-

摘要:

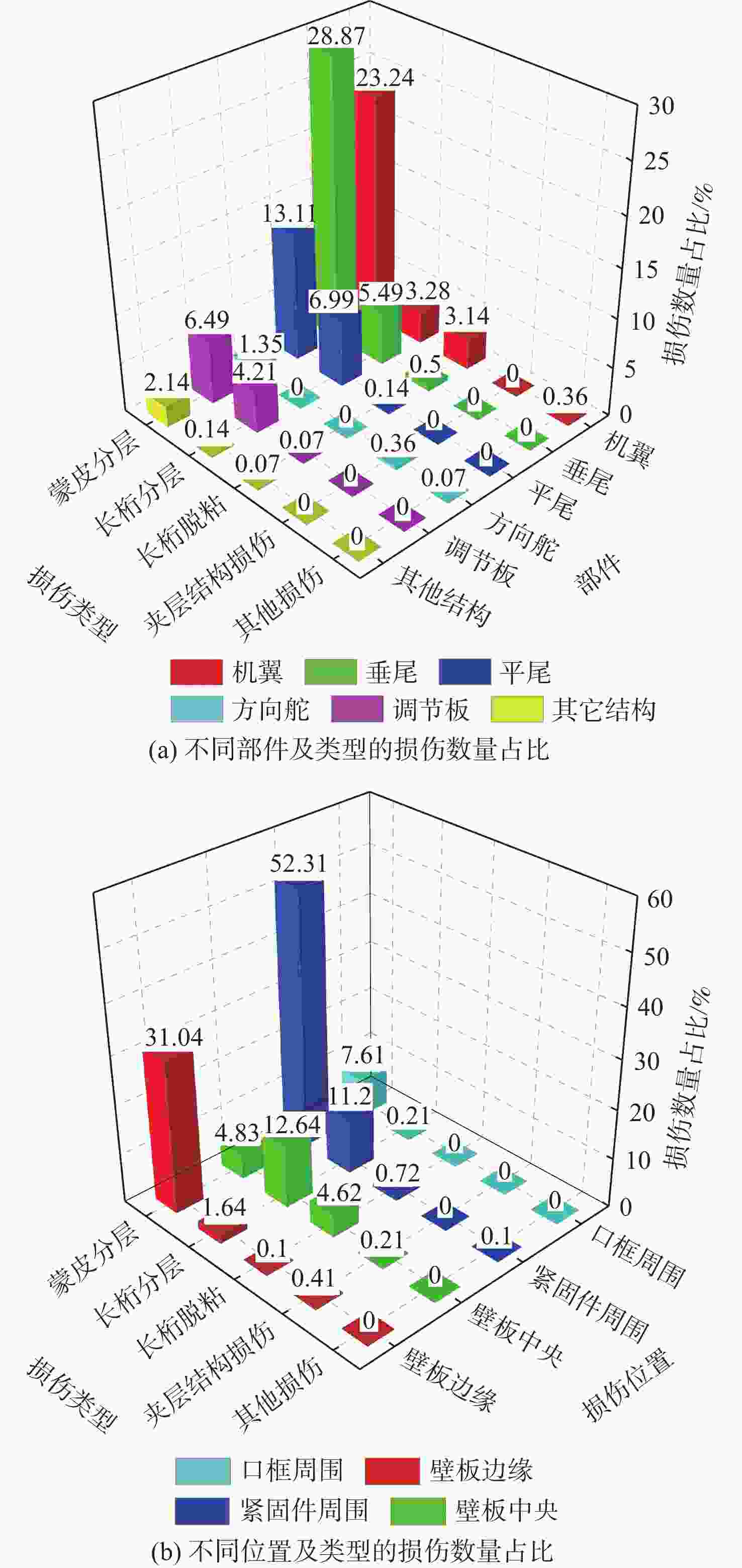

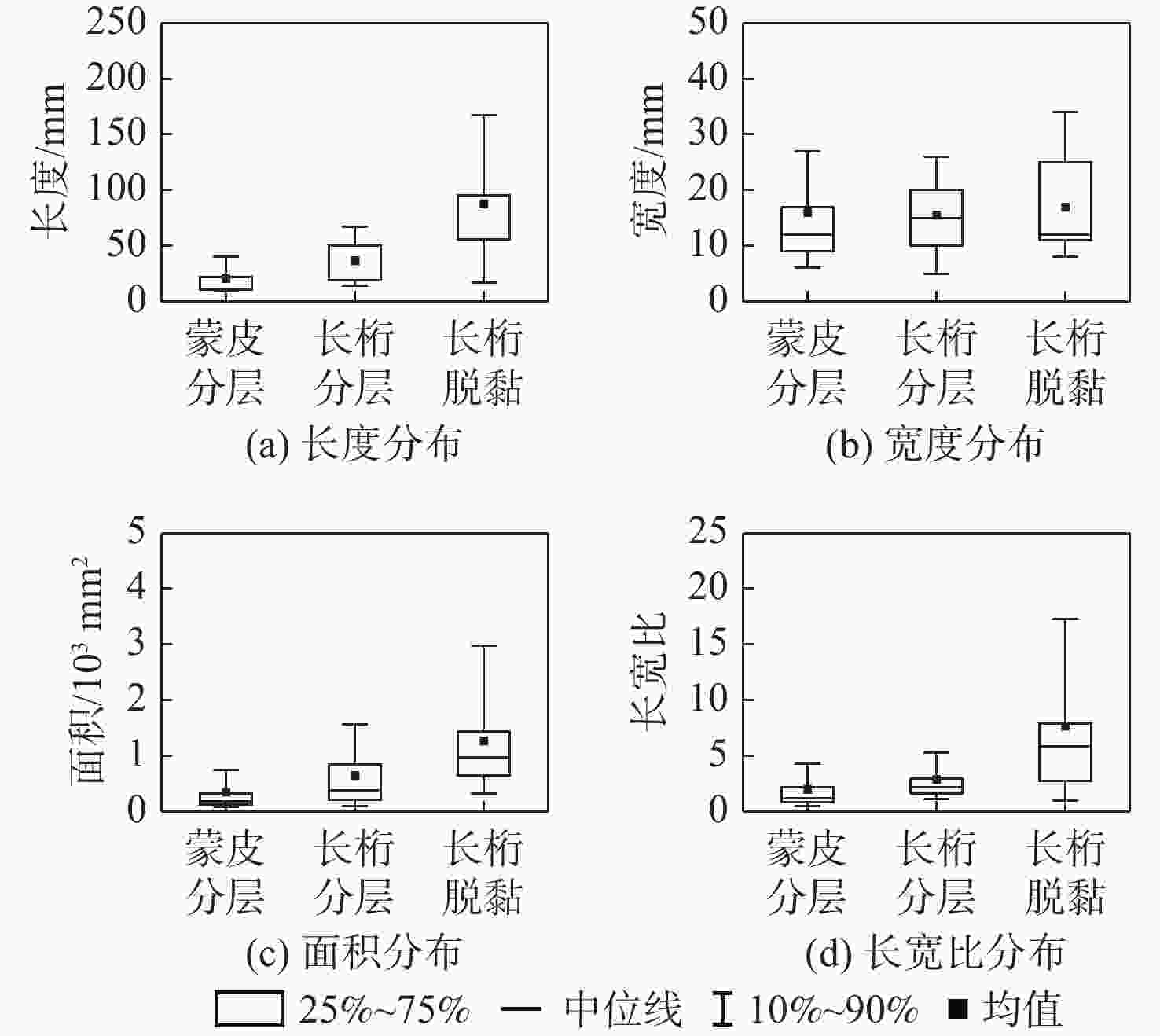

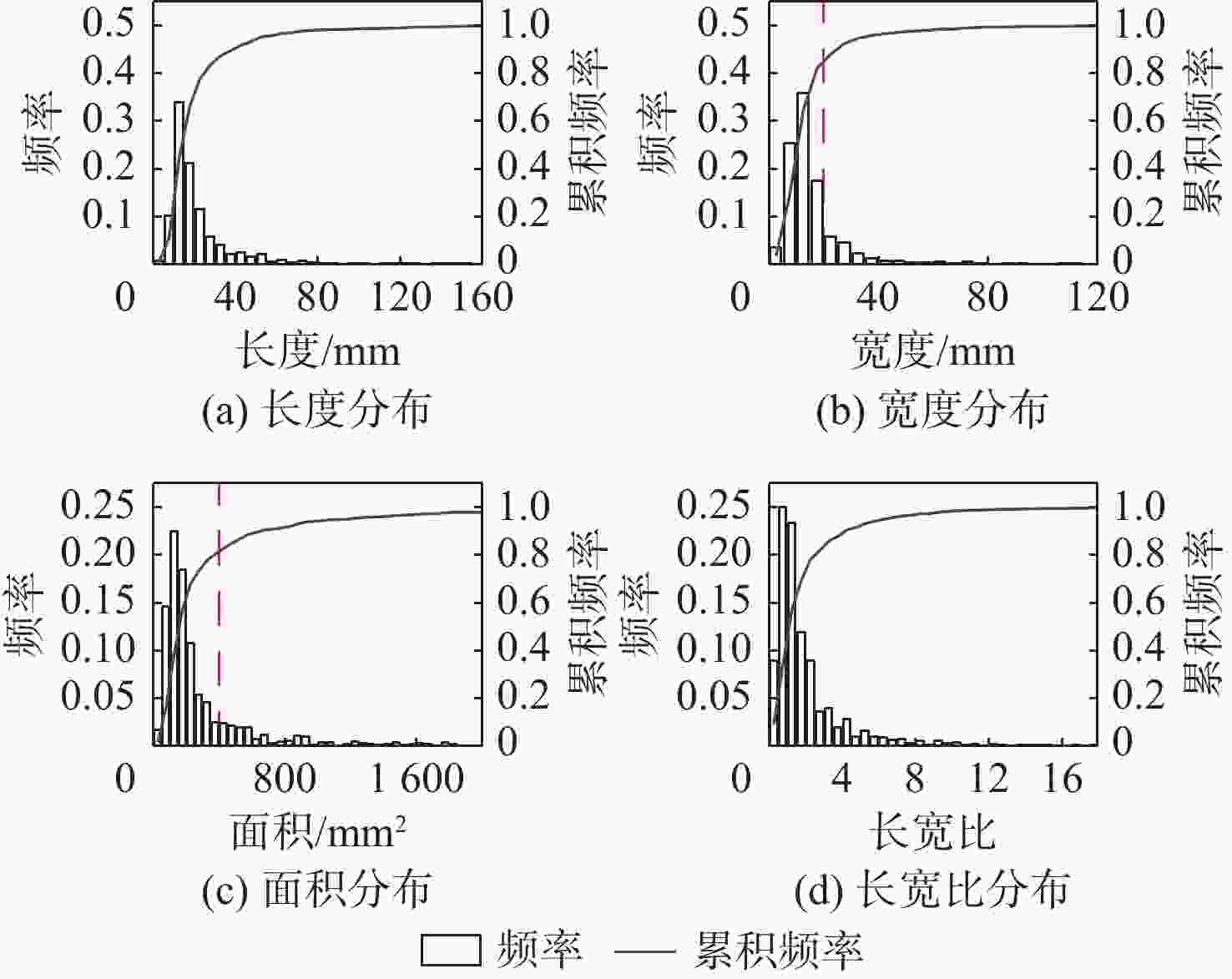

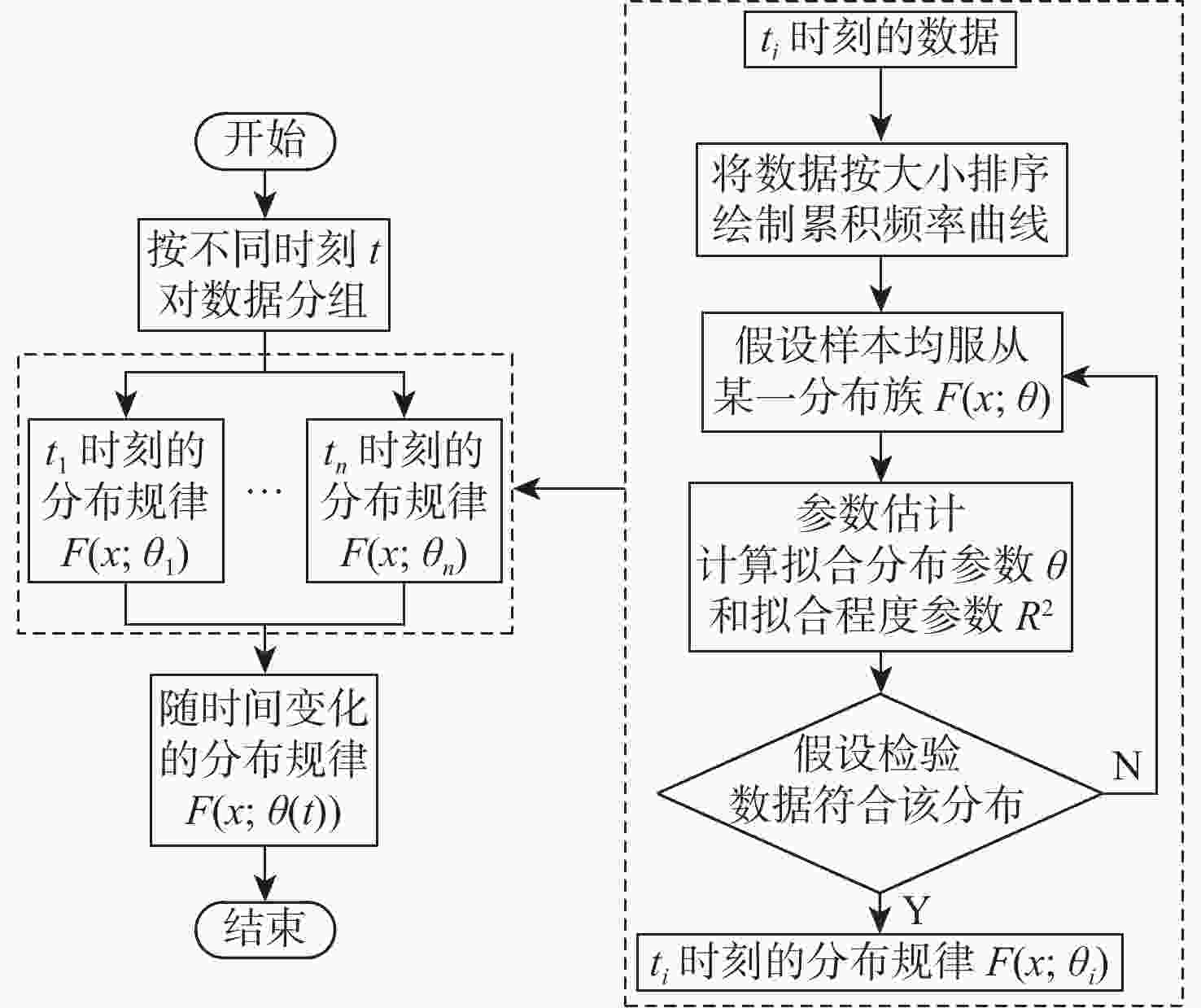

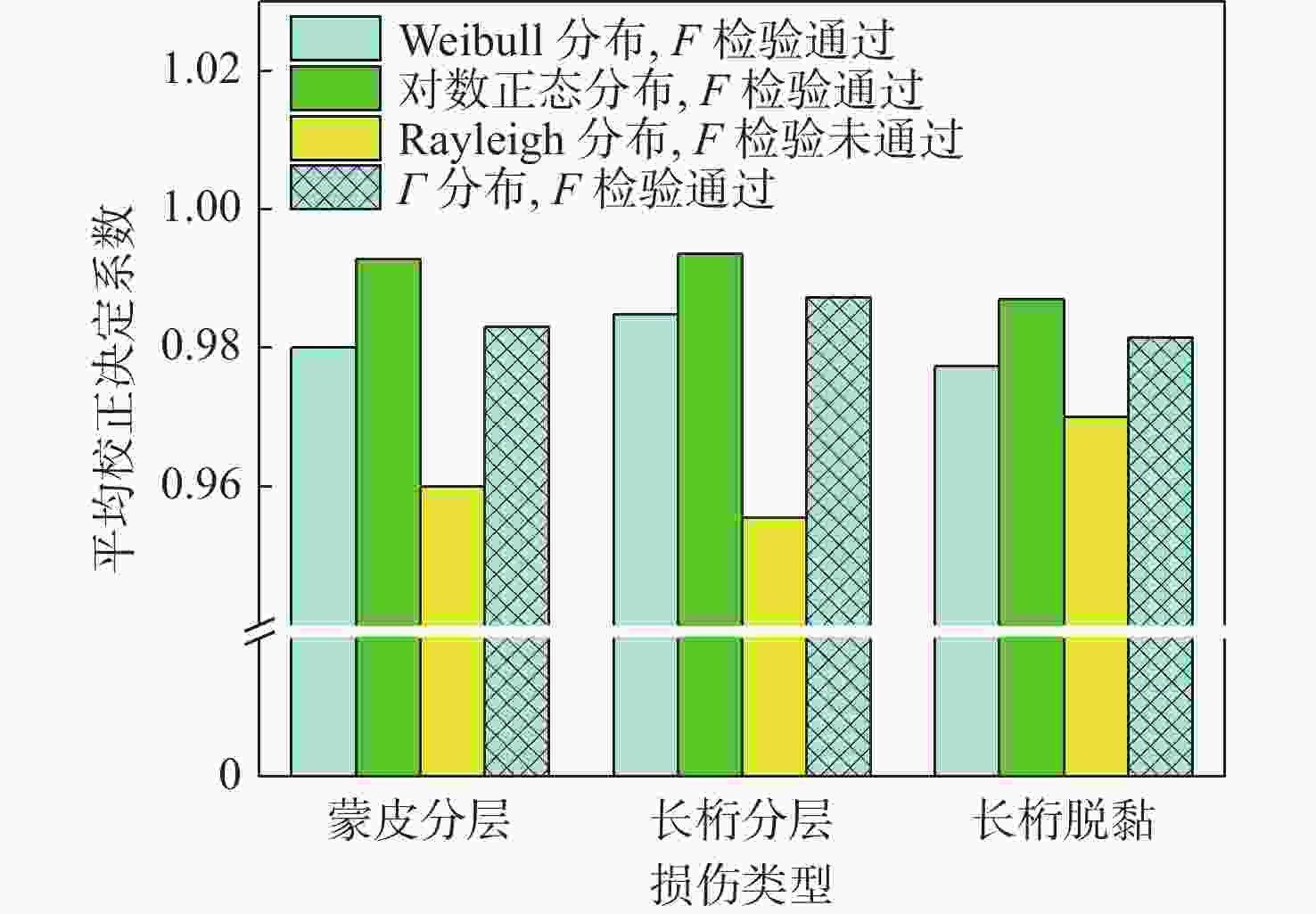

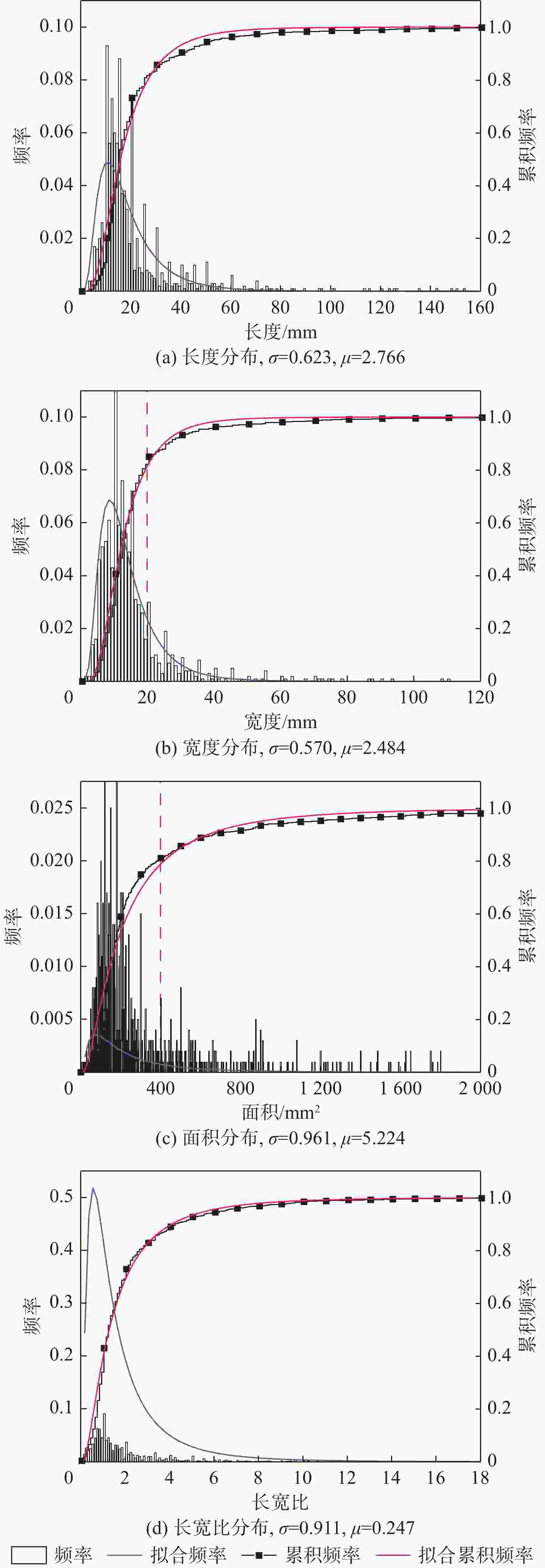

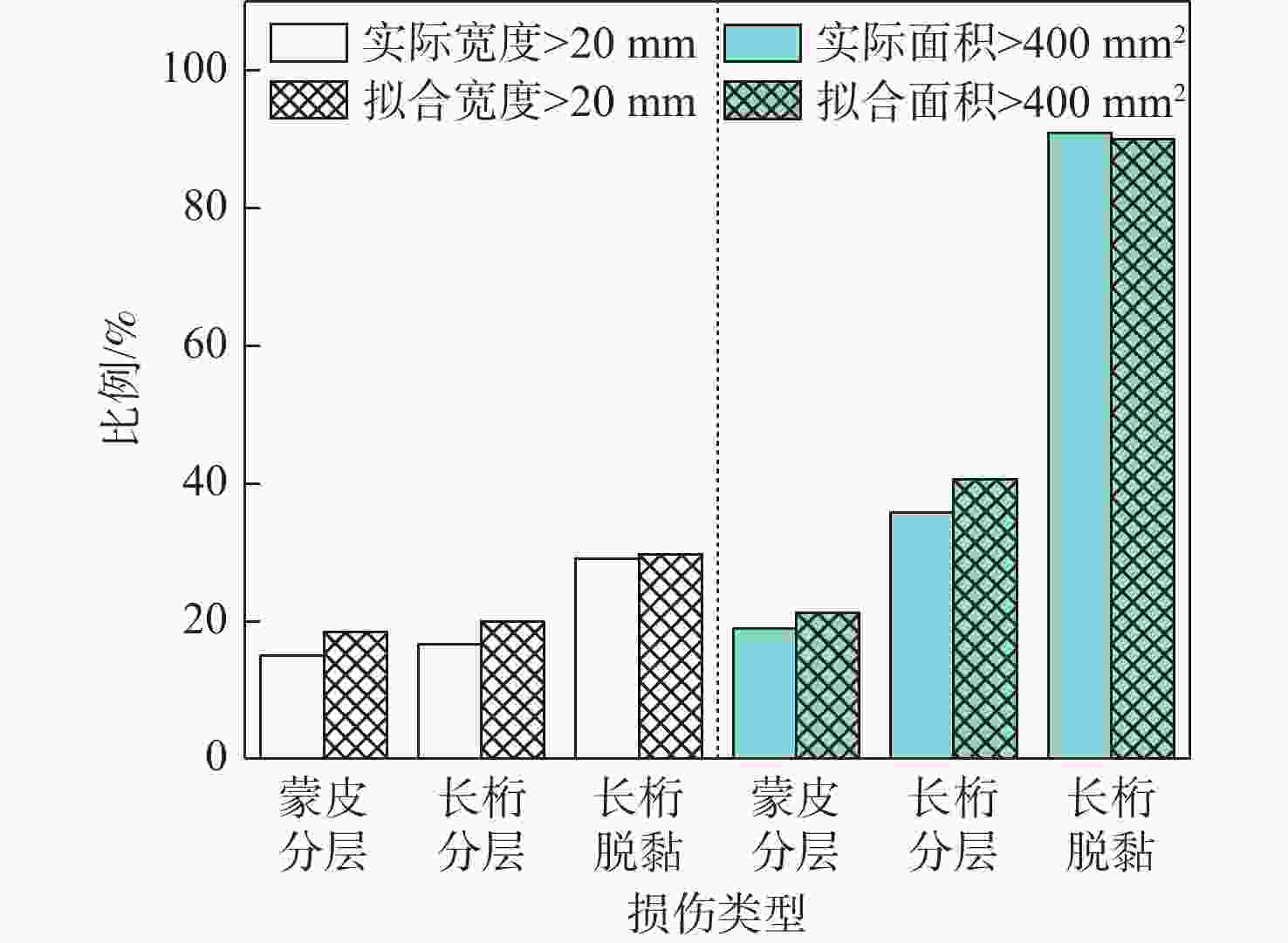

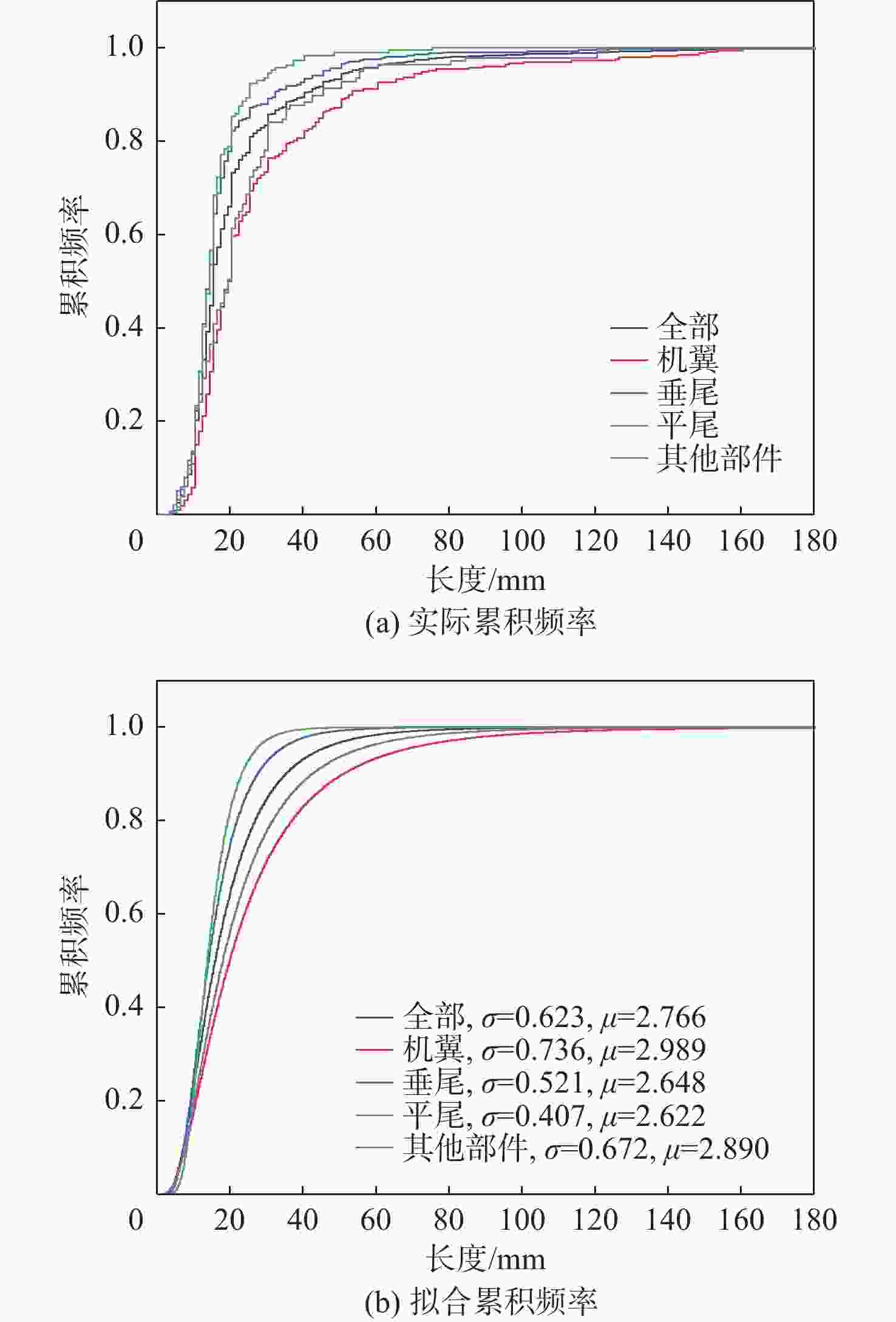

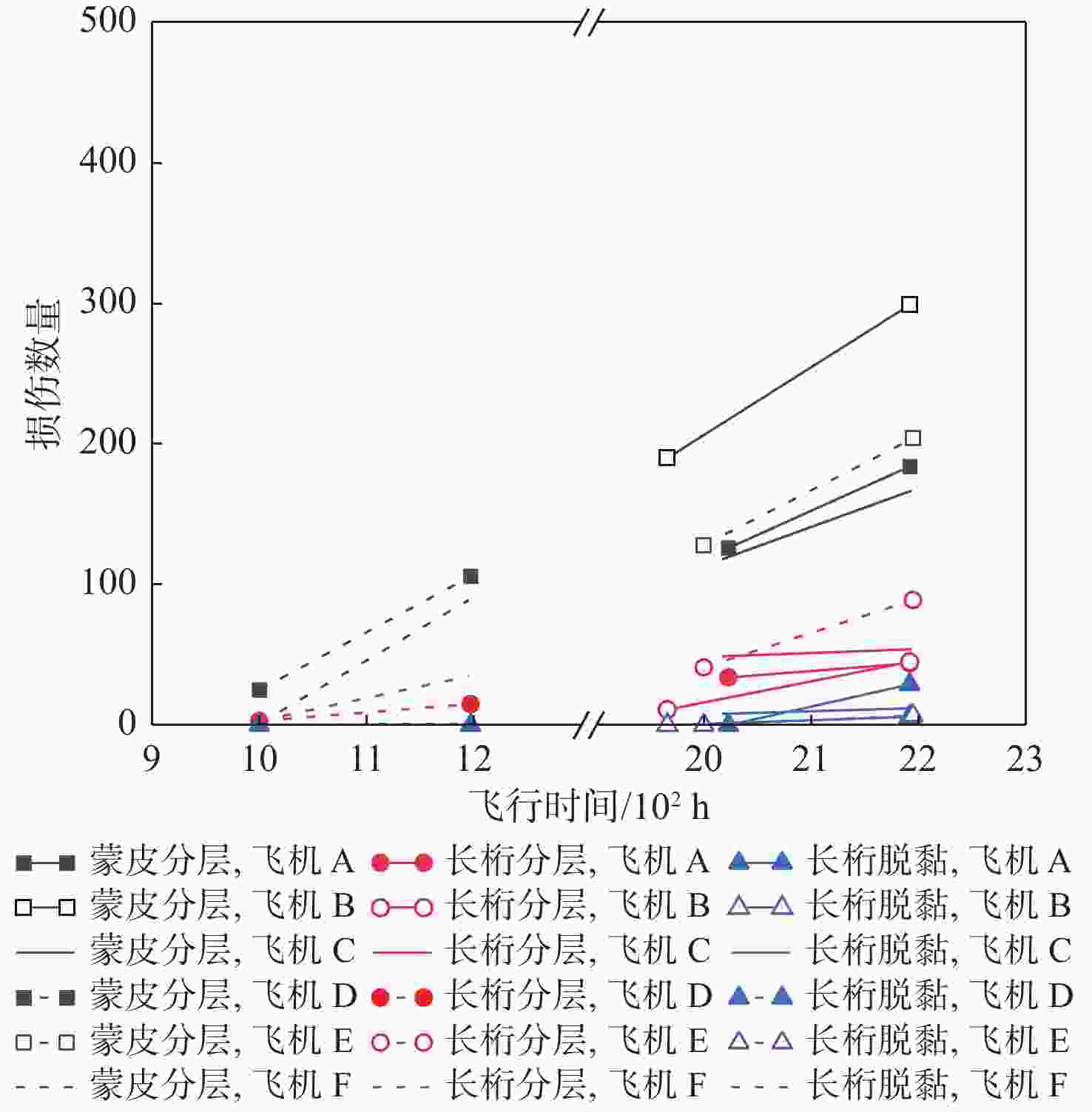

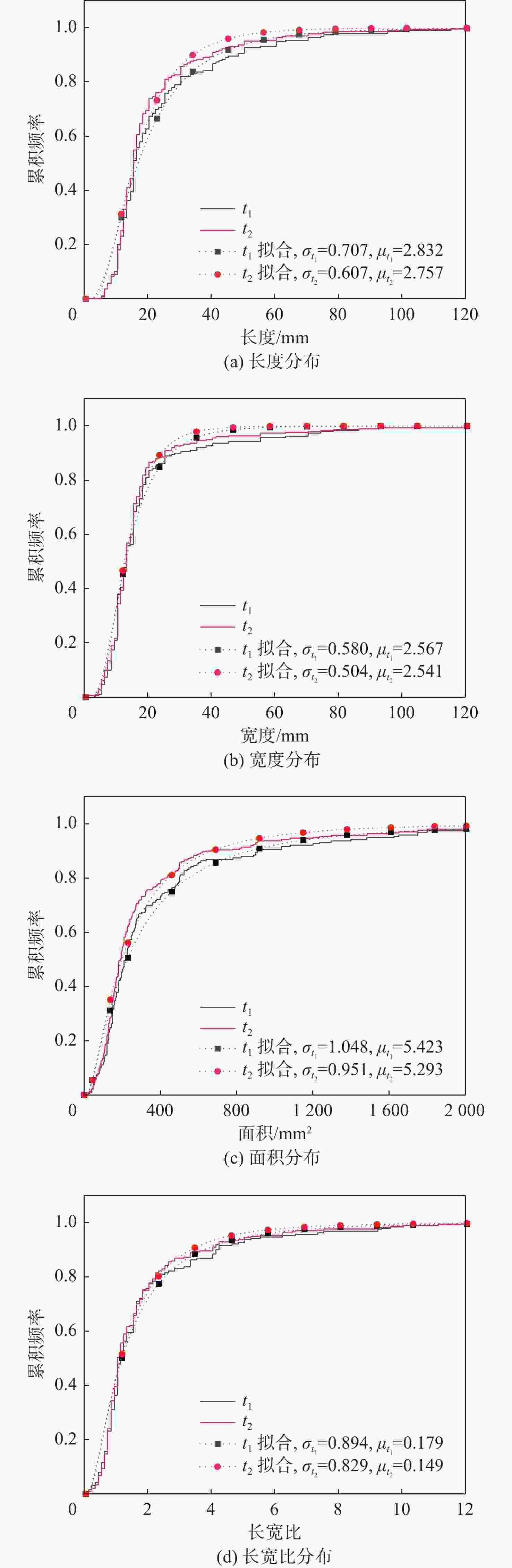

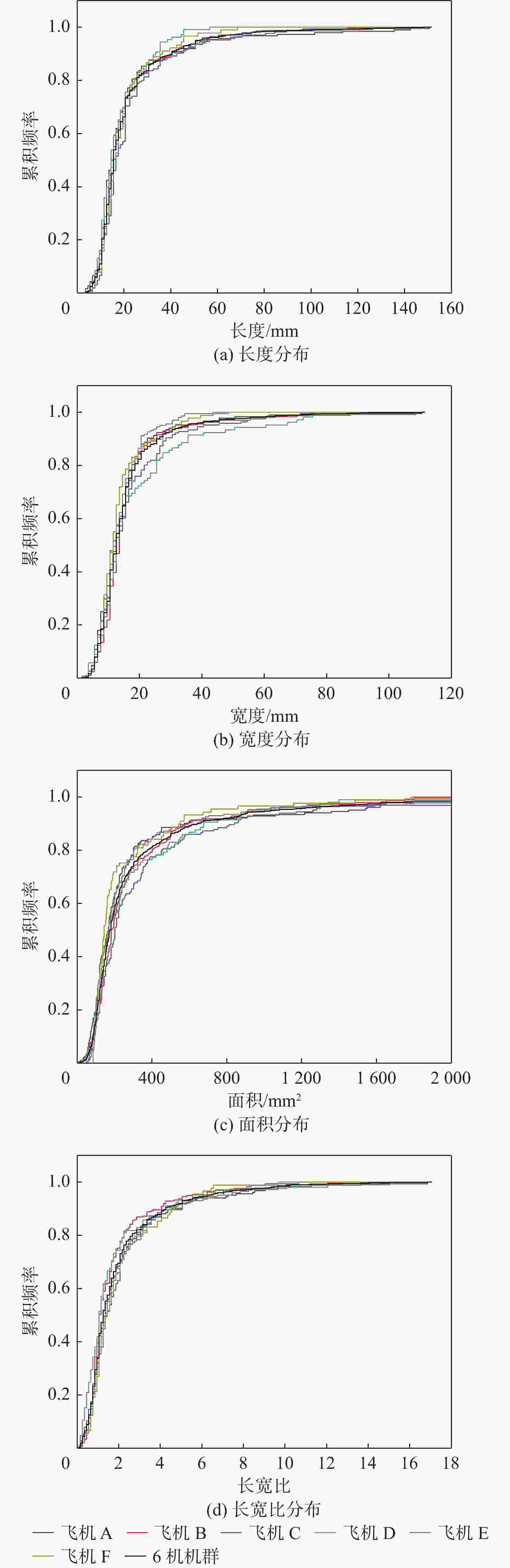

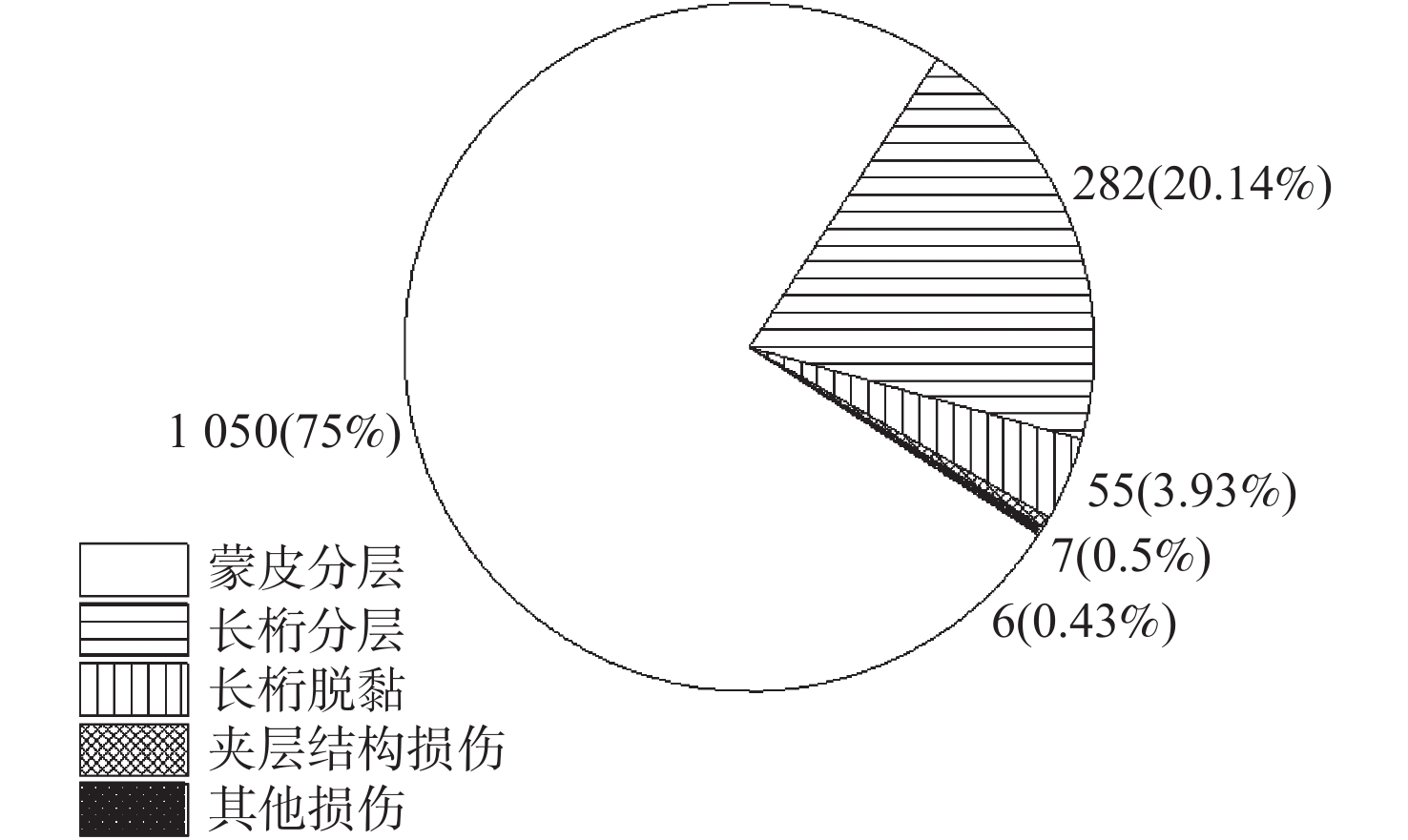

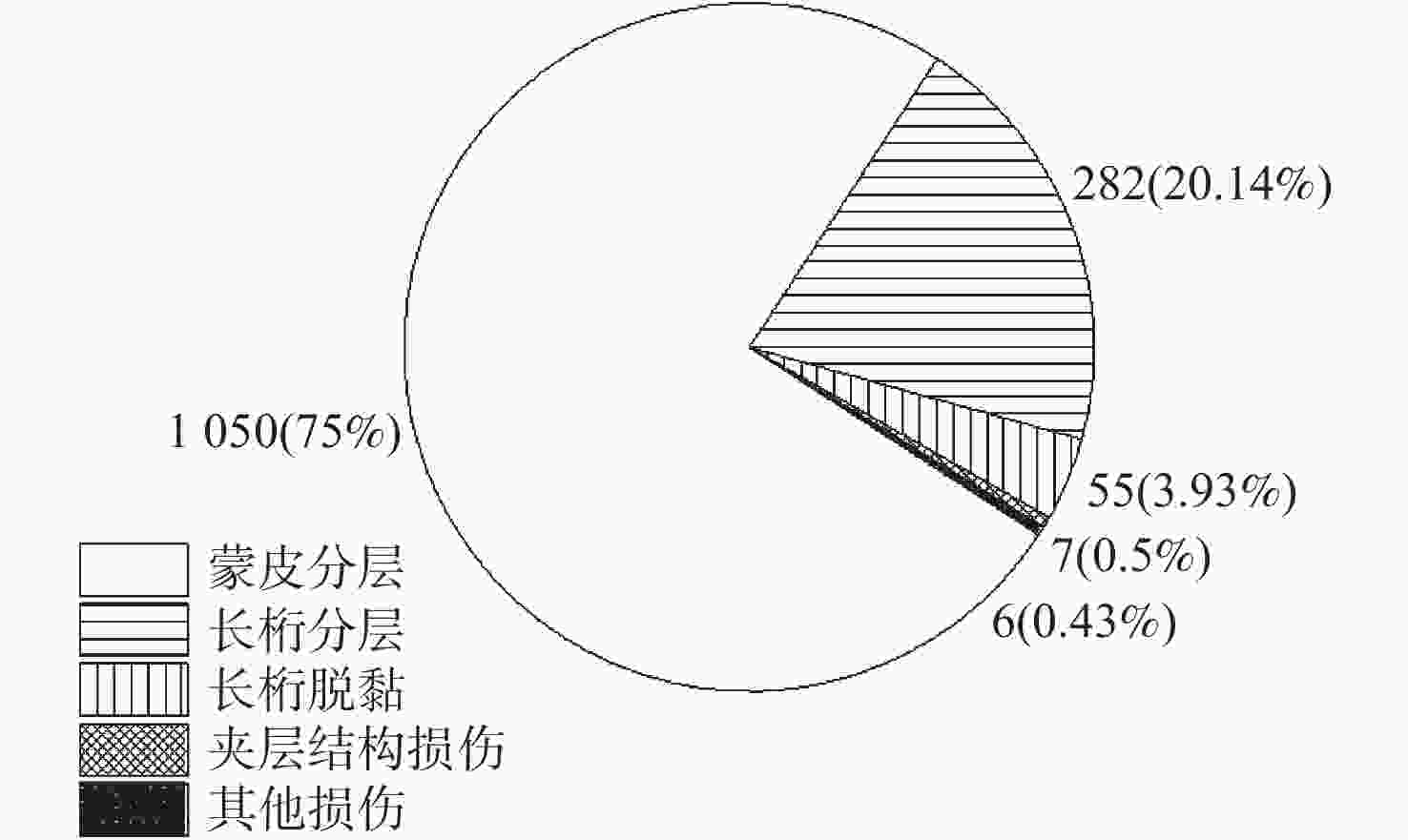

针对飞机复合材料结构的损伤和修理问题,对某型固定翼飞机机翼、机身等部位的复合材料结构应用和损伤情况进行统计,复合材料在该型飞机的主要应用形式主要有实心整体壁板和夹芯层合板2种,建立随时间变化的结构损伤分布模型,利用统计方法对损伤分布进行拟合和检验。结果表明:结构损伤的数量比例分别为蒙皮分层占75%、长桁分层约占20%、长桁脱黏约占4%;对数正态分布、Weibull分布、Γ分布均可以拟合这3种类型损伤的几何参数分布,其中对数正态分布模型的拟合效果最好;单架飞机的损伤几何参数分布规律不随时间变化,同型号飞机之间的损伤几何参数分布规律也高度相似,可采用统一的函数形式描述。

Abstract:To address the damage and repair of aircraft composite structures, the applications and damage of composite structures in a certain type of aircraft, including the wing, fuselage and other components, were statistically analyzed. Structural damage distribution models with time variable were established, and then the damage distributions of the structures were fitted and tested by statistical methods. The results show that the quantitative proportions of structural damage are 75% for skin delamination, 20% for stringer delamination and 4% for stringer debonding. Lognormal distribution, Weibull distribution and Gamma distribution can all be used to fit the geometric parameter distributions of the three types of structural damage, in which the Lognormal distribution model has the best fitting effect. The distribution of structural damage geometric parameters of one aircraft does not vary with time, and the distributions of geometric parameters of the structural damage between the same type of aircraft are also highly similar, which can be expressed in a unified function form.

-

Key words:

- aircraft /

- composite structure /

- structural damage /

- geometric parameters /

- distribution /

- hypothesis testing

-

表 1 复合材料在某型飞机主要部件上的应用

Table 1. Application of composite materials on main components of a certain type of aircraft

应用部件 结构形式 材料体系 机翼 T型筋条加筋壁板(上壁板)

L型筋条加筋壁板(下壁板)碳纤维树脂基复合材料 垂尾 工型筋条加筋壁板 碳纤维树脂基复合材料 方向舵 全高度蜂窝夹层板 碳纤维树脂基复合材料(面板)

蜂窝(芯材)平尾 工型筋条加筋壁板 碳纤维树脂基复合材料 机头雷

达罩全高度蜂窝夹层板 玻璃纤维树脂基复合材料(面板)

蜂窝(芯材)进气道

调节板C型筋条加筋壁板 碳纤维树脂基复合材料 表 2 蒙皮分层几何参数分布的对数正态分布拟合结果

Table 2. Fitting results of lognormal distribution of geometric parameters of skin delamination

拟合对象 几何参数 ${\sigma _{{t_1}}} $ ${\mu _{{t_1}}} $ ${\sigma _{{t_2}}} $ ${\mu _{{t_2}}} $ 飞机A L 0.685 2.762 0.664 2.699 W 0.551 2.404 0.584 2.414 LW 1.007 5.153 0.996 5.085 L/W 0.948 0.330 0.911 0.271 飞机B L 0.707 2.832 0.607 2.757 W 0.580 2.567 0.504 2.541 LW 1.048 5.423 0.951 5.293 L/W 0.894 0.179 0.829 0.149 飞机C L 0.643 2.936 0.622 2.858 W 0.744 2.551 0.671 2.512 LW 1.057 5.491 1.045 5.346 L/W 0.869 0.382 0.876 0.321 飞机D L 0.532 2.692 0.504 2.631 W 1.073 2.685 0.765 2.527 LW 1.316 5.387 0.960 5.210 L/W 1.088 −0.079 0.884 −0.054 飞机E L 0.588 2.889 0.657 2.794 W 0.477 2.434 0.455 2.462 LW 0.888 5.281 0.816 5.198 L/W 0.740 0.453 0.879 0.336 飞机F L 0.536 2.770 W 0.541 2.380 LW 0.813 5.093 L/W 0.833 0.354 注:空白处为仅检出1处损伤因此不予拟合。 表 3 不同飞行时长的损伤分布K-S检验(α=0.05)

Table 3. K-S test of difference in damage distribution at different flight time (α=0.05)

损伤类型 几何参数 假设:fi,j(x;θi,j(t1))=fi,j(x;θi,j(t2)) A B C D E F 蒙皮分层 L √ √ √ √ √ — W √ √ √ √ √ LW √ √ √ √ √ L/W √ √ √ √ √ 长桁分层 L √ √ √ √ × * W √ √ √ √ √ √ LW √ √ √ √ × √ L/W √ √ √ √ * * 长桁脱黏 L — — √ — — — W √ LW √ L/W √ 注:√表示接受假设,即认为2个损伤几何参数分布函数一致;*表示在α=0.05时拒绝假设,但在α=0.01时接受假设,可以认为2个分布相近;×表示拒绝假设,即认为2个损伤几何参数分布函数不一致;—表示前一时刻损伤未检出或极少,无法进行假设检验。 表 4 同一型号不同飞机的损伤几何参数(K-S检验,α=0.05)

Table 4. Damage geometric parameters of different aircraft with the same type (K-S test, α=0.05)

损伤类型 几何参数 假设 A B C D E F 蒙皮分层 L fq(x)=fB(x ) √ 基准 √ √ √ √ W √ √ √ √ * LW * √ √ √ × L/W √ √ √ × √ 长桁分层 L fq(x)=fE(x ) × * × √ 基准 * W √ √ × * × LW √ √ × √ × L/W × × × √ √ 长桁脱粘 L fq(x)=fA(x ) 基准 × √ — √ — W * × √ LW × √ √ L/W × × √ 注:√表示接受假设,即认为2个损伤几何参数分布函数一致;*表示在α=0.05时拒绝假设,但在α=0.01时接受假设,可以认为2个分布相近;×表示拒绝假设,即认为2个损伤几何参数分布函数不一致;—表示当前时刻损伤未检出或极少,无法进行假设检验。 表 5 单架飞机与机群的损伤几何参数(K-S检验,α=0.05)

Table 5. Damage geometric parameters of single aircraft and fleet (K-S test, α=0.05)

损伤类型 几何参数 假设:fq(x)=ffleet(x) A B C D E F 蒙皮分层 L √ √ √ √ √ √ W √ √ √ √ √ √ LW √ √ √ √ √ * L/W √ * √ * √ √ 长桁分层 L * √ × √ * × W √ √ × * √ × LW √ √ × * √ × L/W √ √ × √ × × 长桁脱粘 L √ × √ — √ — W √ * × √ LW √ √ √ √ L/W √ × * √ 注:√表示接受假设,即认为2个损伤几何参数分布函数一致;*表示在α=0.05时拒绝假设,但在α=0.01时接受假设,可以认为2个分布相近;×表示拒绝假设,即认为2个损伤几何参数分布函数不一致;—表示当前时刻损伤未检出或极少,无法进行假设检验。 -

[1] KASSAPOGLOU C. Design and analysis of composite structures: With applications to aerospace structures[M]. New York: John Wiley & Sons Ltd., 2013: 1-7. [2] CASTANIE B, BOUVET C, GINOT M. Review of composite sandwich structure in aeronautic applications[J]. Composites Part C, 2020, 1: 100004. doi: 10.1016/j.jcomc.2020.100004 [3] ZIMMERMANN N, WANG P H. A review of failure modes and fracture analysis of aircraft composite materials[J]. Engineering Failure Analysis, 2020, 115: 104692. doi: 10.1016/j.engfailanal.2020.104692 [4] 贺强, 杨文锋, 唐庆如. 复合材料挖补修理技术研究现状与发展趋势[J]. 玻璃钢/复合材料, 2015(4): 85-90.HE Q, YANG W F, TANG Q R. Current research and future development of scarf repair for composite component[J]. Fiber Reinforced Plastics/Composites, 2015(4): 85-90(in Chinese). [5] ARMSTRONG K B, BEVAN L G, COLE W F. Care and repair of advanced composites [M]. 2nd ed. New York: SAE International, 2005: 6-17. [6] 陈绍杰. 复合材料结构修理指南[M]. 北京: 航空工业出版社, 2001: 66-84.CHEN S J. Composite structures repair guide[M]. Beijing: Aviation Industry Press, 2001: 66-84(in Chinese). [7] 中华人民共和国工业和信息化部. 飞机复合材料结构修理要求: HB 8606-2021[S]. 北京: 中国航空综合技术研究所, 2021: 2-9.Ministry of Industry and Information Technology of the People’s Republic of China. Requirements of composite structure repair for aircraft: HB 8606-2021[S]. Beijing: AVIC China Aero-Ploytechnology Establishment, 2021: 2-9(in Chinese). [8] 王辰, 贺尔铭, 赵志彬, 等. 民机复合材料结构修理容限确定方法研究[J]. 西北工业大学学报, 2020, 38(4): 695-704.WANG C, HE E M, ZHAO Z B, et al. Method for determining repair tolerance of civil aircraft composite structure[J]. Journal of Northwestern Polytechnical University, 2020, 38(4): 695-704(in Chinese). [9] 陆晓华, 邵传金, 左洪福. 飞机复材结构的修理容限确定方法[J]. 系统工程理论与实践, 2019, 39(12): 3217-3228.LU X H, SHAO C J, ZUO H F. Determination of repair tolerance for aircraft composite structure[J]. Systems Engineering-Theory & Practice, 2019, 39(12): 3217-3228(in Chinese). [10] 李鑫, 徐翊竣, 柏宇星, 等. 一种复合材料结构件的修理容限确定方法: 中国, 202111238101.9[P]. 2022-02-01.LI X, XU Y J, BAI Y X, et al. A method for determining repair tolerance of composite structural parts: China, 202111238101.9[P]. 2022-02-01(in Chinese). [11] 中国人民解放军总装备部. 军用飞机结构完整性大纲: GJB 775A-2012[S]. 北京: 总装备部军标出版发行部, 2012: 4-14.The General Armament Department of the PLA. Military aircraft structural integrity program: GJB 775A-2012[S]. Beijing: Military Standard Publishing Department of General Armament Department of the PLA, 2012: 4-14(in Chinese). [12] 杨凯, 金平, 范存智. 飞机结构腐蚀损伤分布及失效规律研究[J]. 航空计算技术, 2010, 40(3): 65-67.YANG K, JIN P, FAN C Z. Study on corrosion damage distribution and failure law of naval aircraft structure[J]. Aeronautical Computing Technique, 2010, 40(3): 65-67(in Chinese). [13] 张波, 李曙林. 基于无损检测的复合材料结构外场损伤特点分析[J]. 航空维修与工程, 2010 (1): 65-66.ZHANG B, LI S L. Analysis of composite structure damage characteristics based on NDT[J]. Aviation Maintenance & Engineering, 2010(1): 65-66(in Chinese). [14] 周福伟. 波音737NG飞机货舱门周围蒙皮损伤小样本分析[J]. 航空维修与工程, 2021(1): 57-59.ZHOU F W. Small sample analysis of skin damage around B737NG cargo door[J]. Aviation Maintenance & Engineering, 2021 (1): 57-59(in Chinese). [15] CHEN X, REN H, BI L C. Inspection intervals optimization for aircraft composite structures considering dent damage[J]. Journal of Aircraft, 2014, 51(1): 303-309. doi: 10.2514/1.C032377 [16] 国防科学技术工业委员会. 纤维增强复合材料无损检验方法 第1部分 超声波检验: GJB 1038.1A-2004[S]. 北京: 国防科工委军标出版发行部, 2004: 1-6.Commission of Science, Technology and Industry for National Defence. Non-destructive inspecting methods for fiber reinforced composite Part 1: ultrasonic testing: GJB 1038.1A-2004[S]. Beijing: Military Standard Publishing Department of Commission of Science, Technology and Industry for National Defence, 2004: 1-6(in Chinese). [17] 国防科学技术工业委员会. 纤维增强复合材料无损检验方法 第2部分 X射线照射检验: GJB 1038.2A-2004[S]. 北京: 国防科工委军标出版发行部, 2004: 1-5.Commission of Science, Technology and Industry for National Defence. Non-destructive inspecting methods for fiber reinforced composite Part 2: radiographic testing: GJB 1038.2A-2004[S]. Beijing: Military Standard Publishing Department of Commission of Science, Technology and Industry for National Defence, 2004: 1-5(in Chinese). [18] 盛骤, 谢式千, 潘承毅. 概率论与数理统计 [M]. 4版. 北京: 高等教育出版社, 2008: 1-5.SHENG Z, XIE S Q, PAN C Y. Probability theory and mathematical statistics [M]. 4th ed. Beijing: Higher Education Press, 2008: 1-5(in Chinese). [19] 茆诗松, 王静龙, 濮晓龙. 高等数理统计 [M]. 2版. 北京: 高等教育出版社, 2006: 7-9.MAO S S, WANG J L, PU X L. Advanced mathematical statistics [M]. 2nd ed. Beijing: Higher Education Press, 2006: 7-9(in Chinese). [20] 徐家进. 疲劳统计学智能化中的高镇同法[J]. 北京航空航天大学学报, 2021, 47(10): 2024-2033. doi: 10.13700/j.bh.1001-5965.2020.0373XU J J. Gao Zhentong method in intelligentization of statistics in fatigue[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(10): 2024-2033(in Chinese). doi: 10.13700/j.bh.1001-5965.2020.0373 [21] 《数学手册》编写组. 数学手册[M]. 北京: 高等教育出版社, 1979: 796-801.Mathematical Handbook Writing Group. Mathematical handbook[M]. Beijing: Higher Education Press, 1979: 796-801(in Chinese). [22] 韩於羹. 应用数理统计[M]. 北京: 北京航空航天大学出版社, 1989: 184-191.HAN Y G. Applied mathematical statistics[M]. Beijing: Beihang University Press, 1989: 184-191(in Chinese). [23] 孙海燕, 周梦, 李卫国, 等. 数理统计[M]. 北京: 北京航空航天大学出版社, 2016: 151-156.SUN H Y, ZHOU M, LI W G, et al. Mathematical statistics[M]. Beijing: Beihang University Press, 2016: 151-156(in Chinese). [24] 阮云凯, 陈剑平, 曹琛, 等. K-S检验在裂隙岩体统计均质区划分中的应用[J]. 东北大学学报(自然科学版), 2015, 36(10): 1471-1475.RUAN Y K, CHEN J P, CAO C, et al. Application of K-S test in structural homogeneity dividing of fractured rock mass[J]. Journal of Northeastern University (Natural Science), 2015, 36(10): 1471-1475(in Chinese). -

下载:

下载: