-

摘要:

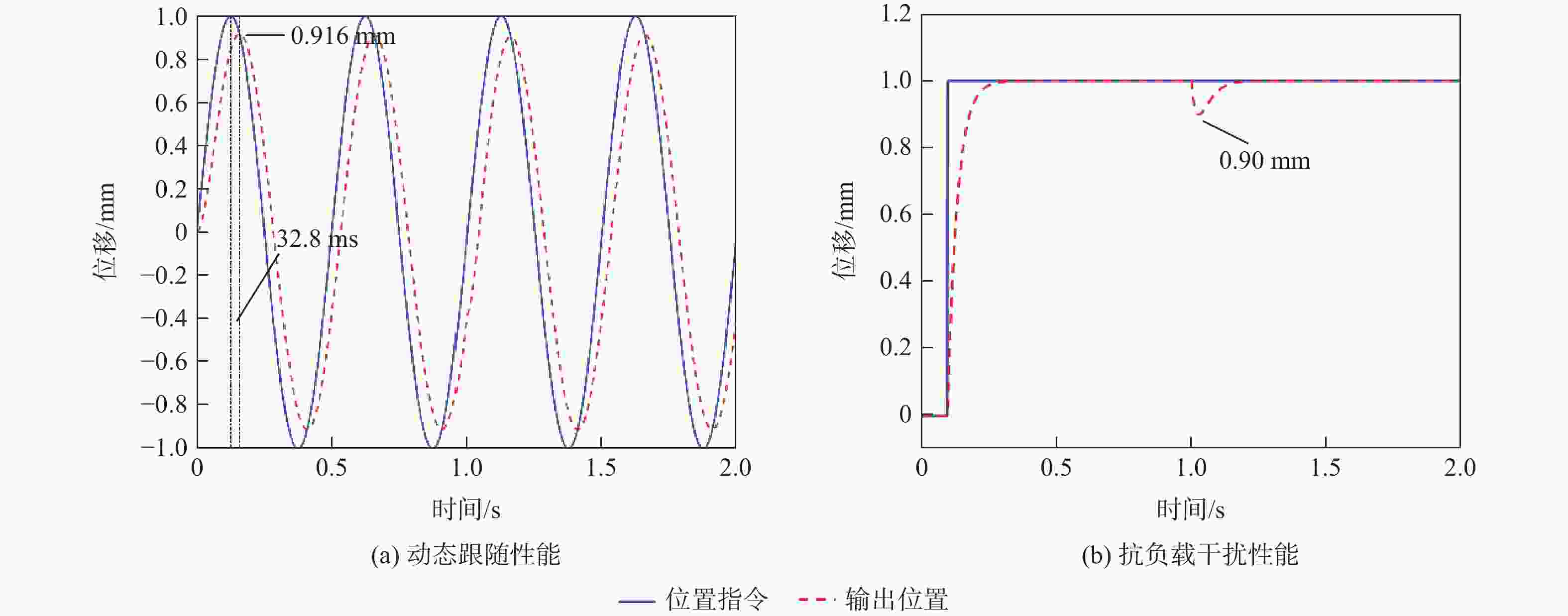

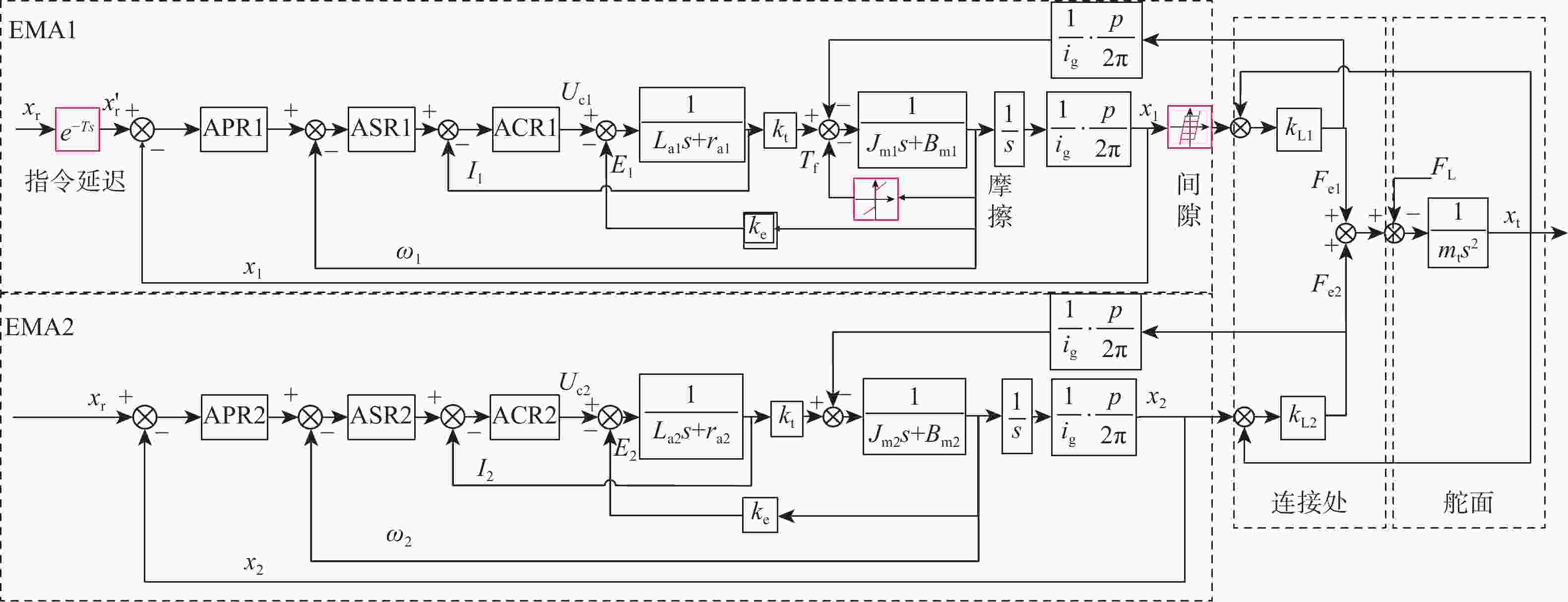

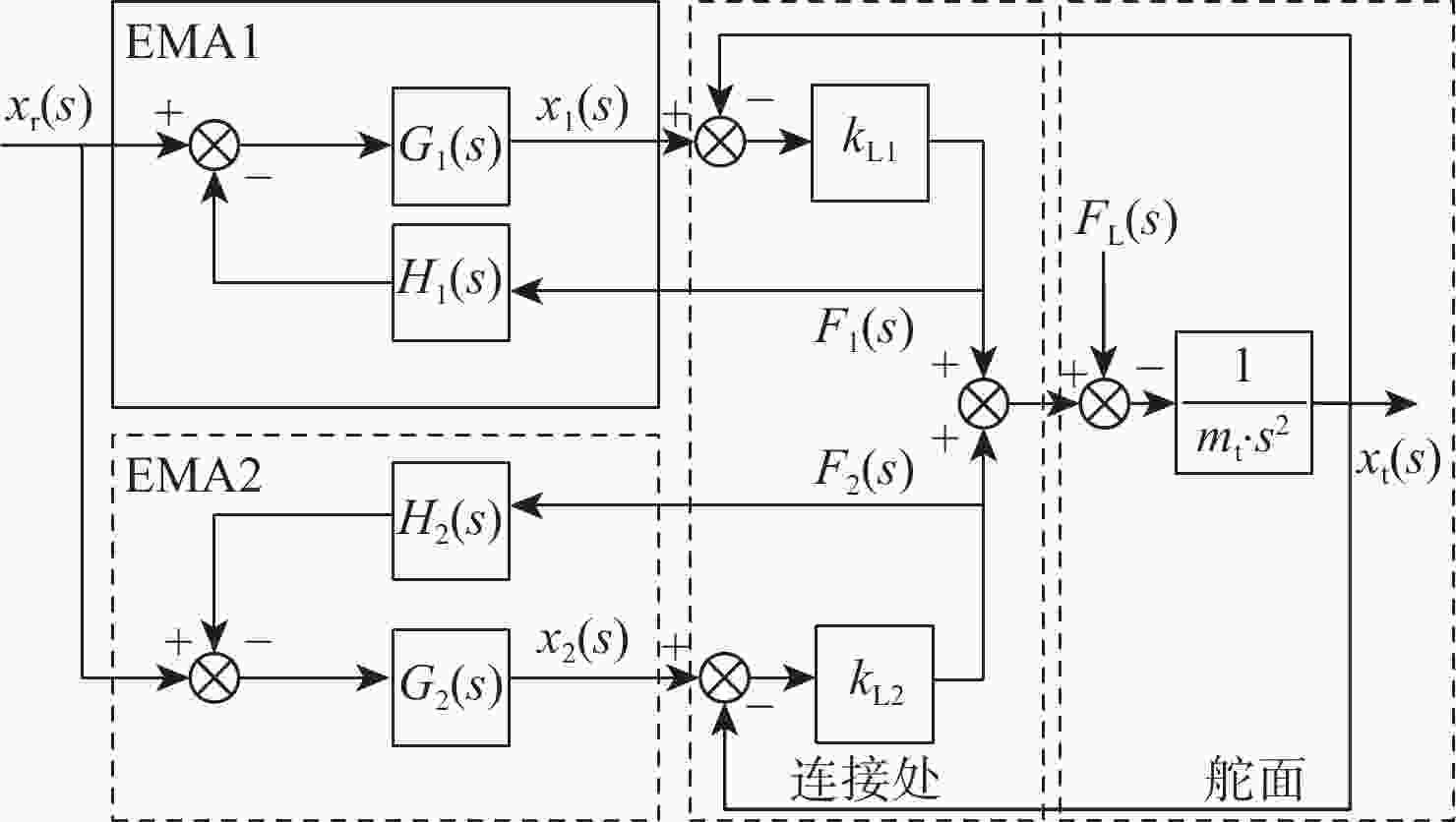

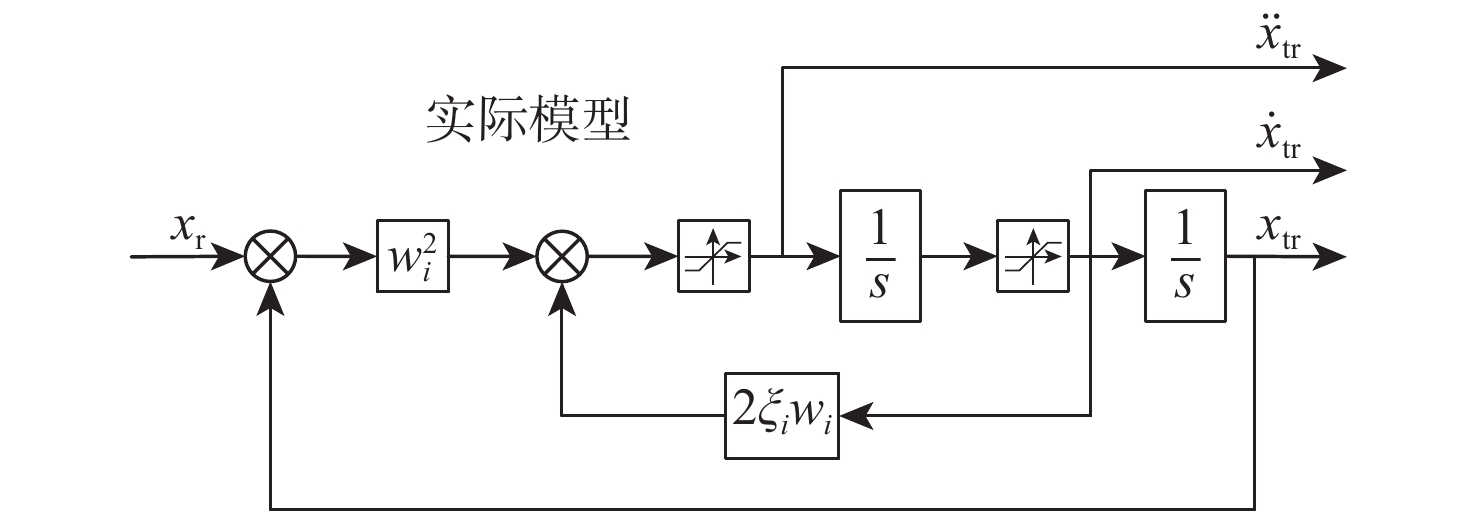

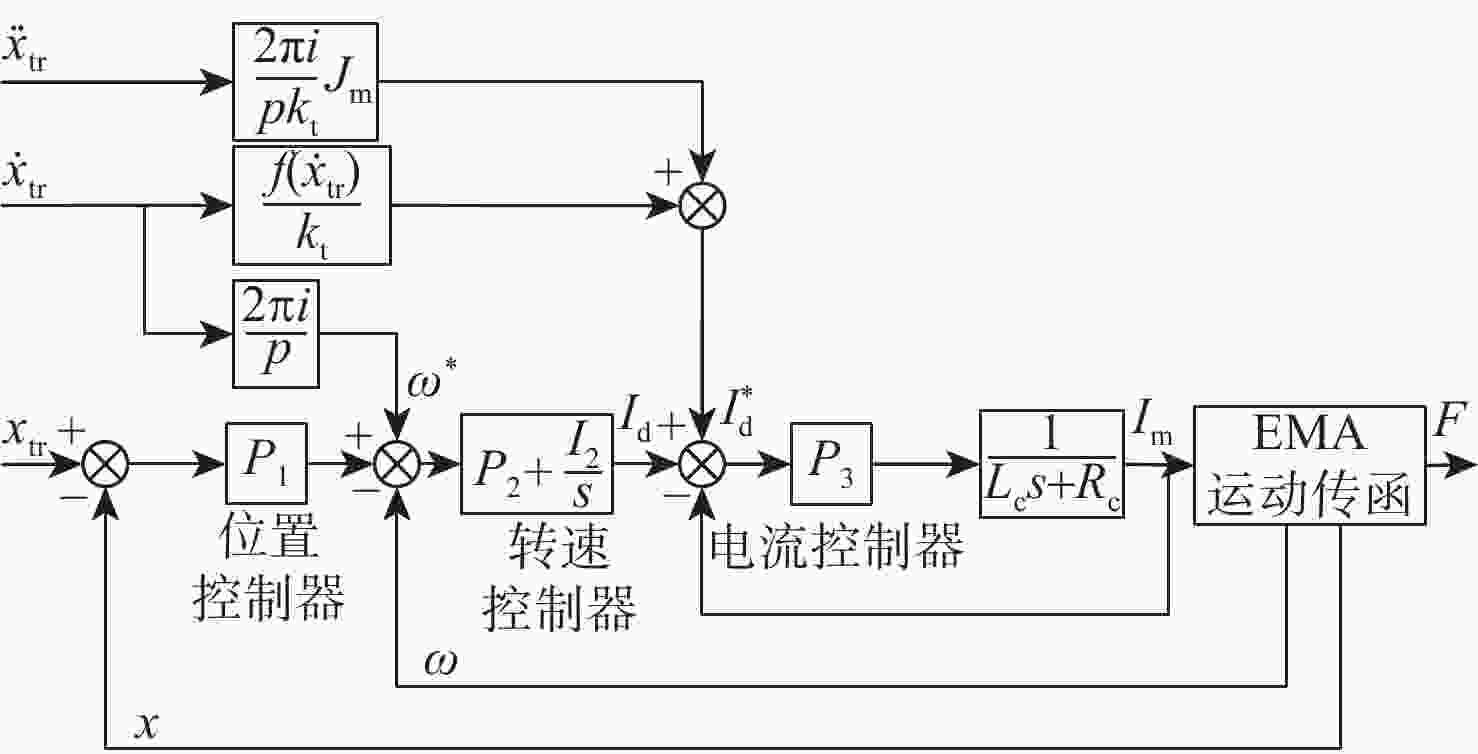

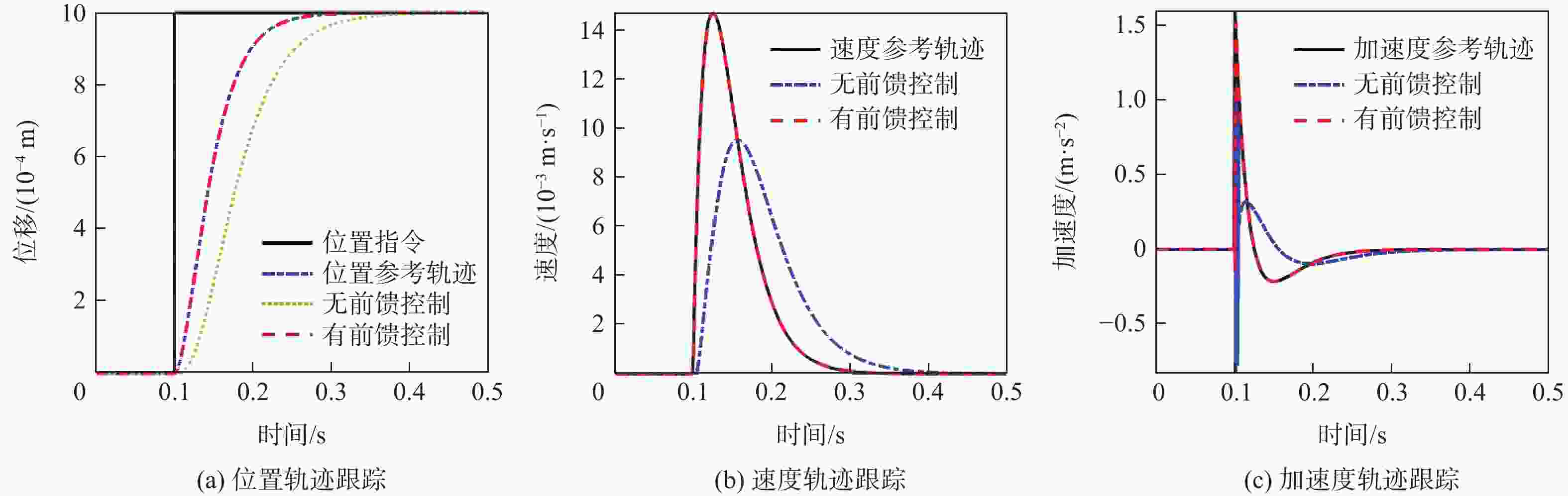

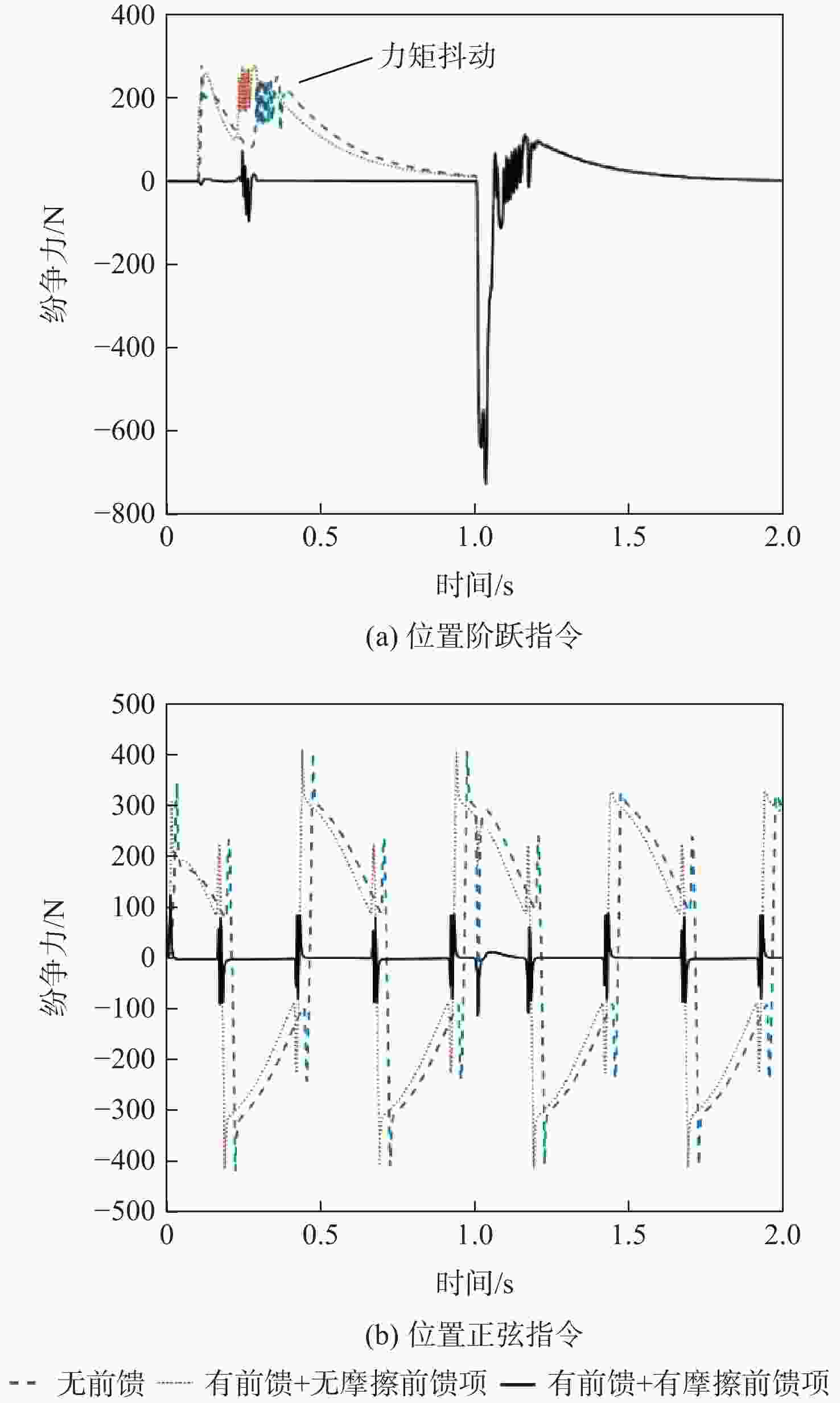

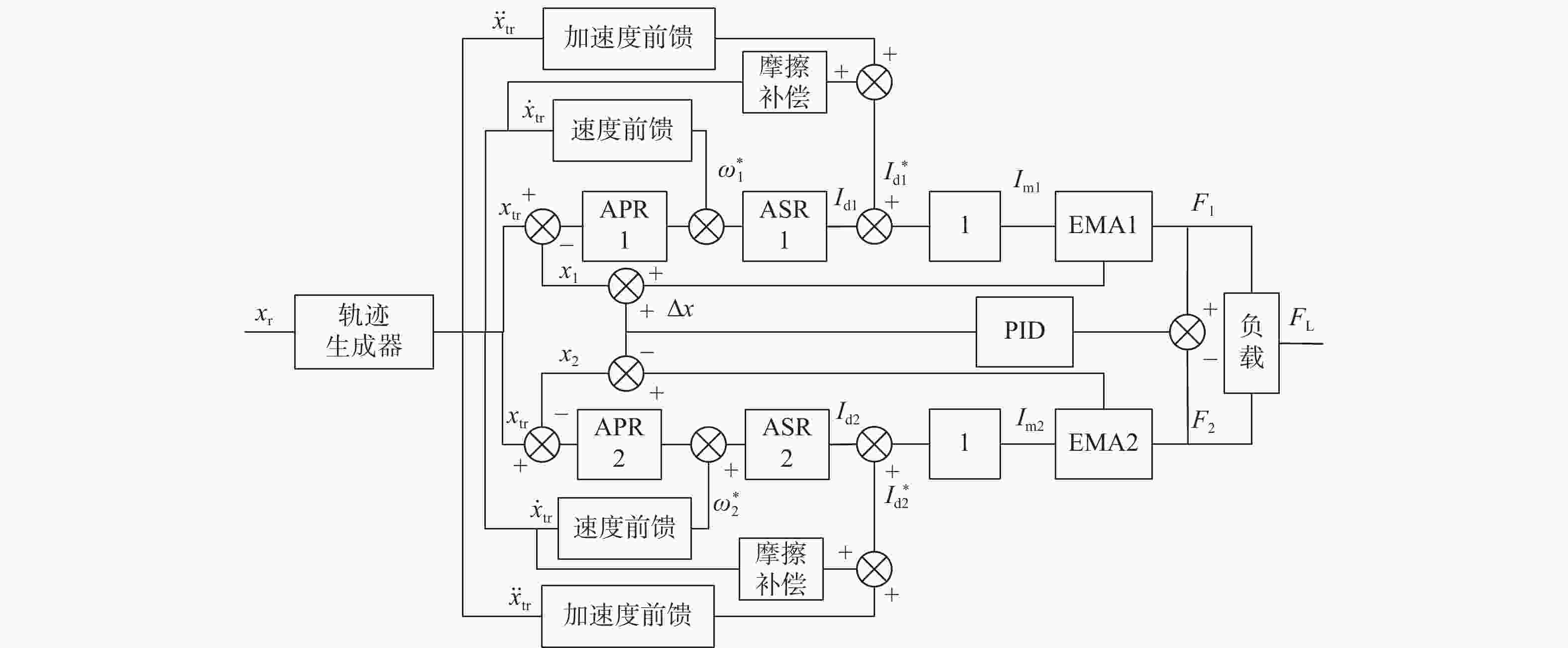

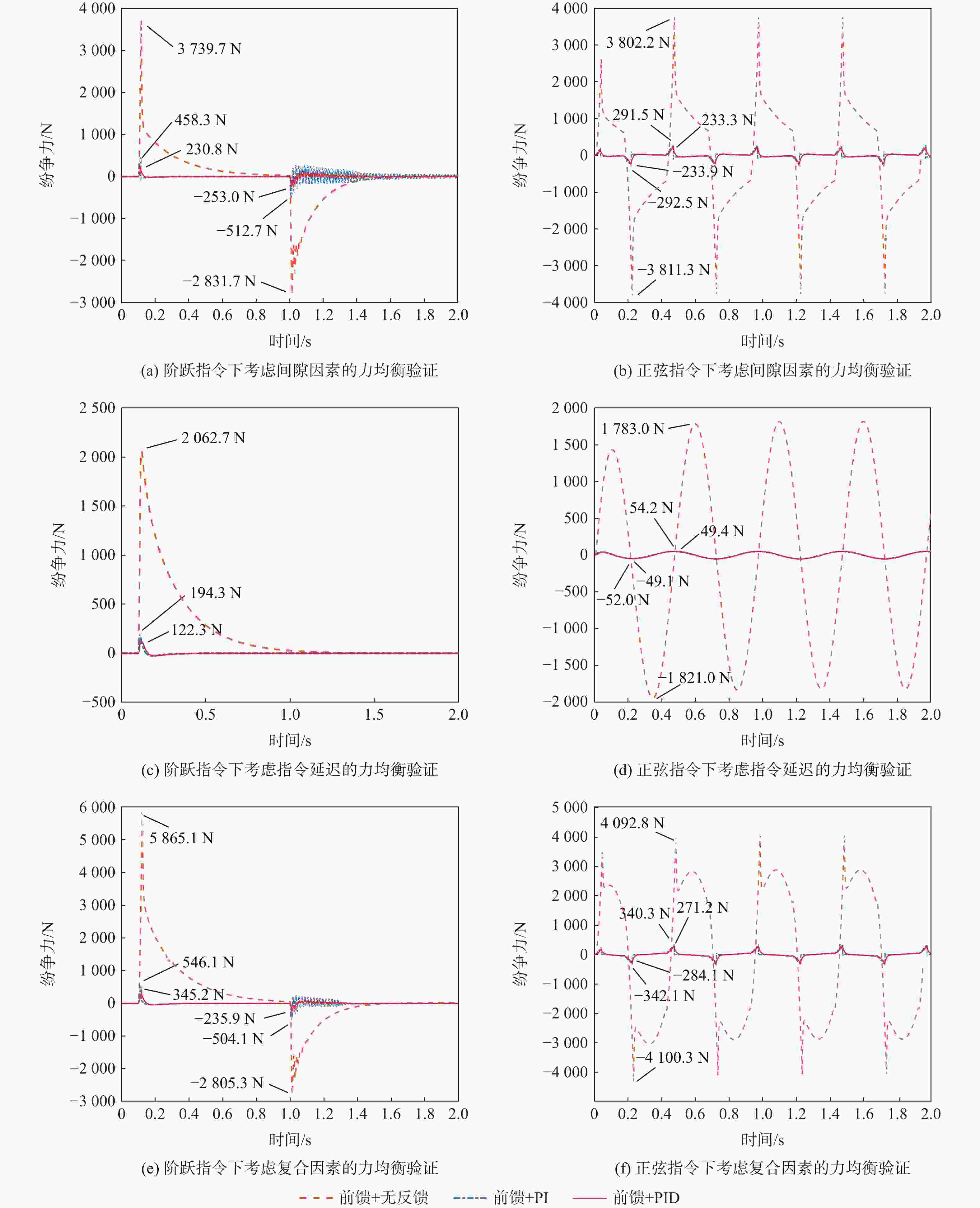

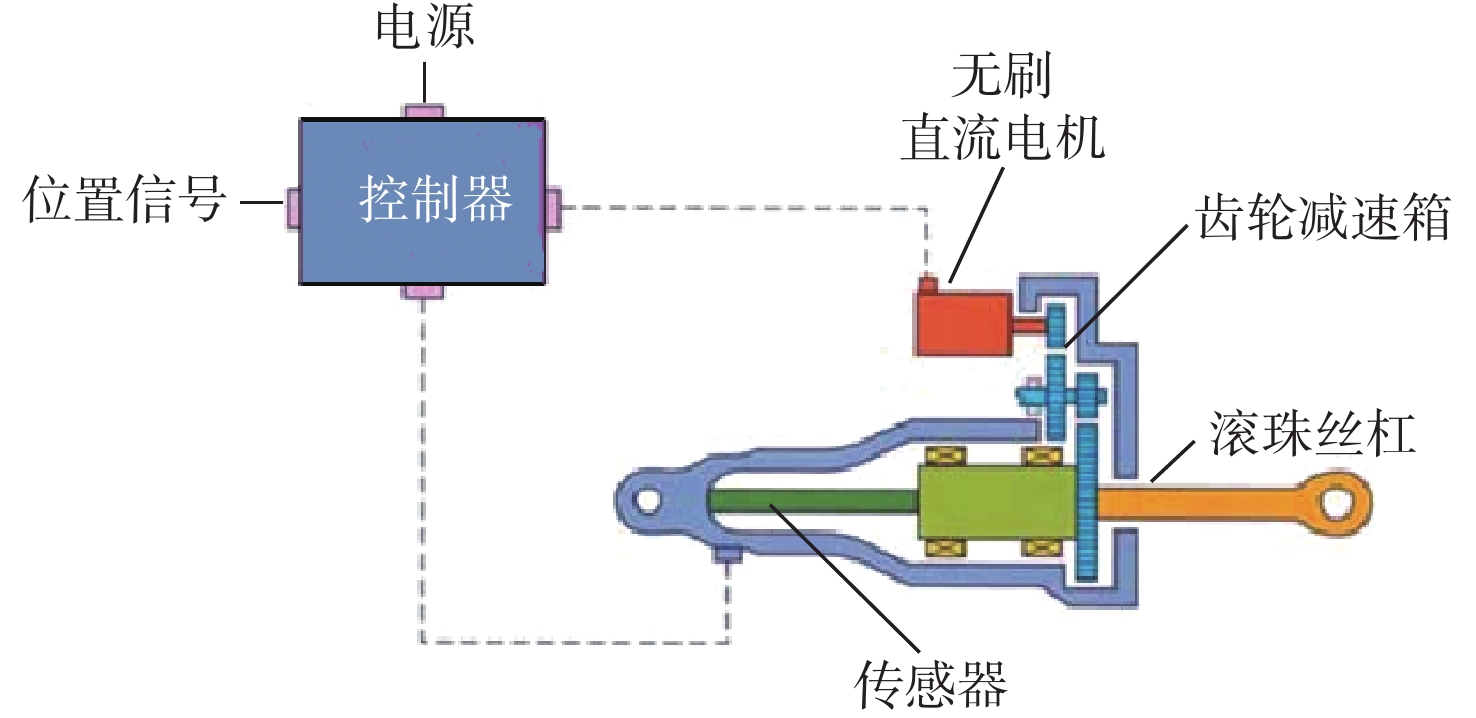

飞机多电/全电化技术的发展使得余度机电作动系统广泛应用于飞控舵面作动系统中,但其在主动/主动工作模式下由于作动器输出不同步而造成的力纷争问题仍需解决。针对该问题,建立了系统完整的线性数学模型,分析了动态力纷争的来源和机理,研究并提出了基于速度和加速度前馈补偿控制、基于力差值反馈的PID控制联合作用的动态力均衡控制方法,并对其均衡能力及鲁棒性进行验证,结论得出所提方法不仅可以有效地减弱摩擦、间隙和指令延迟这3个因素造成的动态力纷争,还对系统中各种参数的扰动有一定的鲁棒性。

Abstract:Redundant electromechanical actuation systems are frequently utilized in flight control surface actuation systems as a result of advancements in more-electric/all-electric aircraft technology. However, a solution to the force fight brought on by actuator output asynchrony in active / active working mode is still pending. To solve this problem, a complete linear mathematical model of the system is established, the causes of dynamic force fight are analyzed, a dynamic force equalization control method based on the combined action of speed and acceleration feedforward compensation control and PID control based on force difference feedback is studied and proposed, and its equalization ability and robustness are verified. The dynamic force equalization is found to be robust against the disturbance of various system parameters and to be able to successfully minimize the dynamic force fight caused by friction, backlash, and command delay.

-

表 1 关键因素模型数值

Table 1. Key factor model values

参数 数值 最大静摩擦力矩/(N∙m) 0.25 库伦摩擦力矩/(N∙m) 0.1 临界速度/(rad·s−1) 9.6 粘滞摩擦系数 0.00137 间隙宽度/mm 0.4 延迟时间/ms 10 表 2 仿真评估指标

Table 2. Simulation evaluation indicators

序号 指标 1 位置指令下的动态力纷争,负峰值DffMin1 2 位置指令下的动态力纷争,正峰值DffMax1 3 外部负载指令下的动态力纷争,负峰值DffMin2 4 外部负载指令下的动态力纷争,正峰值DffMax2 5 位置指令下的静态力纷争Sff1 6 外部负载指令下的静态力纷争Sff2 表 3 仿真参数

Table 3. Simulation parameters

分布类型 参数的数学期望 数值 参数的方差 数值 正态 绕组电阻/Ω 1.77 绕组电阻/Ω2 0.08 正态 绕组电感/H 0.012 绕组电感/H2 0.006 正态 转动惯量/(kg·m2) $1.1 \times {10^{ - 4}}$ 转动惯量/(kg2·m4) $ 5.5 \times {10^{ - 5}} $ 正态 电磁转矩系数 0.067 电磁转矩系数 0.005 正态 反电势系数/(V·s·rad−1) 0.067 反电势系数/(V2·s2·rad−2) 0.005 均匀 传感器反馈增益 −0.02(下限) 传感器反馈增益 0.02(上限) 均匀 指令信号延迟/s 0(下限) 指令信号延迟/s2 0.04(上限) 均匀 传动间隙/m 0(下限) 传动间隙/m2 $4 \times {10^{ - 4}}$(上限) 正态 库伦摩擦/(${\text{N}} \cdot {\text{m}}$) 0.10 库伦摩擦/(${\text{N}}^2 \cdot {\text{m}}^2$) 0.02 正态 最大静摩擦/(${\text{N}} \cdot {\text{m}}$) 0.25 最大静摩擦/(${\text{N}}^2 \cdot {\text{m}}^2$) 0.019 正态 Stribeck速度/(rad·s−1) 9.6 Stribeck速度/(rad2·s−2) 0.48 正态 粘滞摩擦系数 $1.37 \times {10^{ - 3}}$ 粘滞摩擦系数 $2.6 \times {10^{ - 4}}$ 均匀 连接刚度/(${\text{N}} \cdot {\text{m}}$−1) $1.0 \times {10^8}$ 连接刚度/(${\text{N}}^2 \cdot {\text{m}}^{-2}$) $2.0 \times {10^8}$ 外部负载/N 4000 外部负载/N2 4000 -

[1] 中国民用航空局. 运输类飞机适航标准: CCAR-25-R4[S]. 北京: 中国民用航空局, 2011: 129-130.Civil Aviation Administration of China. Airworthiness standard for transport aircraft: CCAR-25-R4[S]. Beijing: Civil Aviation Administration of China, 2011: 129-130. [2] QIAO G, LIU G, SHI Z H, et al. A review of electromechanical actuators for more/all electric aircraft systems[J]. Journal of Mechanical Engineering Science, 2018, 232(22): 4128-4151. [3] JENTINK H W. Exploitation of actuation2015 Pre-standardisation activities on power-by-wire NLR-TP-2016-162[R]. Amsterdam: NLR-Netherlands Aerospace Centre, 2016. [4] IANGRANDE P, GALASSINI A, PAPADOPOULOS S, et al. Considerations on the development of an electric drive for a secondary flight control electromechanical actuator[J]. IEEE Transactions on Industry Applications, 2019, 55(4): 3544-3554. doi: 10.1109/TIA.2019.2907231 [5] DERRIEN J C, SECURITE S D. Electromechanical actuator(ema) advanced technology for flight controls[C]//Proceedings of the 28th International Congress of The Aeronautical Sciences. Brisbane: ICAS Press, 2012: 1-10. [6] 张家盛, 刘波, 何晶晶. 飞机舵面余度作动系统力纷争均衡技术研究[J]. 液压与气动, 2018(6): 99-104. doi: 10.11832/j.issn.1000-4858.2018.06.019ZHANG J S, LIU B, HE J J. Force equalization technology of redundant actuation system for aircraft’s control surface[J]. Hydraulics & Pneumatics, 2018(6): 99-104(in Chinese). doi: 10.11832/j.issn.1000-4858.2018.06.019 [7] 田亮, 张岩山, 王海维. 电传飞控作动系统建模与力纷争均衡研究[J]. 西北工业大学学报, 2020, 38(3): 643-648. doi: 10.3969/j.issn.1000-2758.2020.03.024TIAN L, ZHANG Y S, WANG H W. Fly-by-wire actuation system modeling and force fight equalization research[J]. Journal of Northwestern Polytechnical University, 2020, 38(3): 643-648(in Chinese). doi: 10.3969/j.issn.1000-2758.2020.03.024 [8] 付永领, 范殿梁, 李祝锋. 非相似余度作动系统静态力均衡控制策略[J]. 北京航空航天大学学报, 2014, 40(11): 1492-1499.FU Y L, FAN D L, LI Z F. Static force equalization for dissimilar redundant actuator system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(11): 1492-1499(in Chinese). [9] QI H, MARE J C, FU Y. Force equalization in hybrid actuation systems[C]//Proceedings of the 7th International Conference on Fluid Power Transmission and Control. Piscataway: IEEE Press, 2009: 342-347. [10] KOWALSKI R. Force fight in parallel-redundant electro-mechanical actuation systems[C]//Proceedings of More Electric Aircraft 2017. Piscataway: IEEE Press, 2017: 1-3. [11] KOWALSKI R, WINDELBERG J, LADNER R, et al. Force fight compensation for redundant electro-mechanical flight control actuators[C]//Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences, Belo Horizonte: ICAS Press, 2018: 1-7. [12] 范殿梁, 付永领, 郭彦青, 等. 非相似余度作动系统动态力均衡控制策略[J]. 北京航空航天大学学报, 2015, 41(2): 234-240.FAN D L, FU Y L, GUO Y Q, et al. Dynamic force equalization for dissimilar redundant actuator system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(2): 234-240(in Chinese). [13] WANG L J, MARÉ J C. A force equalization controller for active/active redundant actuation system involving servo-hydraulic and electro-mechanical technologies[J]. Journal of Aerospace Engineering, 2014, 228(10): 1768-1787. doi: 10.1177/0954410013504343 [14] UR REHMAN W, WANG X H, CHENG Y Q, et al. Motion synchronization for the SHA/EMA hybrid actuation system by using an optimization algorithm[J]. Automatika, 2021, 62(3-4): 503-512. doi: 10.1080/00051144.2021.1989891 [15] XUE Y, YAO Z Q. A way to mitigate force-fight oscillation based on pressure and position compensation for fly-by-wire flight control systems[J]. Transactions of the Japan Society for Aeronautical and Space Sciences, 2020, 63(1): 1-7. doi: 10.2322/tjsass.63.1 [16] 孙晓哲, 杨珍书, 杨建忠, 等. 机电作动系统非指令振荡信号的故障影响分析[J]. 北京航空航天大学学报, 2018, 44(7): 1419-1429.SUN X Z, YANG Z S, YANG J Z, et al. Failure effect analysis of uncommand oscillation signals in electromechanical actuation system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(7): 1419-1429(in Chinese). [17] 付永领, 齐海涛, 王利剑, 等. 混合作动系统的工作模式研究[J]. 航空学报, 2010, 31(6): 1177-1184.FU Y L, QI H T, WANG L J, et al. Research on operating modes in hybrid actuation systems[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(6): 1177-1184(in Chinese). [18] 白玉轩. 基于神经网络的飞控机电作动系统传感器故障检测研究[D]. 天津: 中国民航大学, 2020: 12-13.BAI Y X. Sensor fault detection of flight control electromechanical actuation system based on neutral network[D]. Tianjin: Civil Aviation University of China, 2020: 12-13(in Chinese). [19] WANG L. Force equalization for active/active redundant actuation system involving servo-hydraulic and electro-mechanical technologies[D]. Toulouse: INSA, 2012: 25-26. [20] 臧寿松. 机电系统中摩擦辨识与补偿方法的研究与实现[D]. 西安: 西安电子科技大学, 2012: 6-7.ZANG S S. Research and experiment of friction identification and compensation in mechatronic systems[D]. Xi’an : Xidian University, 2012: 6-7(in Chinese). [21] 兰远锋. 电动舵机伺服系统的间隙与摩擦补偿控制[D]. 北京: 北京交通大学, 2016: 15-16.LAN Y F. Compensation control of electric servo systems with backlash and friction[D]. Beijing: Beijing Jiaotong University, 2016: 15-16(in Chinese). [22] 李亚飞. 伺服系统摩擦补偿与控制策略研究[D]. 南京: 南京航空航天大学, 2016: 38-40.LI Y F. Research on friction compensation and control strategy of servo system[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016: 38-40(in Chinese). [23] 袭著燕, 路长厚, 潘伟, 等. 带有摩擦前馈补偿的伺服控制器设计的研究[J]. 组合机床与自动化加工技术, 2006(12): 33-37. doi: 10.3969/j.issn.1001-2265.2006.12.011XI Z Y, LU C H, PAN W, et al. Study on design of servo controller with friction feedforward compensation[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2006(12): 33-37(in Chinese). doi: 10.3969/j.issn.1001-2265.2006.12.011 -

下载:

下载: