Effect of small inclination angle on heat transfer performance of Ω-shaped bending heat pipe

-

摘要:

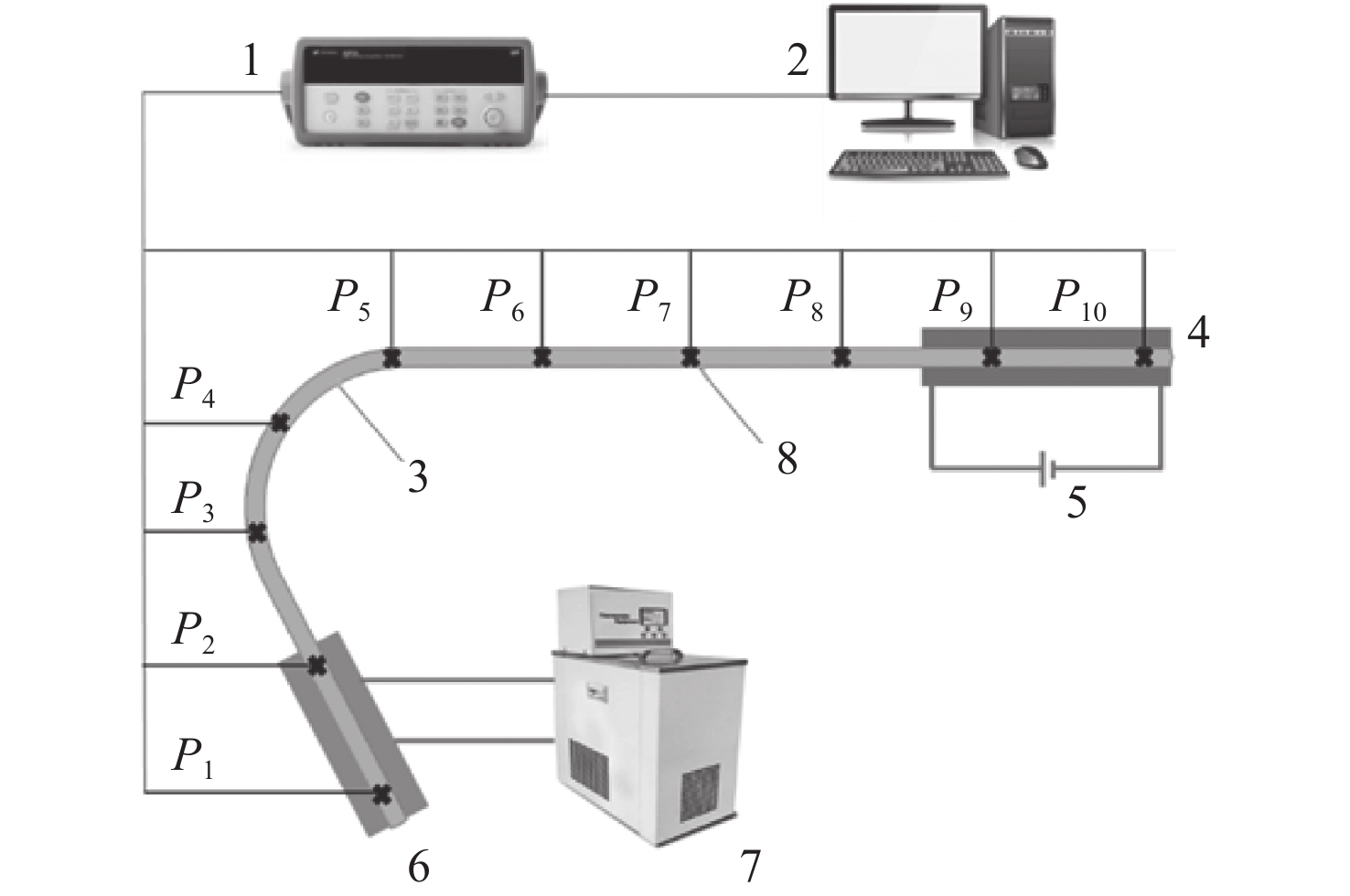

为研究小倾角对Ω形槽道弯曲热管传热特性的影响,搭建了热管传热性能实验台,基于实验对不同小倾角下热管的温度分布、总热阻、当量导热系数和最大输入功率进行分析。结果表明:在相同输入功率下,倾角为0°和倾角为负的热管壁温均匀性优于倾角为正的热管;倾角为正的热管总热阻最大,倾角为0°和倾角为负的热管总热阻相近;热管倾角为0°时的最大输入功率最高。热管安装和应用中易出现重力倾角偏差,研究结果表明,较小倾角会对Ω形槽道弯曲热管的传热性能造成影响。

Abstract:An experimental platform for studying the heat transfer performance of heat pipes was set up to investigate the effect of a small inclination angle on the heat transfer performance of Ω-shaped bending heat pipes. The temperature distribution, total thermal resistance, thermal conductivity, and maximum heat transfer power of heat pipes with different small inclination angles were analyzed in the experiment. The results show that the wall temperature uniformity of heat pipes with zero and negative inclination angles is better than that of heat pipes with positive inclination angles at the same heating power. The heat pipe with a positive inclination angle has the largest total thermal resistance. The total thermal resistance of heat pipes with zero and negative inclination angles is similar. The maximum heat transfer power of heat pipes with zero inclination angle is the highest. In installation and application, the heat pipe will inevitably face gravity inclination angle deviation. The research results indicate that the small inclination angle can affect the heat transfer performance of Ω-shaped bending heat pipes.

-

表 1 热管截面参数

Table 1. Cross-section parameters of heat pipe

横截面宽度$ {L_{\text{a}}} $/mm 横截面高度$ {L_{\text{b}}} $/mm 蒸汽腔直径$ {D_{\text{v}}} $/mm 吸液芯直径$ {D_{\text{l}}} $/mm 两孔圆心间距$ {L_{\text{c}}} $/mm 孔半径$ R $/mm 狭缝宽度$ w $/mm 狭缝高度$ h $/mm 单孔吸液芯通道数目 18.00 9.00 4.00 1.24 9.00 3.60 0.48 0.36 11 -

[1] ABO-ELFADL S, HASSAN H, EL-DOSOKY M F. Energy and exergy assessment of integrating reflectors on thermal energy storage of evacuated tube solar collector-heat pipe system[J]. Solar Energy, 2020, 209: 470-484. doi: 10.1016/j.solener.2020.09.009 [2] 赵佳腾, 王增鹏, 戴宇成, 等. 两亲性纳米流体太阳能重力热管传热性能研究[J]. 化工学报, 2020, 71(12): 5461-5469.ZHAO J T, WANG Z P, DAI Y C, et al. Research on heat transfer performance of amphiphilic nanofluid solar gravity heat pipe[J]. CIESC Journal, 2020, 71(12): 5461-5469(in Chinese). [3] CIMEN M, COLAKOGLU M, GÜNGÖR A. Overheating limitation of thermosiphon solar collectors by controlling heat pipe fluid in all glass evacuated tubes[J]. Solar Energy, 2021, 230: 515-527. doi: 10.1016/j.solener.2021.10.066 [4] LIU X, ZHANG R, LIANG Y, et al. Core thermal-hydraulic evaluation of a heat pipe cooled nuclear reactor[J]. Annals of Nuclear Energy, 2020, 142: 107412. doi: 10.1016/j.anucene.2020.107412 [5] ZHANG Y, GUO K L, WANG C L, et al. Numerical analysis of segmented thermoelectric generators applied in the heat pipe cooled nuclear reactor[J]. Applied Thermal Engineering, 2022, 204: 117949. doi: 10.1016/j.applthermaleng.2021.117949 [6] LEE J, KIM D, MUN J, et al. Heat-transfer characteristics of a cryogenic loop heat pipe for space applications[J]. Energyies, 2020, 13(7): 1616. doi: 10.3390/en13071616 [7] 杨涛, 赵石磊, 高腾, 等. 航天分散热源控温用环路热管设计及飞行应用[J]. 宇航学报, 2021, 42(6): 798-806. doi: 10.3873/j.issn.1000-1328.2021.06.014YANG T, ZHAO S L, GAO T, et al. Design and In-orbit application of temperature controlled loop heat pipe for aerospace distributed heat sources[J]. Journal of Astronautics, 2021, 42(6): 798-806(in Chinese). doi: 10.3873/j.issn.1000-1328.2021.06.014 [8] SIRICHAROENPANICH A, WIRIYASART S, SRICHAT A, et al. Thermal management system of CPU cooling with a novel short heat pipe cooling system[J]. Case Studies in Thermal Engineering, 2019, 15: 100545. doi: 10.1016/j.csite.2019.100545 [9] BEHI H, GHANBARPOUR M, BEHI M. Investigation of PCM-assisted heat pipe for electronic cooling[J]. Applied Thermal Engineering, 2017, 127: 1132-1142. doi: 10.1016/j.applthermaleng.2017.08.109 [10] DELPECH B, AXCELL B, JOUHARA H. Experimental investigation of a radiative heat pipe for waste heat recovery in a ceramics kiln[J]. Energy, 2019, 170: 636-651. doi: 10.1016/j.energy.2018.12.133 [11] WANG Y J, CHEN Y, WANG K, et al. Performance evaluation and thermal analysis of heat pipe flue gas waste heat utilization system[J]. Energy Reports, 2022, 8: 210-217. [12] ANAND A R. Effect of various parameters on heat transport capability of axially grooved heat pipes[J]. Thermal Science and Engineering Progress, 2021, 24: 100890. doi: 10.1016/j.tsep.2021.100890 [13] 朱明汉, 白鹏飞, 胡艳鑫, 等. 烧结多孔槽道吸液芯超薄平板热管的传热性能[J]. 化工学报, 2019, 70(4): 1349-1357.ZHU M H, BAI P F, HU Y X, et al. Heat transfer performance of ultra-thin plate heat pipe with sintered porous channels structures wick[J]. CIESC Journal, 2019, 70(4): 1349-1357(in Chinese). [14] NAGAYAMA G, GYOTOKU S, TSURUTA T. Thermal performance of flat micro heat pipe with converging microchannels[J]. International Journal of Heat and Mass Transfer, 2018, 122: 375-382. doi: 10.1016/j.ijheatmasstransfer.2018.01.131 [15] LI Z S. Design and preliminary experiments of a novel heat pipe using a spiral coil as capillary wick[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1240-1251. doi: 10.1016/j.ijheatmasstransfer.2018.05.110 [16] 韩娜丽, 徐红艳, 陈跃勇, 等. “Ω” 形轴向槽道热管传热系统传热能力试验研究[J]. 低温工程, 2016(2): 38-44.HAN N L, XU H Y, CHEN Y Y, et al. Experimental investigation of heat transfer capability of “Ω” shape axial grooved heat pipe heat transfer system[J]. Cryogenics, 2016(2): 38-44(in Chinese). [17] PIS’MENNYI E N, KHAYRNASOV S M, RASSAMAKIN B M. Heat transfer in the evaporation zone of aluminum grooved heat pipes[J]. International Journal of Heat and Mass Transfer, 2018, 127: 80-88. doi: 10.1016/j.ijheatmasstransfer.2018.07.154 [18] LEDARI B H, SABZPOOSHANI M. A comparative empirical investigation on the thermal performance of gravity-assisted double-bent, double-ended cooling, and single-bent, single-ended cooling heat pipes[J]. International Communications in Heat and Mass Transfer, 2020, 112: 104505. doi: 10.1016/j.icheatmasstransfer.2020.104505 [19] 乔家广, 陶乐仁, 谢荣建, 等. 特殊型槽道热管启动和运行特性研究[J]. 低温与超导, 2019, 47(3): 84-88.QIAO J G, TAO L R, XIE R J, et al. Research on starting and operation characteristics of special grooved heat pipe[J]. Cryogenics & Superconductivity, 2019, 47(3): 84-88(in Chinese). [20] 张畅, 谢荣建, 孙琦, 等. 液氮温区Ω形轴向槽道热管的启动特性与传热性能[J]. 化工进展, 2019, 38(6): 2610-2617.ZHANG C, XIE R J, SUN Q, et al. Start-up and heat transfer performance of a nitrogen cryogenic axial Ω shape grooved heat pipe[J]. Chemical Industry and Engineering Progress, 2019, 38(6): 2610-2617(in Chinese). [21] YU F W, YU C, CAO J G, et al. Experimental analysis of the evaporation regimes of an axially grooved heat pipe at small tilt angles[J]. International Journal of Heat and Mass Transfer, 2018, 126: 334-341. doi: 10.1016/j.ijheatmasstransfer.2018.05.112 [22] ZHANG X, JIANG D Y, WANG H, et al. Experimental analysis on the evaporator startup behaviors in a trapezoidally grooved heat pipe[J]. Applied Thermal Engineering, 2021, 199: 117558. doi: 10.1016/j.applthermaleng.2021.117558 [23] CHI S W. 热管理论与实用[M]. 蒋章焰, 译. 北京: 科学出版社, 1981: 60-62.CHI S W. Heat pipe theory and practice[M]. JIANG Z Y, translated. Beijing: Science Press, 1981: 60-62(in Chinese). -

下载:

下载: