-

摘要:

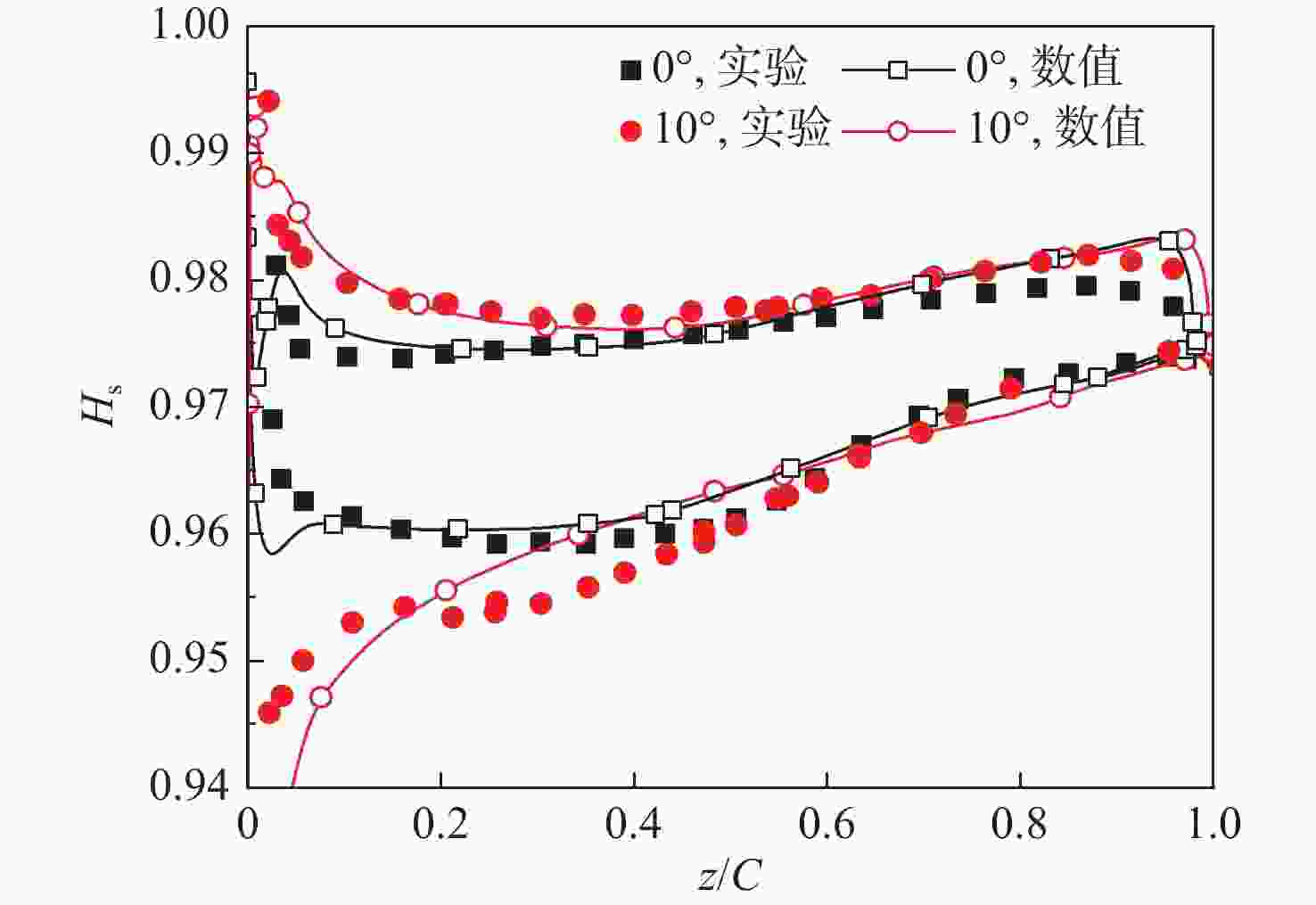

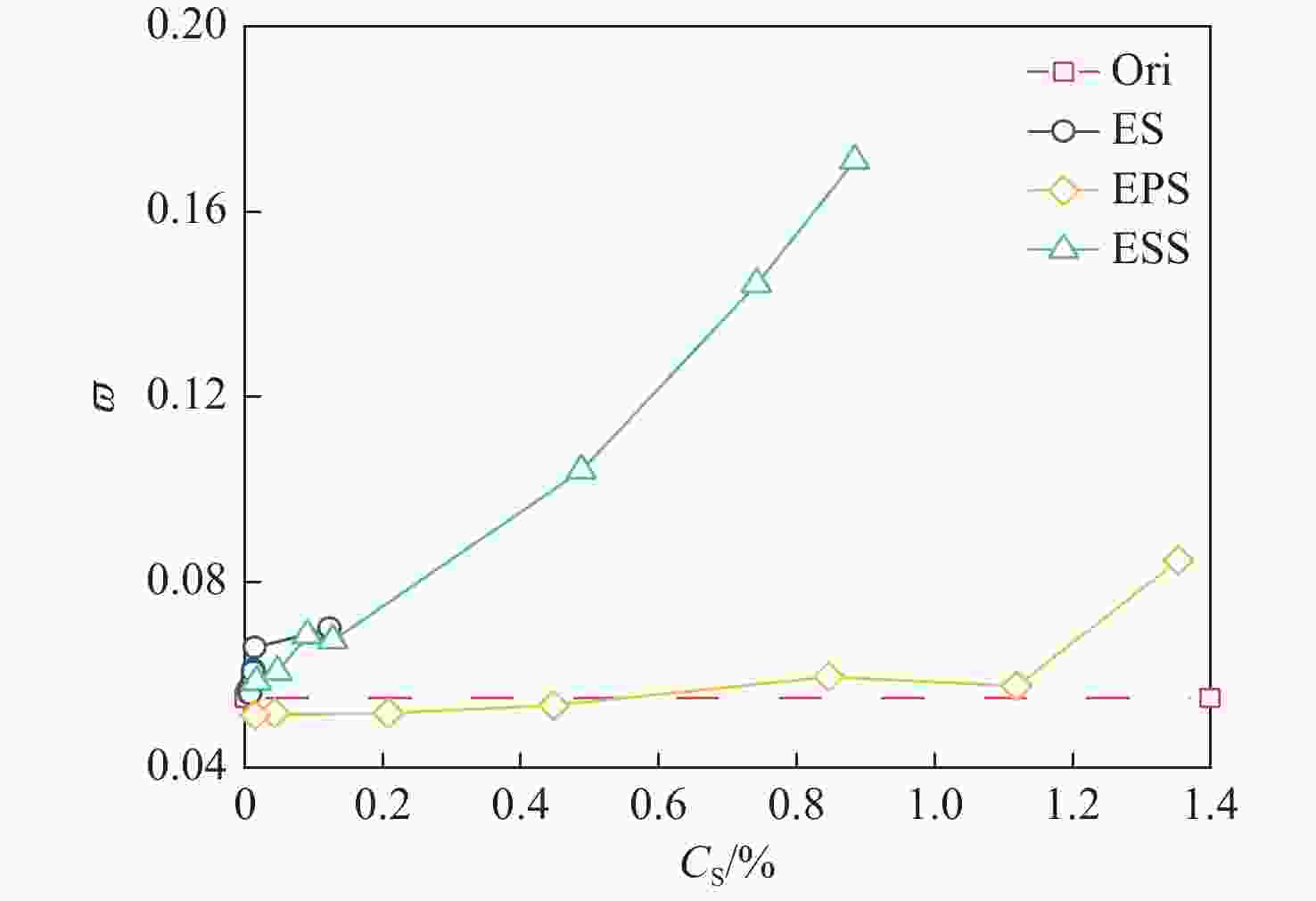

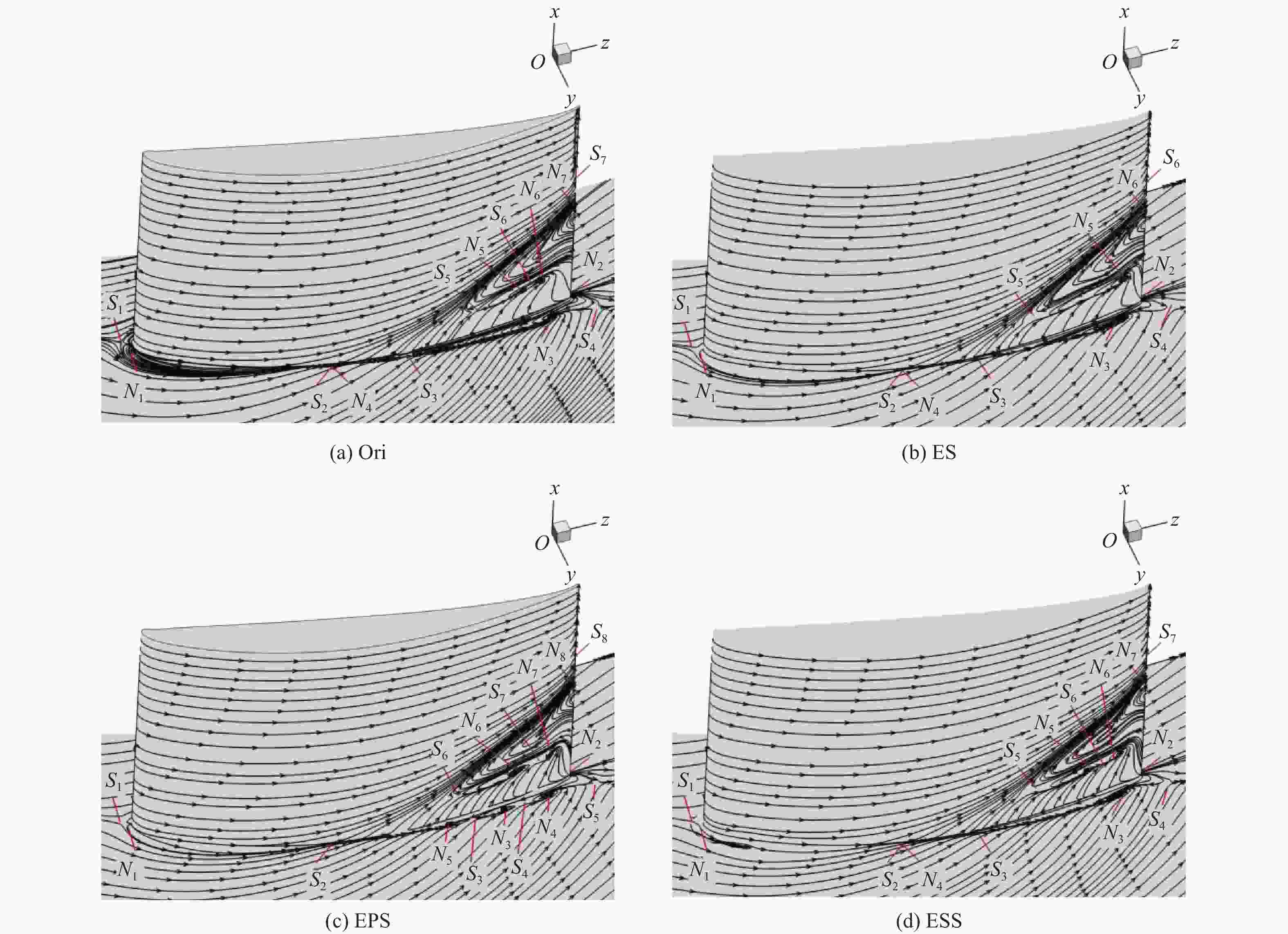

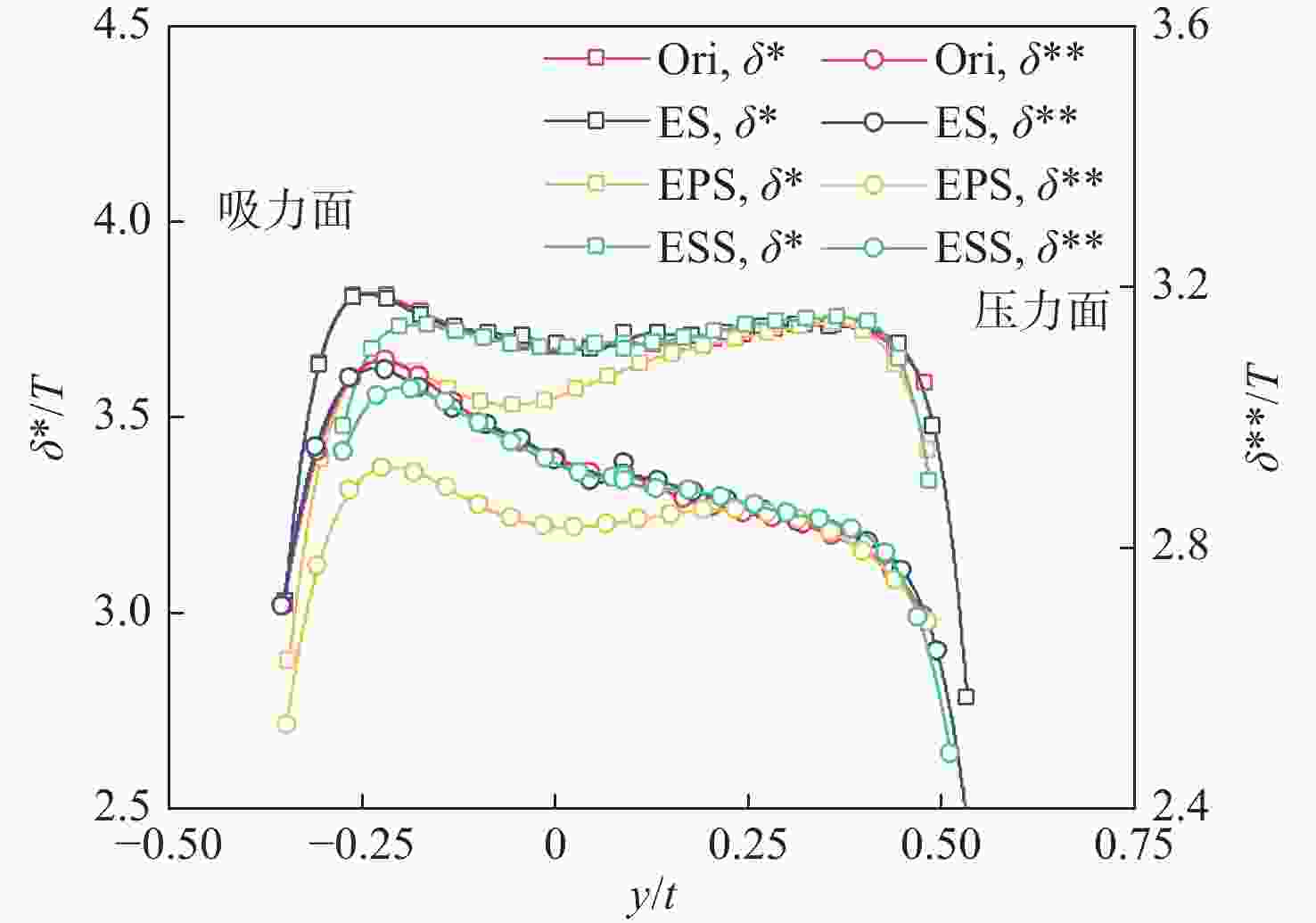

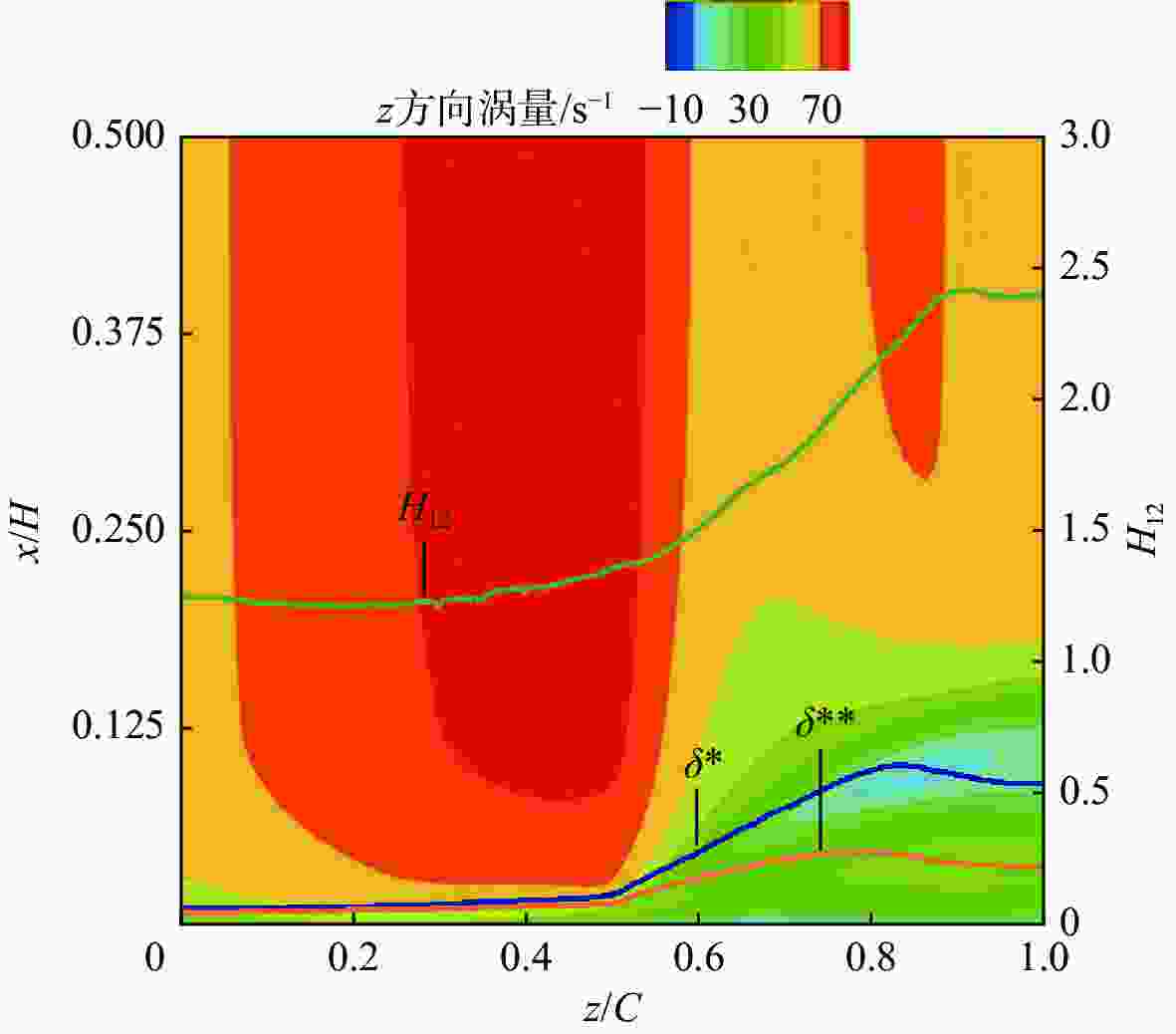

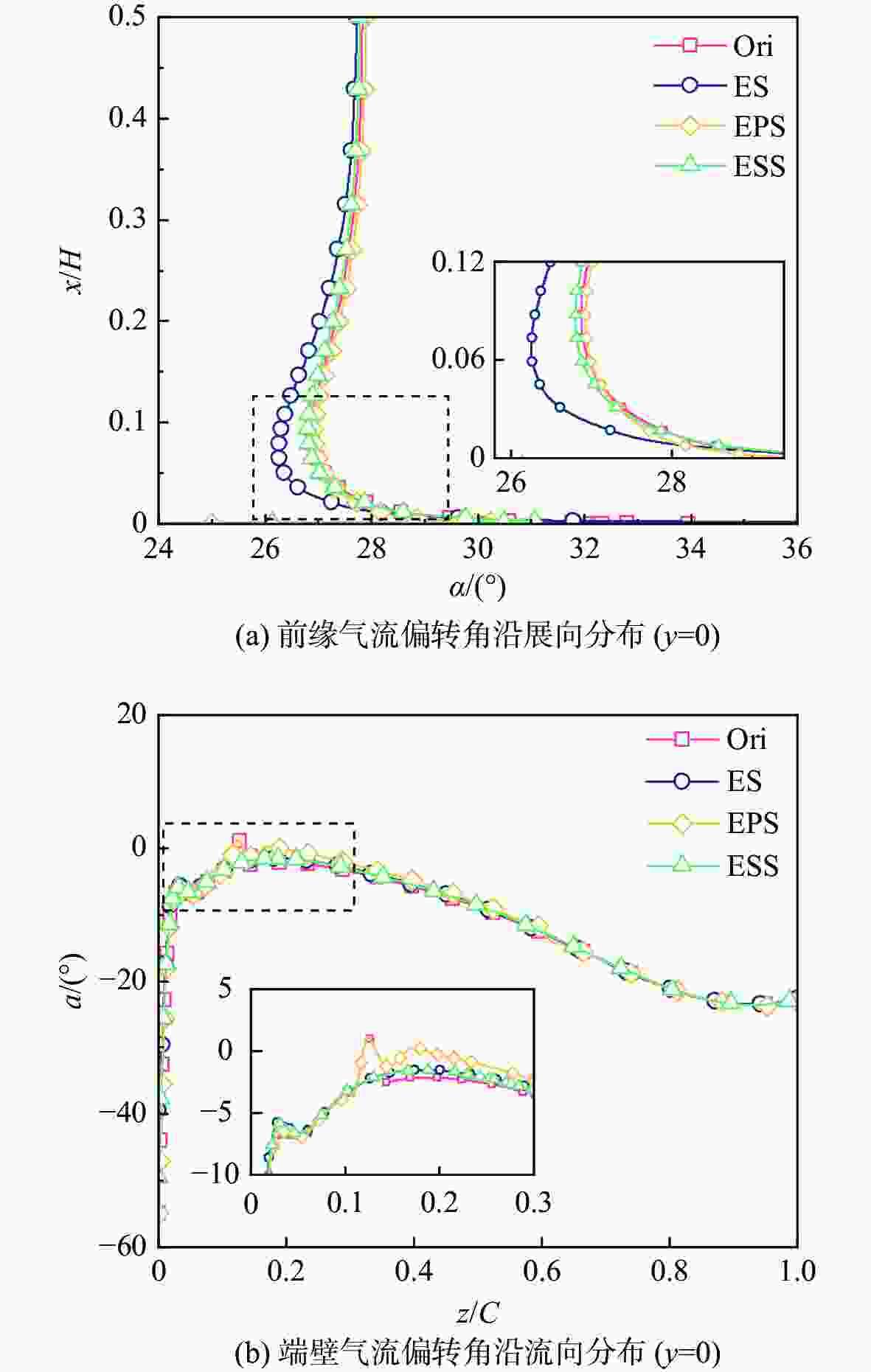

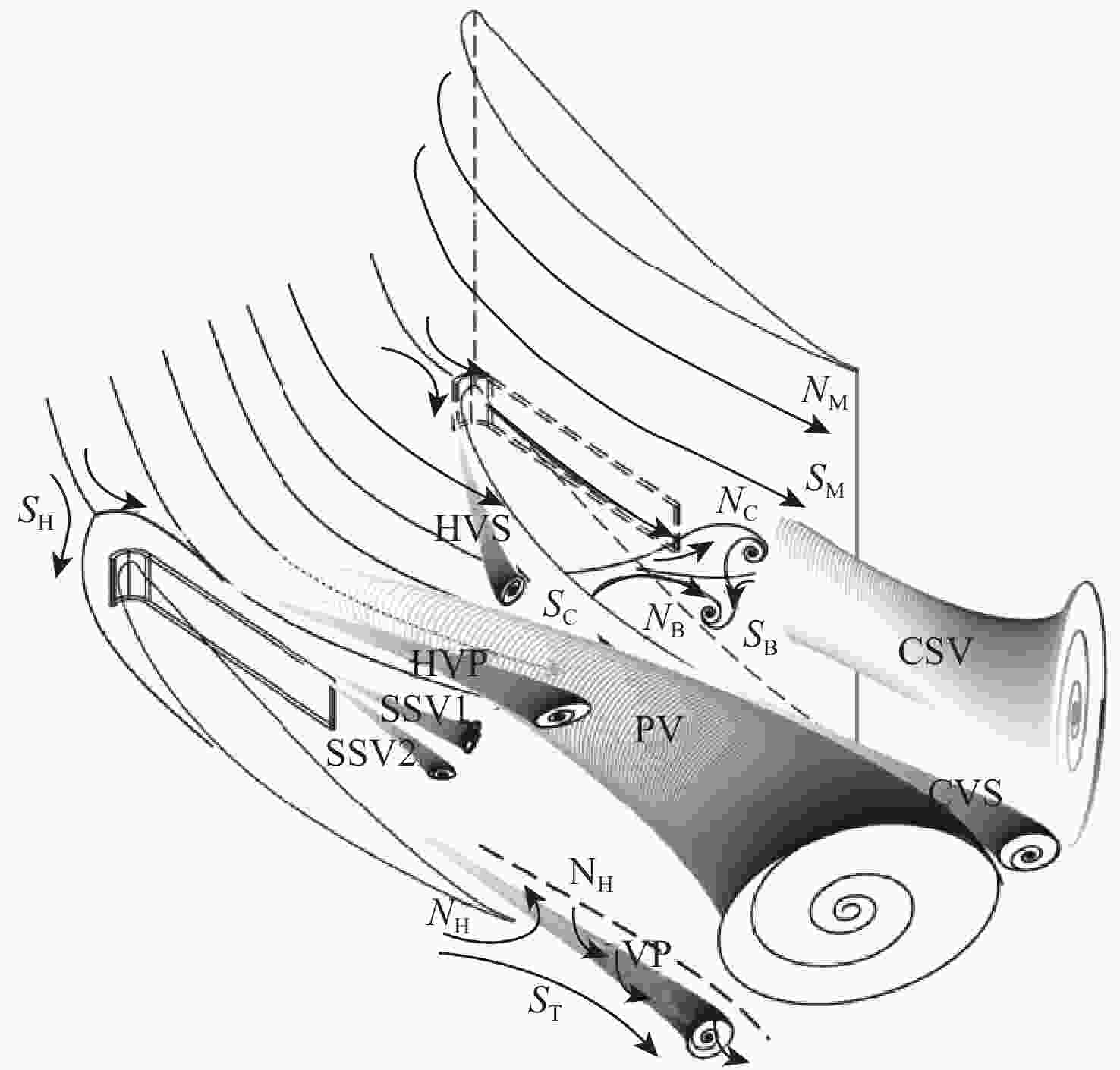

为探究从源头抑制角区分离的流动控制方法,采用数值模拟方法,以NACA65叶栅为研究对象,利用叶栅前缘端壁吸气技术控制马蹄涡,结合拓扑分析对叶栅通道内的三维流动结构进行精确重构,以研究前缘端壁吸气控制马蹄涡进而改善叶栅通道流场结构的机理。结果表明:叶栅前缘端壁吸气技术可以有效推迟马蹄涡形成并削弱其强度,同时在吸气狭缝末端形成一对反旋流向涡对,在向下游发展过程中与通道涡相互作用;前缘端壁吸气通过控制马蹄涡,降低端壁边界层厚度,叶栅前缘通道涡发展受限,由回流组成的叶表分离被抑制;前缘及压力面侧吸气(EPS)直接作用于马蹄涡压力面分支,通道涡强度进一步被削弱,角区分离模式由闭式分离转为不完全闭式分离。最后,对比最优吸气系数下不同方案出口总压损失,发现当吸气量为进口质量流量的0.2%时,EPS方案出口截面总压损失降低5.8%;并且通过调整吸气系数,可以获得较好的变工况控制性能。

Abstract:To explore the source flow control method for the corner separation, this paper takes the NACA65 cascade as the research object and applies the blade leading edge endwall suction technology to control the horseshoe vortex with the numerical simulation method. Combined with topology analysis, the three-dimensional flow field is accurately reconstructed and the control mechanism of the leading edge endwall suction is revealed to improve the cascade channel flow field performance. The results show that the leading edge endwall suction technology can effectively delay the formation of the horseshoe vortex and weaken its strength. Meanwhile, a pair of counter rotating vortices are formed at the end of the suction slit, which interacts with the passage vortex in the process of downstream development. By regulating horseshoe vortices, the suction lessens the thickness of the endwall boundary layer, inhibiting the formation of leading edge passage vortices and preventing surface separation caused by backflow. Because the leading edge and pressure side suction (EPS) directly acts on the pressure side leg of the horseshoe vortex, the passage vortex strength is further weakened, and the corner separation mode changes from closed separation to incomplete closed separation. Finally, the total pressure losses are compared at the outlet under the optimal suction coefficient. It is discovered that when the suction coefficient is 0.2%, the overall pressure loss at the EPS outflow section is decreased by 5.8%. At off-design situations, improved control performance can be attained by modifying the suction coefficient.

-

Key words:

- compressor cascade /

- horseshoe vortex /

- corner separation /

- leading edge suction /

- topology analysis

-

表 1 不同吸气方案总压损失系数

Table 1. Total pressure loss coefficient in different suction scenarios

方案 $ \varpi /\% $ $ {C_{\text{s}}}/\% $ Ori 5.49 ES 5.70 0.0058 EPS 5.17 0.2070 ESS 5.75 0.0162 -

[1] 吴艳辉, 王博, 付裕, 等. 轴流压气机角区分离的研究进展[J]. 航空学报, 2017, 38(9): 107-128.WU Y H, WANG B, FU Y, et al. Research progress of corner separation in axial-flow compressor[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(9): 107-128(in Chinese). [2] BAKER C J. Vortex flow around the bases of obstacles[D]. Cambridge : University of Cambridge, 1979. [3] ROBINSON S K. Coherent motions in the turbulent boundary layer[J]. Annual Review of Fluid Mechanics, 1991, 23(1): 601-639. doi: 10.1146/annurev.fl.23.010191.003125 [4] WANG H, OLSON S J, GOLDSTEIN R J, et al. Flow visualization in a linear turbine cascade of high performance turbine blades[J]. Journal of Turbomachinery, 1997, 119(1): 1-8. doi: 10.1115/1.2841006 [5] PHILIPS D B, CIMBALA J M, TREASTER A L. Suppression of the wing-body junction vortex by body surface suction[J]. Journal of Aircraft, 1992, 29(1): 118-122. doi: 10.2514/3.46134 [6] BLOXHAM M J, BONS J P. Leading-edge endwall suction and midspan blowing to reduce turbomachinery losses[J]. Journal of Propulsion and Power, 2010, 26(6): 1268-1275. doi: 10.2514/1.46105 [7] LIESNER K, MEYER R, LEMKE M, et al. On the efficiency of secondary flow suction in a compressor cascade[C]//Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air. NewYork: ASME, 2010: 151-160. [8] GUO S, LU H, CHEN F, et al. Vortex control and aerodynamic performance improvement of a highly loaded compressor cascade via inlet boundary layer suction[J]. Experiments in Fluids, 2013, 54(7): 1570. doi: 10.1007/s00348-013-1570-y [9] CHEN P, QIAO W, LIESNER K, et al. Effect of segment endwall boundary layer suction on compressor 3D corner separation[C]//Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition. NewYork: ASME, 2015. [10] ZHANG H, CHEN S. A comparative experimental analysis of two unsteady flow control methods in a highly loaded compressor cascade[J]. Experiments in Fluids, 2020, 61(6): 132. doi: 10.1007/s00348-020-02976-w [11] LIANG T, LIU B, SPENCE S. Effect of boundary layer suction on the corner separation in a highly loaded axial compressor cascade[J]. Journal of Turbomachinery, 2021, 143(6): 61002. doi: 10.1115/1.4050148 [12] 赵桂杰. 弯掠扩压叶栅内附面层与二次流控制的研究[D]. 哈尔滨: 哈尔滨工业大学, 2005.ZHAO G J. Study on boundary layer and secondary flow control in bowed-swept diffuser cascade[D]. Harbin: Harbin Institute of Technology, 2005(in Chinese). [13] TOBAK M, PEAKE D J. Topology of three-dimensional separated flows[J]. Annual Review of Fluid Mechanics, 1982, 14(1): 61-85. doi: 10.1146/annurev.fl.14.010182.000425 [14] 刘超群. Liutex-涡定义和第三代涡识别方法[J]. 空气动力学学报, 2020, 38(3): 413-431.LIU C Q, Liutex-third generation of vortex definition and identification methods[J]. Acta Aerodynamica Sinica, 2020, 38(3): 413-431(in Chinese). [15] HAO X, LE C, BAO L, et al. Numerical Investigations on Oscillating aspiration control in high-load compressor cascades[J]. Journal of Propulsion and Power, 2019, 35(4): 850-862. doi: 10.2514/1.B37200 [16] DALLMANN U. Three-dimensional vortex structures and vorticity topology[J]. Fluid Dynamics Research, 1988, 3(1-4): 183-189. doi: 10.1016/0169-5983(88)90063-9 [17] 张华良. 采用叶片弯/掠及附面层抽吸控制扩压叶栅内涡结构的研究[D]. 哈尔滨: 哈尔滨工业大学, 2007.ZHANG H L. Investigation on application of dihedral/swept blade and boundary layer suction to control vortex configuration in compressor cascades[D]. Harbin: Harbin Institute of Technology, 2007(in Chinese). -

下载:

下载: