-

摘要:

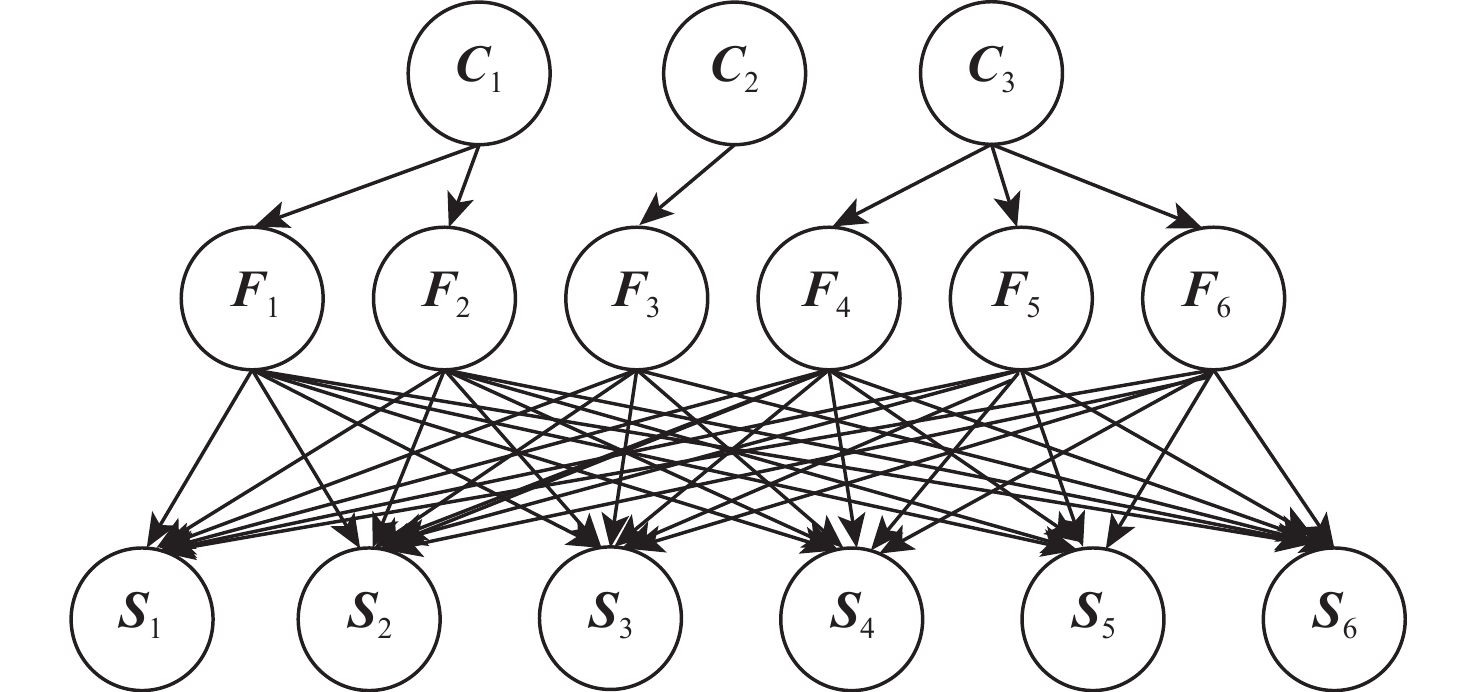

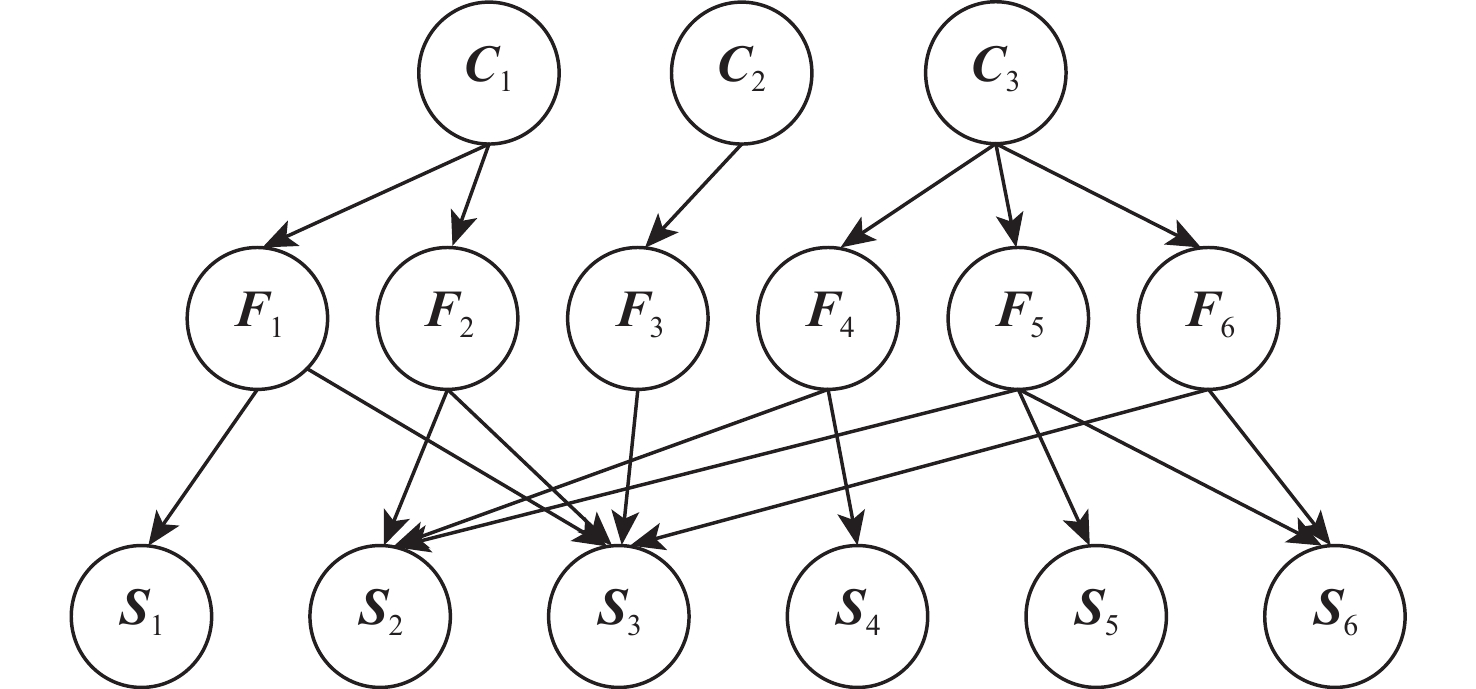

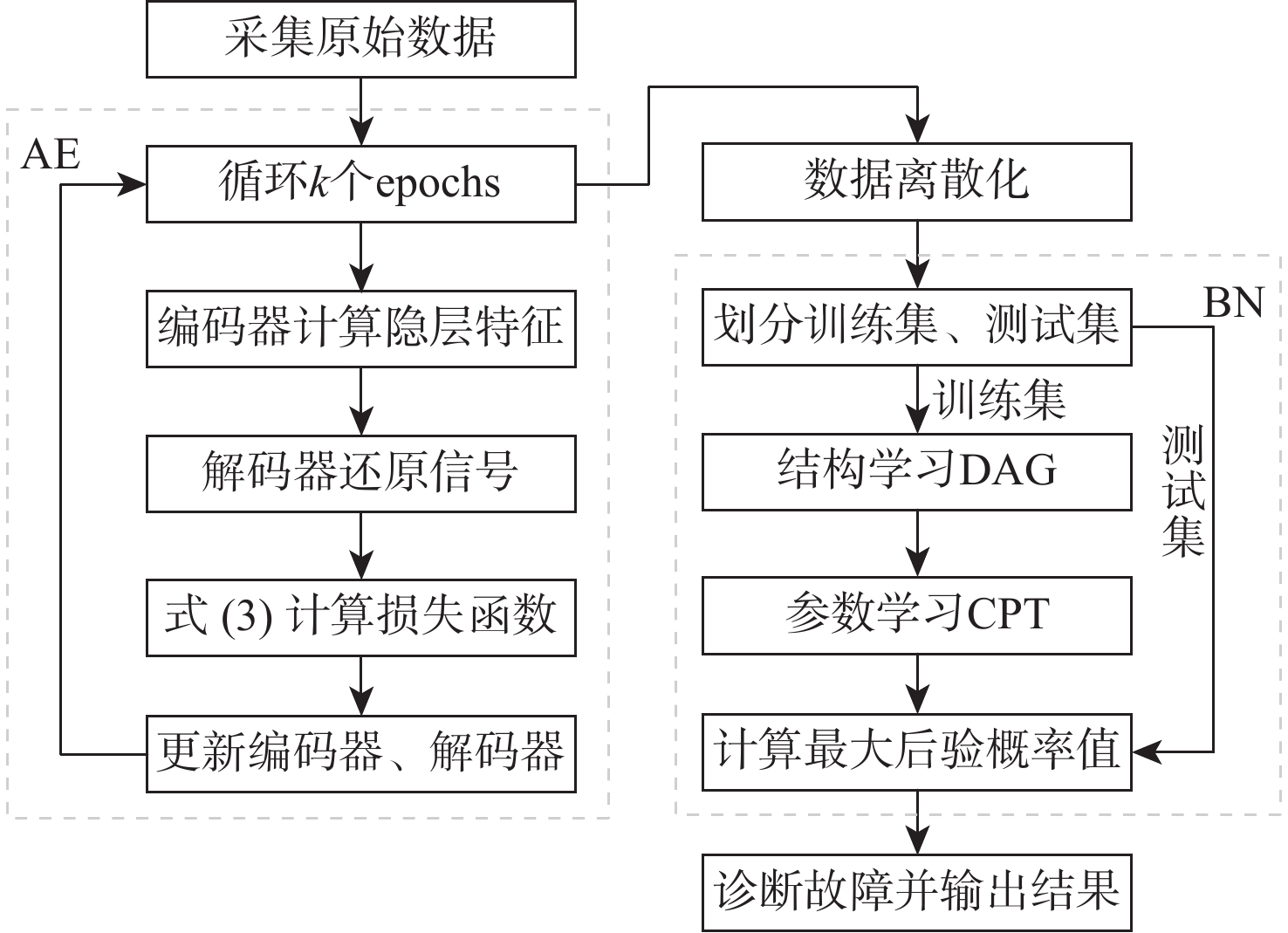

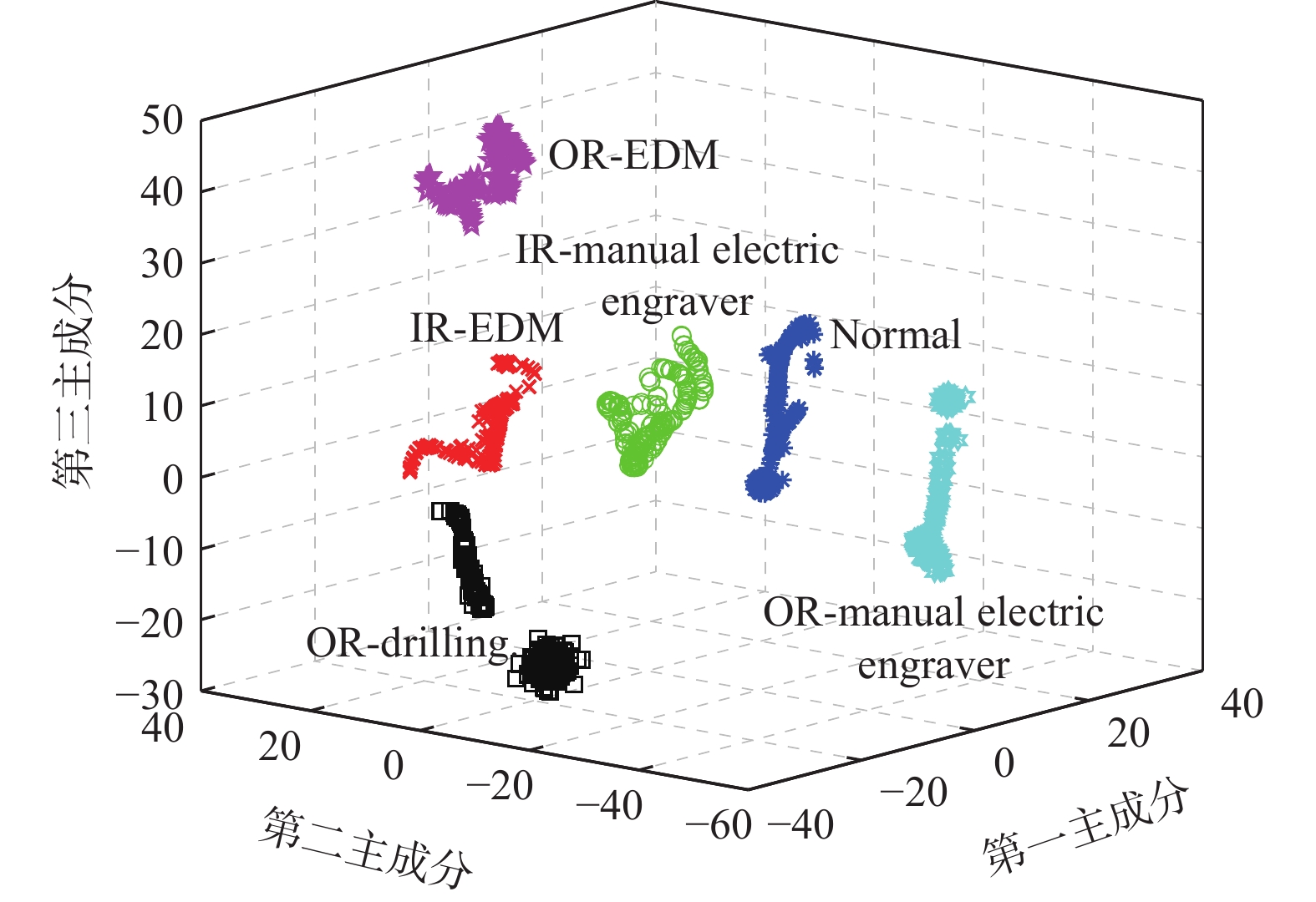

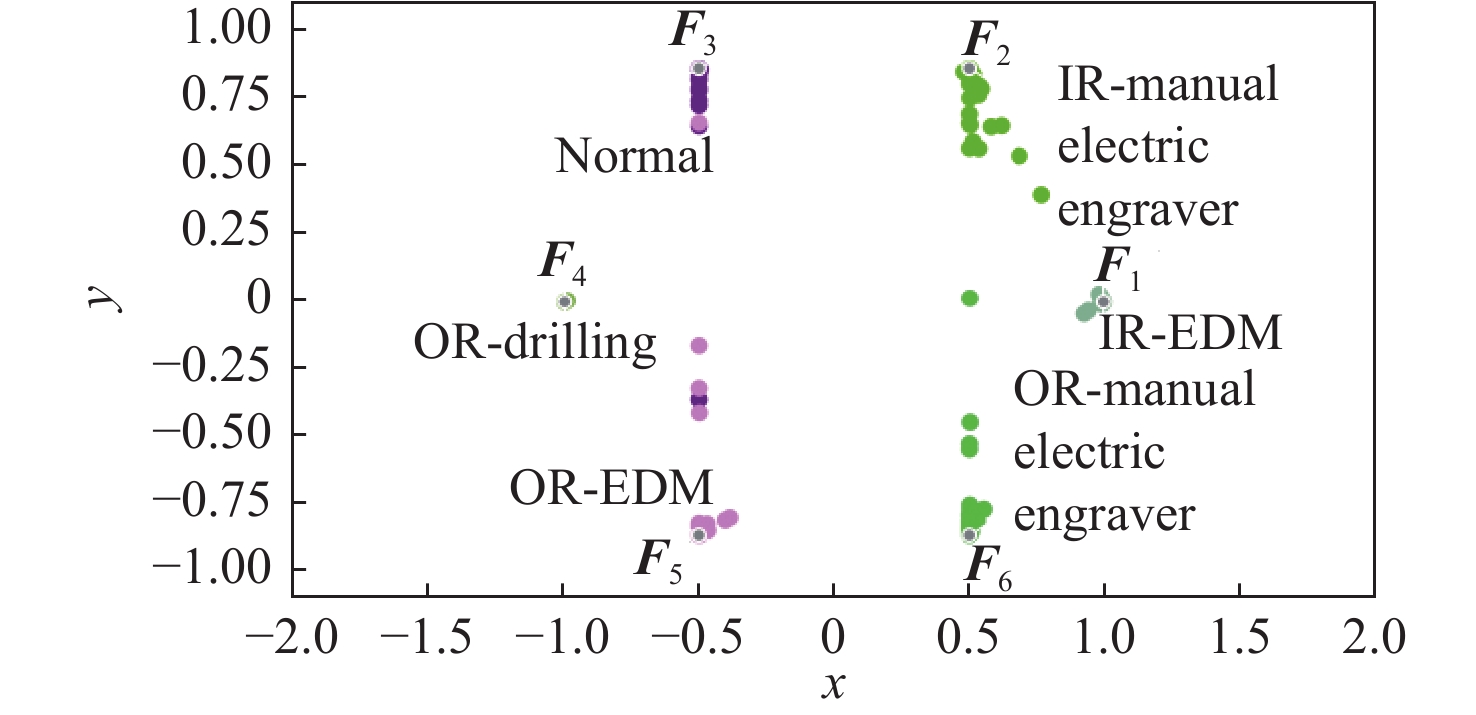

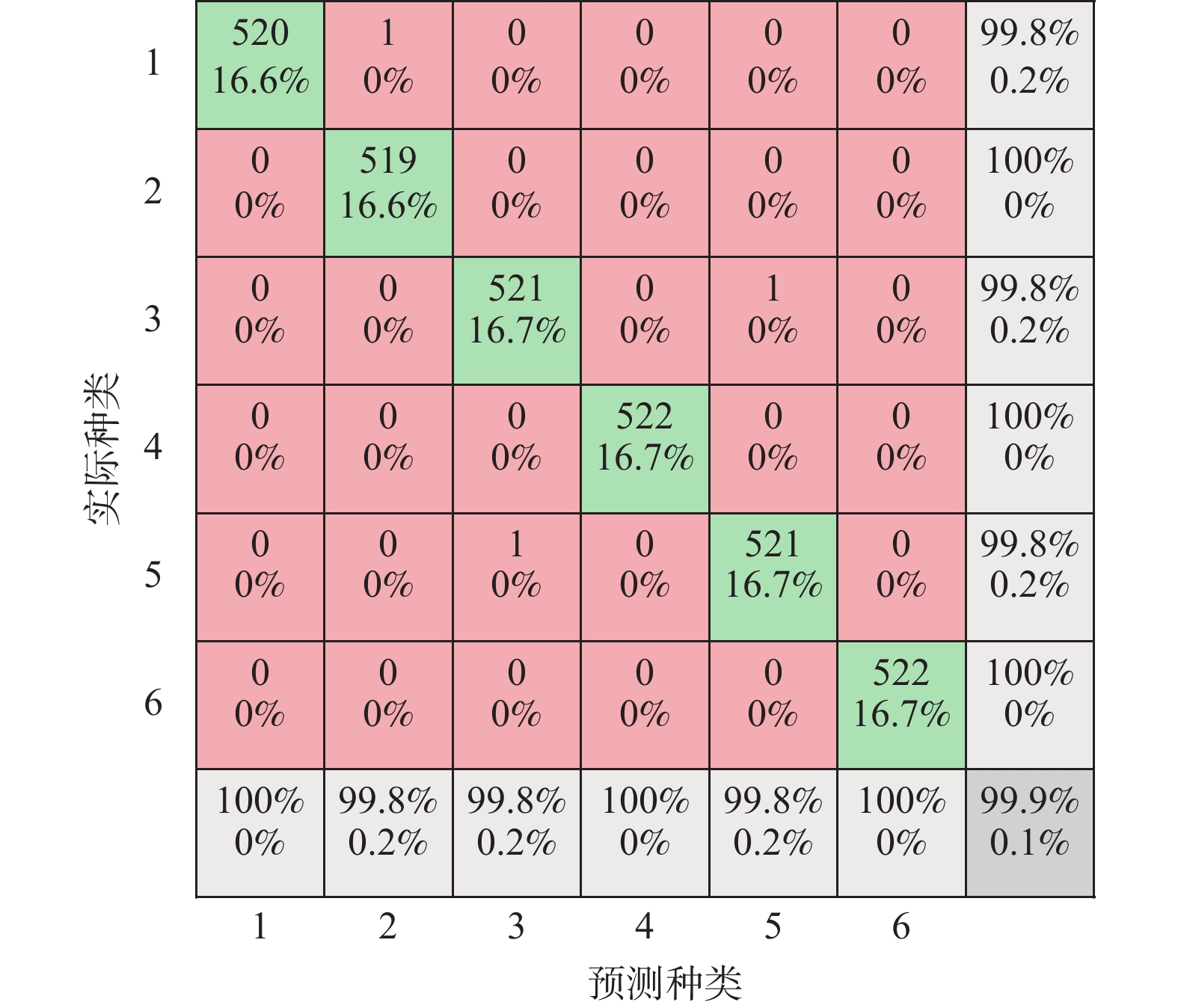

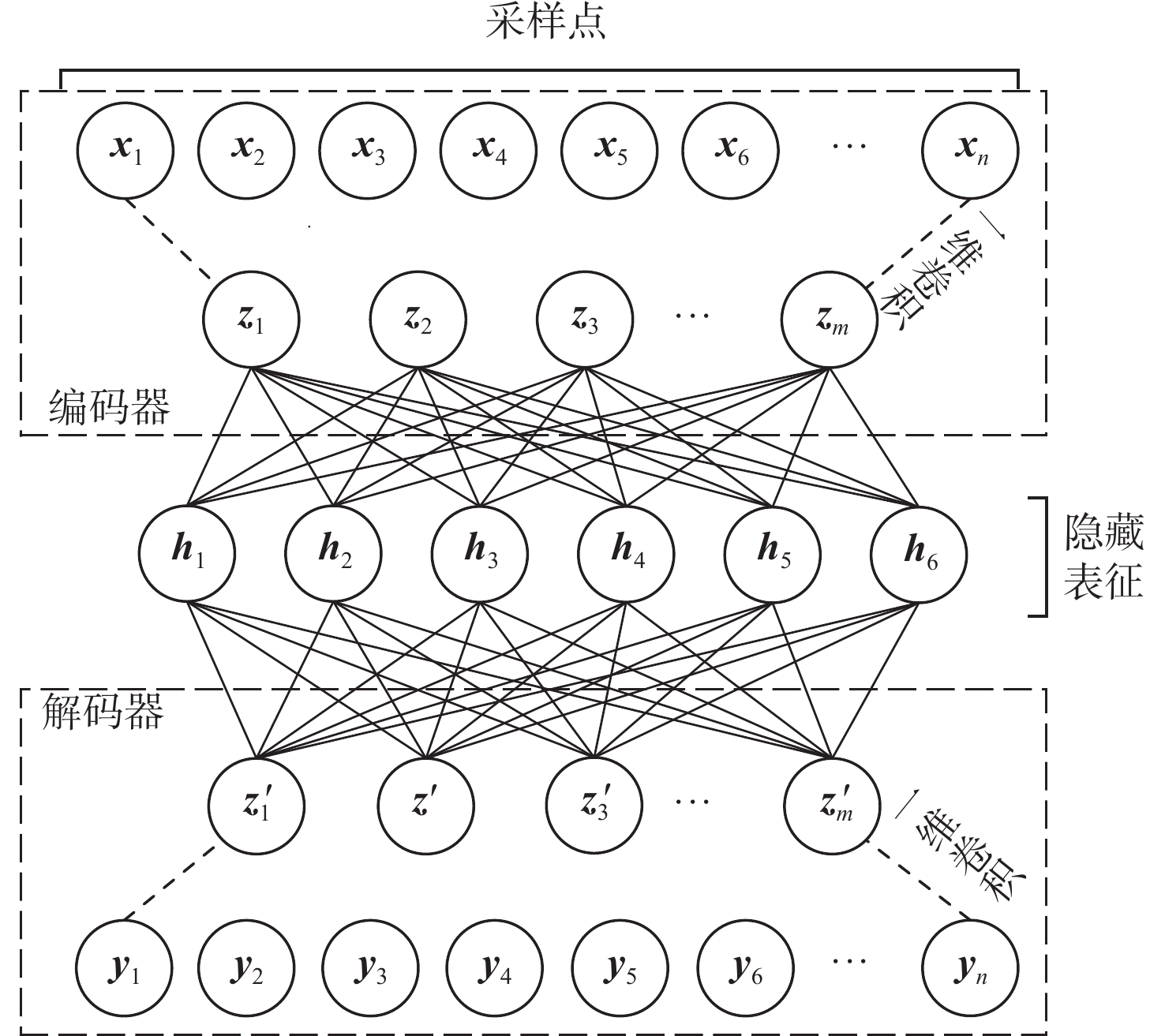

为解决风力发电机在复杂工况及耦合性、不确定性条件下故障识别的准确性问题,提出了一种基于自动编码器(AE)与贝叶斯网络(BN)的AE-BN故障诊断方法。采用AE对电流信号进行特征提取,得到能够高度表征信号的特征分量;基于故障与特征之间的因果关系,建立由故障位置、故障状态和故障特征搭建的三层BN;将AE的特征分量与BN的拓扑结构相结合建立风力发电机故障诊断模型,解决故障诊断中的不确定性问题,提高多故障诊断的准确性。实验结果表明:所提方法能够对故障特征信号进行分析及诊断,精确辨识不同故障类型,相比K近邻算法等具有明显优势。

Abstract:To solve the accuracy of fault identification of wind turbines under complex working conditions, coupling, and uncertainty, an AE-BN fault diagnosis method based on a auto-encoder (AE) and Bayesian network (BN) is proposed. AE is used to extract the characteristics of the current signal, and the characteristic component that can highly characterize the signal is obtained; based on the causal relationship between fault and feature, a three-layer BN composed of fault location, fault state, and fault feature is established; The wind turbine fault diagnostic model is then established, the uncertainty problem in fault diagnosis is solved, and the precision of multi fault diagnosis is enhanced by combining the characteristic component of AE with the topology of BN. Experimental results show that the proposed method can analyze and diagnose fault characteristic signals and accurately identify different fault types, which has obvious advantages over other algorithms.

-

Key words:

- fault diagnosis /

- auto-encoder /

- Bayesian network /

- structure learning /

- feature extraction

-

表 1 结构评分对比

Table 1. Comparison of structure scores

结构搭建方法 BDeu/104 K2/104 BIC/104 贝叶斯搜索方法 −3.2329 −3.2417 −3.2384 贪婪厚细化方法 −3.0882 −3.0993 −3.1018 爬山搜索算法 −2.2358 −2.2754 −2.7692 表 2 不同的运行条件

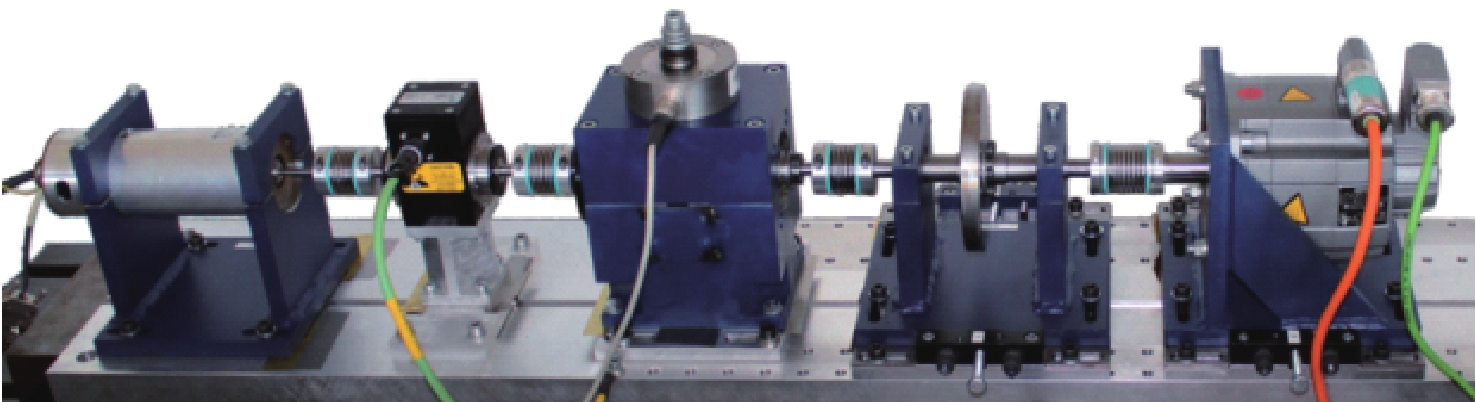

Table 2. Different operating conditions

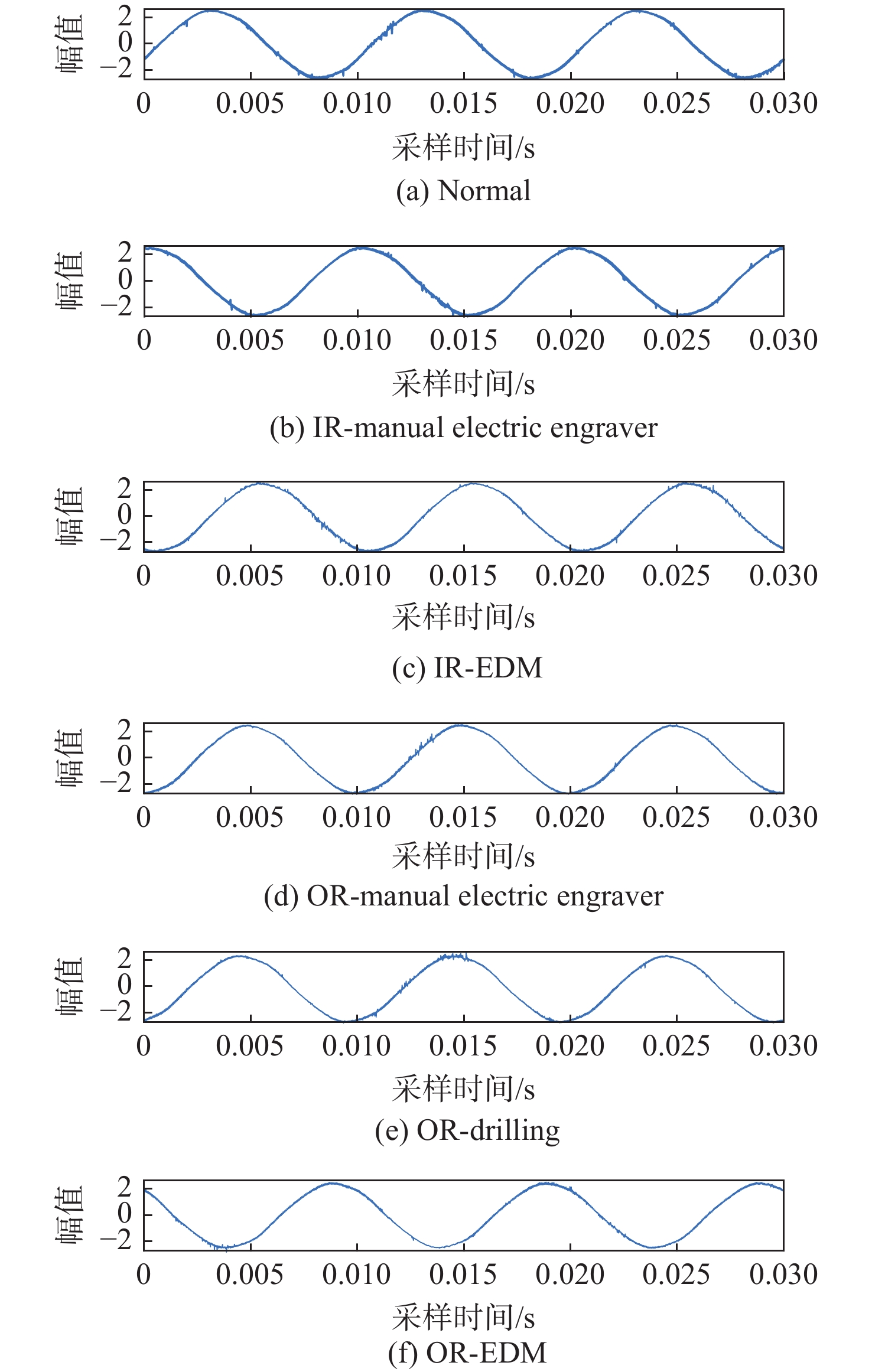

运行工况 转速/(r·min−1) 径向力/N 负载转矩/(N·m) K0 1500 1000 0.7 K1 1500 1000 0.1 K2 900 1000 0.7 K3 1500 400 0.7 表 3 故障类型与状态标签

Table 3. Fault types and status labels

故障位置 故障类型 轴承代码 标签 C1 IR-EDM KI01 1 C1 IR-manual electric engraver KI05 2 C2 Normal K002 3 C3 OR-drilling KA07 4 C3 OR-EDM KA01 5 C3 OR-manual electric engraver KA05 6 注:Normal表示正常数据,将其作为一种特殊的故障与其余5种故障一起进行故障分类的研究。 表 4 贝叶斯网络子节点条件概率

Table 4. Conditional probability of subnodes of Bayesian network

节点 节点取值 父节点取值 条件概率 F1 0 0 0.4807 F2 0 0,1 0.5111 F2 0 1,0 0.4962 F2 0 1,1 0.5128 F3 0 0,0 0.3068 F3 0 0,1 0.6031 F3 0 1,0 0.5204 F3 0 1,1 0.3753 F4 0 0.3050 F5 0 0.4033 F6 0 0,1 0.4929 F6 0 1,0 0.4872 表 5 4种工况下不同故障诊断模型的分类精度对比

Table 5. Comparison of classification accuracy of different fault diagnosis models under four types of working conditions

运行工况 VMD-KNN AE-KNN AE-BN K0 0.7124 0.8733 0.9983 K1 0.6324 0.8914 0.9772 K2 0.7231 0.8932 0.9955 K3 0.7377 0.8715 0.9981 -

[1] 曾军, 陈艳峰, 杨苹, 等. 大型风力发电机组故障诊断综述[J]. 电网技术, 2018, 42(3): 849-860. doi: 10.13335/j.1000-3673.pst.2017.2311ZENG J, CHEN Y F, YANG P, et al. Review of fault diagnosis methods of large-scale wind turbines[J]. Power System Technology, 2018, 42(3): 849-860(in Chinese). doi: 10.13335/j.1000-3673.pst.2017.2311 [2] 陈是扦, 彭志科, 周鹏. 信号分解及其在机械故障诊断中的应用研究综述[J]. 机械工程学报, 2020, 56(17): 91-107. doi: 10.3901/JME.2020.17.091CHEN S Q, PENG Z K, ZHOU P. Review of signal decomposition theory and its applications in machine fault diagnosis[J]. Journal of Mechanical Engineering, 2020, 56(17): 91-107(in Chinese). doi: 10.3901/JME.2020.17.091 [3] 唐贵基, 王晓龙. 参数优化变分模态分解方法在滚动轴承早期故障诊断中的应用[J]. 西安交通大学学报, 2015, 49(5): 73-81. doi: 10.7652/xjtuxb201505012TANG G J, WANG X L. Parameter optimized variational mode decomposition method with application to incipient fault diagnosis of rolling bearing[J]. Journal of Xi’an Jiaotong University, 2015, 49(5): 73-81(in Chinese). doi: 10.7652/xjtuxb201505012 [4] ZHONG J, YANG K. Failure prediction for linear ball bearings based on wavelet transformation and self-organizing map[C]//2018 IEEE 4th Information Technology and Mechatronics Engineering Conference (ITOEC). Piscataway: IEEE Press, 2018: 34-38. [5] 张超, 陈建军, 郭迅. 基于EMD能量熵和支持向量机的齿轮故障诊断方法[J]. 振动与冲击, 2010, 29(10): 216-220. doi: 10.3969/j.issn.1000-3835.2010.10.004ZHANG C, CHEN J J, GUO X. A gear fault diagnosis method based on EMD energy entropy and SVM[J]. Journal of Vibration and Shock, 2010, 29(10): 216-220(in Chinese). doi: 10.3969/j.issn.1000-3835.2010.10.004 [6] CHIANG L H, KOTANCHEK M E, KORDON A K, et al. Fault diagnosis based on Fisher discriminant analysis and support vector machines[J]. Computers & Chemical Engineering, 2004, 28(8): 1389-1401. [7] SHAO S, MCALEER S, YAN R, et al. Highly accurate machine fault diagnosis using deep transfer learning[J]. IEEE Transactions on Industrial Informatics, 2019, 15(4): 2446-2455. doi: 10.1109/TII.2018.2864759 [8] SHAO H, JIANG H, ZHAO H, et al. A novel deep autoencoder feature learning method for rotating machinery fault diagnosis[J]. Mechanical Systems and Signal Processing, 2017, 95: 187-204. doi: 10.1016/j.ymssp.2017.03.034 [9] 陈东超. 基于贝叶斯网络的汽轮发电机组故障诊断方法及应用研究[D]. 北京: 华北电力大学(北京), 2018.CHEN D C. Research on methods and application of fault diagnosis for turbo-generator unit based on bayesian network[D]. Beijing: North China Electric Power University (Beijing), 2018(in Chinese). [10] 王双成, 张立, 郑飞. 异步动态贝叶斯网络分类器研究[J]. 计算机学报, 2020, 43(9): 1737-1754. doi: 10.11897/SP.J.1016.2020.01737WANG S C, ZHANG L, ZHENG F. Asynchronous dynamic Bayesian network classifiers[J]. Chinese Journal of Computers, 2020, 43(9): 1737-1754(in Chinese). doi: 10.11897/SP.J.1016.2020.01737 [11] 仝兆景, 芦彤, 秦紫霓. 基于PSO-VMD与贝叶斯网络的滚动轴承故障诊断[J]. 河南理工大学学报(自然科学版), 2021, 40(1): 95-104. doi: 10.16186/j.cnki.1673-9787.2019060034TONG Z J, LU T, QIN Z N. Fault diagnosis of rolling bearing based on PSO-VMD and Bayesian network[J]. Journal of Henan Polytechnic University (Natural Science), 2021, 40(1): 95-104(in Chinese). doi: 10.16186/j.cnki.1673-9787.2019060034 [12] 王金鑫, 王忠巍, 马修真, 等. 基于贝叶斯网络的柴油机润滑系统多故障诊断[J]. 控制与决策, 2019, 34(6): 1187-1194. doi: 10.13195/j.kzyjc.2017.1399WANG J X, WANG Z W, MA X Z, et al. Diagnosis of multiple faults of diesel engine lubrication system based on Bayesian networks[J]. Control and Decision, 2019, 34(6): 1187-1194(in Chinese). doi: 10.13195/j.kzyjc.2017.1399 [13] 尹爱军, 王昱, 戴宗贤, 等. 基于变分自编码器的轴承健康状态评估[J]. 振动、测试与诊断, 2020, 40(5): 1011-1016.YIN A J, WANG Y, DAI Z X, et al. Evaluation method of bearing health state based on variational auto-encoder[J]. Journal of Vibration, Measurement & Diagnosis, 2020, 40(5): 1011-1016(in Chinese). [14] 孙叶, 王钢, 魏东. 贝叶斯网络在智能电网研究中的应用[J]. 自动化应用, 2020(7): 108-109. doi: 10.19769/j.zdhy.2020.07.039SUN Y, WANG G, WEI D. The application of Bayesian network in the research of smart grid[J]. Automation Application, 2020(7): 108-109(in Chinese). doi: 10.19769/j.zdhy.2020.07.039 [15] CAI B, HUANG L, XIE M. Bayesian networks in fault diagnosis[J]. IEEE Transactions on Industrial Informatics, 2017, 13(5): 2227-2240. doi: 10.1109/TII.2017.2695583 [16] 李硕豪, 张军. 贝叶斯网络结构学习综述[J]. 计算机应用研究, 2015, 32(3): 641-646. doi: 10.3969/j.issn.1001-3695.2015.03.001LI S H, ZHANG J. Review of Bayesian networks structure learning[J]. Application Research of Computers, 2015, 32(3): 641-646(in Chinese). doi: 10.3969/j.issn.1001-3695.2015.03.001 [17] WEN Z, KVETON B, ERIKSSON B, et al. Sequential Bayesian search[C]//Proceedings of the 30th International Conference on Machine Learning. New York: ACM, 2013: 226-234. [18] CHENG J, BELL D A, LIU W. An algorithm for Bayesian belief network construction from data[C]//Proceedings of the 6th International Workshop on Artificial Intelligence and Statistics. Amsterdam: Elesvier, 1997: 83-90. [19] CONSTANTINOU A C, LIU Y, CHOBTHAM K, et al. Large-scale empirical validation of Bayesian network structure learning algorithms with noisy data[J]. International Journal of Approximate Reasoning, 2021, 131: 151-188. doi: 10.1016/j.ijar.2021.01.001 [20] BEHJATI S, BEIGY H. Improved K2 algorithm for Bayesian network structure learning[J]. Engineering Applications of Artificial Intelligence, 2020, 91: 103617. doi: 10.1016/j.engappai.2020.103617 [21] 刘浩然, 王念太, 王毅, 等. 基于V-结构&对数似然函数定向与禁忌爬山的贝叶斯网络结构算法[J]. 电子与信息学报, 2021, 43(11): 3272-3281. doi: 10.11999/JEIT210032LIU H R, WANG N T, WANG Y, et al. Bayesian network structure algorithm based on V-structure & Log-likelihood orientation and tabu hill climbing[J]. Journal of Electronics & Information Technology, 2021, 43(11): 3272-3281(in Chinese). doi: 10.11999/JEIT210032 [22] LESSMEIER C, KIMOTHO J K, ZIMMER D, et al. Condition monitoring of bearing damage in electromechanical drive systems by using motor current signals of electric motors: A benchmark data set for data-driven classification[C]//European Conference of the Prognostics and Health Management Society, 2016: 1-17. [23] VAN DER MAATEN L, HINTON G. Visualizing data using t-SNE[J]. Journal of Machine Learning Research, 2008, 9: 2579-2605. -

下载:

下载: