-

摘要:

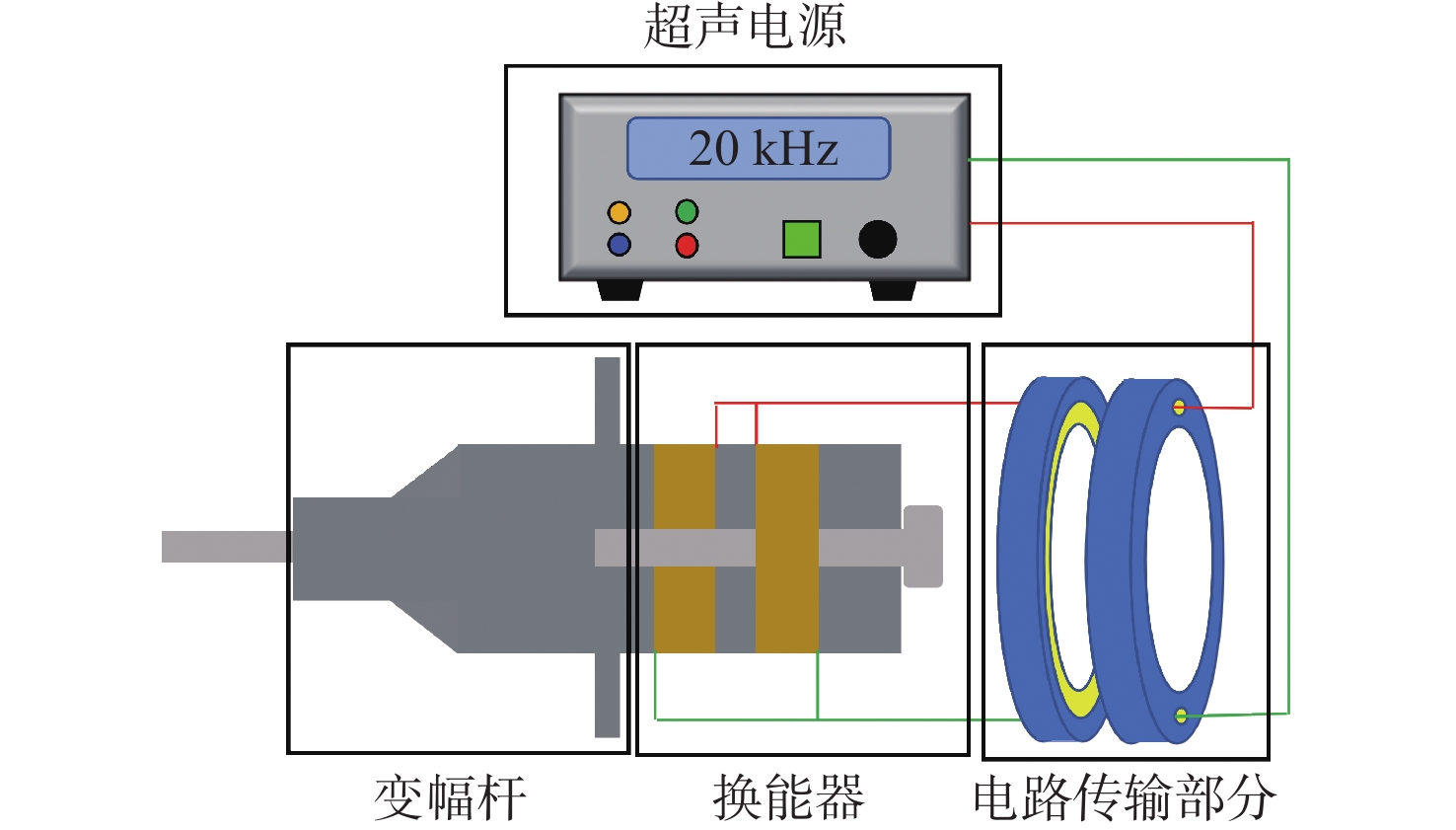

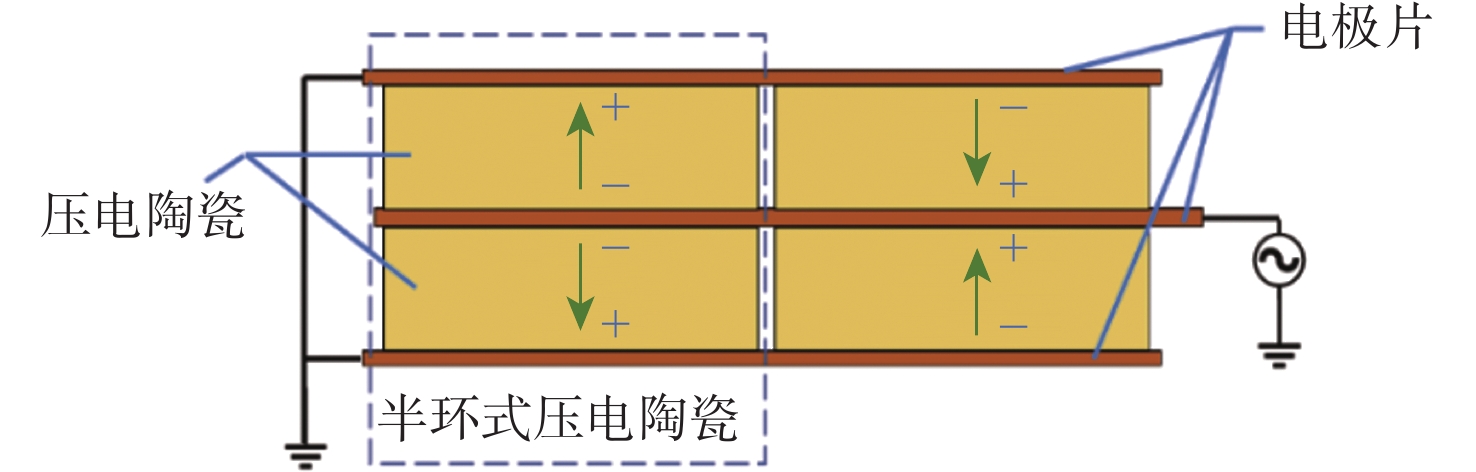

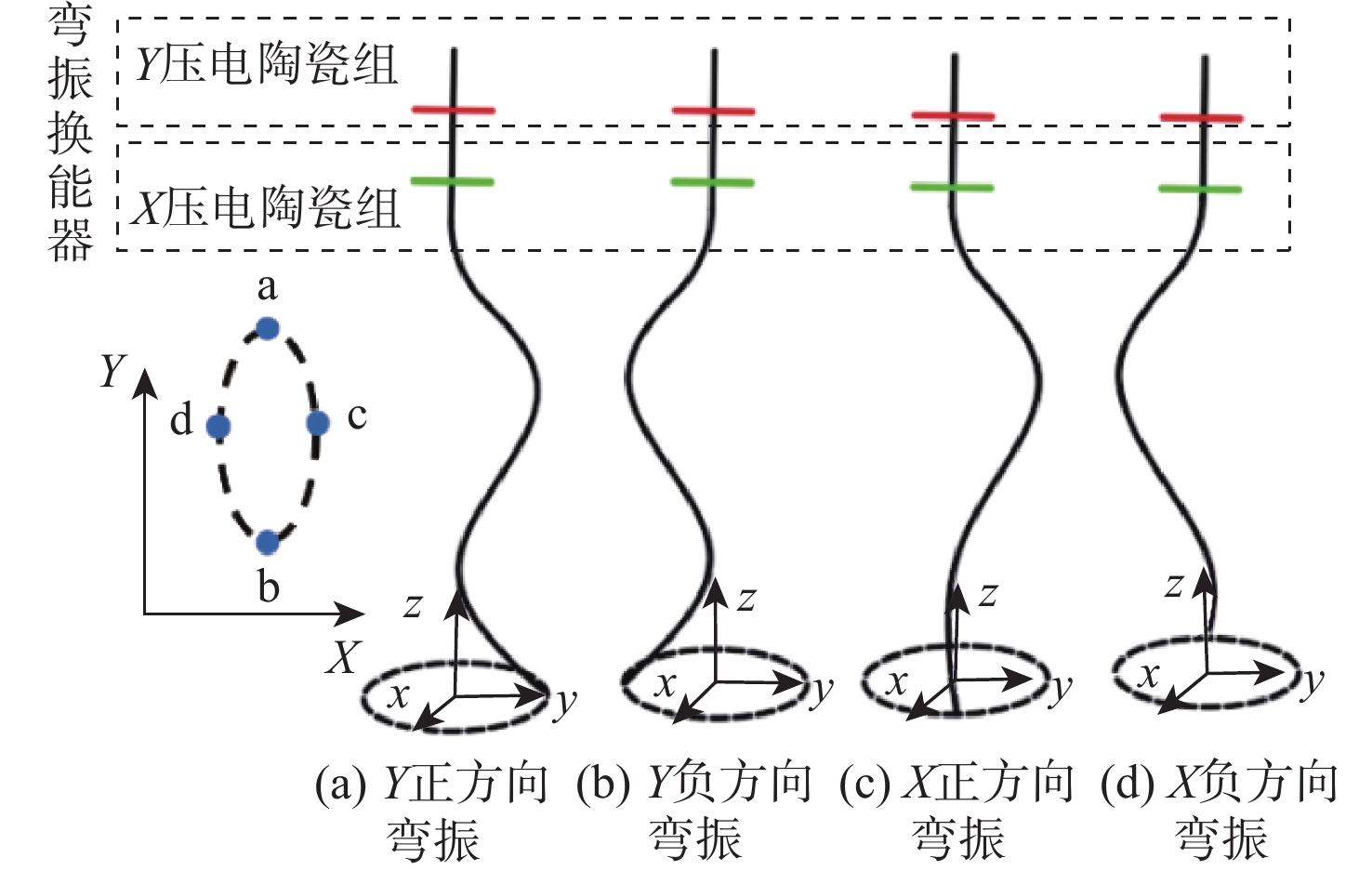

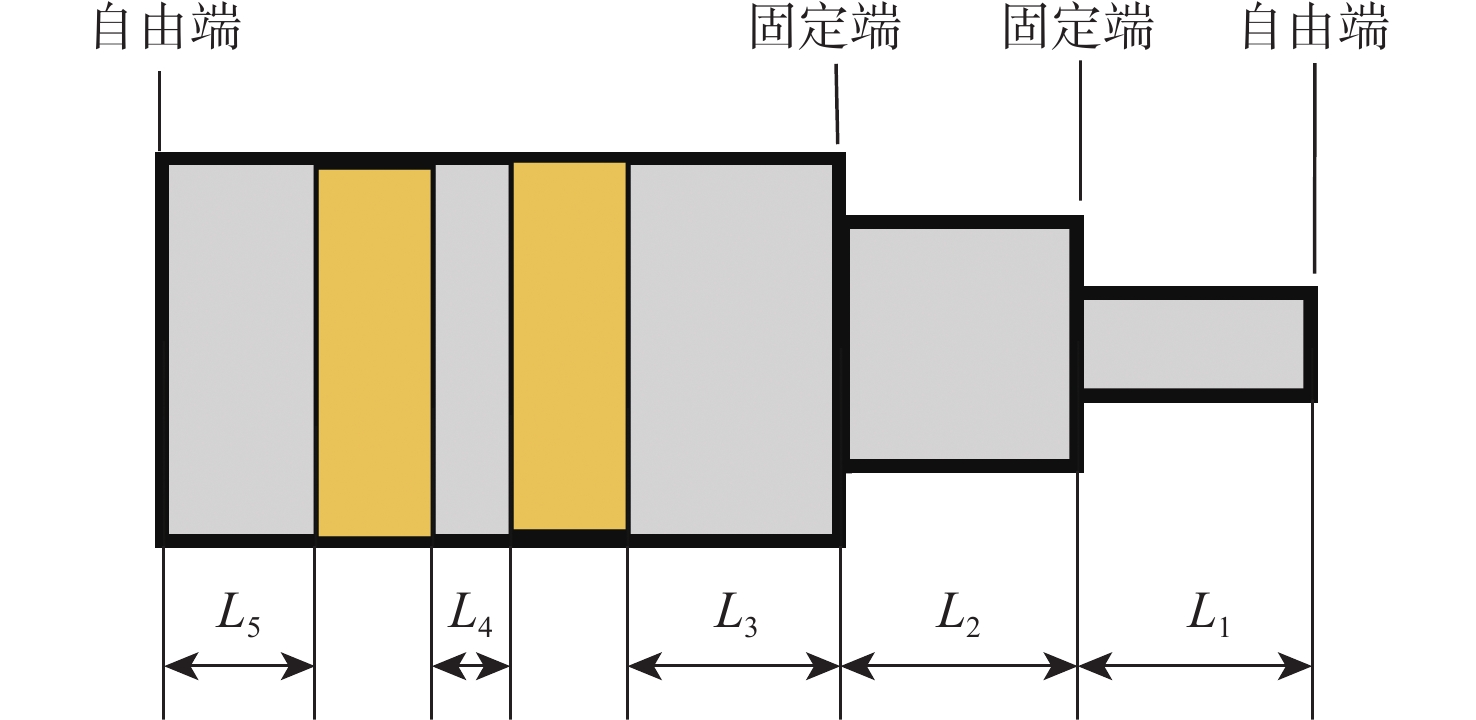

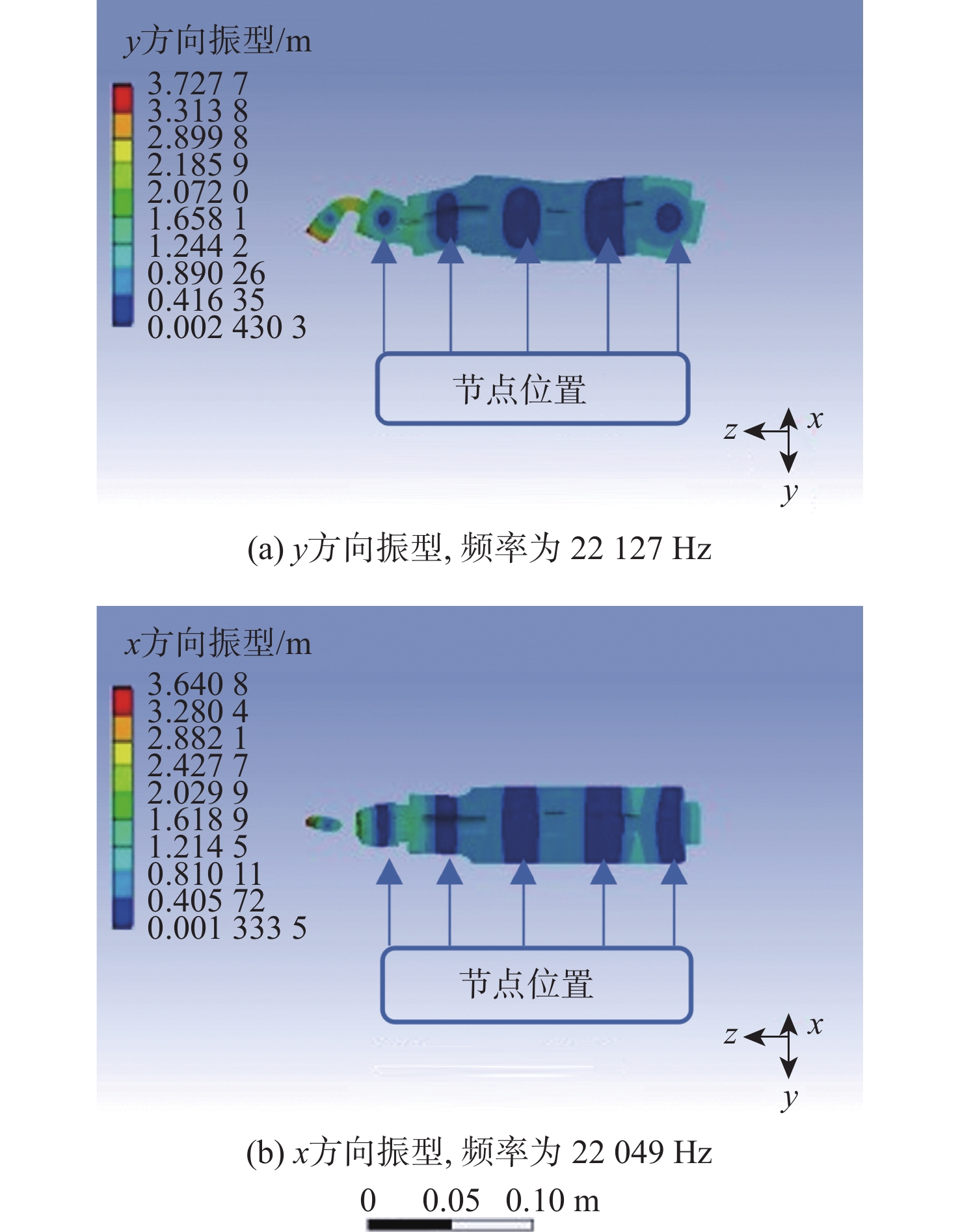

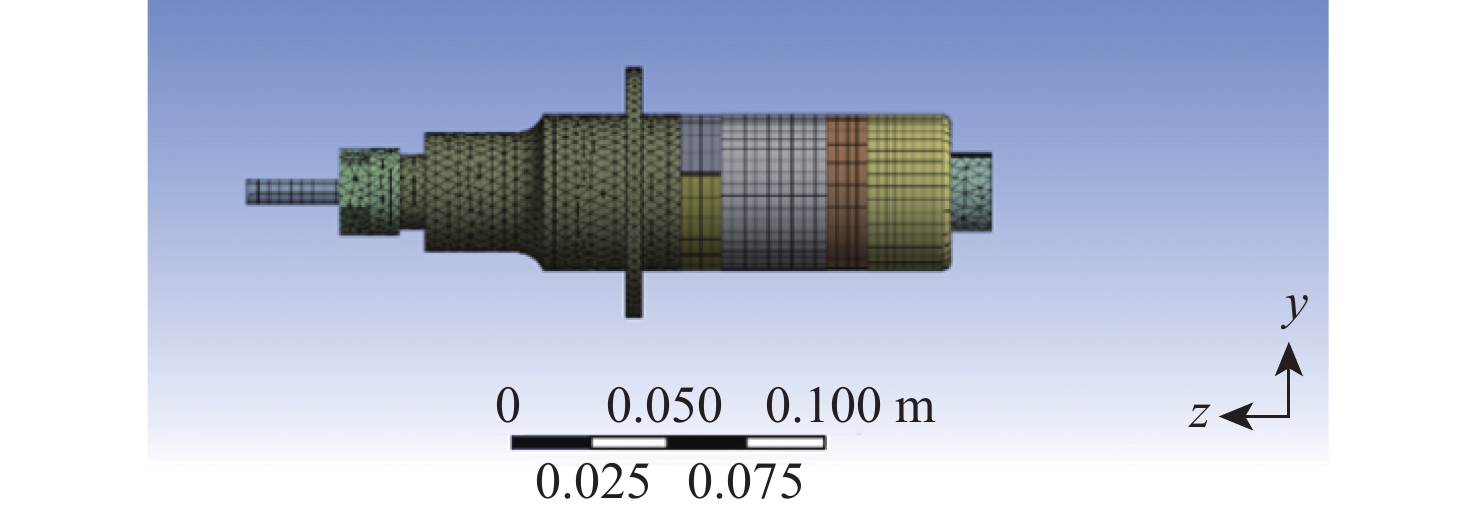

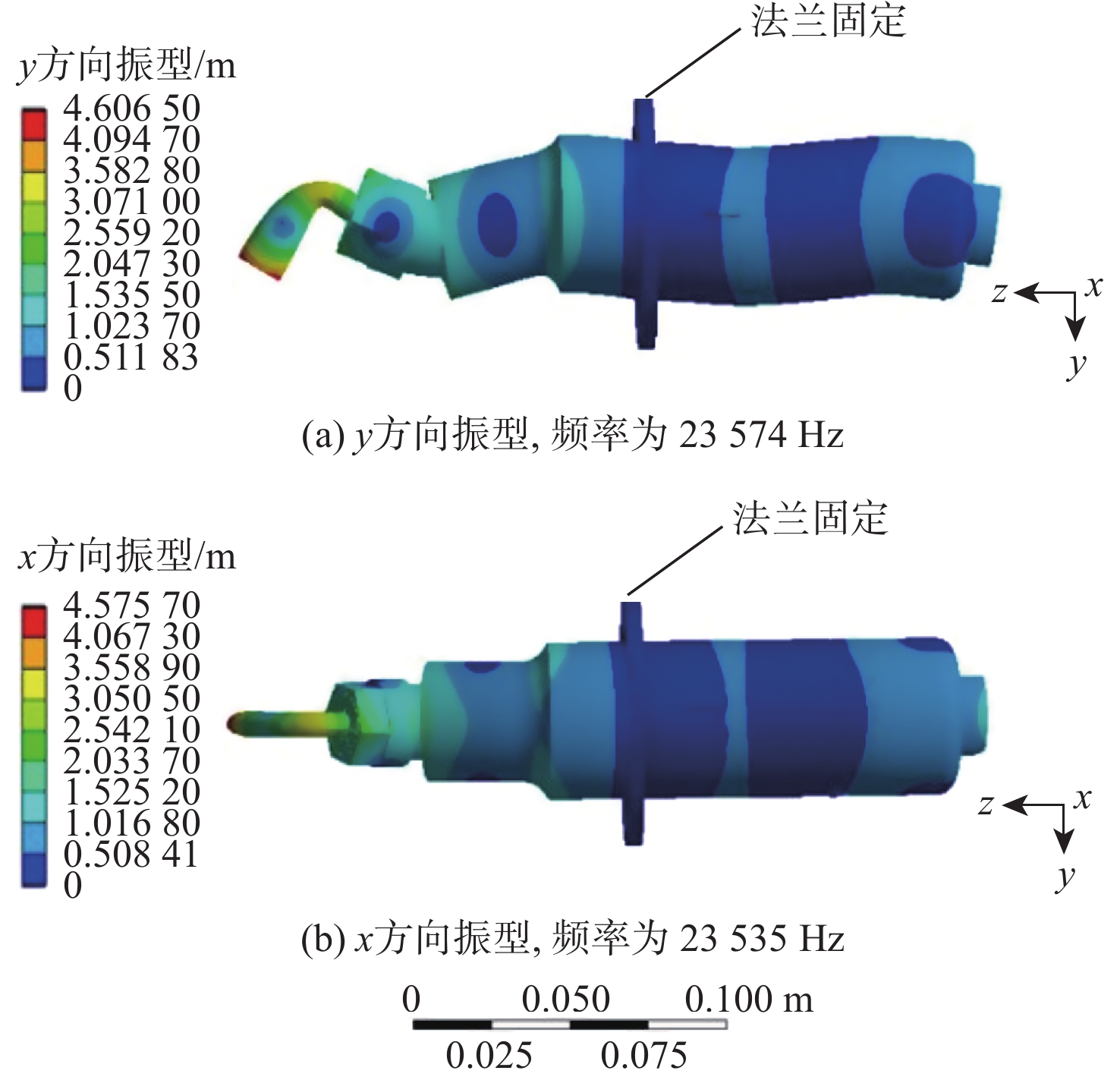

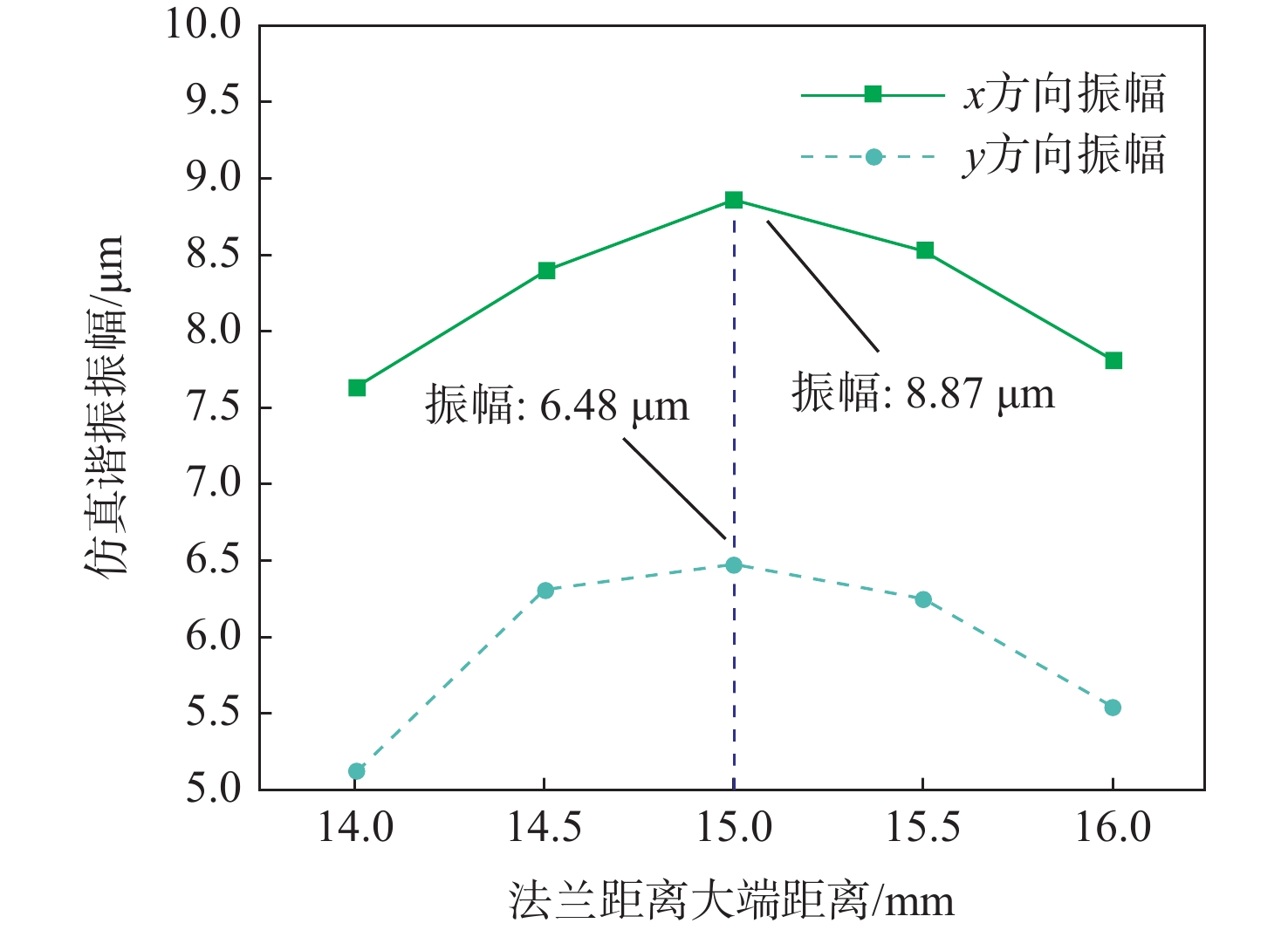

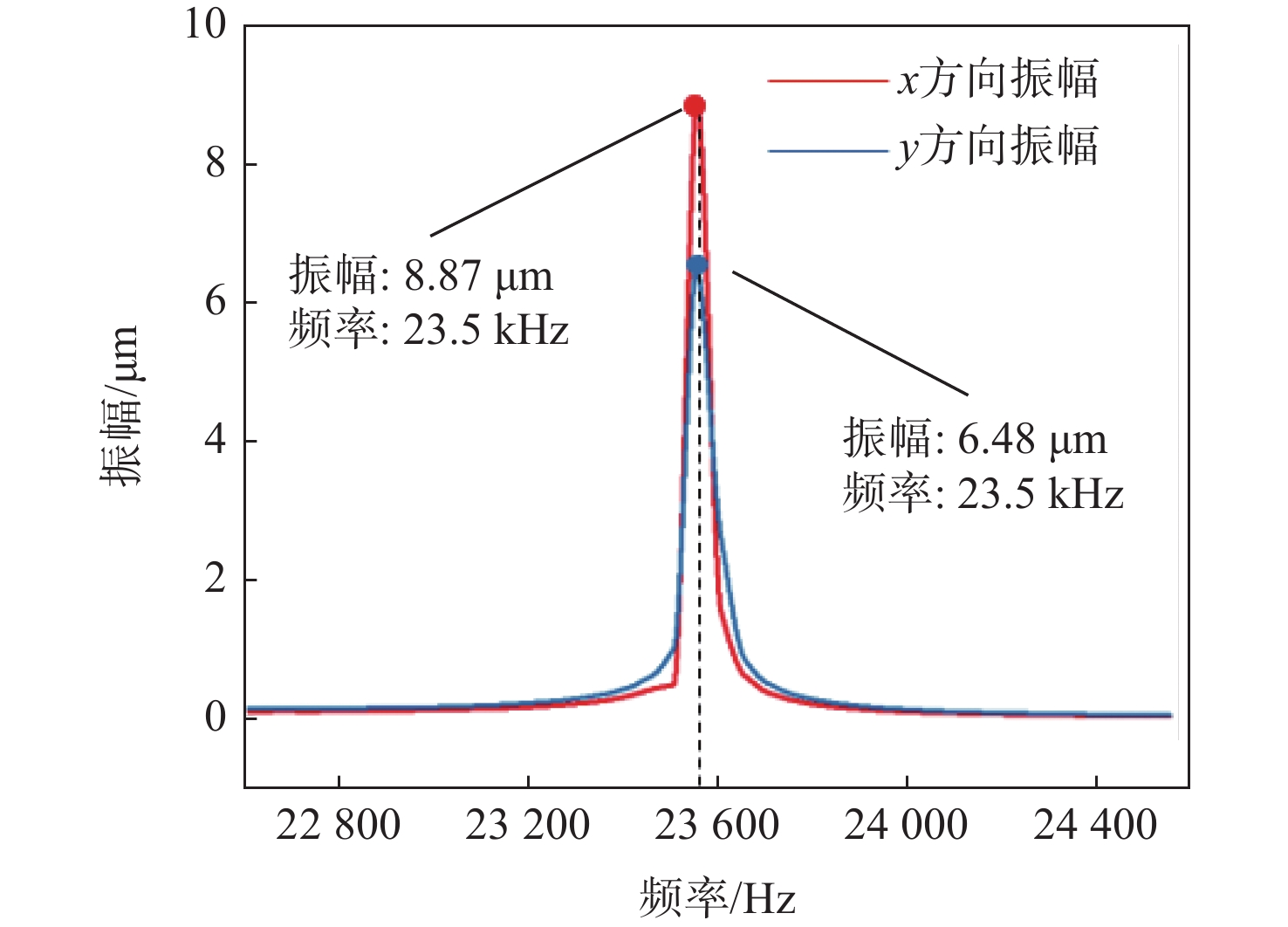

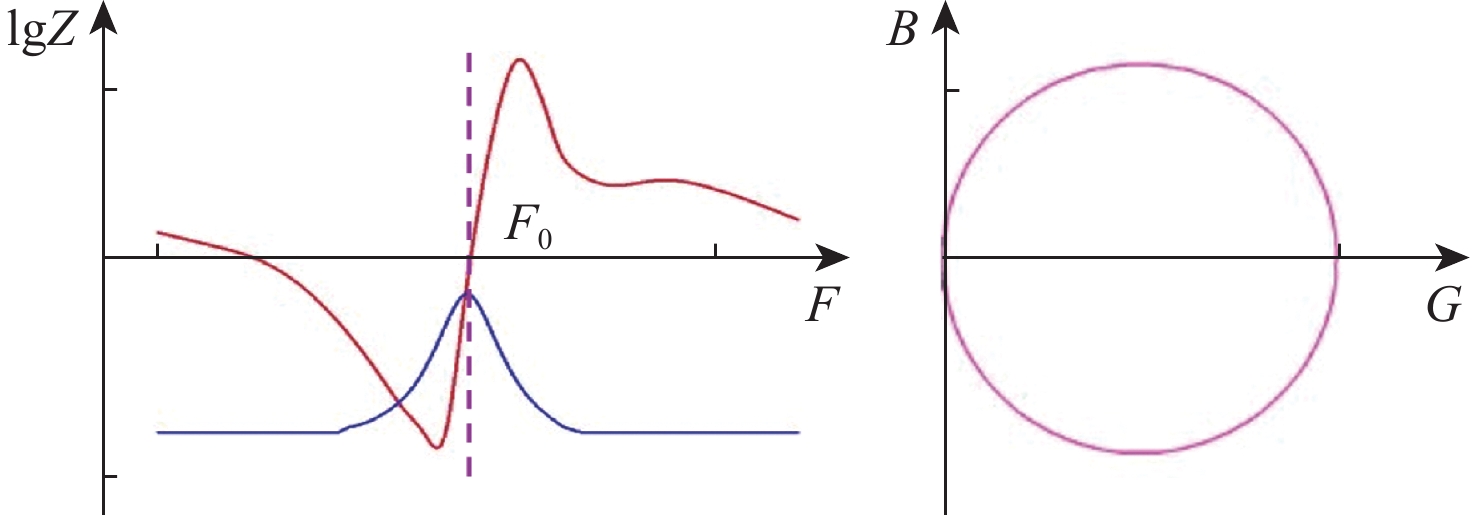

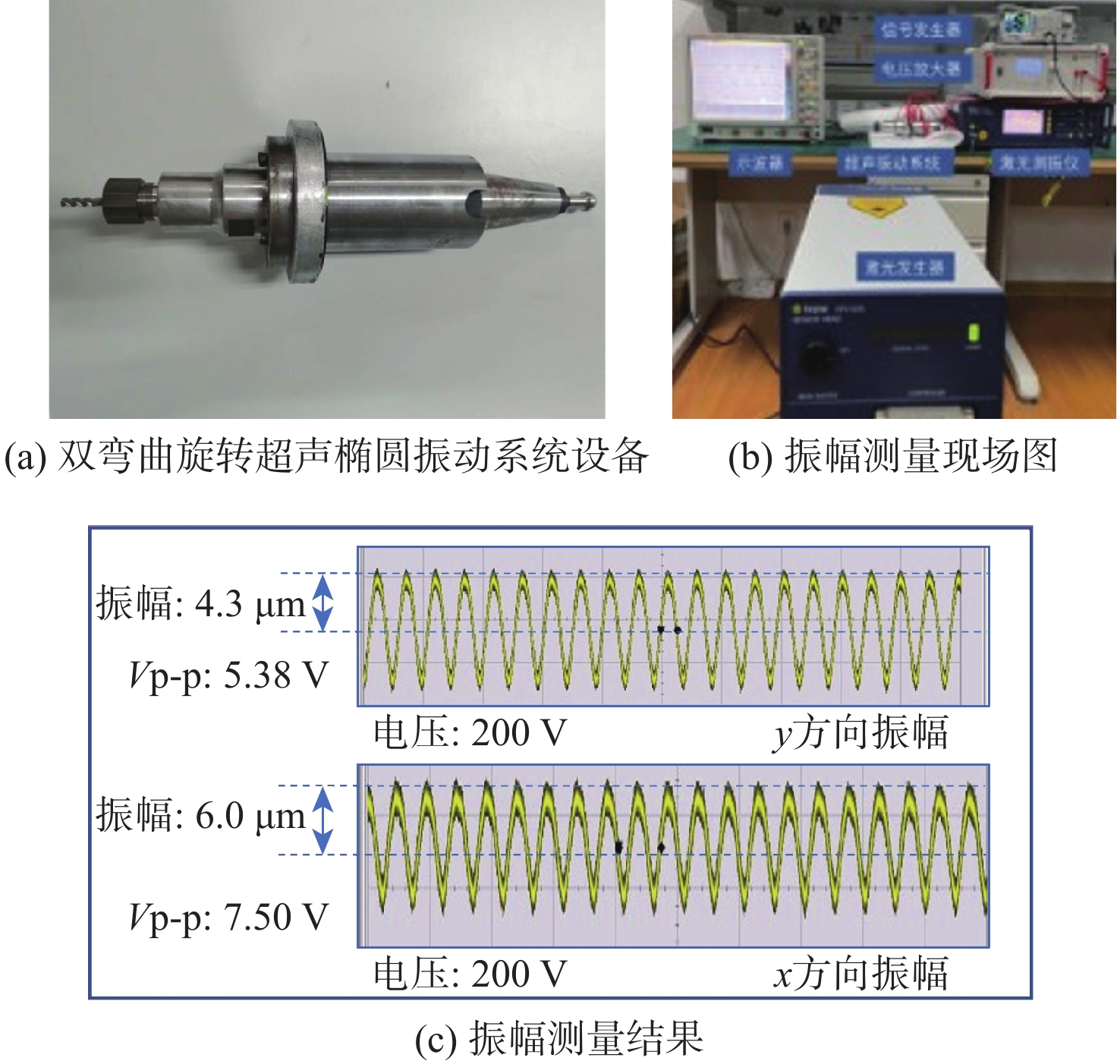

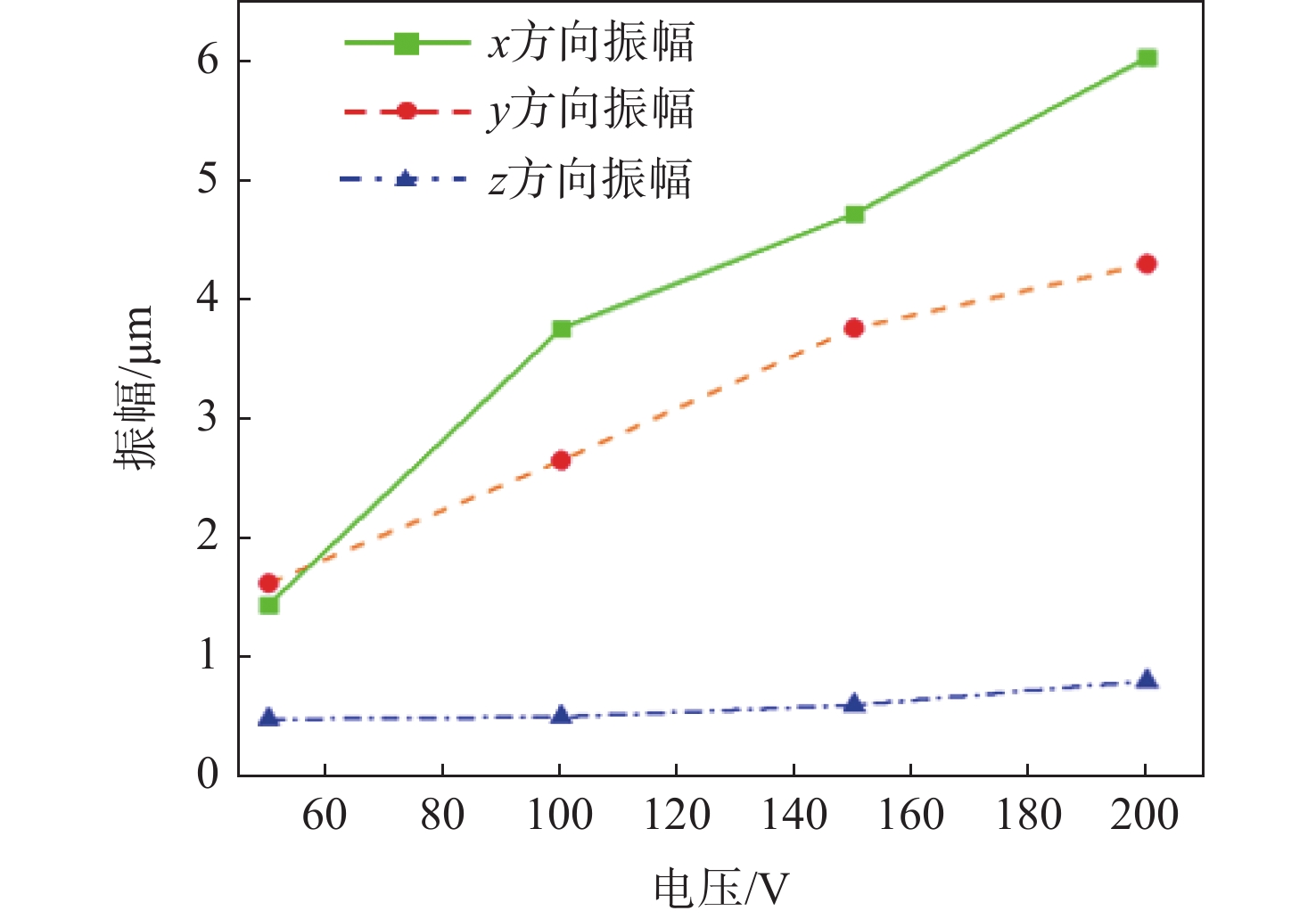

由于旋转超声单一振动模式加工效率提升有限,因此采用超声振动激励源耦合法设计了一种双弯曲旋转超声椭圆振动加工系统。推导弯曲波动方程,计算的弯曲超声振动系统参数与仿真结果的理论分析误差仅为5%。耦合双弯曲旋转超声椭圆振动加工系统2个不同方向的振动,控制弯振频率偏差低于1%。对超声刀柄的法兰位置与形状进行有限元分析发现,开设减振槽有利于增大弯振振幅,并确定了法兰的最佳位置。对双弯曲旋转超声椭圆振动加工系统的振动频率和振幅进行测试,结果表明:所设计系统在工作频率和2个方向的振幅均满足设计预期。

Abstract:The processing efficiency of the rotary ultrasonic single vibration mode is limited. Therefore, an elliptical vibration processing system with double-bending ultrasonic vibrations was designed using the ultrasonic vibration excitation source coupling method. The bending wave equation was derived, and the calculated parameters of the bending ultrasonic vibration system showed only a 5% error compared to the simulation results in theoretical analysis. The coupled double-bending rotary ultrasonic elliptical vibration processing system combines vibrations in two different directions, controlling the bending vibration frequency deviation to be less than 1%. Finite element analysis was performed on the flange position and shape of the ultrasonic tool holder, revealing that the inclusion of damping grooves helps increase the bending vibration amplitude and determines the optimal position of the flange. Finally, the vibration frequency and amplitude of the double-bending rotary ultrasonic elliptical vibration processing system were tested, and the results indicated that the operating frequency and amplitudes in both directions met the design expectations.

-

表 1 材料属性

Table 1. Material properties

材料 密度/(kg·m−3) 杨氏模量/GPa 泊松比 45#钢 7850 208 0.28 PZT-8 7650 90 0.3 表 2 超声振动系统各零件有限元分析材料属性

Table 2. Material properties of ultrasonic vibration system by finite element analysis

零件 材料 密度/(kg·m3) 弹性模量/Pa 泊松比 后盖板 45#钢 7800 2.08×1011 0.28 前盖板 45#钢 7800 2.08×1011 0.28 压电陶瓷 PZT-8 7800 8.2×1010 0.29 预紧螺栓 40cr 7900 2.14×1011 0.3 刀具 硬质合金YG8 14000 1.9×1011 0.3 表 3 双弯曲旋转超声椭圆振动加工系统弯曲频率

Table 3. Bending frequency of double bending rotary ultrasonic elliptical vibration machining system

法兰

距离/mmx方向自

由频率/Hzy方向自

由频率/Hzx方向固

定频率/Hzy方向固

定频率/Hz14 22410 22414 23480 23528 14.5 22301 22405 23619 23569 15 22596 22693 23535 23574 15.5 22281 22385 23761 23812 16 22269 22375 23856 23914 -

[1] 郑侃, 廖文和, 孙连军, 等. 机器人纵振与纵扭超声铣削稳定性对比研究[J]. 机械工程学报, 2021, 57(7): 10-17. doi: 10.3901/JME.2021.07.010ZHENG K, LIAO W H, SUN L J, et al. Comparative study on stability of robotic longitudinal vibration and longitudinal-torsional ultrasonic milling[J]. Journal of Mechanical Engineering, 2021, 57(7): 10-17(in Chinese). doi: 10.3901/JME.2021.07.010 [2] 廖文和, 郑侃, 孙连军, 等. 大型复杂构件机器人加工稳定性研究进展[J]. 航空学报, 2022, 43(1): 026061.LIAO W H, ZHENG K, DONG S, et al. Burr characteristics of robotic rotary ultrasonic drilling aluminum alloy stacked components[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(1): 026061(in Chinese). [3] 胡力闯, 郑侃, 董松, 等. 机器人旋转超声钻削铝合金叠层构件毛刺特性[J]. 北京航空航天大学学报, 2020, 46(2): 164-183.HU L C, ZHEN K, DONG S, et al. Burr characteristics of robotic rotary ultrasonic drilling aluminum alloy stacked components[J]. Journal of Beijing University of Aeronautics and Astronantics, 2020, 46(2): 164-183(in Chinese). [4] YANG Z C, ZHU L D, ZHANG G X, et al. Review of ultrasonic vibration-assisted machining in advanced materials[J]. International Journal of Machine Tools and Manufacture, 2020, 156: 103594. doi: 10.1016/j.ijmachtools.2020.103594 [5] SHU J, LIAO W H, ZHENG K, et al. Effect of rotary ultrasonic machining on surface structure and ablation resistance of C/C composite[J]. Ceramics International, 2022, 48(13): 18246-18256. doi: 10.1016/j.ceramint.2022.03.083 [6] XUE F, ZHENG K, LIAO W H, et al. Investigation on fiber fracture mechanism of c/sic composites by rotary ultrasonic milling[J]. International Journal of Mechanical Sciences, 2021, 191: 106054. doi: 10.1016/j.ijmecsci.2020.106054 [7] ZHANG M L, ZHANG D Y, GENG D X, et al. Effects of tool vibration on surface integrity in rotary ultrasonic elliptical end milling of Ti–6Al–4V[J]. Journal of Alloys and Compounds, 2020, 821: 153266. doi: 10.1016/j.jallcom.2019.153266 [8] 张德远, 彭振龙, 耿大喜, 等. 高效低损伤高速波动式超声加工技术进展[J]. 航空制造技术, 2022, 65(8): 22-33.ZHANG D Y, PENG Z L, GENG D X, et al. Development of high-speed wave-motion ultrasonic machining technology with high efficiency and low damage[J]. Aeronautical Manufacturing Technology, 2022, 65(8): 22-33(in Chinese). [9] 彭振龙, 张翔宇, 张德远. 航空航天难加工材料高速超声波动式切削方法[J]. 航空学报, 2022, 43(4): 525587. doi: 10.7527/j.issn.1000-6893.2022.4.hkxb202204007PENG Z L, ZHANG X Y, ZHANG D Y. High-speed ultrasonic vibration cutting for difficult-to-machine materials in aerospace field[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(4): 525587(in Chinese). doi: 10.7527/j.issn.1000-6893.2022.4.hkxb202204007 [10] 高泽, 张德远, 李哲, 等. 高速超声椭圆振动铣削腹板表面质量研究[J]. 机械工程学报, 2019, 55(7): 249-256. doi: 10.3901/JME.2019.07.249GAO Z, ZHANG D Y, LI Z, et al. Research on surface quality of titanium alloy webs via high-speed ultrasonic elliptical vibration milling[J]. Journal of Mechanical Engineering, 2019, 55(7): 249-256(in Chinese). doi: 10.3901/JME.2019.07.249 [11] 刘佳佳, 姜兴刚, 高泽, 等. 高速旋转超声椭圆振动侧铣削振幅对钛合金表面完整性影响的研究[J]. 机械工程学报, 2019, 55(11): 215-223. doi: 10.3901/JME.2019.11.215LIU J J, JIANG X G, GAO Z, et al. Investigation of the effect of vibration amplitude on the surface integrity in high-speed rotary ultrasonic elliptical machining for side milling of Ti-6Al-4V[J]. Journal of Mechanical Engineering, 2019, 55(11): 215-223(in Chinese). doi: 10.3901/JME.2019.11.215 [12] GAO J, ALTINTAS Y. Chatter stability of synchronized elliptical vibration assisted milling[J]. CIRP Journal of Manufacturing Science and Technology, 2020, 28: 76-86. doi: 10.1016/j.cirpj.2019.11.006 [13] LU H, ZHU L D, YANG Z C, et al. Research on the generation mechanism and interference of surface texture in ultrasonic vibration assisted milling[J]. International Journal of Mechanical Sciences, 2021, 208: 106681. doi: 10.1016/j.ijmecsci.2021.106681 [14] WANG H, PEI Z J, CONG W L. A feeding-directional cutting force model for end surface grinding of CFRP composites using rotary ultrasonic machining with elliptical ultrasonic vibration[J]. International Journal of Machine Tools and Manufacture, 2020, 152: 103540. doi: 10.1016/j.ijmachtools.2020.103540 [15] PANG Y, FENG P F, ZHANG J F, et al. Frequency coupling design of ultrasonic horn with spiral slots and performance analysis of longitudinal-torsional machining characteristics[J]. The International Journal of Advanced Manufacturing Technology, 2020, 106(9): 4093-4103. [16] CHEN P, TONG J L, ZHAO J S, et al. A study ofthe surface microstructure and tool wear of titanium alloys after ultrasonic longitudinal-torsional milling[J]. Journal of Manufacturing Processes, 2020, 53: 1-11. doi: 10.1016/j.jmapro.2020.01.040 [17] 顾磊, 郑侃, 董松. 纵扭共振旋转超声加工系统设计[J]. 南京理工大学学报, 2020, 44(2): 127-133.GU L, ZHENG K, DONG S. Design of miniature longitudinal-torsional ultrasonic machining system[J]. Journal of Nanjing University of Science and Technology, 2020, 44(2): 127-133(in Chinese). [18] WANG J J, LIAO W H, GUO P. Modulated ultrasonic elliptical vibration cutting for ductile-regime texturing of brittle materials with 2-D combined resonant and non-resonant vibrations[J]. International Journal of Mechanical Sciences, 2020, 170: 105347. doi: 10.1016/j.ijmecsci.2019.105347 [19] BAI W, WANG K, DU D X, et al. Design of an ultrasonic elliptical vibration device with two stationary points for ultra-precision cutting[J]. Ultrasonics, 2022, 120: 106662. doi: 10.1016/j.ultras.2021.106662 [20] DU P F, HAN L, QIU X, et al. Development of a high-precision piezoelectric ultrasonic milling tool using longitudinal-bending hybrid transducer[J]. International Journal of Mechanical Sciences, 2022, 222: 107239. doi: 10.1016/j.ijmecsci.2022.107239 [21] 王晓雪, 张臣, 王生才. 纵弯椭圆振动辅助钻削装置的设计与优化研究[J]. 航空制造技术, 2020, 63(12): 70-79.WANG X X, ZHANG C, WANG S C. Design and optimization of longitude-bend complex mode elliptical vibration assisted drilling device[J]. Aeronautical Manufacturing Technology, 2020, 63(12): 70-79(in Chinese). [22] 张若愚. 用于旋转超声加工的半波谐振超声振子设计及实验研究[D]. 杭州: 浙江大学, 2020: 50-51.ZHANG R Y. Design and experimental study of half-wave resonant ultrasonic oscillator for rotary ultrasonic machining[D]. Hangzhou: Zhejiang University, 2020: 50-51(in Chinese). 期刊类型引用(1)

1. 李君恩,丁天明,韩喜红,刘虎. 基于改进麻雀搜索算法的USV路径规划. 舰船科学技术. 2025(05): 153-158 .  百度学术

百度学术其他类型引用(1)

-

下载:

下载:

百度学术

百度学术