-

摘要:

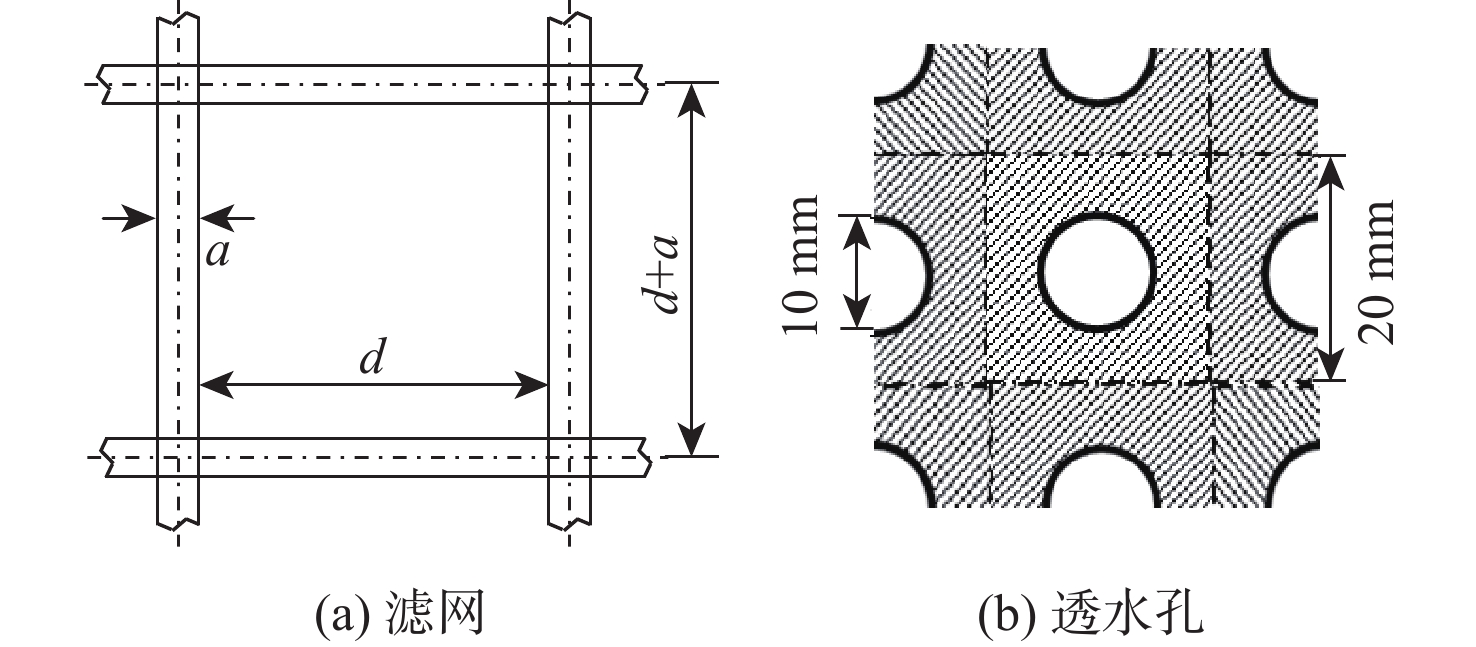

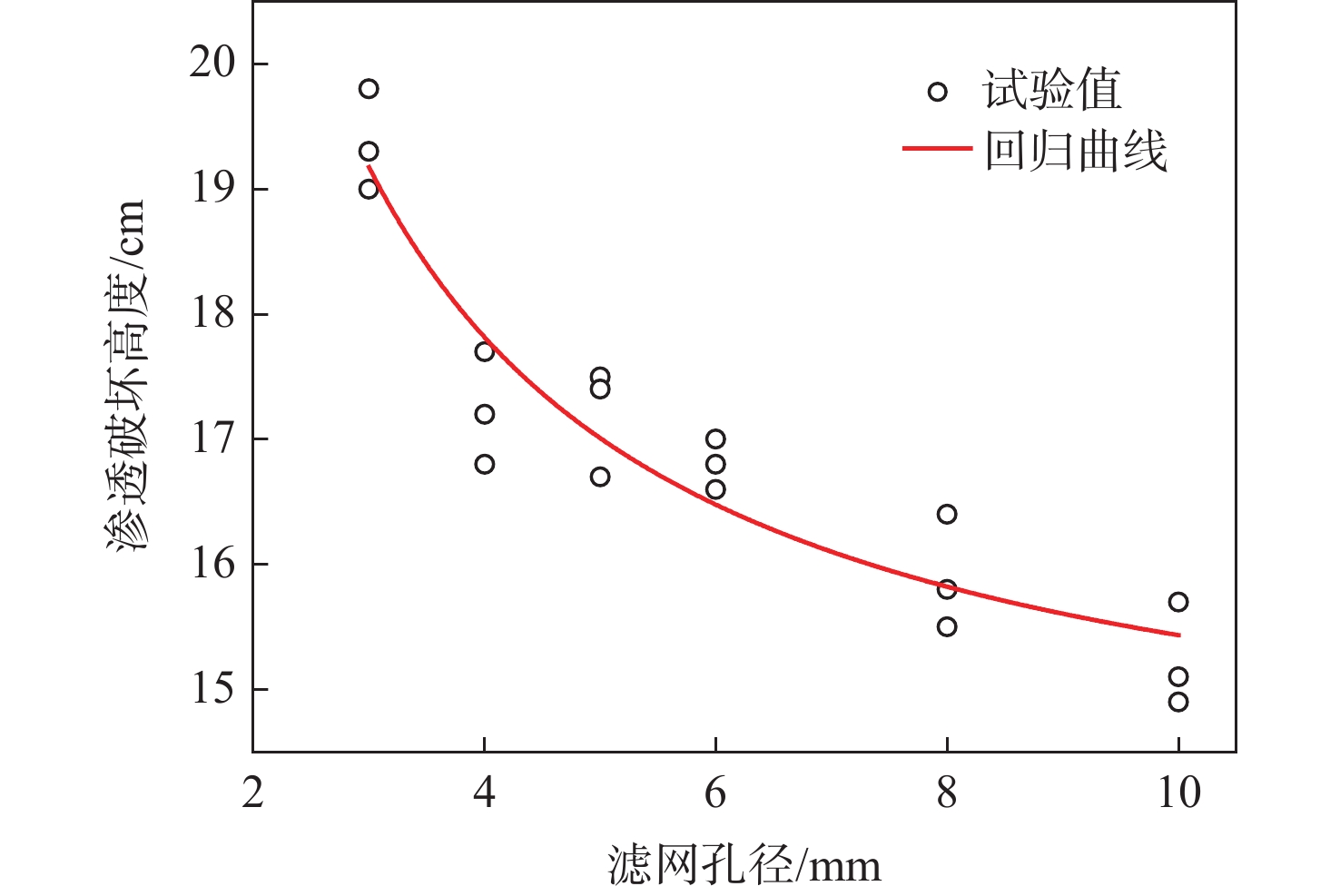

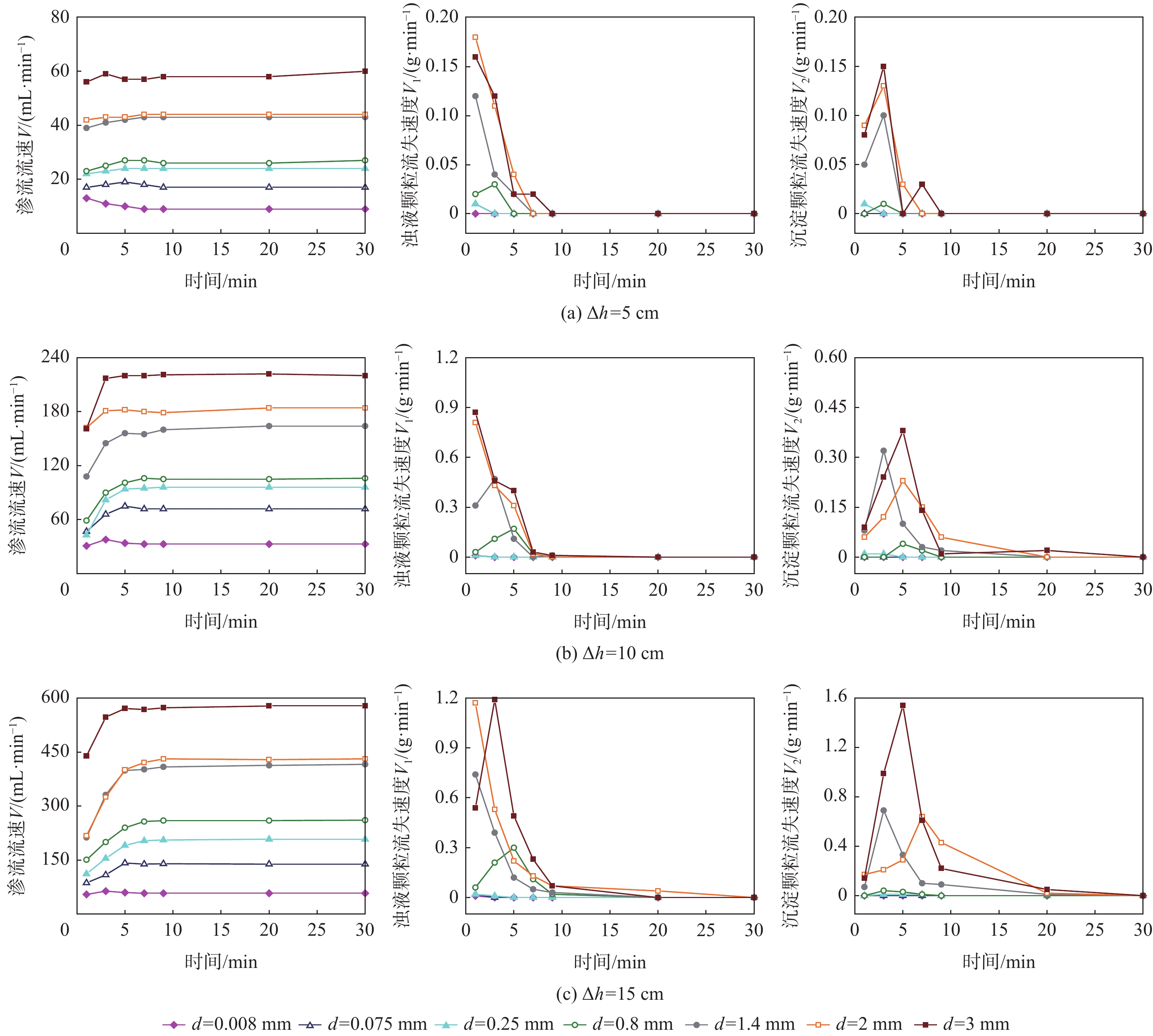

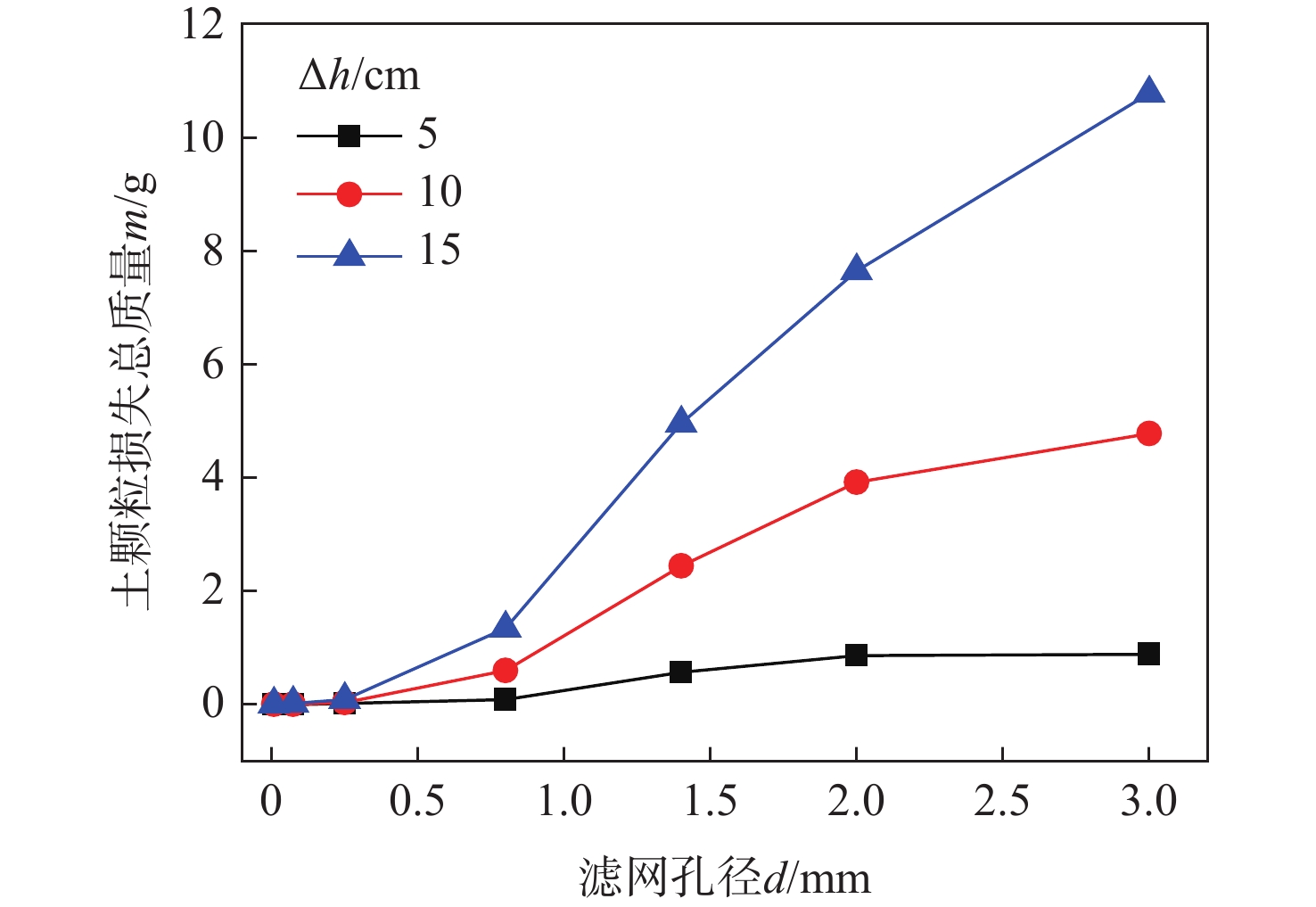

为了研究渗透破坏的机理,基于自行研发的径向渗透试验仪,开展了系列的不同滤网孔径条件下的砂土渗透破坏试验和砂土稳定渗透试验,研究了滤网孔径对砂土径向渗流特性的影响规律,分析了渗透试验过程中滤网孔径对渗透破坏的临界水头差、稳定渗流流速、土颗粒损失质量、土体径向渗透系数的影响。试验结果表明:滤网孔径对砂土的径向渗流特性具有重要影响;在渗透破坏试验中,减小滤网孔径可增大渗透破坏的临界水头差;在稳定渗透试验中,减小滤网孔径可有效降低砂土的渗透系数;同时土的细颗粒先于粗颗粒发生质量流失,仅当土颗粒的质量流失为零时,渗流流速才会达到最终稳定。

Abstract:Based on the self-developed radial penetration tester, a series of seepage failure tests and stable seepage tests on sand were carried out under various filter pore size conditions to study the influence of filter pore size on the radial permeation characteristics of sand. The influences of filter pore size on critical water head difference, seepage flow, mass loss of soil particles and radial permeability coefficient of sand were analyzed. The results show that the filter pore size has an important effect on the radial permeability of sand; The critical water head difference can be increased by decreasing the filter pore size in the seepage failure tests; Sand’s permeability coefficient can be efficiently decreased in the stable seepage tests by reducing the filter pore size; The mass loss of fine particles precedes that of coarse particles. If there is none of the mass loss of soil particles, the seepage velocity will be stable.

-

Key words:

- sand /

- penetration /

- filter /

- water /

- seepage failure

-

表 1 渗透破坏试验中的滤网孔径和丝径

Table 1. Pore diameter and wire diameter of filter selected for seepage failure tests

mm 滤网孔径 滤网丝径 3 0.5 4 0.6 5 0.7 6 0.9 8 1.2 10 表 2 稳定渗透试验中的滤网孔径和丝径

Table 2. Pore diameter and wire diameter of filter selected for stable seepage tests

mm 滤网孔径 滤网丝径 0.008 0.001 0.075 0.01 0.25 0.04 0.8 0.12 1.4 0.21 2 0.3 3 0.5 表 3 稳定渗透试验的最终渗流流速和土颗粒损失总质量

Table 3. Final seepage velocity and total mass loss of soil particles in stable permeability tests

滤网孔径/mm 稳定渗流流速/(mL·min−1) 土颗粒损失总质量/g 水头差5 cm 水头差10 cm 水头差15 cm 水头差5 cm 水头差10 cm 水头差15 cm 0.008 9 33 58 0 0.01 0.01 0.075 17 72 139 0 0.01 0.02 0.25 24 96 208 0.02 0.04 0.09 0.8 27 106 261 0.09 0.6 1.35 1.4 43 164 416 0.57 2.45 4.96 2 44 184 431 0.87 3.92 7.65 3 60 220 578 0.89 4.78 10.78 表 4 不同水头差的稳定渗流状态条件下的渗透系数

Table 4. Permeability coefficient of steady seepage flow at different water head heights

滤网孔径/mm 渗透系数/(cm·s−1) 水头差5 cm 水头差10 cm 水头差15 cm 0.008 0.001 73 0.001 58 0.001 23 0.075 0.003 35 0.003 45 0.002 96 0.25 0.004 60 0.004 60 0.004 43 0.8 0.005 07 0.005 08 0.005 56 1.4 0.008 33 0.007 86 0.008 86 2 0.008 55 0.008 86 0.009 00 3 0.011 50 0.010 54 0.012 37 -

[1] KE L, TAKAHASHI A. Strength reduction of cohesionless soil due to internal erosion induced by one-dimensional upward seepage flow[J]. Soils and Found, 2012, 52(4): 698-711. doi: 10.1016/j.sandf.2012.07.010 [2] MOFFAT R, FANNIN R J, GARNER S J. Spatial and temporal progression of internal erosion in cohesionless soil[J]. Canadian Geotechnical Journal, 2011, 48(3): 399-412. doi: 10.1139/T10-071 [3] 田大浪, 谢强, 宁越, 等. 间断级配砂砾石土的渗透变形试验研究[J]. 岩土力学, 2020, 41(11): 3663-3670. doi: 10.16285/j.rsm.2020.0253TIAN D L, XIE Q, NING Y, et al. Experimental investigation on seepage deformation of gap-graded sand-gravel soils[J]. Rock and Soil Mechanics, 2020, 41(11): 3663-3670(in Chinese). doi: 10.16285/j.rsm.2020.0253 [4] SION P V, LUCA M, AVRAM M. Researches concerning the configuration of geotextiles in the execution of regulatory works in the riverbeds[J]. The Annals of "Dunarea de Jos" University of Galati. Fascicle IX, Metallurgy and Materials Science, 2020, 43(3): 54-60. [5] FANNIN J. Karl Terzaghi: From theory to practice in geotechnical filter design[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2008, 134(3): 267-276. doi: 10.1061/(ASCE)1090-0241(2008)134:3(267) [6] 杨佩瑶, 王红雨, 张刚, 等. 不同反滤准则及其在宁南山区水库设计中的应用[J]. 水利水运工程学报, 2021(1): 86-94. doi: 10.12170/20191227001YANG P Y, WANG H Y, ZHANG G, et al. Different filter design criteria and their applications to reservoir design in mountainous areas of southern Ningxia[J]. Hydro-Science and Engineering, 2021(1): 86-94(in Chinese). doi: 10.12170/20191227001 [7] 段国军, 张顺福, 介玉新. 滤网孔径和层数对反滤保土效果的影响分析[J]. 水利水电技术, 2020, 51(1): 39-45. doi: 10.13928/j.cnki.wrahe.2020.01.005DUAN G J, ZHANG S F, JIE Y X. Influence of pore size and filter layers on soil retention effect[J]. Water Resources and Hydropower Engineering, 2020, 51(1): 39-45(in Chinese). doi: 10.13928/j.cnki.wrahe.2020.01.005 [8] 康顺祥, 陆世强. 天然滤层模型[J]. 防渗技术, 1997, 3(4): 1-5.KANG S X, LU S Q. Modal of natural filtering layer[J]. Technique of Seepage Prevention, 1997, 3(4): 1-5(in Chinese). [9] WATSON P D J, JOHN N W M. Geotextile filter design and simulated bridge formation at the soil-geotextile interface[J]. Geotextiles and Geomembranes, 1999, 17(5-6): 265-280. doi: 10.1016/S0266-1144(99)00013-8 [10] 朱积军, 简鸿福, 吕辉. 反滤土工布淤堵对土坝渗流稳定影响分析[J]. 水利规划与设计, 2019(6): 99-101. doi: 10.3969/j.issn.1672-2469.2019.06.027ZHU J J, JIAN H F, LV H. Analysis of influence of anti-filter geotextiles silting on seepage stability of earth dam[J]. Water Resources Planning and Design, 2019(6): 99-101(in Chinese). doi: 10.3969/j.issn.1672-2469.2019.06.027 [11] 唐正涛, 孙爱国, 熊荣军, 等. 模拟现场工况条件下的无纺布淤堵试验研究[J]. 水运工程, 2017(5): 87-91. doi: 10.3969/j.issn.1002-4972.2017.05.016TANG Z T, SUN A G, XIONG R J, et al. Clogging tests study on non-woven fabrics under simulated on-site operating conditions[J]. Port & Waterway Engineering, 2017(5): 87-91(in Chinese). doi: 10.3969/j.issn.1002-4972.2017.05.016 [12] 杨春和, 李泽华, 冒海军, 等. 尾矿坝排渗系统淤堵机理试验研究[J]. 广西大学学报(自然科学版), 2019, 44(3): 845-854. doi: 10.13624/j.cnki.issn.1001-7445.2019.0845YANG C H, LI Z H, MAO H J, et al. Experimental study on the clogging mechanism of drainage system in tailings dam[J]. Journal of Guangxi University(Natural Science Edition), 2019, 44(3): 845-854(in Chinese). doi: 10.13624/j.cnki.issn.1001-7445.2019.0845 [13] 邓惠森. 岩土层垂向渗透系数与径向渗透系数[J]. 工程勘察, 1993, 21(1): 44-45.DENG H S. The vertical permeability coefficient and radial permeability coefficient of strata[J]. Geotechnical Investigation and Surveying, 1993, 21(1): 44-45(in Chinese). [14] RICHARDS K S, REDDY K R. Experimental investigation of initiation of backward erosion piping in soils[J]. Géotechnique, 2012, 62(10): 933-942. [15] 殷延洲, 崔一飞, 刘定竺, 等. 松散土体中细颗粒运移的微观过程研究[J]. 工程科学与技术, 2019, 51(4): 21-29.YIN Y Z, CUI Y F, LIU D Z, et al. Study on microscopic process of fine particle migration in loose soil[J]. Advanced Engineering Sciences, 2019, 51(4): 21-29(in Chinese). 期刊类型引用(0)

其他类型引用(2)

-

下载:

下载: