEMS.0007.892889 [2] MENG B, FU M W, FU C M, et al.Ductile fracture and deformation behavior in progressive microforming[J].Materials & Design, 2015, 83:14-25. http://cn.bing.com/academic/profile?id=5fde5d3f208ccca700e3e273b5009a96&encoded=0&v=paper_preview&mkt=zh-cn [3] RAZALI A R, QIN Y.A review on micro-manufacturing, micro-forming and their key issues[J].Procedia Engineering, 2013, 53(7):665-672. http://cn.bing.com/academic/profile?id=8ba000890df14e07c46404499f4cb0e3&encoded=0&v=paper_preview&mkt=zh-cn [4] MANABE K, SHIMIZU K, KOYAMA T, et al.Validation of FE simulation based on surface roughness model in micro-deep drawing[J].Journal of Materials Processing Technology, 2008, 204(1-3):89-93. doi: 10.1016/j.jmatprotec.2007.10.081 [5] YEH F H, LI C L, LU Y H.Study of thickness and grain size effects on material behavior in micro-forming[J].Journal of Materials Processing Technology, 2008, 201(1-3):237-241. doi: 10.1016/j.jmatprotec.2007.11.138 [6] FU M W, WANG J L, KORSUNSKY A M.A review of geometrical and microstructural size effects in micro-scale deformation processing of metallic alloy components[J].International Journal of Machine Tools & Manufacture, 2016(109):94-125. http://cn.bing.com/academic/profile?id=1c3689bd1effe58ef72a8f6fe2728dae&encoded=0&v=paper_preview&mkt=zh-cn [7] MENG B, FU M W.Size effect on deformation behavior and ductile fracture in microforming of pure copper sheets considering free surface roughening[J].Materials & Design, 2015, 83:400-412. http://cn.bing.com/academic/profile?id=7a2599a9e5f1476eddef29d798a329fb&encoded=0&v=paper_preview&mkt=zh-cn [8] FU M W, CHAN W L.A review on the state-of-the-art microforming technologies[J].International Journal of Advanced Manufacturing Technology, 2013, 67(9-12):2411-2437. doi: 10.1007/s00170-012-4661-7 [9] DUBOS P A, FLEURIER G, HUG E.An experimental investigation of the size effects in forming processes of high-purity thin metallic sheets[C]//Materials Science Forum, 2017: 459-464. [10] PENG L F, XU Z T, FU M W, et al.Forming limit of sheet metals in meso-scale plastic forming by using different failure criteria[J].International Journal of Mechanical Sciences, 2017, 120:190-203. doi: 10.1016/j.ijmecsci.2016.11.021 [11] HANNON A, TIERNAN P.A review of planar biaxial tensile test systems for sheet metal[J].Journal of Materials Processing Technology, 2008, 198(1):1-13. http://cn.bing.com/academic/profile?id=dc1608d47da9c1dd57052f233c3c3ac8&encoded=0&v=paper_preview&mkt=zh-cn [12] BANABIC D, BARLAT F, CAZACU O, et al.Advances in anisotropy and formability[J].International Journal of Material Forming, 2010, 3(3):165-189. doi: 10.1007/s12289-010-0992-9 [13] CHEN H, YE D, CHE R.High speed deformation measurement using digital speckle correlation method[C]//27th International Congress on High-Speed Photography and Photonics.Bellingham: SPIE, 2007: 62791O. [14] 陈华.基于数字散斑相关方法的视觉变形测量技术研究[D].哈尔滨: 哈尔滨工业大学, 2008: 15-22. http://cdmd.cnki.com.cn/Article/CDMD-10213-2009224157.htmCHEN H.Study of vision deformation measurement technologies based on digital speckle correlation method[D].Harbin: Harbin Institute of Technology, 2008: 15-22(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10213-2009224157.htm [15] MA S P, JI G C.Digital speckle correlation method improved by genetic algorithm[J].Acta Mechanica Solida Sinica, 2003, 16(4):366-373. http://cn.bing.com/academic/profile?id=d02663ba4b65cd246fa1349d72132ac4&encoded=0&v=paper_preview&mkt=zh-cn [16] 汪海波, 周波, 方斯琛.永磁同步电机调速系统的滑模控制[J].电工技术学报, 2009, 24(9):71-77. doi: 10.3321/j.issn:1000-6753.2009.09.011WANG H B, ZHOU B, FANG S C.PMSM sliding mode control system based on exponential reaching law[J].Transactions of China Electrotechnical Society, 2009, 24(9):71-77(in Chinese). doi: 10.3321/j.issn:1000-6753.2009.09.011 [17] 陈鹏展.交流伺服系统控制参数自整定策略研究[D].武汉: 华中科技大学, 2010: 19-27. http://cdmd.cnki.com.cn/Article/CDMD-10487-2010184585.htmCHEN P Z.Study on the self-tuning strategy of control parameters for AC servo system[D].Wuhan: Huazhong University of Science and Technology, 2010: 19-27(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10487-2010184585.htm [18] 王述彦, 师宇, 冯忠绪.基于模糊PID控制器的控制方法研究[J].机械科学与技术, 2011, 30(1):166-172. http://cdmd.cnki.com.cn/Article/CDMD-10422-2007088775.htmWANG S Y, SHI Y, FENG Z X.A method for controlling a loading system based on a fuzzy PID controller[J].Mechanical Science and Technology for Aerospace Engineering, 2011, 30(1):166-172(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10422-2007088775.htm -

下载:

下载: