Redundancy design of a FADS system on a complex leading-edge vehicle using neural network approach

-

摘要:

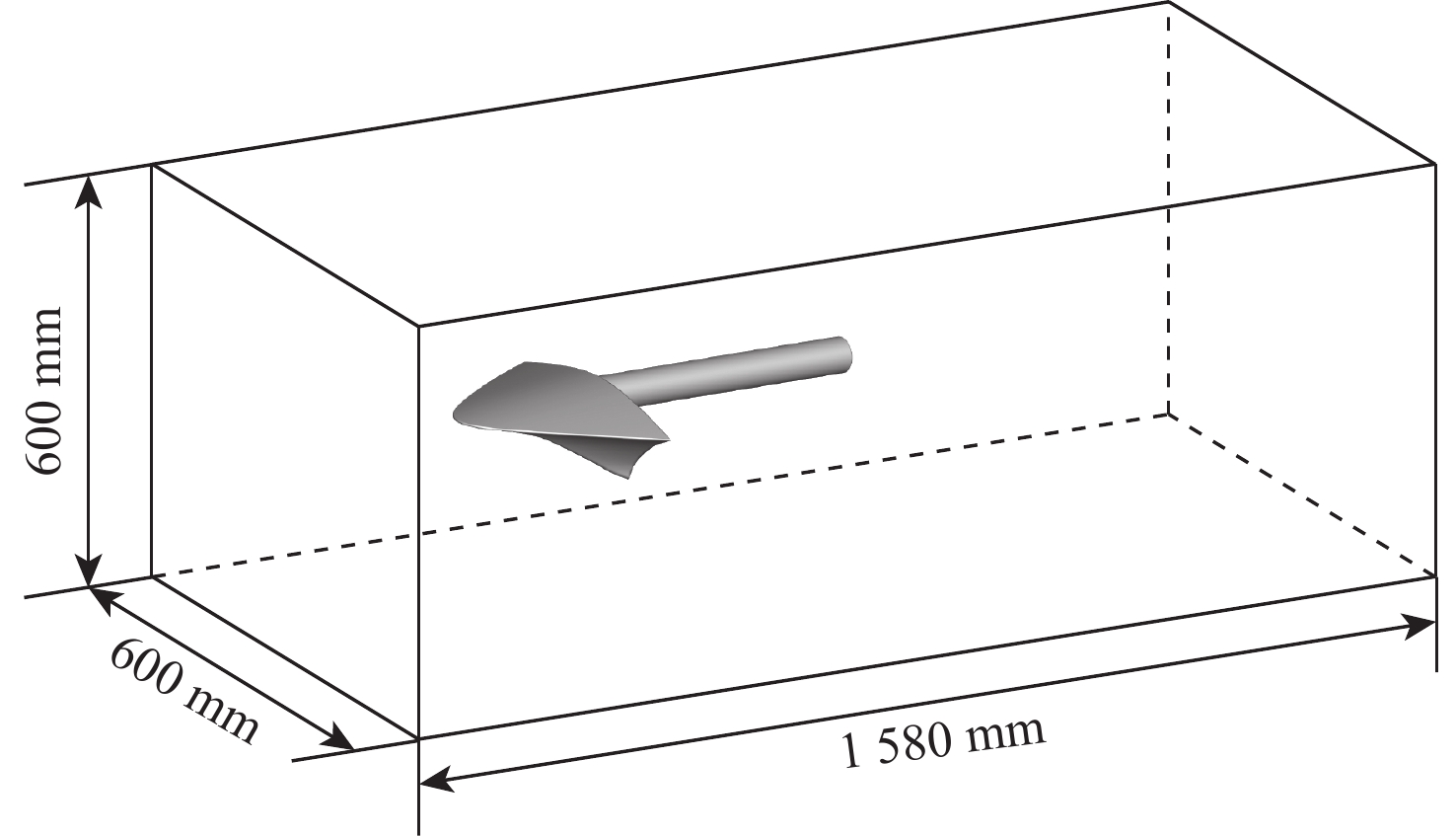

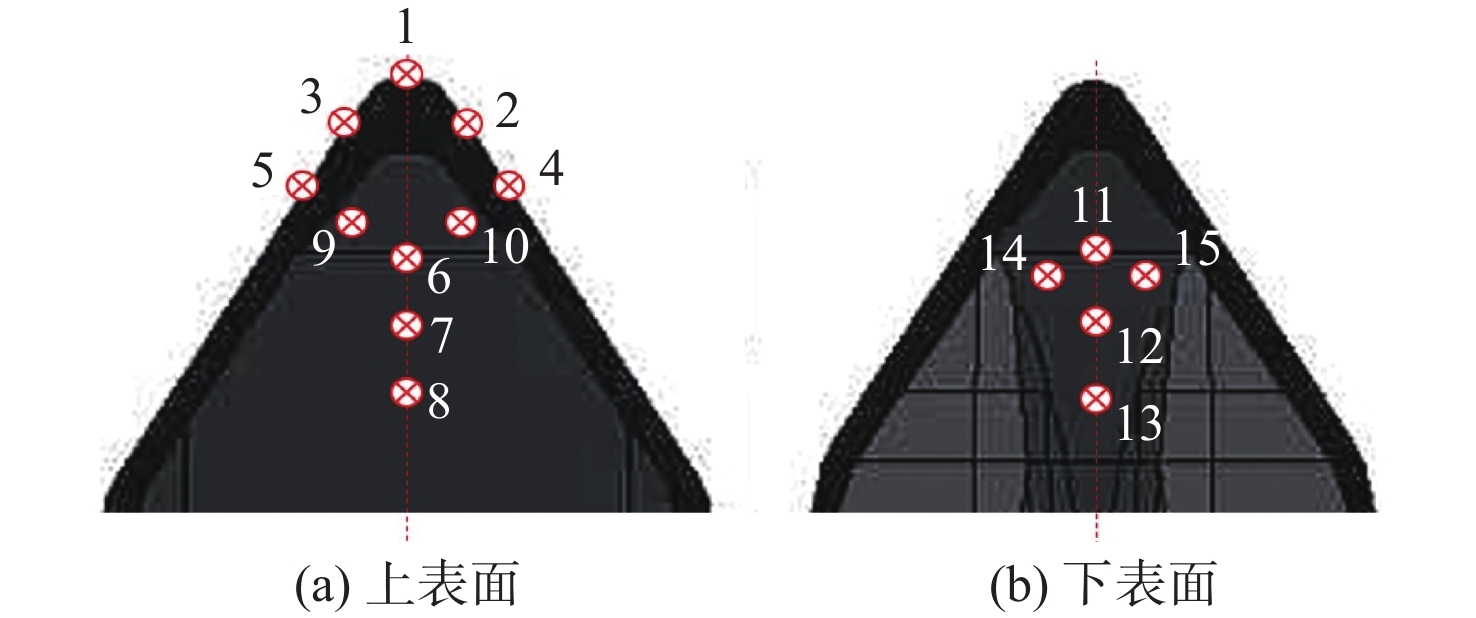

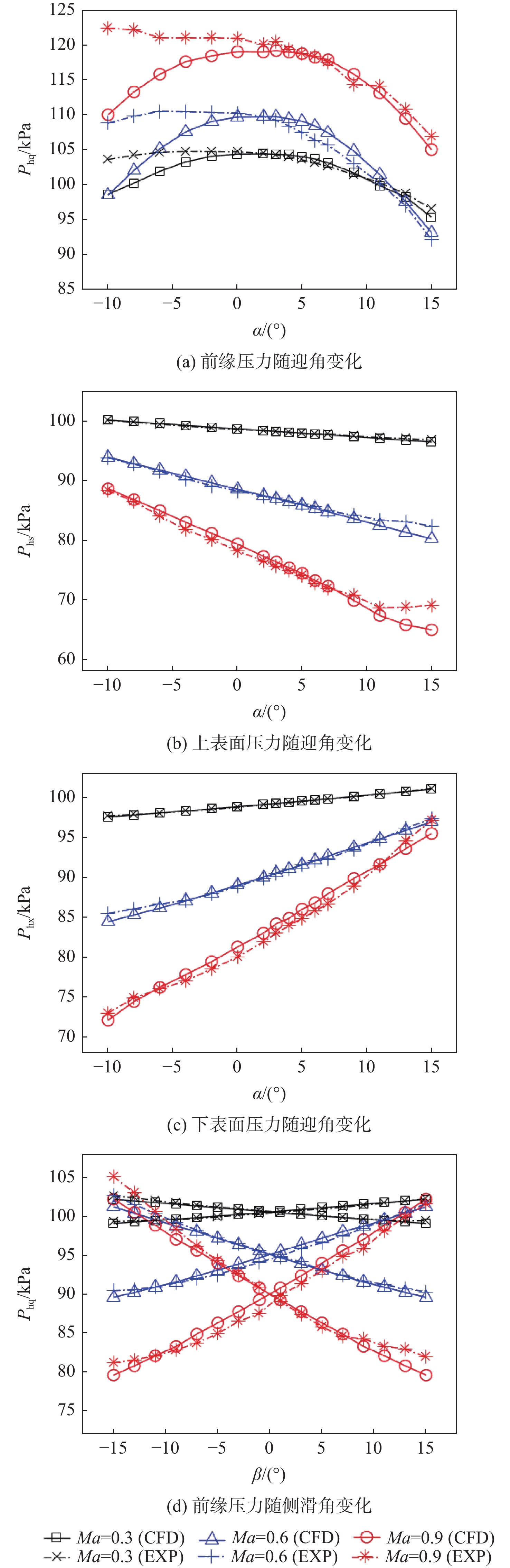

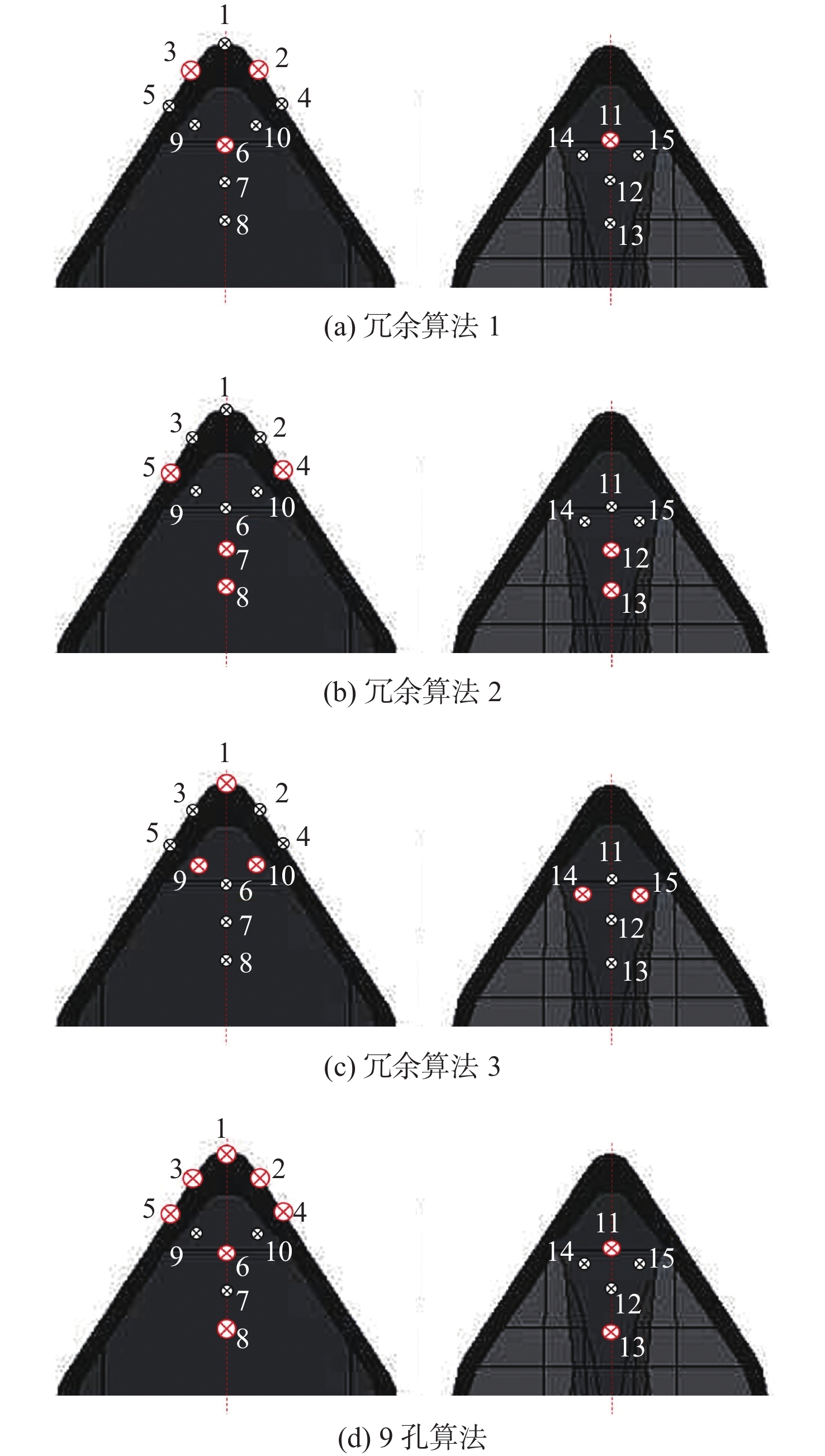

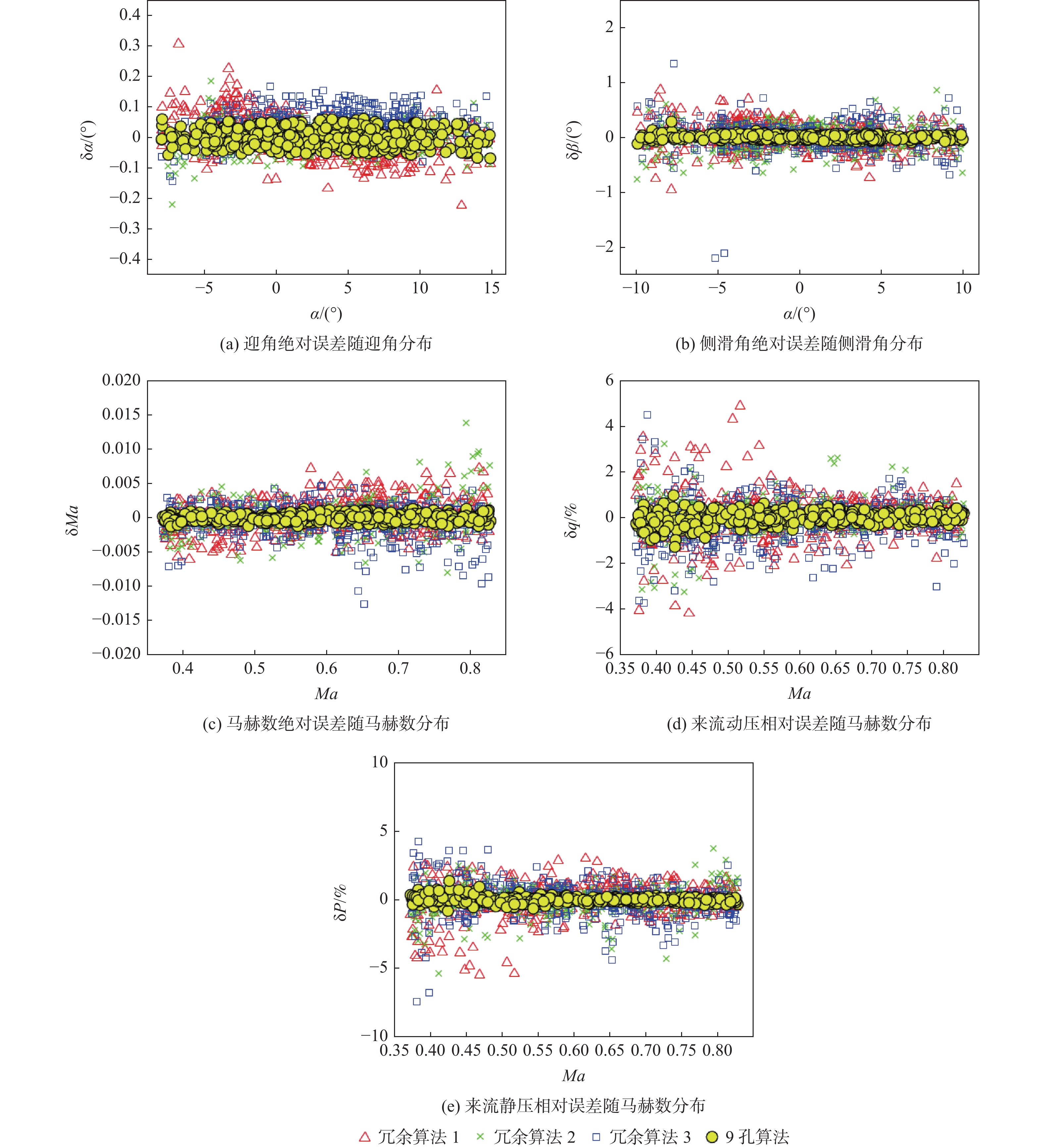

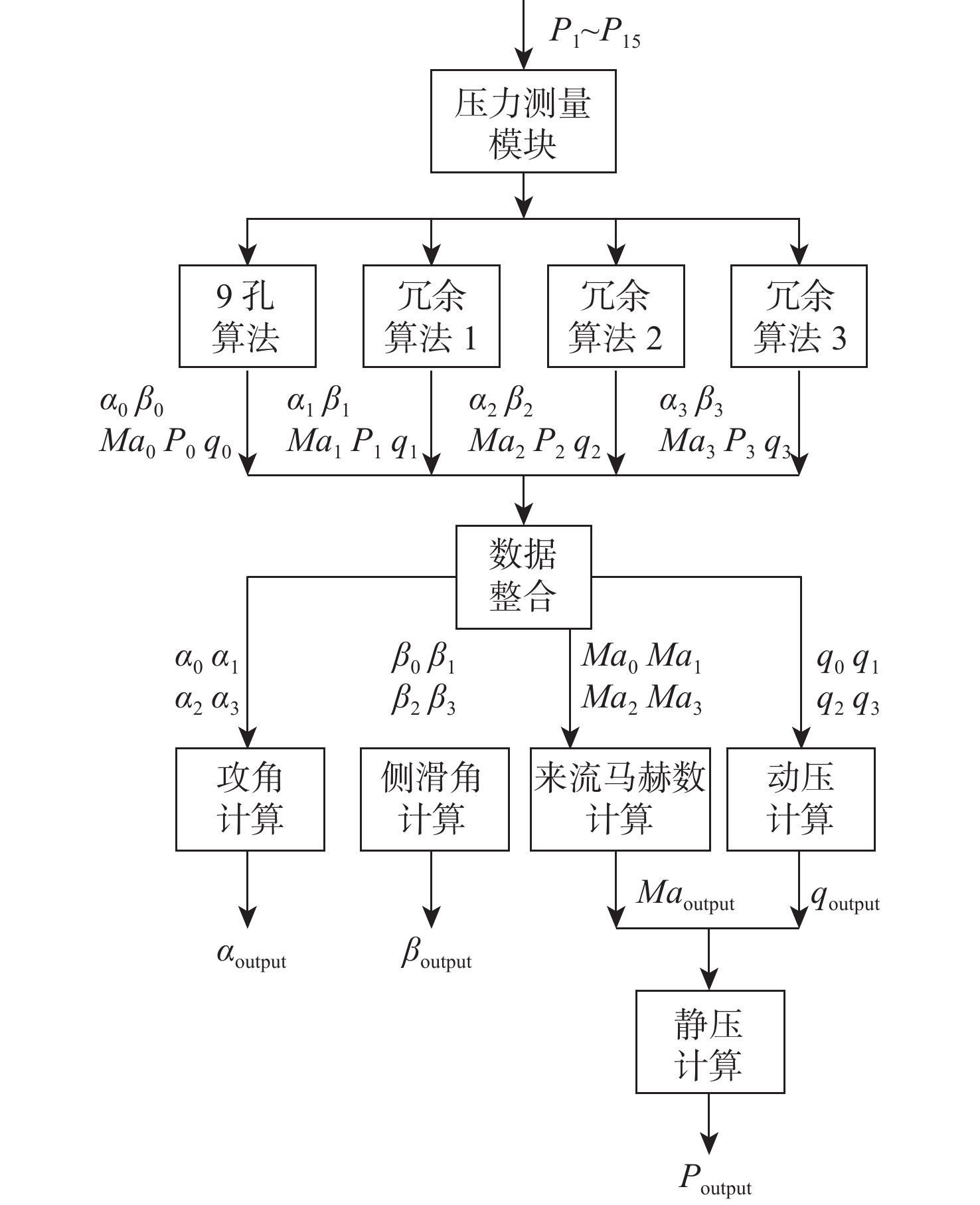

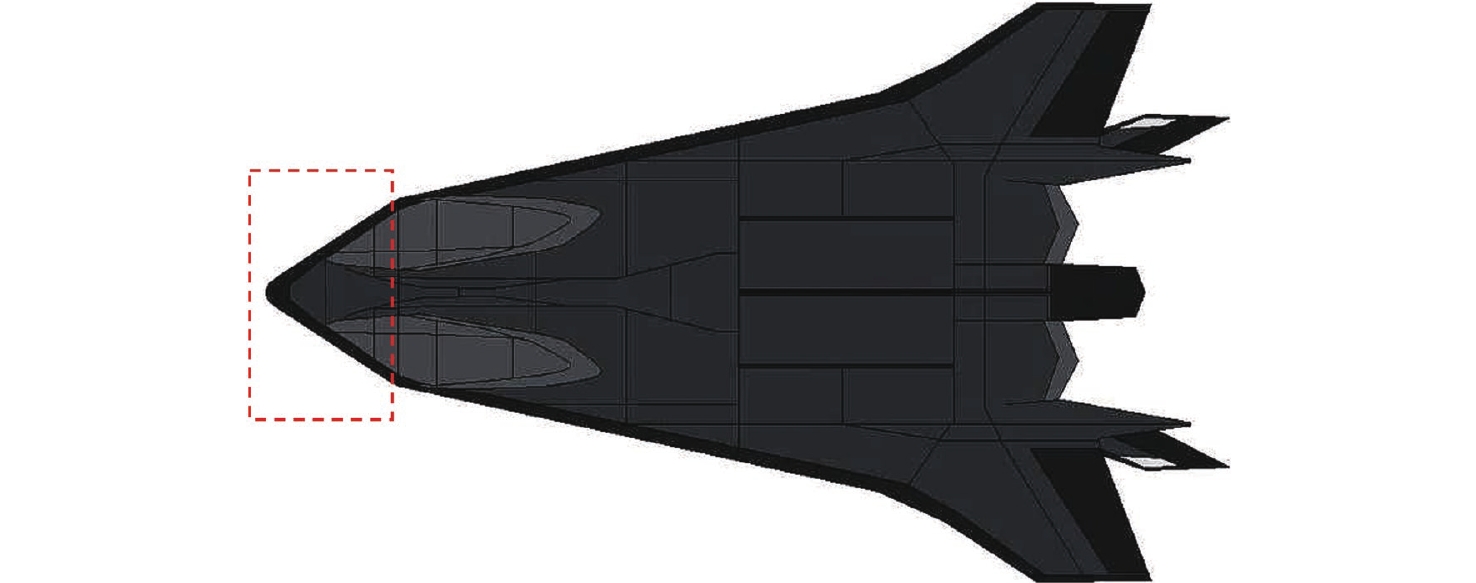

嵌入式大气数据传感(FADS)系统基于飞行器表面压力测量解算迎角、侧滑角、马赫数、来流动压与静压等飞行参数,能够有效解决探出机体的空速管前缘无法适应高超声速飞行器在巡航阶段所面临的严酷气动加热问题,同时满足飞行器对隐身性能的需求。目前,关于神经网络方法及FADS系统用于复杂型面前缘飞行器的分析和研究工作较少。针对自主返回的高超声速飞行器在着陆阶段的亚/跨声速条件,考虑薄前缘和进气道部件等影响开展复杂前缘飞行器的头部FADS系统冗余设计和验证。在复杂前缘飞行器头部开设15个测压孔,通过大量精细化数值仿真建立飞行器在不同来流条件下的压力数据库,并利用风洞试验对典型工况进行验证。针对复杂型面前缘飞行器,基于压力数据建立4套神经网络算法并开展冗余设计研究,包括1套9孔算法与3套冗余算法。其中,9孔算法的精度较高,对迎角的解算误差在0.07°以内,对侧滑角的解算误差在0.3°以内,对马赫数的解算误差在0.0012以内,对来流动压与静压的解算相对误差均在1.5%以内。此外,建立具有一定容错性的系统解算流程,在任意单个测压孔失效的情况下能够继续保持来流参数的有效输出。

-

关键词:

- 嵌入式大气数据传感系统 /

- 复杂前缘 /

- 神经网络 /

- 数值模拟 /

- 风洞试验

Abstract:In order to gather airspeed and aerodynamic orientation for hypersonic vehicles, flush air data sensing (FADS) systems are used in place of pitot tubes. This eliminates the issue of intense hypersonic heating caused by the poked-out pitot tube and concurrently enhances the vehicle's stealth performance. At present, there is less analysis and research work on neural network methods and FADS systems for complex profile leading-edge hypersonic vehicles. The impacts of thin leading edge and inlet components were taken into consideration during the redundant design and verification of the FADS systems with complicated profile leading edge, which was aimed at the subsonic/transonic conditions of autonomous return hypersonic vehicles in the landing stage. In the present study, the FADS systems on a typical complex profile sharp-nosed hypersonic vehicles with 15 integrated pressure orifices have been investigated numerically and experimentally. The pressure database has been set up by numerical simulations, with typical conditions verified through wind tunnel experiments. For complex leading-edge vehicle, four sets of FADS algorithms were constructed based on the neural network approach and redundancy design research was carried out, including 1 nine-orifice algorithm and 3 redundant algorithms. Results showed relatively high accuracy in the nine-orifice algorithm, where the estimation error is within 0.07° for an angle of attack, 0.3° for an angle of sideslip, 0.0012 for Mach number, and 1.5% for far-field static and dynamic pressure. Further, a fault management scheme has been proposed, where failure in individual orifice does not lead to fatal degradation in system performance.

-

表 1 神经网络模型训练数据库

Table 1. Database for neural network training

迎角/(°) 侧滑角/(°) 高度/km 马赫数 −10, −8, −6, −2, 0, 1, 2, 3, 4, 5, 6, 7,

8, 9, 10, 11, 13, 15, 17, 20−15, −13, −11, −9, −7, −5, −3, −2, −1,

0, 1, 2, 3, 5, 7, 9, 11, 13, 150, 2, 4, 6, 8, 10 0.3, 0.35, 0.4, 0.45, 0.5, 0.55, 0.6,

0.65, 0.7, 0.75, 0.8, 0.85, 0.9表 2 各算法最大误差

Table 2. Maximum estimation error of each algorithm

算法 迎角/(°) 侧滑角/(°) 马赫数 动压/% 静压/% 冗余算法1 0.31 0.94 0.0072 4.9 5.5 冗余算法2 0.22 0.86 0.014 3.3 5.4 冗余算法3 0.17 2.20 0.013 4.5 7.4 9孔算法 0.068 0.29 0.0013 1.3 1.4 表 3 各算法99%数据误差包络

Table 3. The 99% data error envelope for each algorithm

算法 迎角/(°) 侧滑角/(°) 马赫数 动压/% 静压/% 冗余算法1 0.17 0.73 0.0065 3.9 4.6 冗余算法2 0.13 0.65 0.0081 3.0 3.3 冗余算法3 0.14 0.72 0.0084 3.3 4.2 9孔算法 0.060 0.11 0.0012 0.91 0.77 -

[1] 陈广强, 豆国辉, 魏昊功, 等. 火星探测器大气数据测量方法[J]. 航空学报, 2022, 43(3): 626619.CHEN G Q, DOU G H, WEI H G, et al. Air data sensing technology of Mars probe[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(3): 626619(in Chinese). [2] WHITMORE S, COBLEIGH B, HAERING E. Design and calibration of the X-33 flush airdata sensing (FADS) system[C]// Proceedings of the 36th AIAA Aerospace Sciences Meeting and Exhibit. Reston: AIAA, 1998: 201. [3] ROHLOFF T J, WHITMORE S A, CATTON I. Air data sensing from surface pressure measurements using a neural network method[J]. AIAA Journal, 1998, 36: 2094-2101. doi: 10.2514/2.312 [4] ROHLOFF T J, WHITMORE S A, CATTON I. Fault-tolerant neural network algorithm for flush air data sensing[J]. Journal of Aircraft, 1999, 36(3): 541-549. doi: 10.2514/2.2489 [5] WHITMORE S A, MOES T R. Measurement uncertainty and feasibility study of a flush airdata system for a hypersonic flight experiment: NASA TM-4627[R]. California: NASA, 1994: 3-15. [6] BAUMANN E, PAHLE J W, DAVIS M C, et al. X-43A flush airdata sensing system flight-test results[J]. Journal of Spacecraft and Rockets, 2010, 47(1): 48-61. doi: 10.2514/1.41163 [7] PRUETT C D, WOLF H, HECK M L, et al. Innovative air data system for the Space Shuttle Orbiter[J]. Journal of Spacecraft and Rockets, 1983, 20(1): 61-69. doi: 10.2514/3.28357 [8] KELLY G M, FINDLAY J T, COMPTON H R. Shuttle subsonic horizontal wind estimation[J]. Journal of Spacecraft and Rockets, 1983, 20(4): 390-397. doi: 10.2514/3.25612 [9] KARLGAARD C D, KUTTY P, SCHOENENBERGER M. Coupled inertial navigation and flush air data sensing algorithm for atmosphere estimation[J]. Journal of Spacecraft and Rockets, 2017, 54(1): 128-140. doi: 10.2514/1.A33331 [10] 王鹏. 尖楔前体飞行器FADS系统的径向基网络建模及验证[J]. 气体物理, 2019, 4(3): 23-33.WANG P. RBF neural network modeling and validation for FADS system applied to the vehicle with sharp wedged fore-bodies[J]. Physics of Gases, 2019, 4(3): 23-33(in Chinese). [11] 王鹏, 胡远思, 金鑫, 等. 尖楔前体飞行器FADS系统的神经网络算法[J]. 空气动力学学报, 2017, 35(6): 777-780.WANG P, HU Y S, JIN X, et al. Neural network algorithm for FADS system applied to the vehicles with sharp wedged fore-bodies[J]. Acta Aerodynamica Sinica, 2017, 35(6): 777-780(in Chinese). [12] 王鹏, 金鑫. 尖锥前体飞行器FADS系统的人工神经网络建模及风洞试验研究[J]. 实验流体力学, 2019, 33(5): 57-63.WANG P, JIN X. Study on artificial neural network modeling and wind tunnel test for the FADS system applied to the vehicle with sharp nosed fore-bodies[J]. Journal of Experiments in Fluid Mechanics, 2019, 33(5): 57-63(in Chinese). [13] 王鹏, 胡远思, 金鑫. 尖楔前体飞行器FADS系统驻点压力对神经网络算法精度的影响[J]. 宇航学报, 2016, 37(9): 1072-1079.WANG P, HU Y S, JIN X. Effect of stagnation pressure on the neural network algorithm accuracy for FADS system applied to the vehicle with sharp wedged fore-bodies[J]. Journal of Astronautics, 2016, 37(9): 1072-1079(in Chinese). [14] 王鹏, 金鑫. 尖楔前体飞行器FADS系统测压孔故障对算法精度的影响[J]. 力学与实践, 2021, 43(6): 833-841.WANG P, JIN X. Numerical effect of pressure ports fault in the fads system applied to flight vehicle with sharp wedged fore-bodies[J]. Mechanics in Engineering, 2021, 43(6): 833-841(in Chinese). [15] 王鹏, 李秋红, 胡远思, 等. 尖楔前体飞行器FADS-α的求解精度研究[J]. 中国科学: 物理学 力学 天文学, 2015, 45(12): 98-108.WANG P, LI Q H, HU Y S, et al. Research on solving accuracy for FADS-α applied to the vehicle with sharp wedged fore-bodies[J]. Scientia Sinica (Physica, Mechanica & Astronomica), 2015, 45(12): 98-108(in Chinese). [16] 张斌, 于盛林. 嵌入式飞行参数传感系统的神经网络算法[J]. 航空学报, 2006, 27(2): 294-298.ZHANG B, YU S L. Neural network algorithm for flush airdata sensing system[J]. Acta Aeronautica et Astronautica Sinica, 2006, 27(2): 294-298(in Chinese). [17] 贾乾磊, 章卫国, 史静平, 等. FADS系统故障诊断方法研究[J]. 西北工业大学学报, 2020, 38(6): 1210-1217. doi: 10.1051/jnwpu/20203861210JIA Q L, ZHANG W G, SHI J P, et al. Research on fault detection method of FADS system[J]. Journal of Northwestern Polytechnical University, 2020, 38(6): 1210-1217(in Chinese). doi: 10.1051/jnwpu/20203861210 [18] 丁智坚, 周欢, 吴东升, 等. 嵌入式大气数据测量系统技术研究进展[J]. 宇航学报, 2019, 40(3): 247-257.DING Z J, ZHOU H, WU D S, et al. Review of flush air data sensing system[J]. Journal of Astronautics, 2019, 40(3): 247-257(in Chinese). -

下载:

下载: