-

摘要:

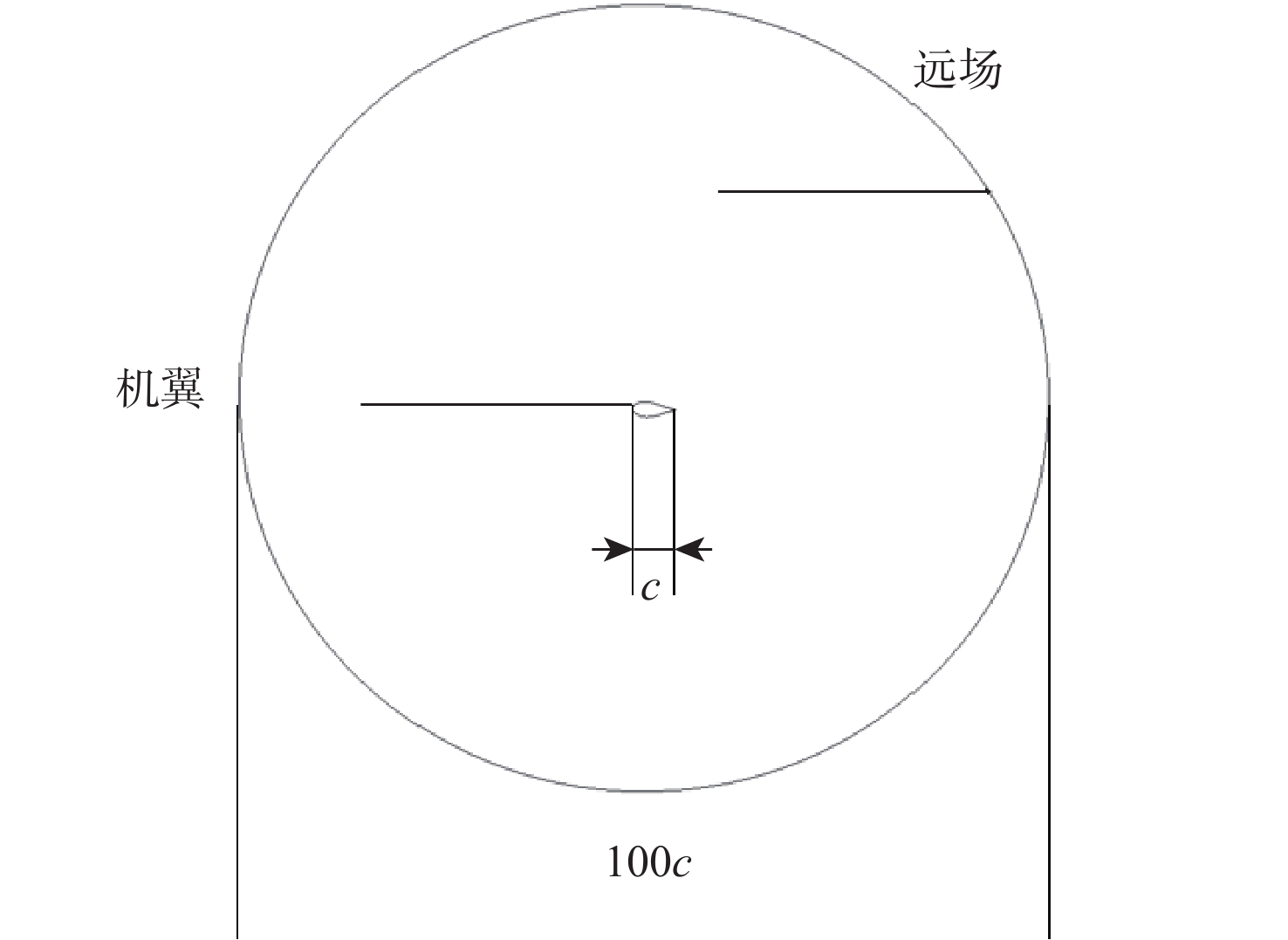

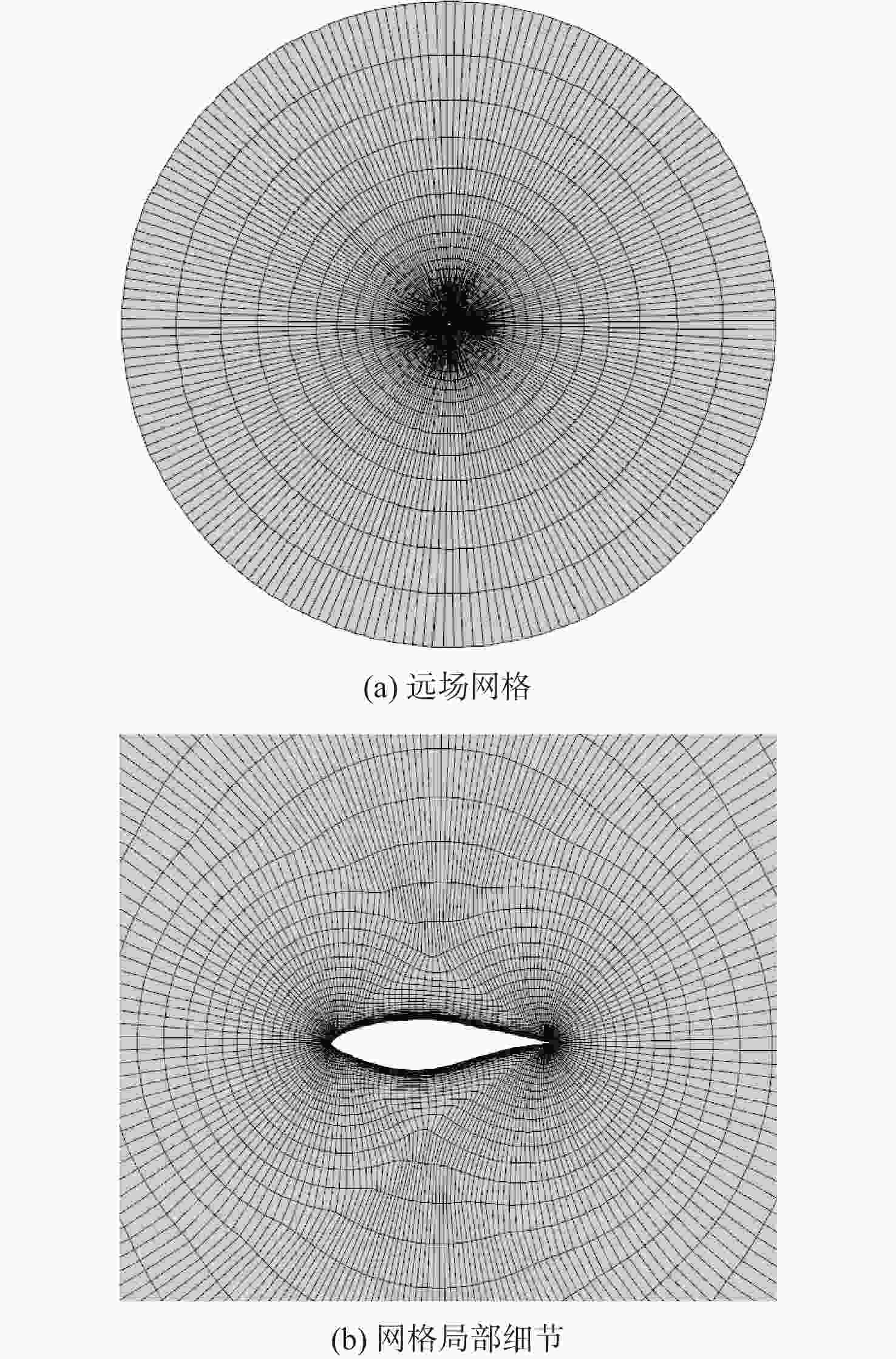

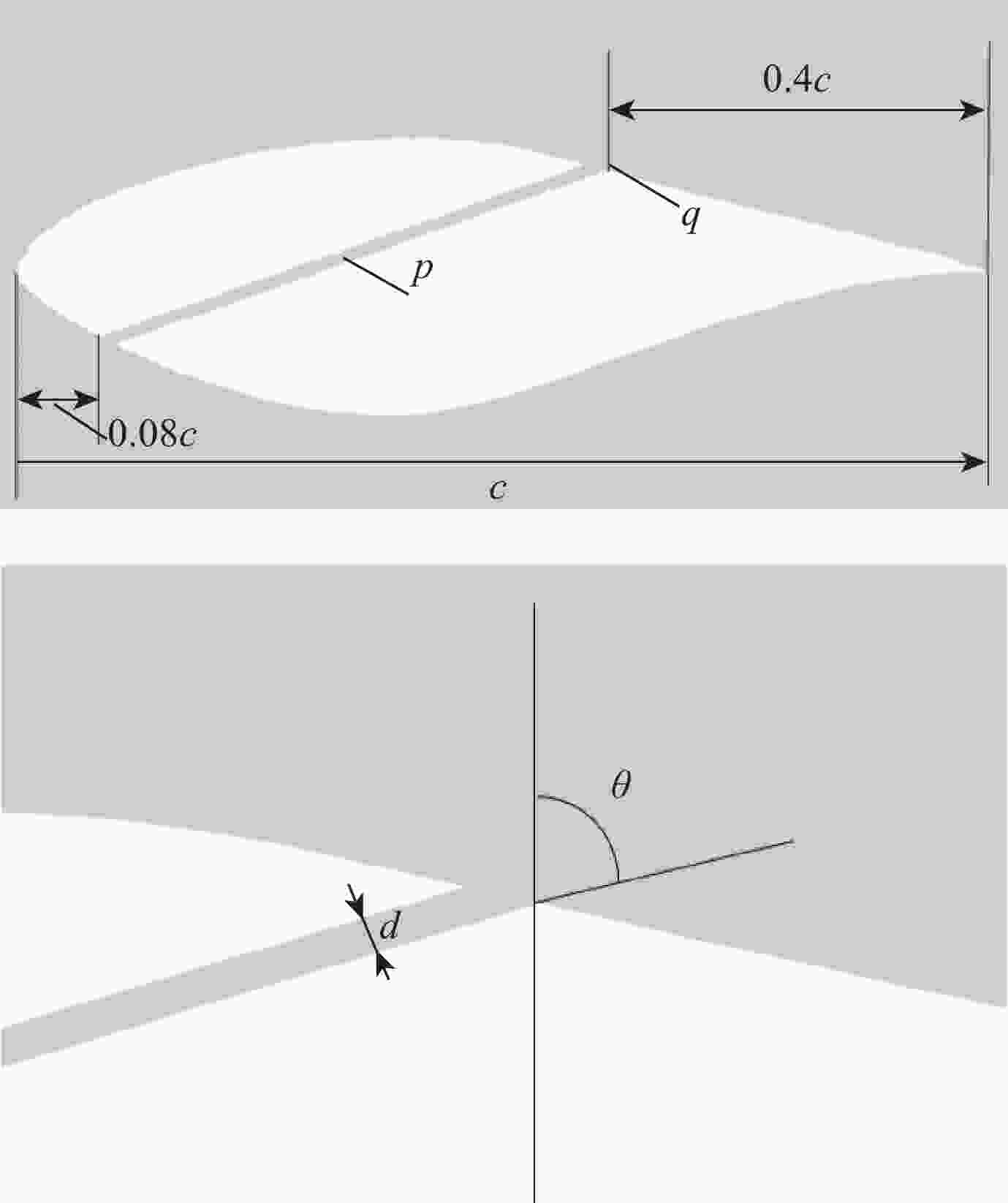

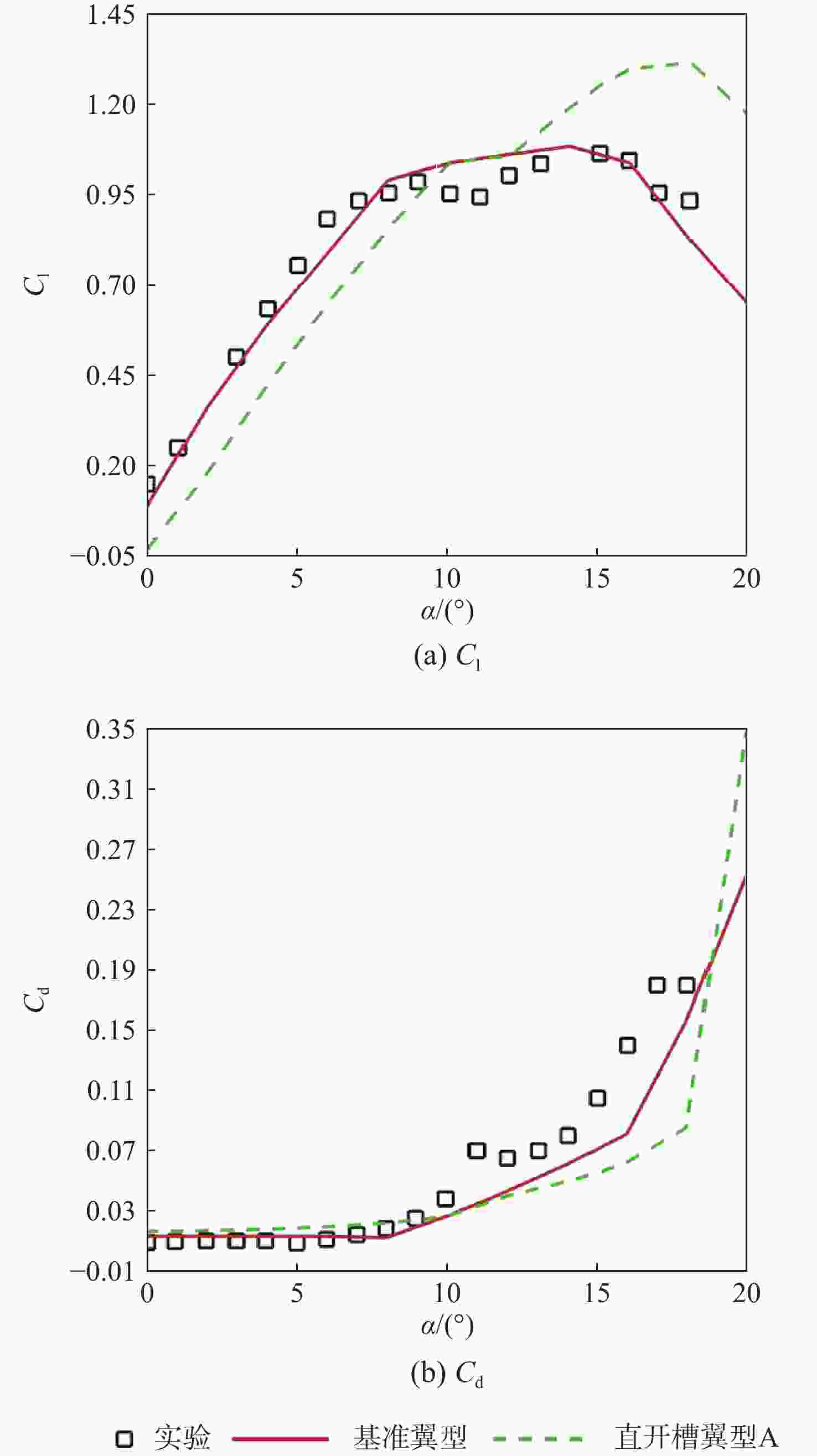

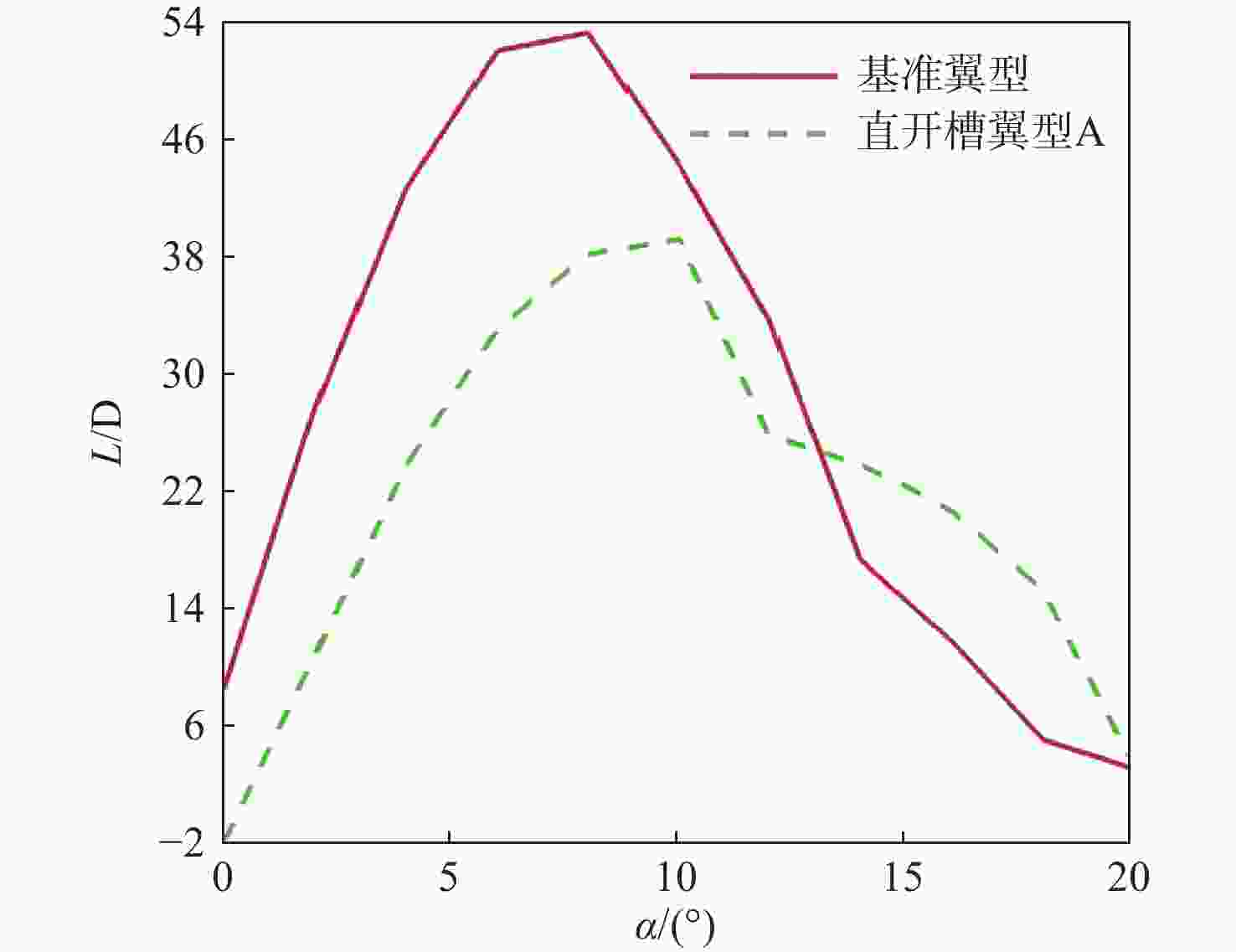

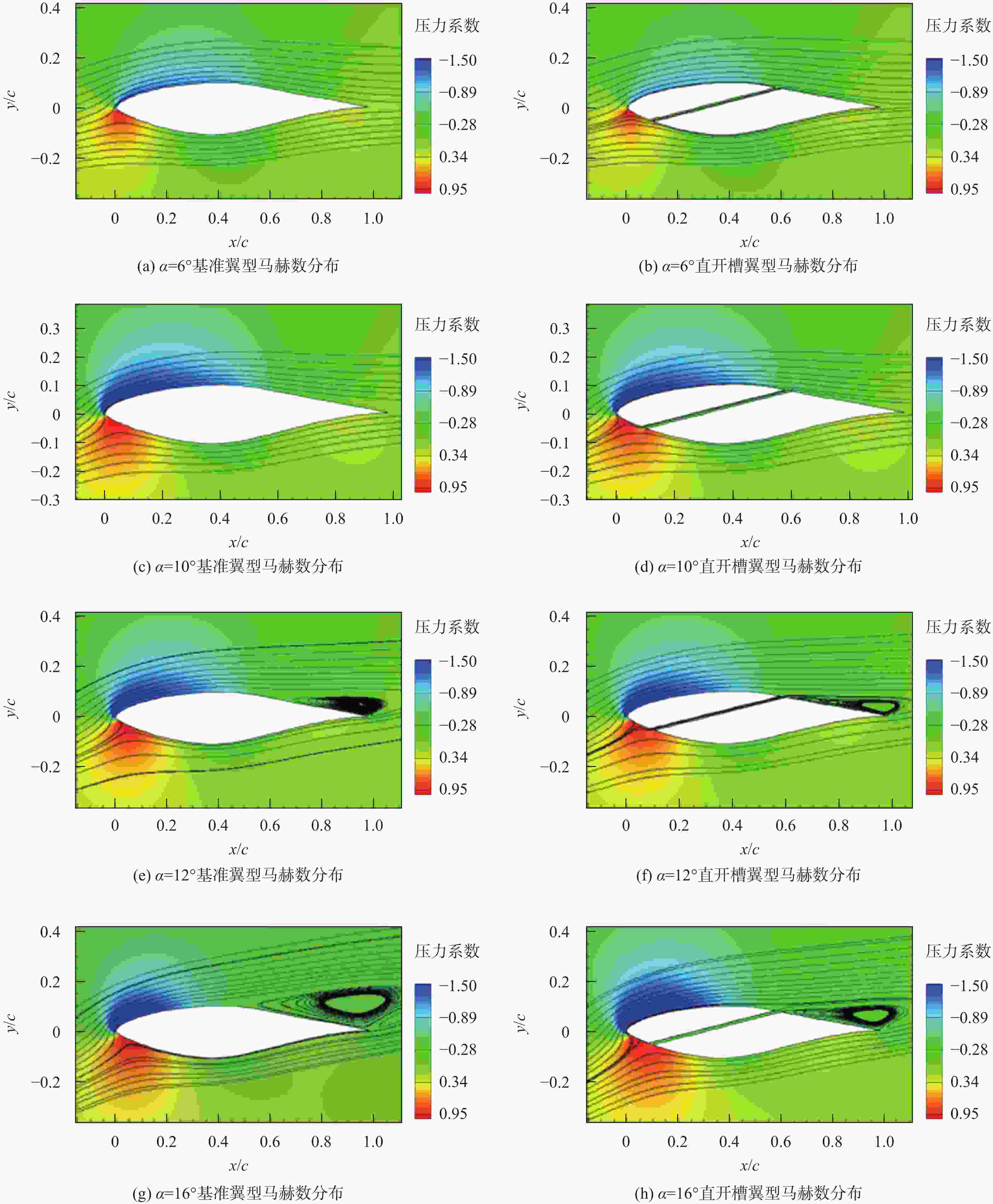

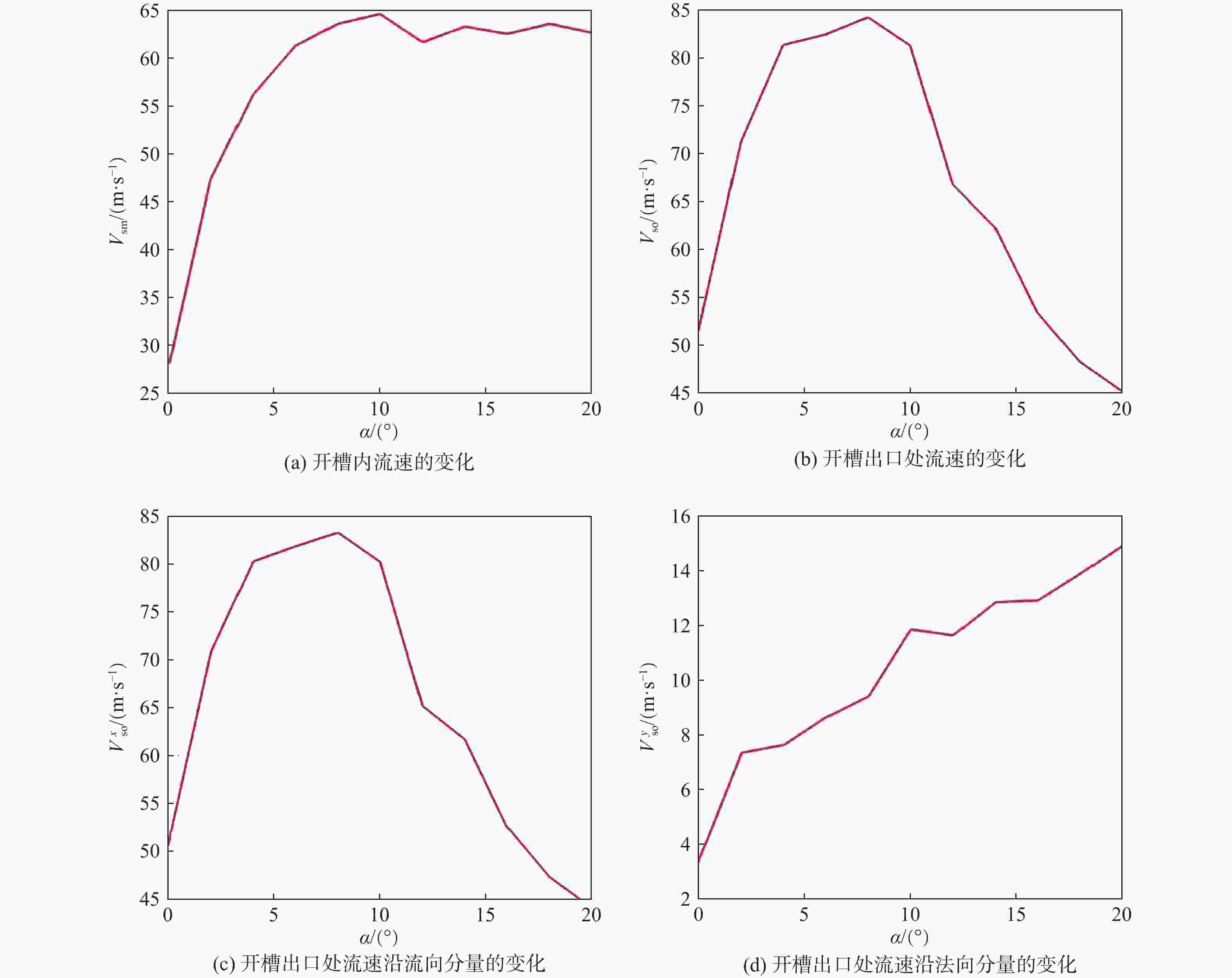

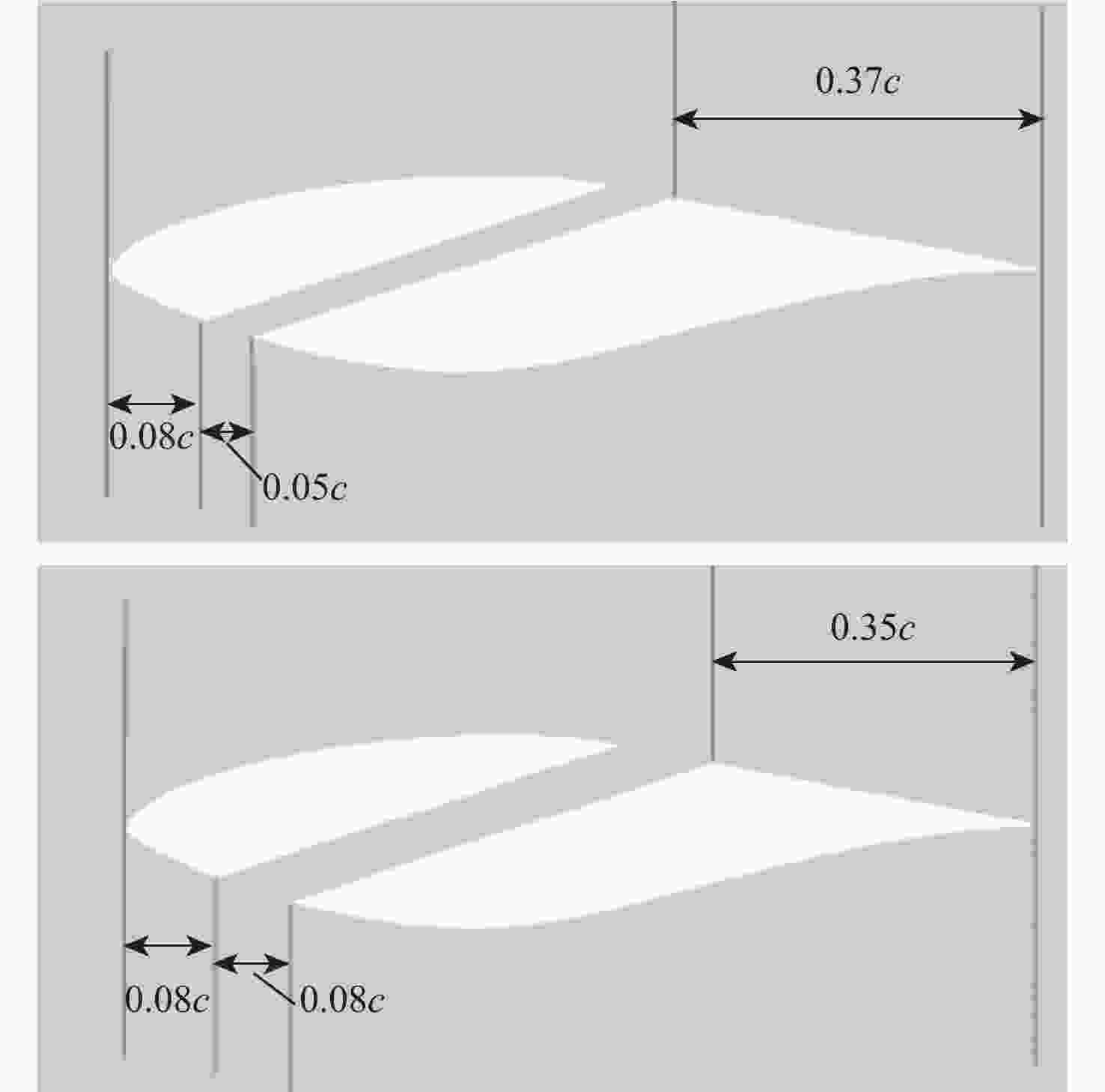

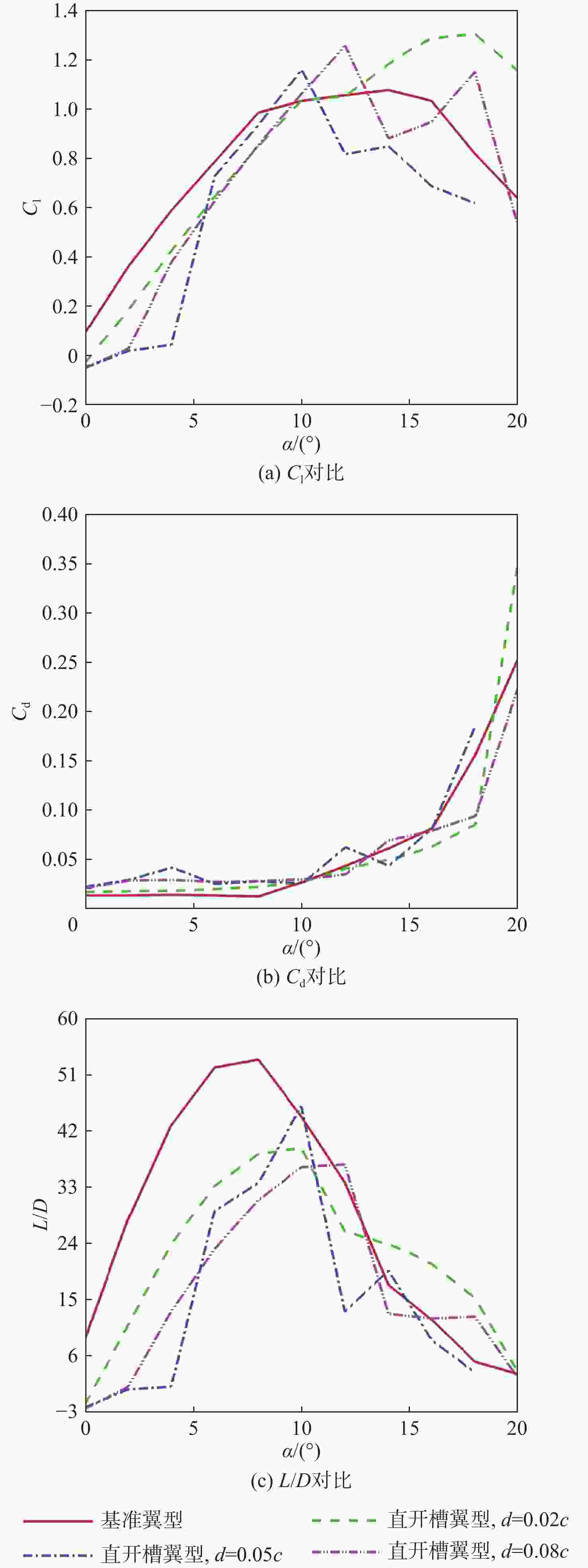

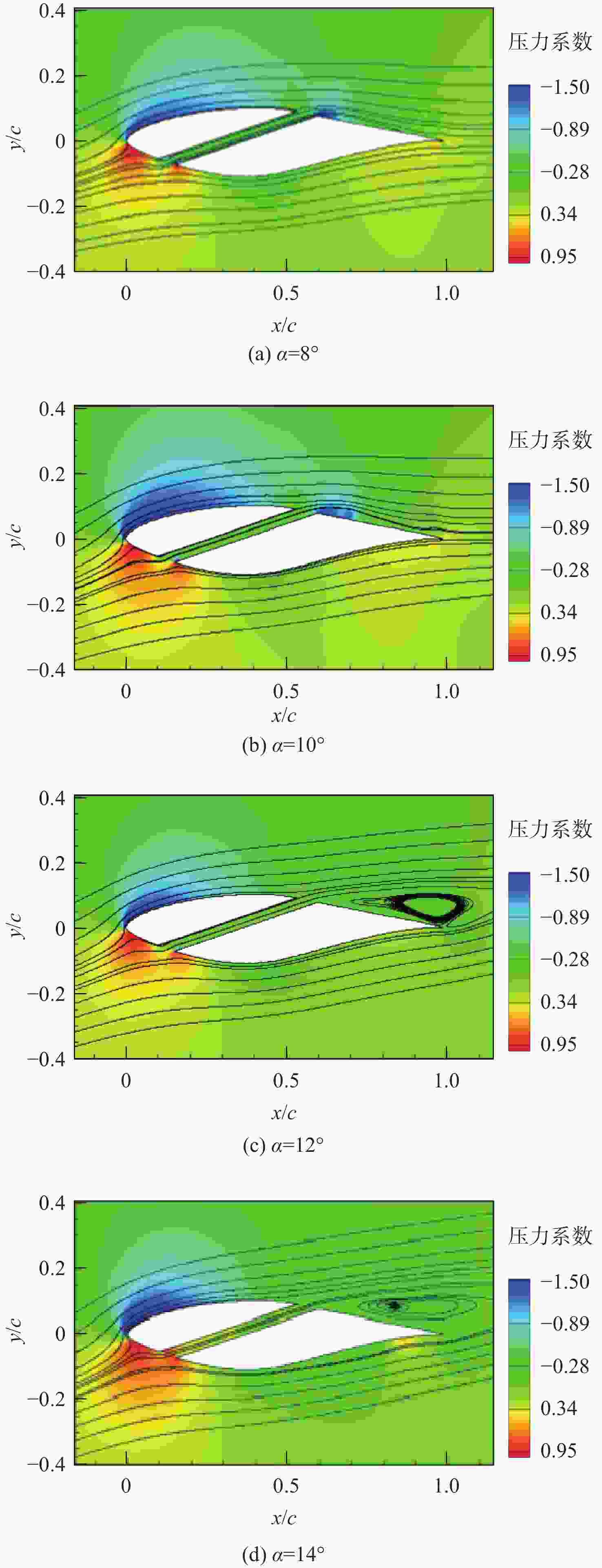

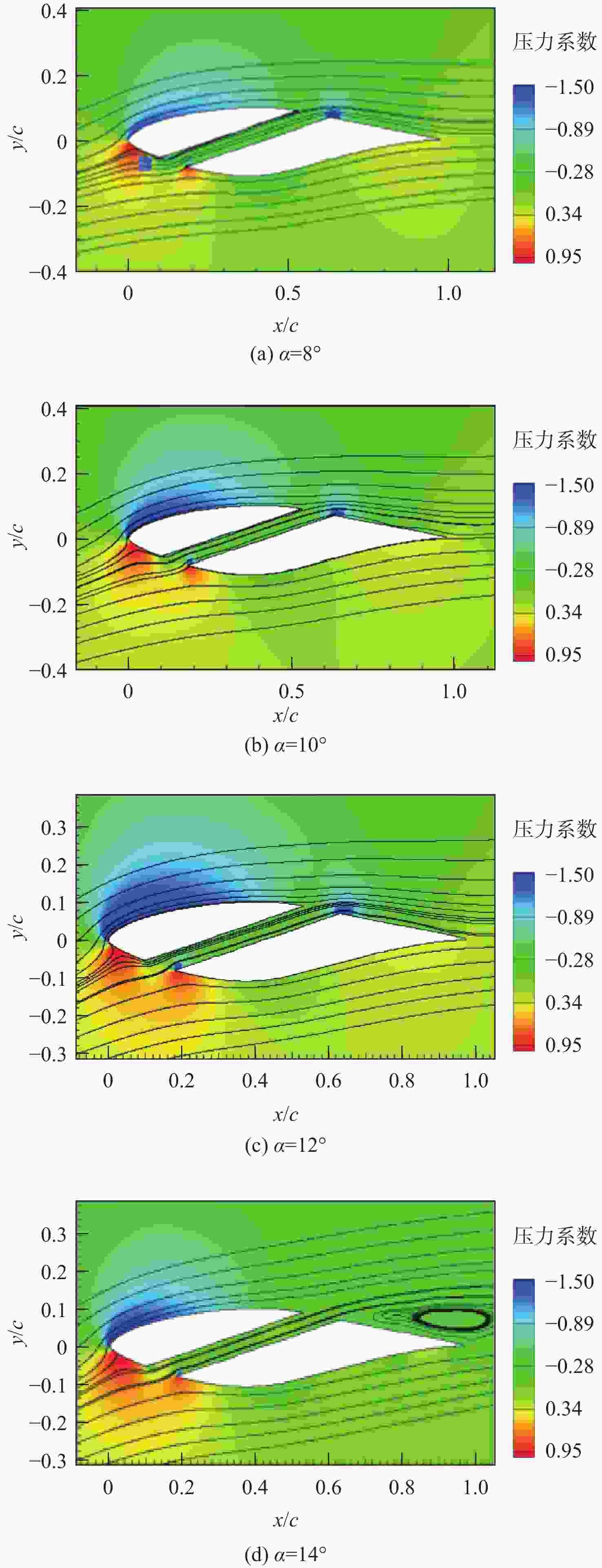

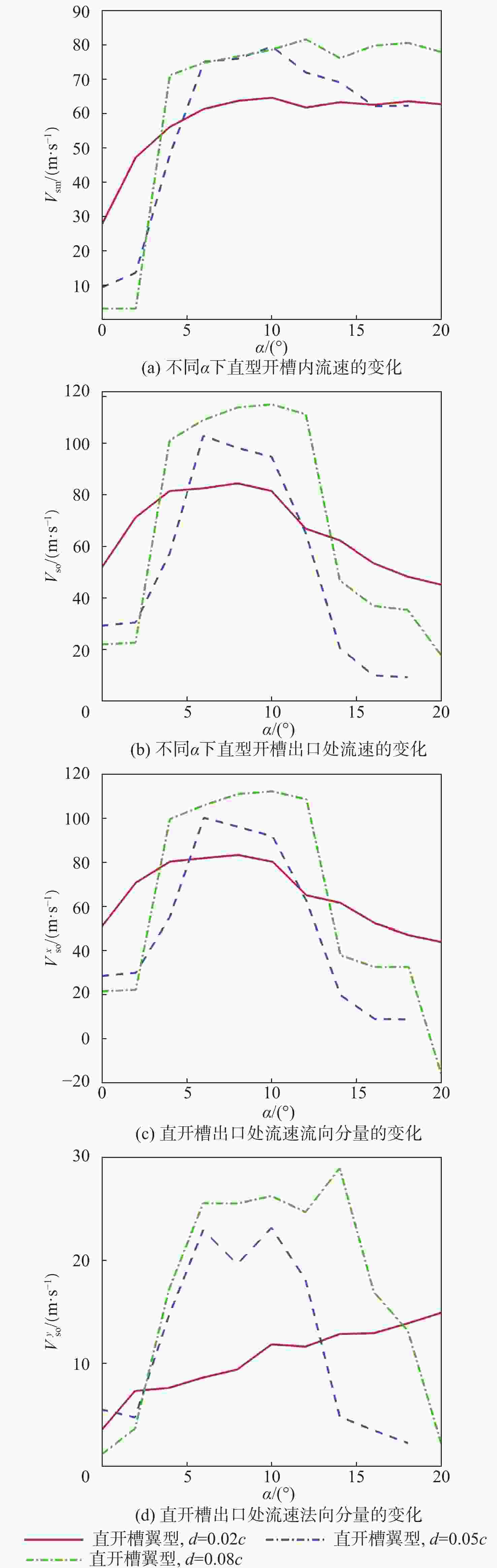

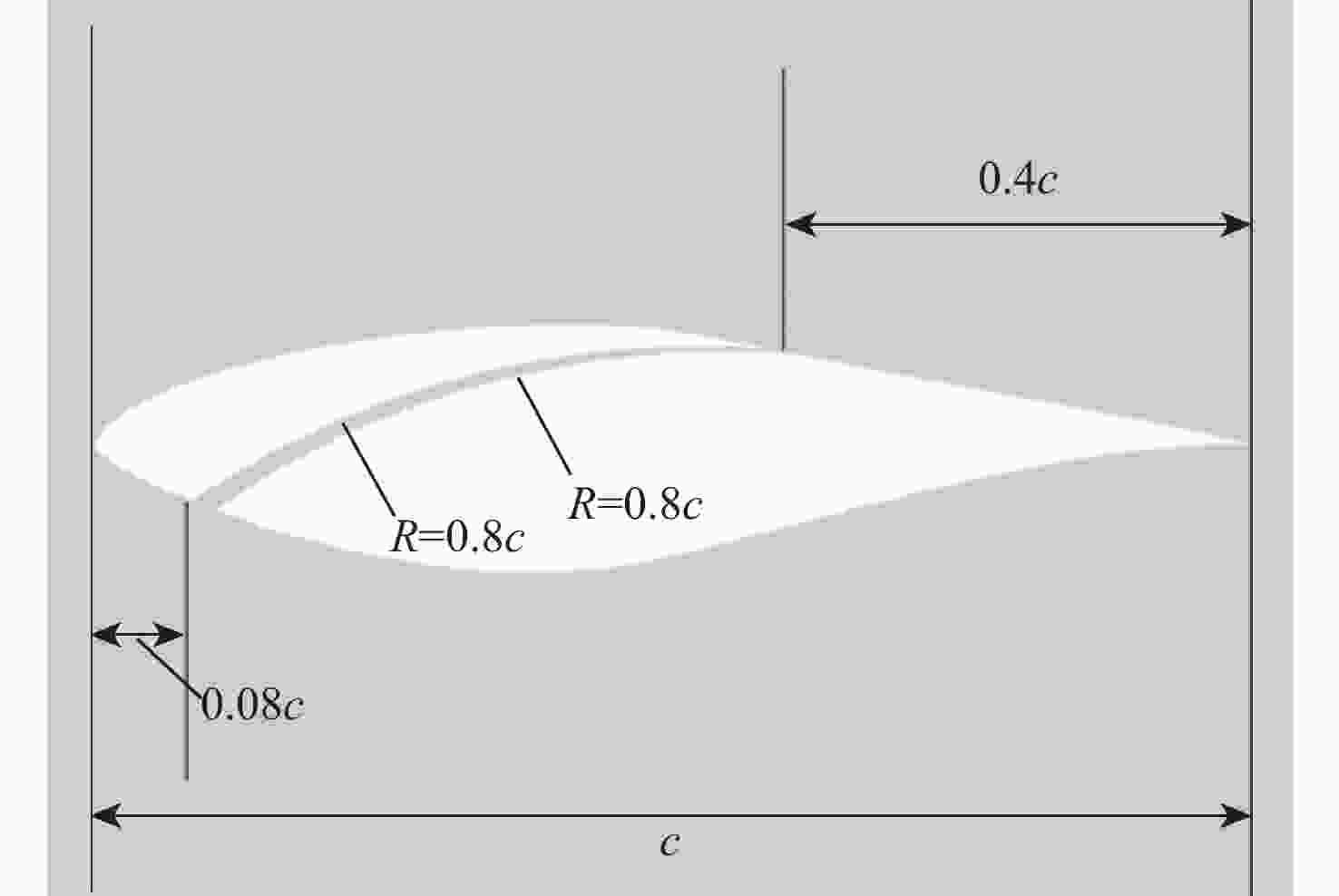

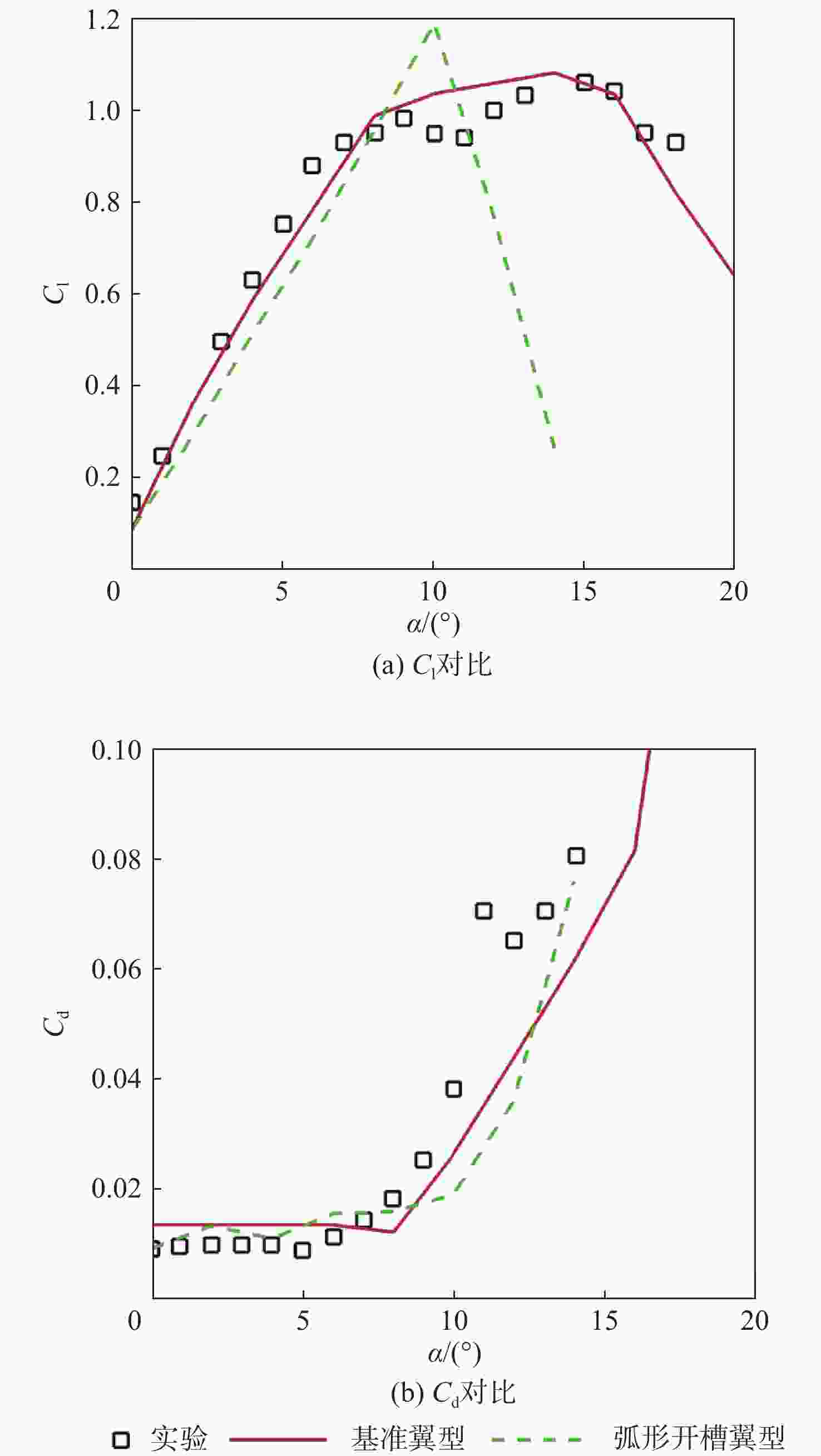

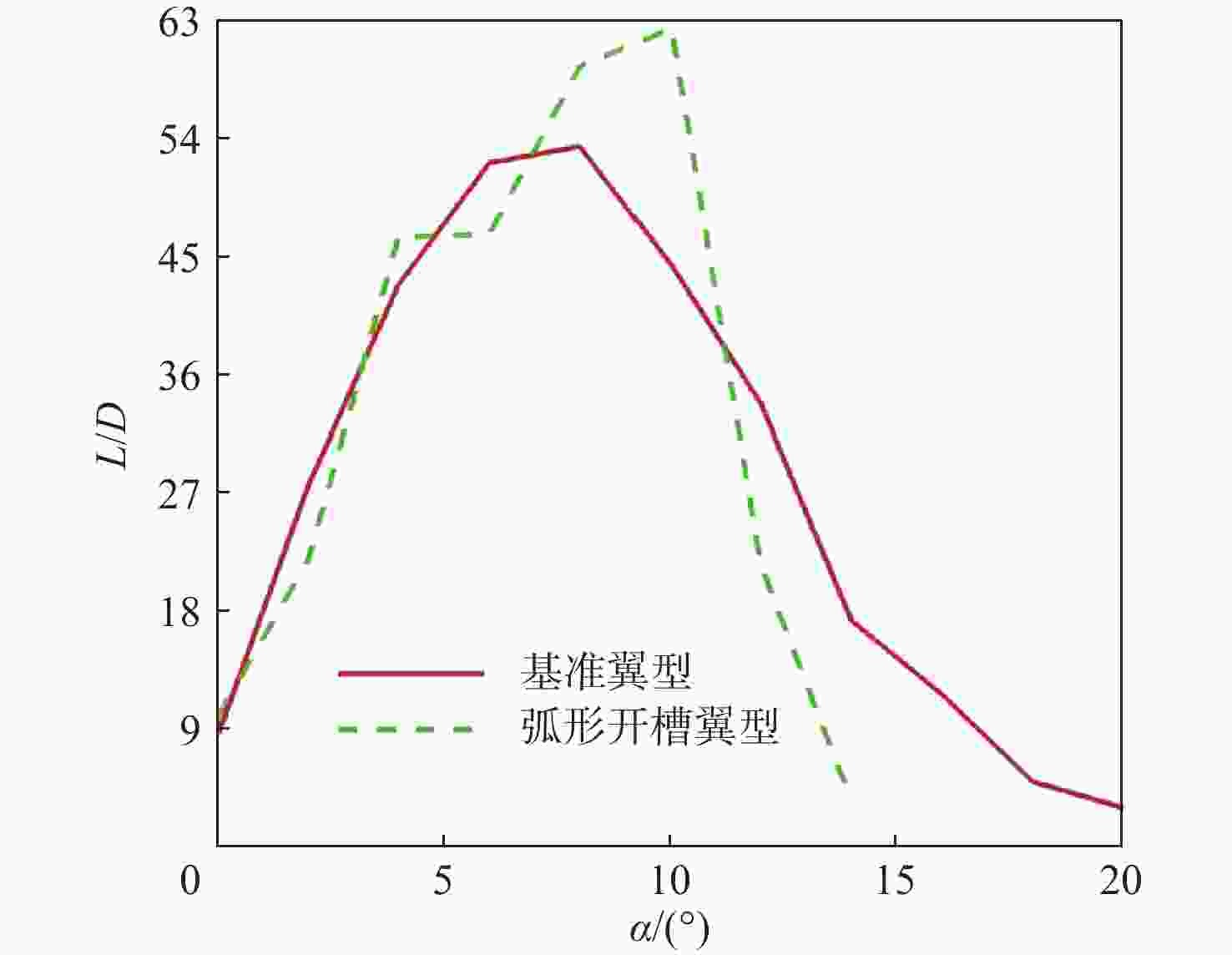

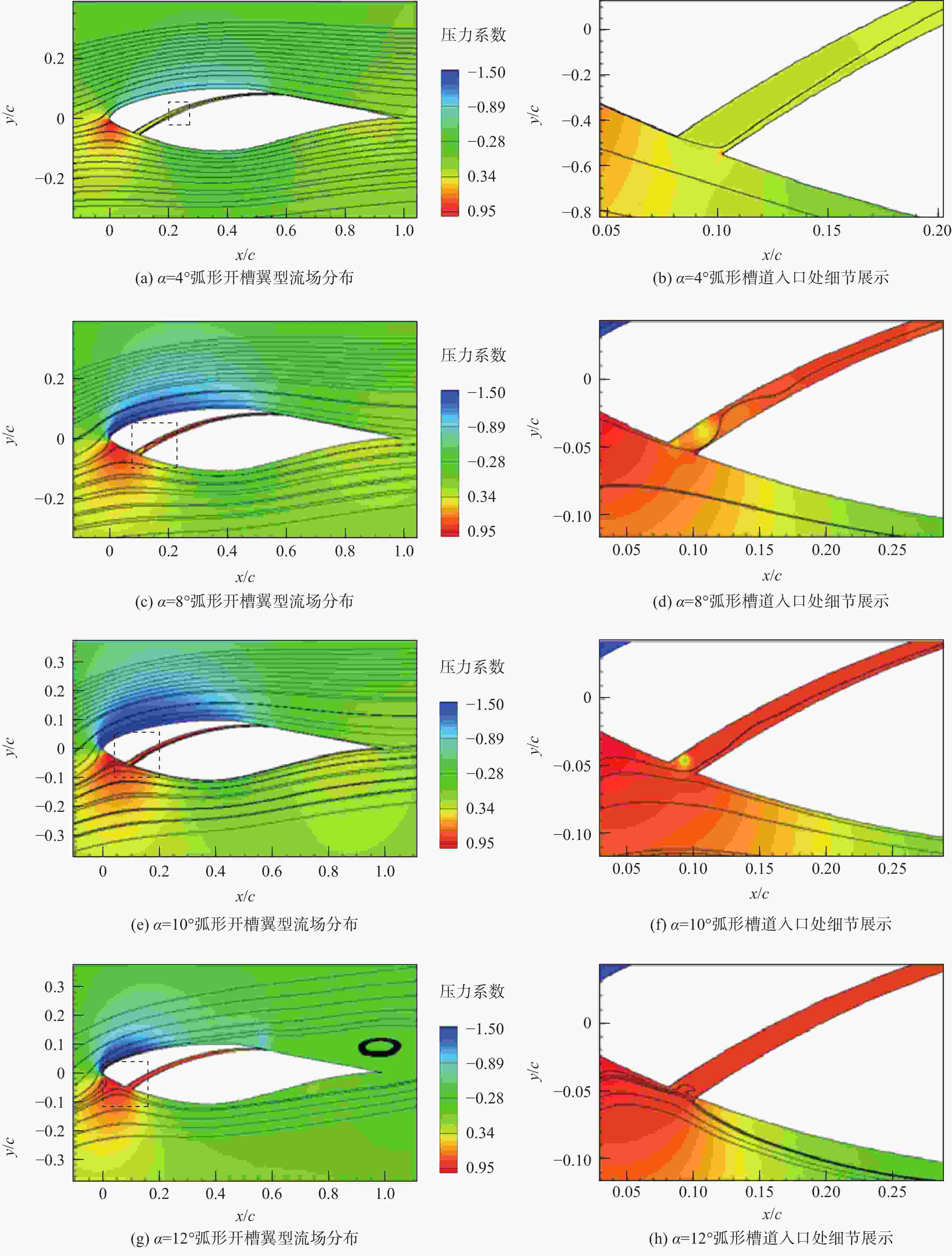

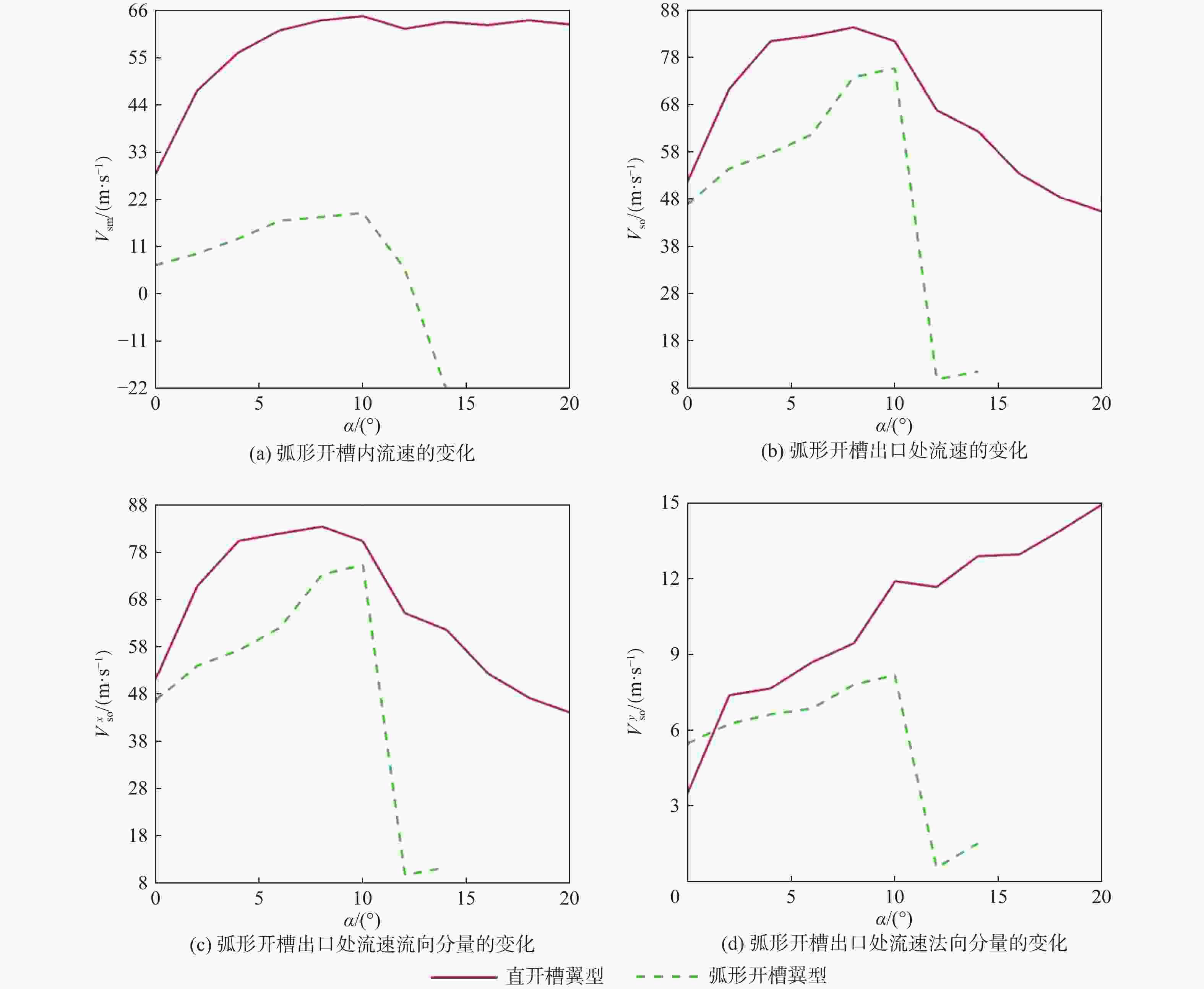

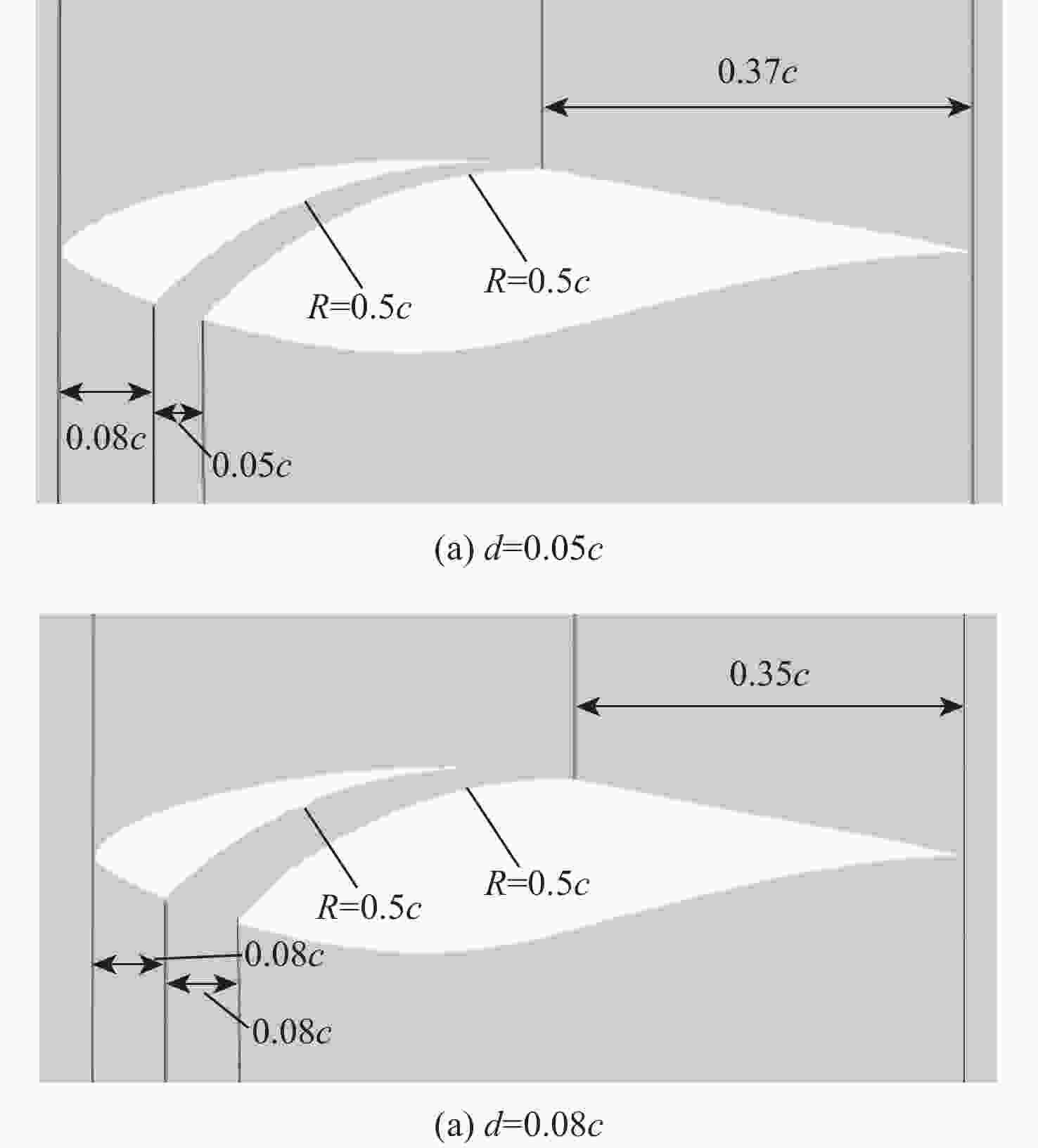

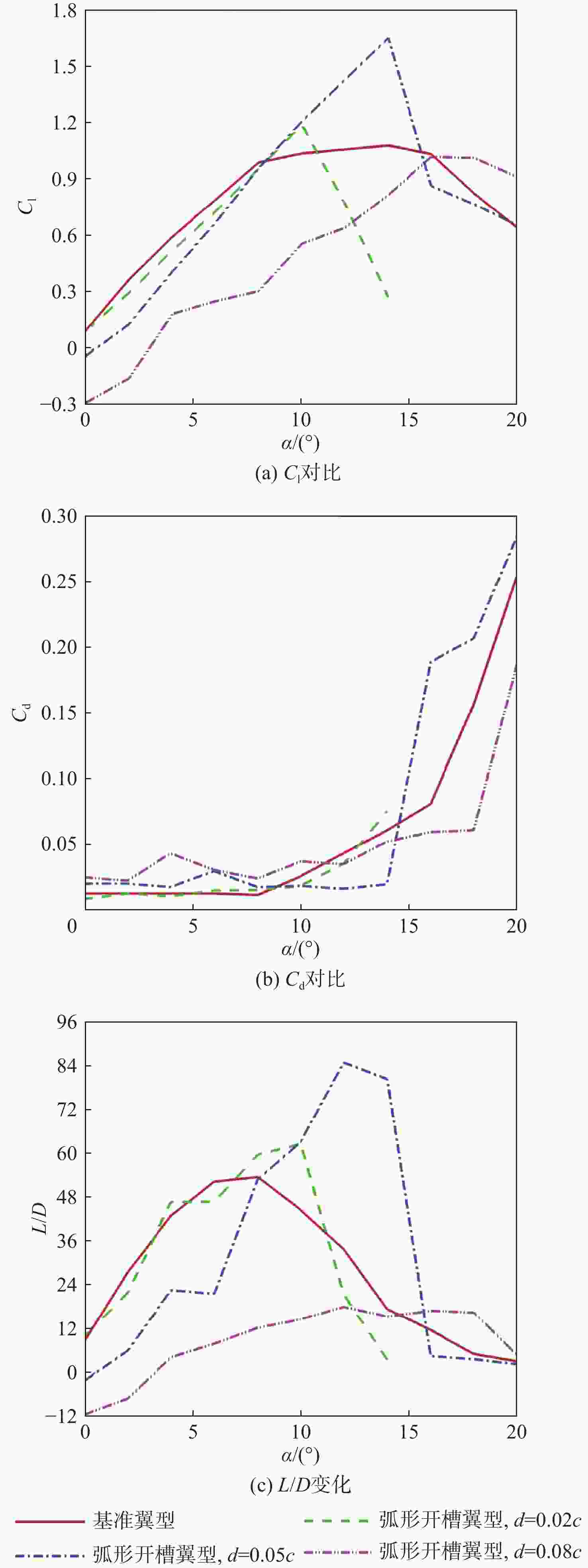

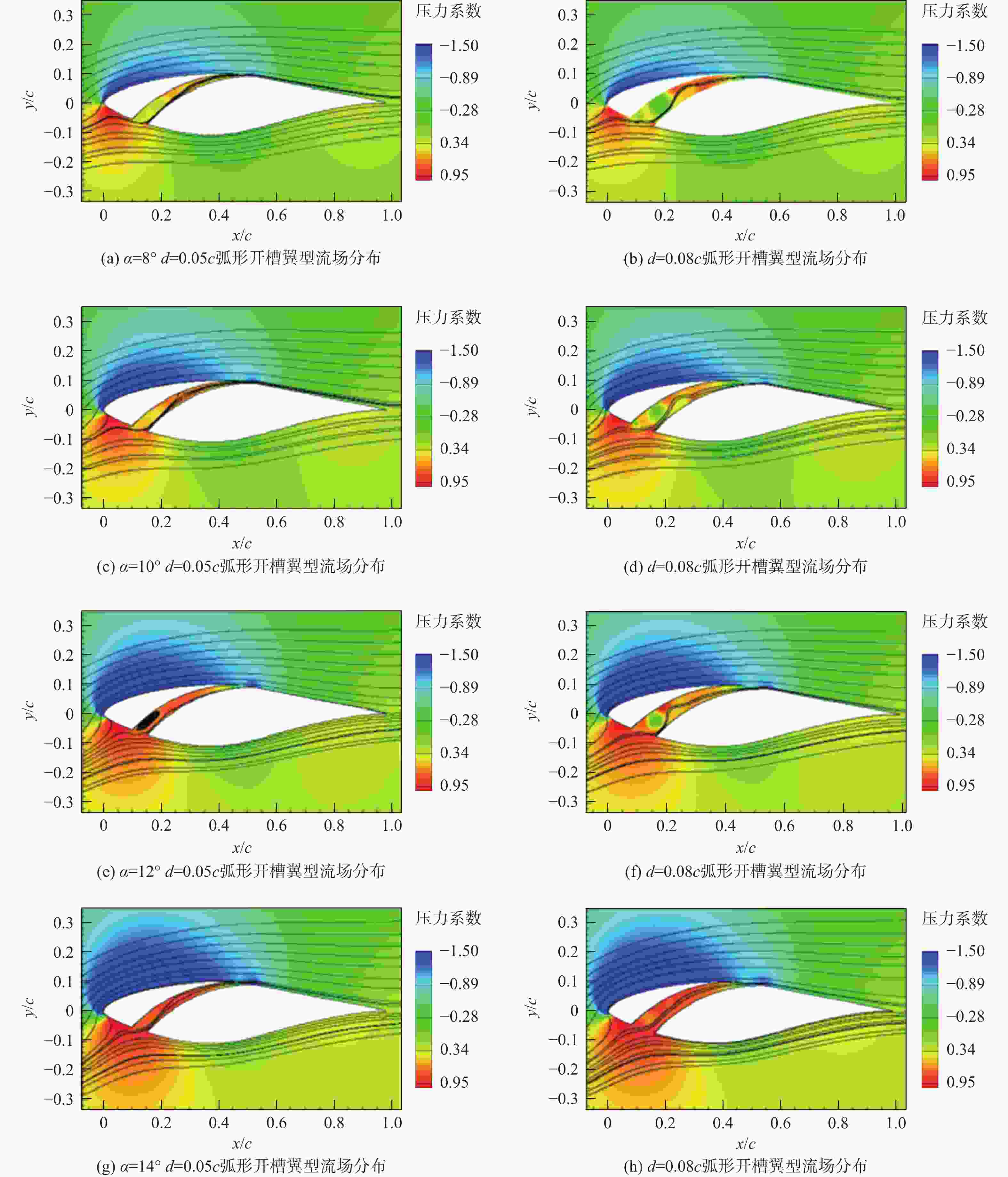

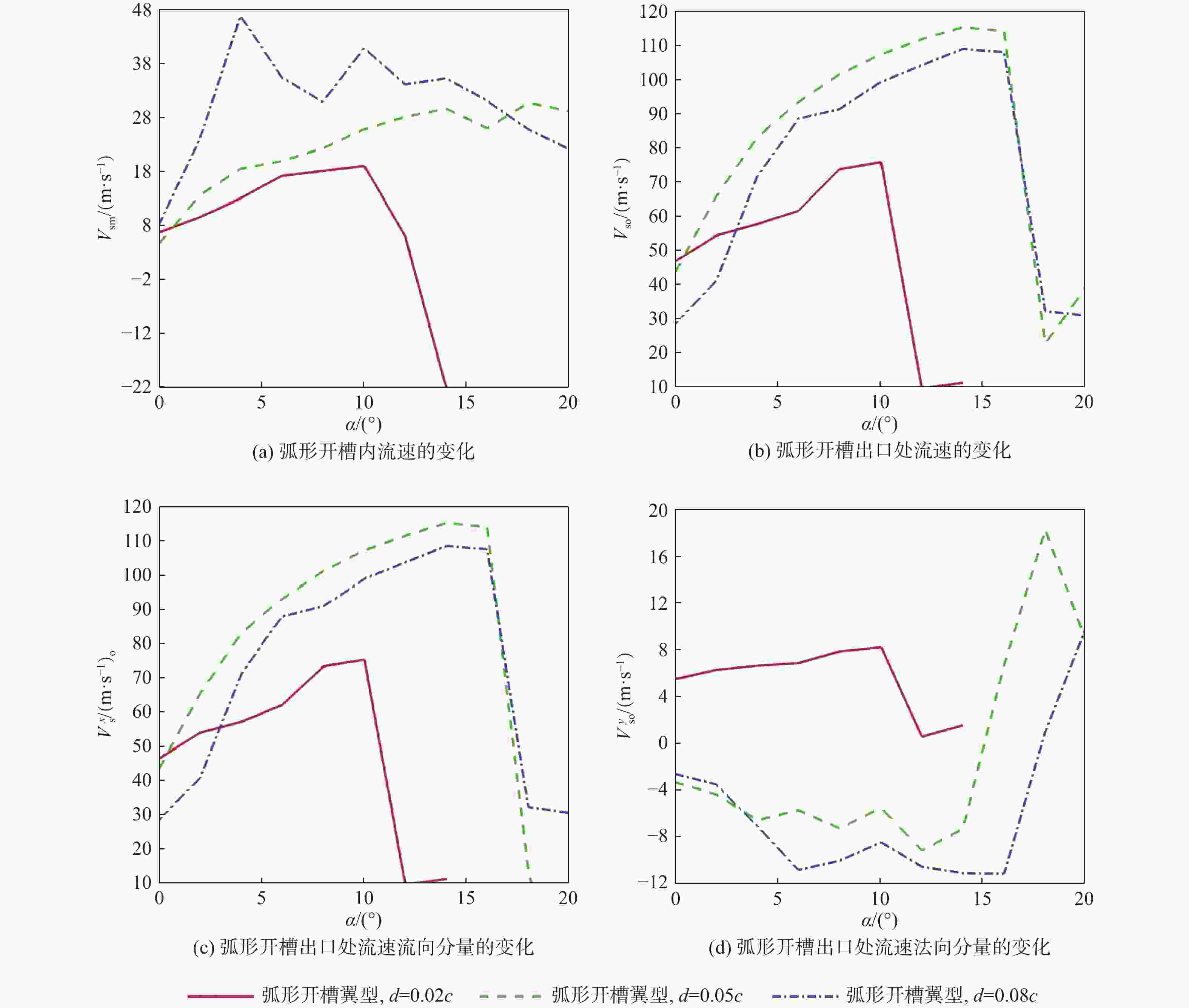

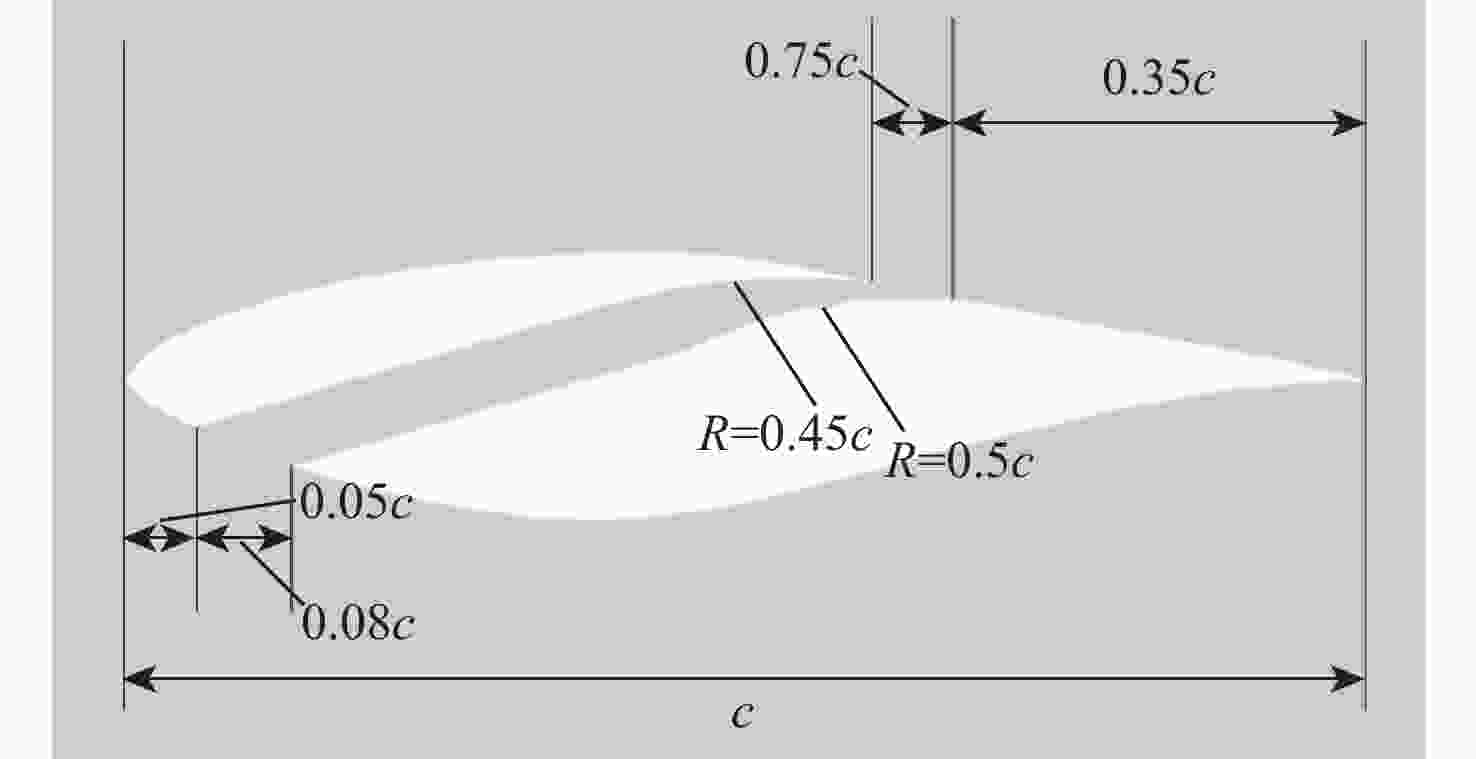

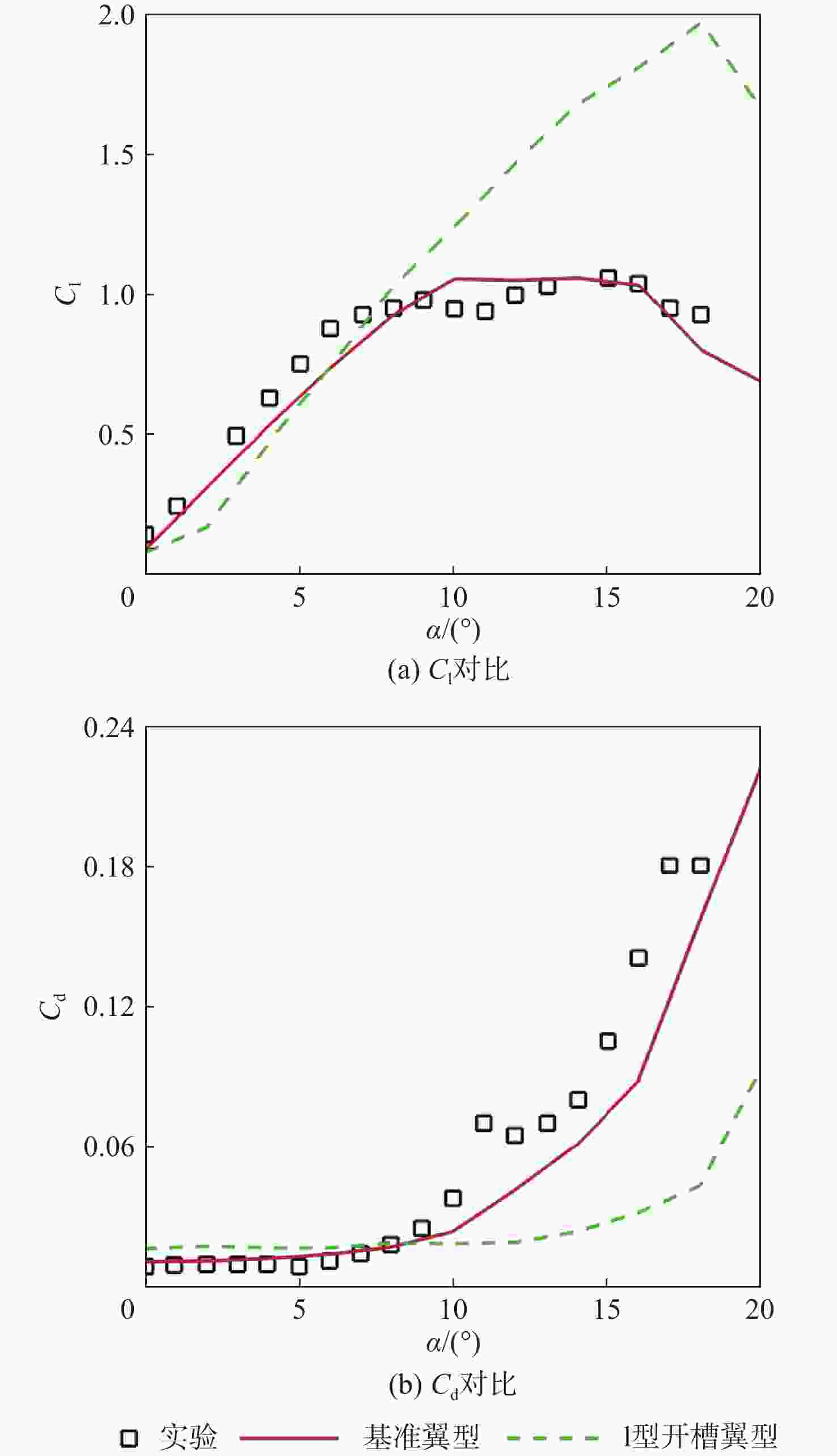

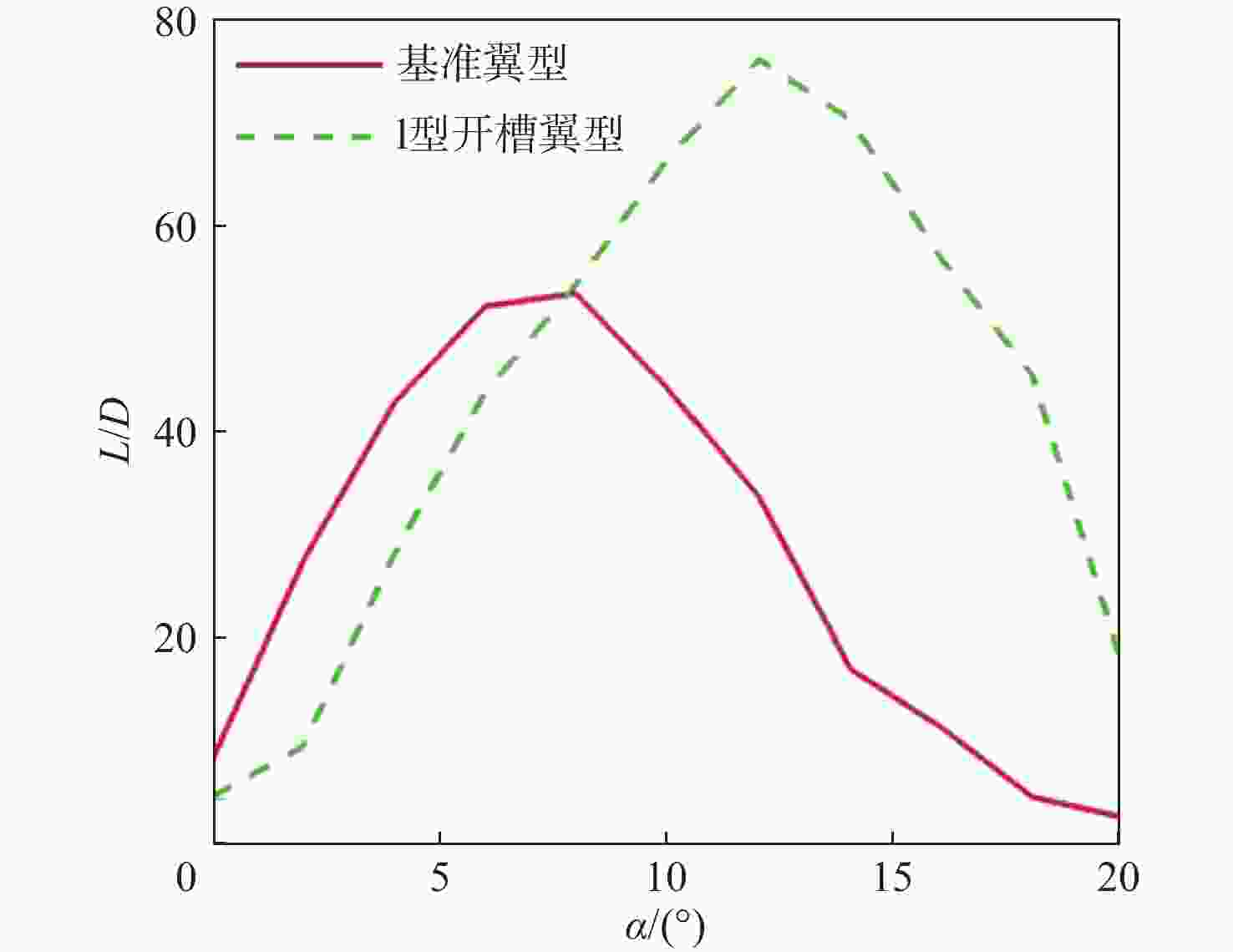

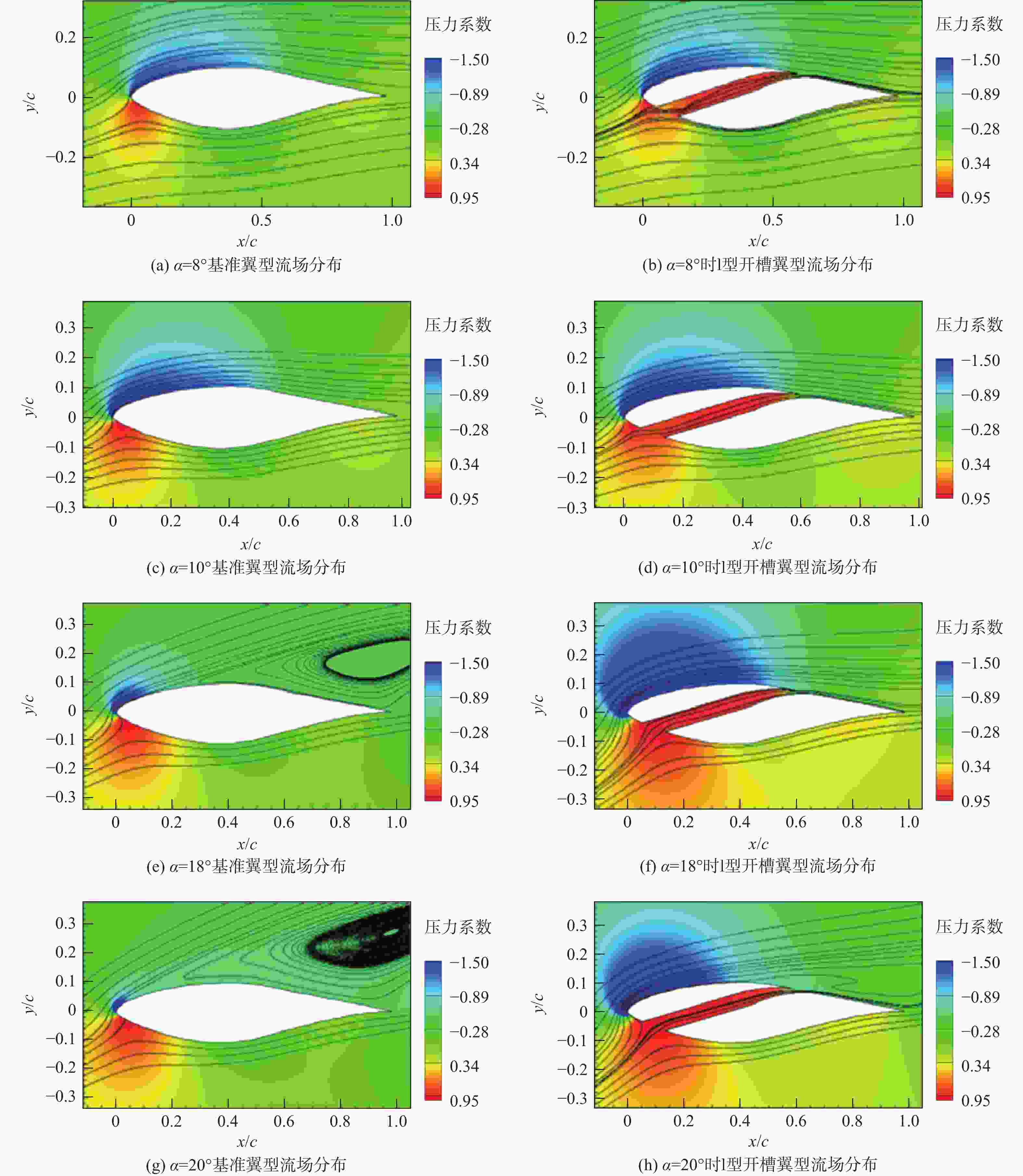

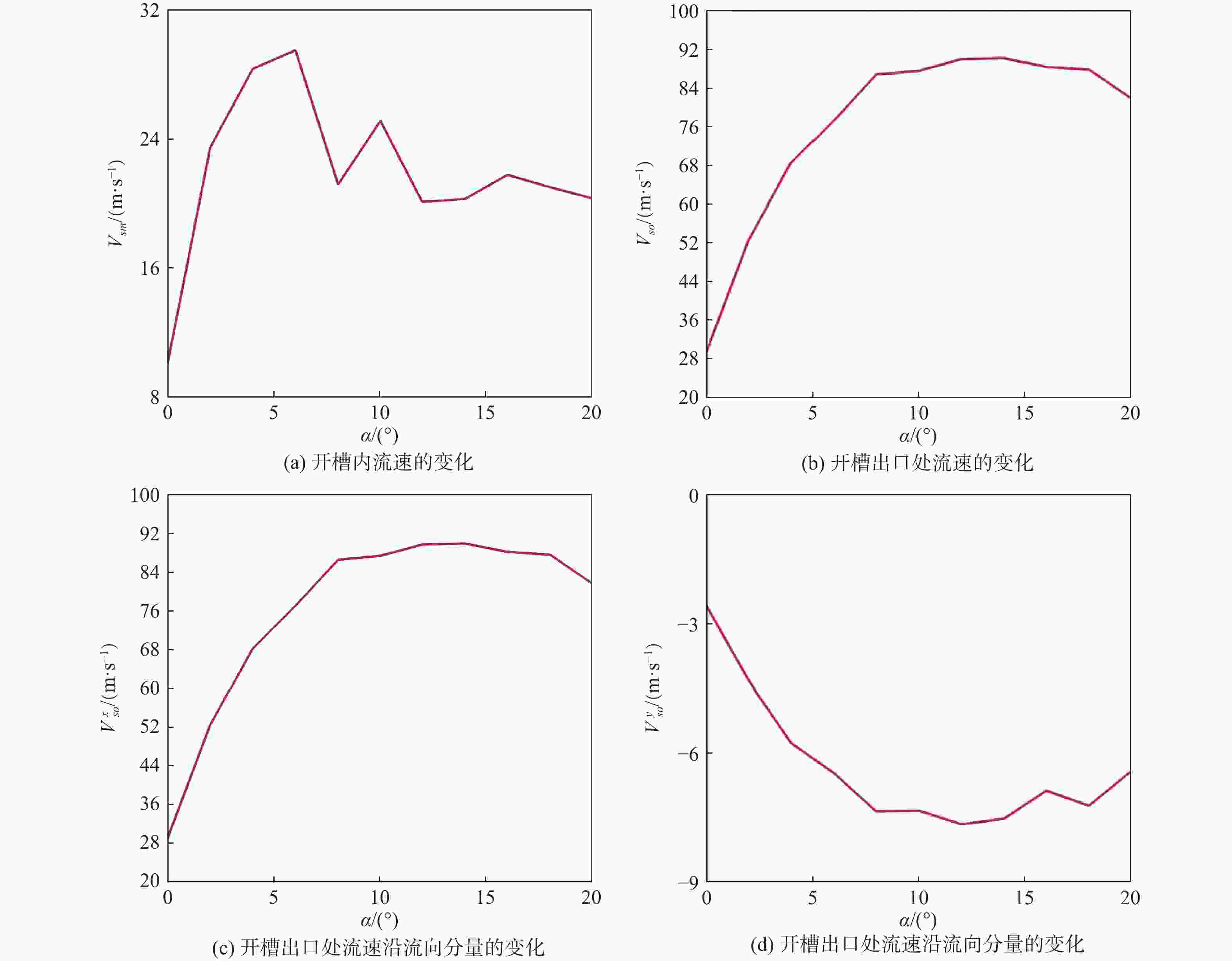

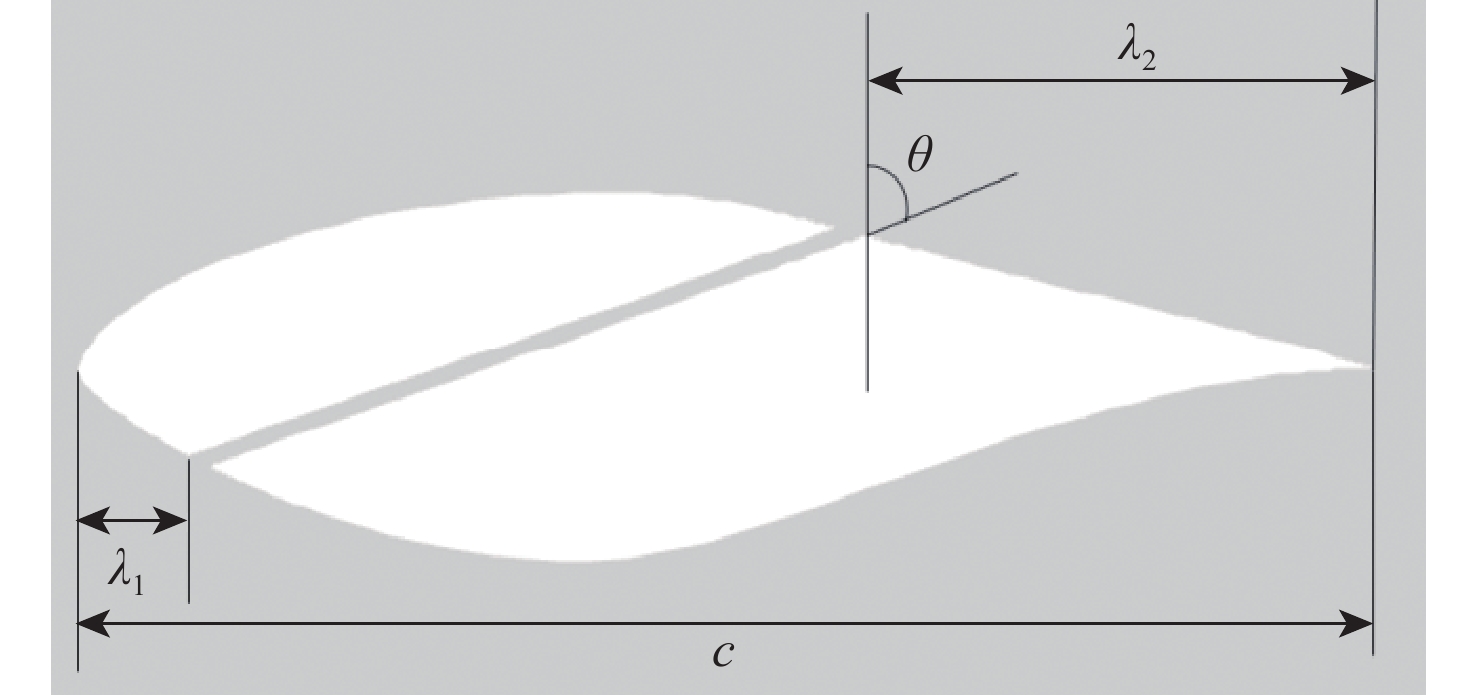

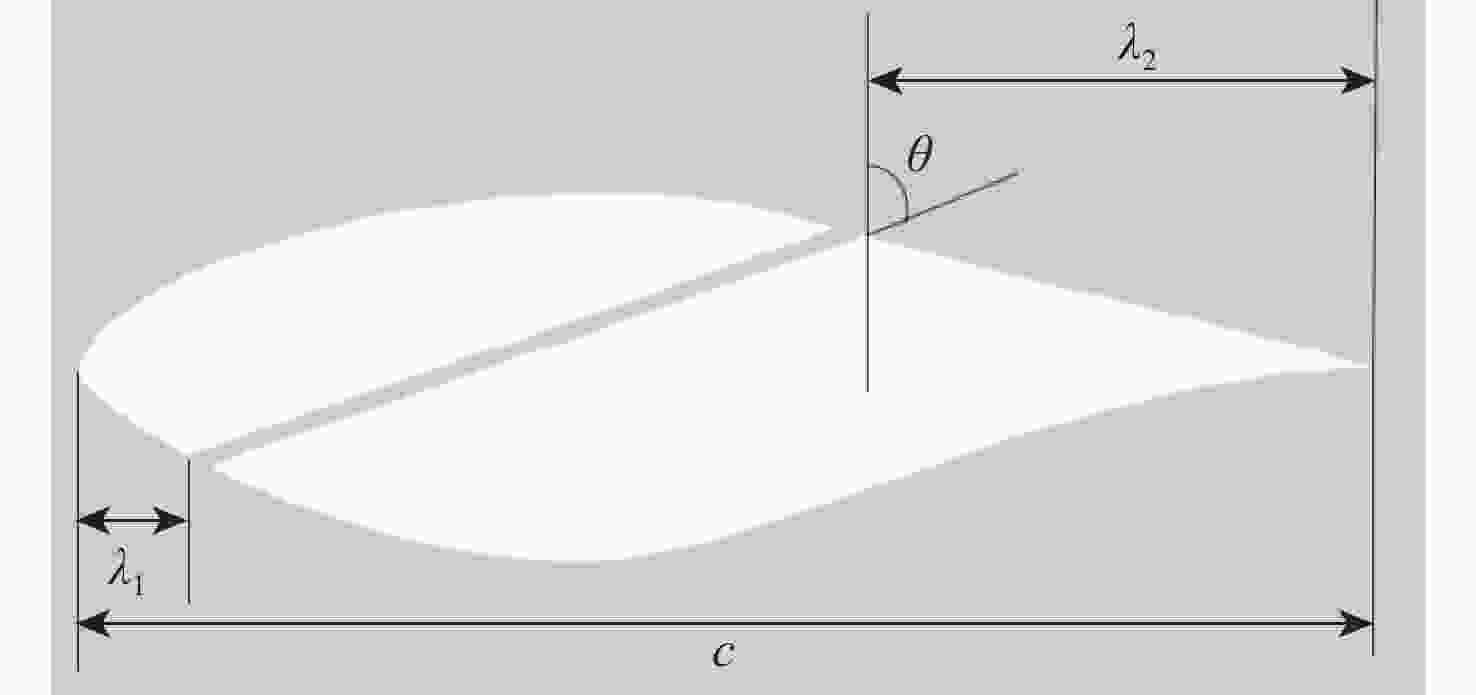

翼型失速问题是风力机设计过程中需要重点考虑的气动现象,而引起失速的主要原因是附面层内流动能量不足,无法提供足够的附着力。利用翼型内部开槽,将大迎角状态时翼型下方的高动量气流引射进上部分离区可以有效解决这一问题。为了设计出具有更好气动特性的开槽翼型,研究了在不同宽度下2种不同形状的开槽对翼型气动特性的影响,通过观察不同开槽翼型的流场图和分析不同开槽翼型槽内、槽出口的气流流速,优化出具有更好气动特性的开槽翼型。经过优化设计的开槽翼型在深失速环境下,失速迎角增大了8°,相较于初始翼型,有了较大的气动性能的提升,并证明了开槽在较大迎角时有改善翼型气动特性的特征。

Abstract:Airfoil stall is an aerodynamic phenomenon that needs to be considered in the design of wind turbines, and the main reason for stall is that the flow energy in the boundary layer is insufficient to provide sufficient adhesion. This problem can be effectively solved by injecting the high-momentum airflow under the airfoil into the upper separation zone when the airfoil is at a high angle of attack by using the internal slot of the airfoil. This research investigates the effects of two distinct slotted airfoil forms with varying widths on aerodynamic characteristics in an effort to improve the design of slotted airfoils. By observing the flow field diagram of different slotted airfoils and analyzing the flow velocity in and at the outlet of different slotted airfoils, the slotted airfoils with better aerodynamic characteristics can be optimized. In the deep stall environment, the Angle of attack of the optimized slotted airfoil increases by 8°. It has been demonstrated that the slotted airfoil can enhance the aerodynamic properties of the airfoil at larger angles of attack, as its aerodynamic performance has significantly increased when compared to the original airfoil.

-

Key words:

- wind turbine airfoil /

- airfoil stall /

- inclined channel /

- boundary layer separation /

- flow velocity

-

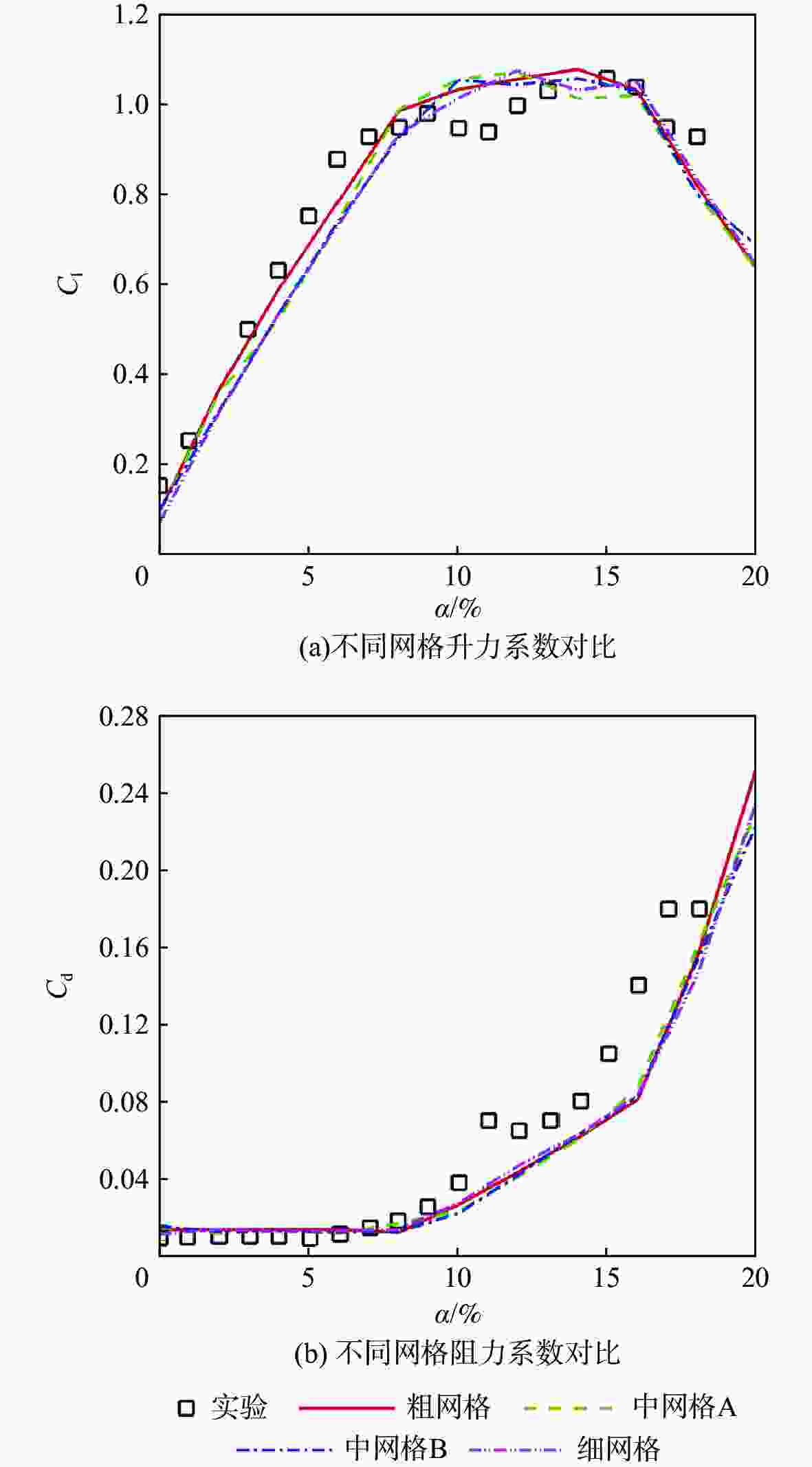

表 1 网格收敛性研究使用的网格簇

Table 1. Cluster of mesh used in mesh convergence studies

网格类型 节点数量 网格数量 粗网格 10 404 10 200 中网格A 18 727 18 420 中网格B 19 927 19 620 细网格 24 827 24 420 -

[1] KHALED M, IBRAHIM M M, ABDEL HAMED H E, et al. Investigation of a small Horizontal-Axis wind turbine performance with and without winglet[J]. Energy, 2019, 187: 115921. doi: 10.1016/j.energy.2019.115921 [2] ZHU B, SUN X J, WANG Y, et al. Performance characteristics of a horizontal axis turbine with fusion winglet[J]. Energy, 2017, 120: 431-440. doi: 10.1016/j.energy.2016.11.094 [3] MNAFAR-SEFIDDASHTI M, NILI-AHMADABADI M, SAEEDI-RIZI B, et al. Visualization of flow over a thick airfoil with circular cross-sectional riblets at low Reynolds numbers[J]. Journal of Visualization, 2019, 22(5): 877-888. doi: 10.1007/s12650-019-00576-3 [4] SEFIDDASHTI M N, NILI-AHMADABADI M, RIZI B S. Experimental study of effects of circular-cross-section riblets on the aerodynamic performance of Risø airfoil at transient flow regime[J]. Journal of Mechanical Science and Technology, 2018, 32(2): 709-716. doi: 10.1007/s12206-018-0119-z [5] BELAMADI R, DJEMILI A, ILINCA A, et al. Aerodynamic performance analysis of slotted airfoils for application to wind turbine blades[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2016, 151: 79-99. doi: 10.1016/j.jweia.2016.01.011 [6] SEO S H, HONG C H. Performance improvement of airfoils for wind blade with the groove[J]. International Journal of Green Energy, 2016, 13(1): 34-39. doi: 10.1080/15435075.2014.910777 [7] AFUNGCHUI D, KAMOUN B, HELALI A. Vortical structures in the wake of the savonius wind turbine by the discrete vortex method[J]. Renewable Energy, 2014, 69: 174-179. doi: 10.1016/j.renene.2014.03.038 [8] LI X K, LIU W, ZHANG T J, et al. Experimental and numerical analysis of the effect of vortex generator installation angle on flow separation control[J]. Energies, 2019, 12(23): 4583. doi: 10.3390/en12234583 [9] ARAMENDIA I, SAENZ-AGUIRRE A, FERNANDEZ-GAMIZ U, et al. Gurney flap implementation on a DU91W250 airfoil[C]//Proceedings of the 2nd International Research Conference on Sustainable Energy, Engineering, Materials and Environment. Basel: MDPI, 2018, 1448: 2-6. [10] NIKOUEEYAN P, STRIKE J A, MAGSTADT A S, et al. Aerodynamic response of a wind turbine airfoil to gurney flap deployment[C]// Proceedings of the 33rd Wind Energy Symposium. Reston: AIAA, 2015. [11] FRANCIS P H. Variable-camber rib for aeroplane-wings: US1341758[P]. 1920-06-01. [12] WEICK F E, SHORTAL J A . The effect of multiple fixed slots and a trailing-edge flap on the lift and drag of a Clark Y airfoil, NACA-TR-427[R]. Boston: The National Advisory Committee for Aeronautics, 1933:531-536. [13] DIDANE D H, MOHD S, SUBARI Z, et al. An aerodynamic performance analysis of a perforated wind turbine blade[J]. IOP Conference Series: Materials Science and Engineering, 2016, 160: 012039. doi: 10.1088/1757-899X/160/1/012039 [14] IBRAHIM M, ALSULTAN A, SHEN S H, et al. Advances in horizontal axis wind turbine blade designs: introduction of slots and tubercle[J]. Journal of Energy Resources Technology, 2015, 137(5): 051205. doi: 10.1115/1.4030399 [15] PRINCE S A, BADALAMENTI C, REGAS C. The application of passive air jet vortex-generators to stall suppression on wind turbine blades[J]. Wind Energy, 2017, 20(1): 109-123. doi: 10.1002/we.1994 [16] RAMZI M, ABDERRAHMANE G. Passive control via slotted blading in a compressor cascade at stall condition[J]. Journal of Applied Fluid Mechanics, 2013, 6(4): 3-9. [17] NI Z, DHANAK M, SU T. Improved performance of a slotted blade using a novel slot design[J]. Journal of Wind Engineering and Industrial, 34(44): 2-9. [18] MOHAMED O S, IBRAHIM A A, ETMAN A K, et al. Numerical investigation of Darrieus wind turbine with slotted airfoil blades[J]. Energy Conversion and Management: X, 2020, 5: 100026. doi: 10.1016/j.ecmx.2019.100026 [19] SIMMS D, SCHRECK S, HAND M, et al. NREL unsteady aerodynamics experiment in the NASA-Ames wind tunnel: A comparison of predictions to measurements, NREL/TP-500-29494[R]. Golden: National Renewable Energy Laboratory, 2001: 24-51. [20] MOSHFEGHI M, SHAMS S, HUR N. Aerodynamic performance enhancement analysis of horizontal axis wind turbines using a passive flow control method via split blade[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2017, 167: 148-159. doi: 10.1016/j.jweia.2017.04.001 [21] MENTER F. Improved two-equation $k {\text{-}}\omega $ turbulence models for aerpdynamic flows: NASA-TM 103975[R]. Washington D. C.: NASA, 1992. -

下载:

下载: