-

摘要:

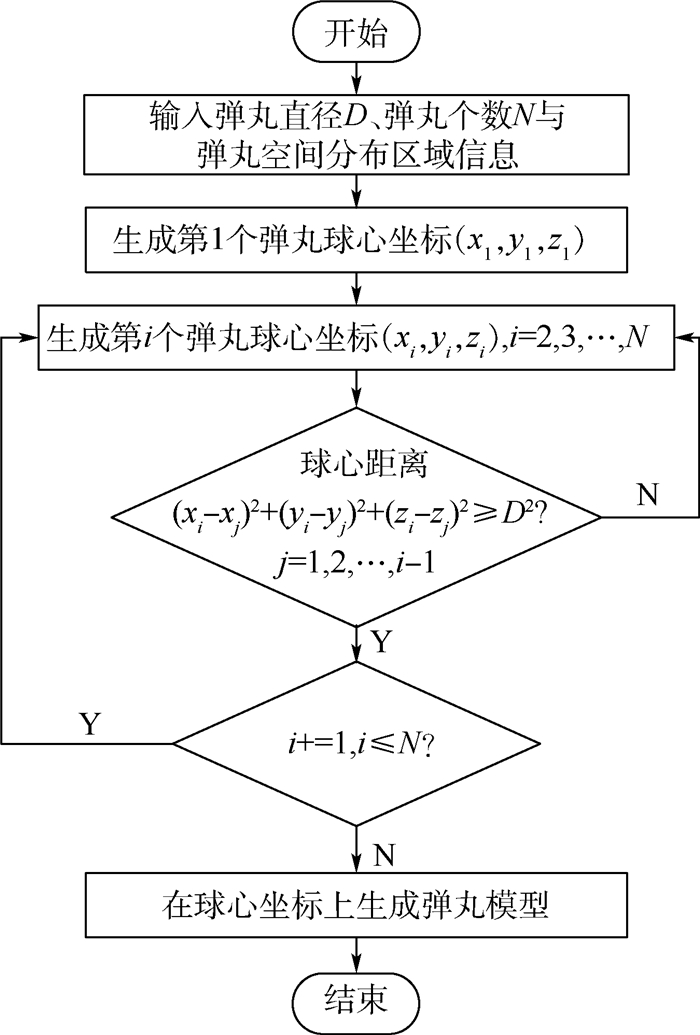

针对目前喷丸有限元仿真研究中弹丸规则排列、覆盖率无法精确计算的研究现状,基于ABAQUS二次开发建立了弹丸空间位置随机分布、弹丸数量由覆盖率决定的多弹丸喷丸有限元模型,实现了不同工况、不同喷丸覆盖率条件下所需弹丸个数的精确计算;在此基础上研究了不同喷丸参数对TC4钛合金材料表面残余应力与表面粗糙度的影响规律。进行了TC4喷丸试验,将得到的残余应力分布、表面粗糙度与仿真结果进行对比,验证了该有限元模型的合理性。研究成果对喷丸工艺参数的确定具有一定的指导意义。

Abstract:In view of the current research status on the finite element simulation study of shot peening, such as the projectiles' regular arrangement and the peening coverage cannot be calculated precisely, a finite element model with multiple randomly distributed shots whose number depends on the peening coverage was secondarily developed with ABAQUS, in which accurate number of required shots under different working conditions and different peening coverage is calculated. The influence of peening parameters on the surface residual stress and the surface roughness of TC4 titanium alloy material was studied. The TC4 shot peening experiment was carried out, residual stress distribution and surface roughness obtained by experiment were compared with those by simulation, and the results verified the reasonable prediction of residual stress distribution and surface roughness by the model, which has certain guiding significance for the determination of shot peening process parameters.

-

Key words:

- TC4 titanium alloy /

- shot peening model /

- random distribution /

- coverage /

- residual compressive stress

-

表 1 基本材料参数

Table 1. Basic material parameters

参数 TC4 弹丸 密度/(t·mm-3) 4.428×10-9 7.8×10-9 弹性模量/GPa 110 200 泊松比 0.342 0.3 屈服强度/GPa 1.098 抗拉强度/GPa 1.092 参数 数值 A/MPa 1 098 B/MPa 1 092 n 0.93 m 1.1 熔点/K 1 878 参考温度/K 298 C 0.014

1 表 3 不同喷丸工况下达到98%覆盖率时所需弹丸个数

Table 3. Number of projectiles required to achieve 98% coverage under different shot peening conditions

工况 弹坑半径

ap/mm覆盖率达到98%

以上时所需

弹丸个数弹丸粒度/mm 弹丸速度/

(m·s-1)0.3 65 0.084 110 0.4 65 0.101 90 0.5 65 0.135 65 0.6 65 0.152 45 0.7 65 0.169 30 0.5 70 0.135 65 0.5 75 0.135 65 0.5 80 0.135 65 0.5 85 0.135 65 -

[1] MIAO H, ZUO D W, WANG M, et al. Numerical calculation and experimental research on residual stresses in precipitation-hardening layer of NAK80 steel for shot peening[J].Chinese Journal of Mechanical Engineering, 2011, 24(3):439-445. doi: 10.3901/CJME.2011.03.439 [2] 张洪伟, 张以都, 吴琼.喷丸强化残余应力场三维数值分析[J].航空动力学报, 2010, 25(3):603-609. http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201003020ZHANG H W, ZHANG Y D, WU Q.Three-dimensional numerical analysis of residual stress field for shot-peening[J].Journal of Aeronautical Power, 2010, 25(3):603-609(in Chinese). http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201003020 [3] MORI K, OSAKADA K, MATSUOKA N.Finite element analysis of peening process with plastically deforming shot[J].Journal of Materials Processing Technology, 1994, 45(1-4):607-612. doi: 10.1016/0924-0136(94)90406-5 [4] GUAGLIANO M.Relating Almen intensity to residual stresses induced by shot peening:A numerical approach[J].Journal of Materials Processing Technology, 2001, 110(3):277-286. doi: 10.1016/S0924-0136(00)00893-1 [5] MEGUID S A, SHAGAL G, STRANART J C.3D FE analysis of peening of strain-rate sensitive materials using multiple impingement model[J].International Journal of Impact Engineering, 2002, 27(2):119-134. doi: 10.1016/S0734-743X(01)00043-4 [6] HONG T, OOI J Y, SHAW B A.A numerical study of the residual stress pattern from single shot impacting on a metallic component[J].Advances in Engineering Software, 2008, 39(9):743-756. doi: 10.1016/j.advengsoft.2007.10.002 [7] BARAGETTI S.Three-dimensional finite-element procedures for shot peeening residual stress filed prediction[J].International Journal of Computer Applications in Technology, 2001, 14(1-3):51-63. http://www.researchgate.net/publication/242933983_Three-dimensional_finite-element_procedures_for_shot_peening_residual_stress_field_prediction [8] KLEMENZ M, SCHULZE V, VÖHRINGER O, et al.Finite element simulation of the residual stress states after shot peening[C]//Materials Science Forum, 2006, 524-525: 349-354. [9] MAJZOOBI G H, AZIZI R, NIA A A.A three-dimensional simulation of shot peening process using multiple shot impacts[J].Journal of Materials Processing Technology, 2005, 164(20):1226-1234. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=97aacd73a632614e542a2e34e2adea3e [10] WANG C, WANG L, WANG X G, et al.Numerical study of grain refinement induced by severe shot peening[J].International Journal of Mechanical Sciences, 2018, 146-147:280-294. doi: 10.1016/j.ijmecsci.2018.08.005 [11] STRANART J C.Finite element modelling of shot-peening residual stresses[J].Journal of Materials Processing Technology, 1999, 92-93(9):401-404. doi: 10.1016-j.msea.2006.03.097/ [12] MEO M, VIGNJEVIC R.Finite element analysis of residual stress induced by shot peening process[J].Advances in Engineering Software, 2003, 34(9):569-575. doi: 10.1016/S0965-9978(03)00063-2 [13] 夏明莉, 刘道新, 杜东兴, 等.喷丸强化对TC4钛合金表面完整性及疲劳性能的影响[J].机械科学与技术, 2012, 31(8):1349-1353. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxkxyjs201208031XIA M L, LIU D X, DU D X, et al.Effects of shot peening on surface integrity and fatigue properties of TC4 titanium alloy[J].Mechanical Science and Technology for Aerospace Engineering, 2012, 31(8):1349-1353(in Chinese). http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxkxyjs201208031 [14] 鲁世红, 何宁.TC4钛合金动态本构模型与高速切削有限元模拟[J].兵器材料科学与工程, 2009, 32(1):5-9. doi: 10.3969/j.issn.1004-244X.2009.01.002LU S H, HE N.Dynamic constitutive model of TC4 alloy material and finite element simulation of orthogonal high-speed cutting[J].Ordnance Material Science and Engineering, 2009, 32(1):5-9(in Chinese). doi: 10.3969/j.issn.1004-244X.2009.01.002 [15] LEUSE D.Experimental investigation of material models for Ti6AI4V and 202-T3 aluminum: DOT/FAA/AR-00/25[R].Washington, D.C.: FAA, 2000. [16] 温爱玲, 陈春焕, 郑德有, 等.高能喷丸表面纳米化对工业纯钛组织性能的影响[J].表面技术, 2003, 32(3):16-18. doi: 10.3969/j.issn.1001-3660.2003.03.006WEN A L, CHEN C H, ZHEN D Y, et al.Effects of surface nanocrystallization induced by high energy shot peening on commercial pure titanicum[J].Surface Technology, 2003, 32(3):16-18(in Chinese). doi: 10.3969/j.issn.1001-3660.2003.03.006 [17] 吕鹤婷.喷丸对疲劳寿命影响的数值模拟研究[D].济南: 山东大学, 2016: 19. http://d.wanfangdata.com.cn/Thesis/Y3035257LV H T.Numerical simulation research of the effect of shot-peening on fatigue life[D].Jinan: Shangdong University, 2016: 19(in Chinese). http://d.wanfangdata.com.cn/Thesis/Y3035257 [18] 全国产品尺寸和几何技术规范标准化技术委员会.产品几何技术规范(GPS)表面结构轮廓法表面粗糙度参数及其数值: GB/T 1031-2009[S].北京: 中国标准出版社, 2009: 1-5.National Technical Committee for Product Dimensions and Geometric Specifications.Geometrical product specifications (GPS)-Surface texture: Profile method-Surface roughness parameters and their values: GB/T 1031-2009[S].Beijing: China Standard Press, 2009: 1-5(in Chinese). -

下载:

下载: