Multi-sensor measurement based position and pose adjustment method for automatic docking of spacecraft cabins

-

摘要:

针对航天器舱段对接通常采用的手工操作方式效率低、精度差和可靠性难以保证的问题,研发了一种基于多传感器测量的舱段自动对接装置,其中舱体位姿的测量和调整是保证对接质量和效率的关键因素。提出了一种基于激光轮廓传感器和CCD图像传感器等多传感器协同测量的舱段六自由度位姿估计和调整方法。首先,采用激光轮廓传感器对舱体进行扫描,获取位姿三维点云信息,并采用改进的最小二乘法对被测舱段位姿进行求解;然后,通过CCD图像传感器获取舱段对接孔位置,通过圆拟合计算角度偏差,求解和拟合的结果将反馈至控制系统进行调姿和对接。采用Gocator 2350激光轮廓传感器及大恒MER-1810-21U3C工业相机进行舱体测量和对接实验,结果表明,舱体位姿调整精度和效率均达到对接要求。该方法结合了激光轮廓传感器的可靠性和机器视觉的灵活性,有效提高了自动对接系统的效率、稳定性和一致性,足以满足未来军用以及民用的需求。

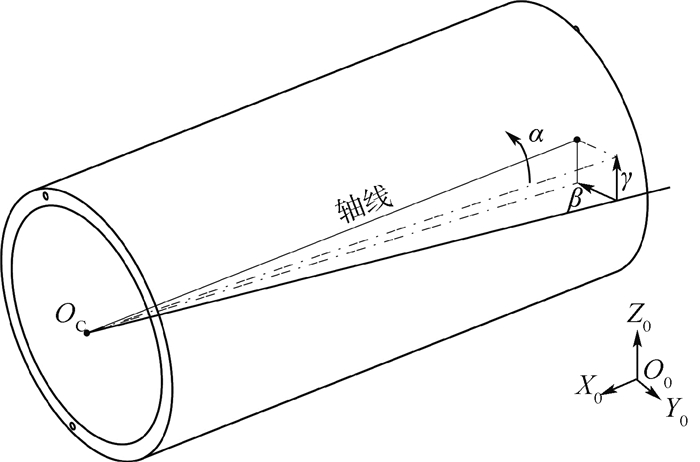

Abstract:In view of the shortcomings of the manual operation methods commonly used in the docking of spacecraft cabins, such as low efficiency, poor precision, and difficulty in ensuring reliability, an automatic docking device for cabins based on multi-sensor measurement has been developed. The measurement and adjustment of the cabin position and pose is the key factor to ensure the quality and efficiency of the docking. Therefore, this paper proposes a six-degree-of-freedom position and pose estimation and adjustment method based on multi-sensor collaborative measurement of laser contour sensor and CCD image sensor. The specific method is as follows:the laser contour sensor is used to scan the cabin, the three-dimensional point cloud information of the position and pose is obtained, and the posture of the measured cabin is solved by the improved least squares method. On this basis, the position of the docking hole of the cabin is obtained by the image sensor, and the angular deviation is calculated by the circle fitting. The result of the solution and fitting will be fed back to the control system for posture adjustment and docking. The project uses the Gocator 2350 laser profile sensor and the Daheng MER-1810-21U3C industrial camera for cabin measurement and docking experiments. The experimental results show that the accuracy and efficiency of the cabin position adjustment meet the docking requirements. This method combines the reliability of the laser profile sensor with the flexibility of machine vision to effectively improve the efficiency, stability and consistency of the automatic docking system, which is sufficient for future military and civilian needs.

-

表 1 舱段位姿测量误差

Table 1. Measurement error of cabin position and pose

误差 β/(°) γ/(°) XC/mm YC/mm ZC/mm 绝对误差均值 0.007 8 0.011 3 0.022 3 0.022 2 0.016 5 绝对误差最大值 0.012 5 0.013 7 0.028 1 0.028 7 0.025 9 重复测量标准差 0.001 4 0.000 3 0.000 9 0.012 1 0.001 4 重复测量极差 0.002 8 0.000 5 0.001 7 0.002 1 0.002 8 表 2 各舱段调整前后位姿数据

Table 2. Each cabin position and pose data before and after adjustment

舱段号 调整前/后 β/(°) γ/(°) XC/mm YC/mm ZC/mm 1 前 0.875 2 -0.002 1 -39.121 266.051 38.033 后 0.006 4 -0.001 7 -38.951 266.109 38.011 2 前 0.781 1 -0.631 5 2 888.416 266.151 38.021 后 0.008 4 -0.004 4 2 888.426 266.176 37.936 3 前 0.675 4 0.124 5 4 278.601 266.165 37.965 后 0.007 3 -0.001 2 4 278.578 266.171 37.986 表 3 舱段孔之间夹角测量

Table 3. Measurement of angle between cabin holes

(°) 舱段号 夹角 API 相机 误差 1 孔1、孔2夹角 4.971 32 4.977 63 0.006 31 孔2、孔3夹角 5.010 37 4.995 33 -0.015 04 孔1、孔3夹角 9.981 69 9.972 96 -0.008 73 2 孔1、孔2夹角 5.001 19 4.991 57 -0.009 62 孔2、孔3夹角 5.018 04 5.011 90 -0.006 14 孔1、孔3夹角 10.019 20 10.003 91 -0.015 29 表 4 调姿前后相邻舱段相对自转角测量数据

Table 4. Relative segment angle measurement of adjacent cabins before and after posture adjustment

舱段号 调整前/后 Δα/(°) 1和2 前 5.734 5 后 0.000 3 2和3 前 4.667 4 后 0.001 2 -

[1] 吴宝中, 龚京忠, 李国喜, 等.导弹总装几何量数字化测量流程及其表达[J].国防制造技术, 2009(2):39-43. http://www.cnki.com.cn/Article/CJFDTOTAL-GFZZ200902019.htmWU B Z, GONG J Z, LI G X, et al.Measurement process and its express of geometry features in missile assembly[J].Defencse Manufacturing Technology, 2009(2):39-43(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GFZZ200902019.htm [2] MORIN P, SAMSON C, POMET J B, et al.Time-varying feedback stabilization of the attitude of a rigid spacecraft with two controls[J].Systems & Control Letters, 2014, 25(5):375-385. http://cn.bing.com/academic/profile?id=0c6337c2f3042e6e4f5e333fa157ee8a&encoded=0&v=paper_preview&mkt=zh-cn [3] TILLERSON M, INALHAN G, HOW J P.Co-ordination and control of distributed spacecraft systems using convex optimization techniques[J].International Journal of Robust & Nonlinear Control, 2016, 12:207-242. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=6949bb9294307a35a351980355e54f1a [4] 郭志敏, 蒋君侠, 柯映林.基于POGO柱三点支撑的飞机大部件调姿方法[J].航空学报, 2009, 30(7):1319-1324. doi: 10.3321/j.issn:1000-6893.2009.07.023GUO Z M, JIANG J X, KE Y L.Posture alignment for large aircraft parts based on three POGO sticks distributed support[J].Acta Aeronautica et Astronautica Sinica, 2009, 30(7):1319-1324(in Chinese). doi: 10.3321/j.issn:1000-6893.2009.07.023 [5] 文科, 杜福洲, 张铁军, 等.舱段类部件数字化柔性对接系统设计与试验研究[J].航空制造技术, 2017, 530(11):24-31. http://d.old.wanfangdata.com.cn/Periodical/hkgyjs201711003WEN K, DU F Z, ZHANG T J, et al.Research on design and experiment for digital flexible aligning system of cabin components[J].Aeronautical Manufacturing Technology, 2017, 530(11):24-31(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hkgyjs201711003 [6] 高超.导弹柔性装配系统关键技术研究[D].哈尔滨: 哈尔滨工业大学, 2014. http://cdmd.cnki.com.cn/Article/CDMD-10213-1014084058.htmGAO C.Research on key technologies of missile flexible assembly system[D].Harbin: Harbin Institute of Technology, 2014(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10213-1014084058.htm [7] 于斌.航天器舱段自动对接技术研究与仿真[D].秦皇岛: 燕山大学, 2016. http://cdmd.cnki.com.cn/Article/CDMD-10216-1016764021.htmYU B.The research and simulation of the spacecraft cabin automatic docking technology[D].Qinhuangdao: Yanshan University, 2016(in Chinese). http://cdmd.cnki.com.cn/Article/CDMD-10216-1016764021.htm [8] 邹冀华, 刘志存, 范玉青.大型飞机部件数字化对接装配技术研究[J].计算机集成制造系统, 2007, 13(7):1367-1373. doi: 10.3969/j.issn.1006-5911.2007.07.019ZOU J H, LIU Z C, FAN Y Q.Large-size airplane parts digital assembly technology[J].Computer Integrated Manufacturing Systems, 2007, 13(7):1367-1373(in Chinese). doi: 10.3969/j.issn.1006-5911.2007.07.019 [9] 金贺荣, 刘达, 于斌, 等.舱段自动装配位姿求解方法研究[J].中国机械工程, 2017, 28(1):88-92. doi: 10.3969/j.issn.1004-132X.2017.01.015JIN H R, LIU D, YU B, et al.Research on the method of solving the automatic assembly position of the cabin[J].China Mechanical Engineering, 2017, 28(1):88-92(in Chinese). doi: 10.3969/j.issn.1004-132X.2017.01.015 [10] VENTURA J A, WAN W.Accurate matching of two-dimensional shapes using the minimal tolerance zone error[J].Image and Vision Computing, 1997, 15(12):889-899. doi: 10.1016/S0262-8856(97)00038-3 [11] DAVID P, DEMENTHON D, DURAISWAMI R, et al.Simultaneous pose and correspondence determination using line features[C]//Proceedings of the 2003 IEEE Computer Society Conference on Computer Vision and Pattern Recognition.Piscataway, NJ: IEEE Press, 2003: 424-431. https://www.researchgate.net/publication/2856990_Simultaneous_Pose_and_Correspondence_Determination_using_Line_Features [12] CYR C M, KIMIA B B.3D object recognition using shape similiarity-based aspect graph[C]//Proceedings of 8th IEEE International Conference on Computer Vision.Piscataway, NJ: IEEE Press, 2001: 254-261. https://www.researchgate.net/publication/221110231_3D_Object_Recognition_Using_Shape_Similarity-Based_Aspect_Graph [13] NGUYEN H, LEE B.Laser-vision-based quality inspection system for small-bead laser welding[J].International Journal of Precision Engineering and Manufacturing, 2014, 15(3):415-423. doi: 10.1007/s12541-014-0352-7 [14] RAHAYEM M R, KJELLANDER J A.Quadric segmentation and fitting of data captured by a laser profile scanner mounted on an industrial robot[J].The International Journal of Advanced Manufacturing Technology, 2011, 52(1):155-169. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=37b509452685e8841fd55d98eaf324ad [15] SCHALK P, O'LEARY P, OFNER R, et al.Measuring and analyzing cross-sectional profiles of rotating objects using light sectioning[J].IEEE Transactions on Instrumentation and Measurement, 2008, 57(10):2329-2338. doi: 10.1109/TIM.2008.920033 [16] BELLANDI P, DOCCHIO F, SANSONI G.Roboscan:A combined 2D and 3D vision system for improved speed and flexibility in pick-and-place operation[J].The International Journal of Advanced Manufacturing Technology, 2013, 69(5-8):1873-1886. doi: 10.1007/s00170-013-5138-z [17] RAHAYEM M, WERGHI N, KJELLANDER J.Best ellipse and cylinder parameters estimation from laser profile scan sections[J].Optics and Lasers in Engineering.2012, 50(9):1242-1259. doi: 10.1016/j.optlaseng.2012.03.014 [18] HALÍŘ R, FLUSSER J.Numerically stable direct least squares fitting of ellipses[C]//Proceedings of the Sixth International Conference in Central Europe on Computer Graphics and Visualization, 1998: 125-132. [19] AHN S J, RAUH W, HANS-JVRGEN W.Least-squares orthogonal distances fitting of circle, sphere, ellipse, hyperbola, and parabola[J].Pattern Recognition, 2001, 34(12):2283-2303. doi: 10.1016/S0031-3203(00)00152-7 [20] FITZGIBBON A, PILU M, FISHER R B.Direct least square fitting of ellipses[J].IEEE Transactions on Pattern Analysis and Machine Intelligence, 1999, 21(5):476-480. doi: 10.1109/34.765658 [21] ROUHANI M, SAPPA A D.Implicit polynomial representation through a fast fitting error estimation[J].IEEE Transactions on Image Processing, 2012, 21(4):2089-2098. doi: 10.1109/TIP.2011.2170080 [22] RAHAYEM M R, KJELLANDER J A P.Quadric segmentation and fitting of data captured by a laser profile scanner mounted on an industrial robot[J].International Journal of Advanced Manufacturing Technology, 2011, 52(1-4):155-169. doi: 10.1007/s00170-010-2713-4 [23] 化春键, 陈莹.高精度尺度不变特征点匹配方法及其应用[J].中国机械工程, 2014, 25(12):1655-1658. doi: 10.3969/j.issn.1004-132X.2014.12.018HUA C J, CHEN Y.Precise scale invariant feature matching and its application[J].China Mechanical Engineering, 2014, 25(12):1655-1658(in Chinese). doi: 10.3969/j.issn.1004-132X.2014.12.018 [24] 金贺荣, 刘达.面向筒类舱段自动装配的两点定位调姿方法[J].中国机械工程, 2018, 29(12):1467-1474. doi: 10.3969/j.issn.1004-132X.2018.12.013JIN H R, LIU D.Two-point positioning and attitude adjustment method for automatic assembly of cylinder section[J].China Mechanical Engineering, 2018, 29(12):1467-1474(in Chinese). doi: 10.3969/j.issn.1004-132X.2018.12.013 [25] 方俊涛, 何桢, 宋琳曦, 等.响应曲面建模的稳健M-回归方法[J].工业工程, 2012, 15(3):98-103. doi: 10.3969/j.issn.1007-7375.2012.03.019FANG J T, HE Z, SONG L X, et al.The robust M-estimators in response surface modeling[J].Industrial Engineering Journal, 2012, 15(3):98-103(in Chinese). doi: 10.3969/j.issn.1007-7375.2012.03.019 -

下载:

下载: