Topological optimization method for conformal cellular structures on surfaces based on co-simulation

-

摘要:

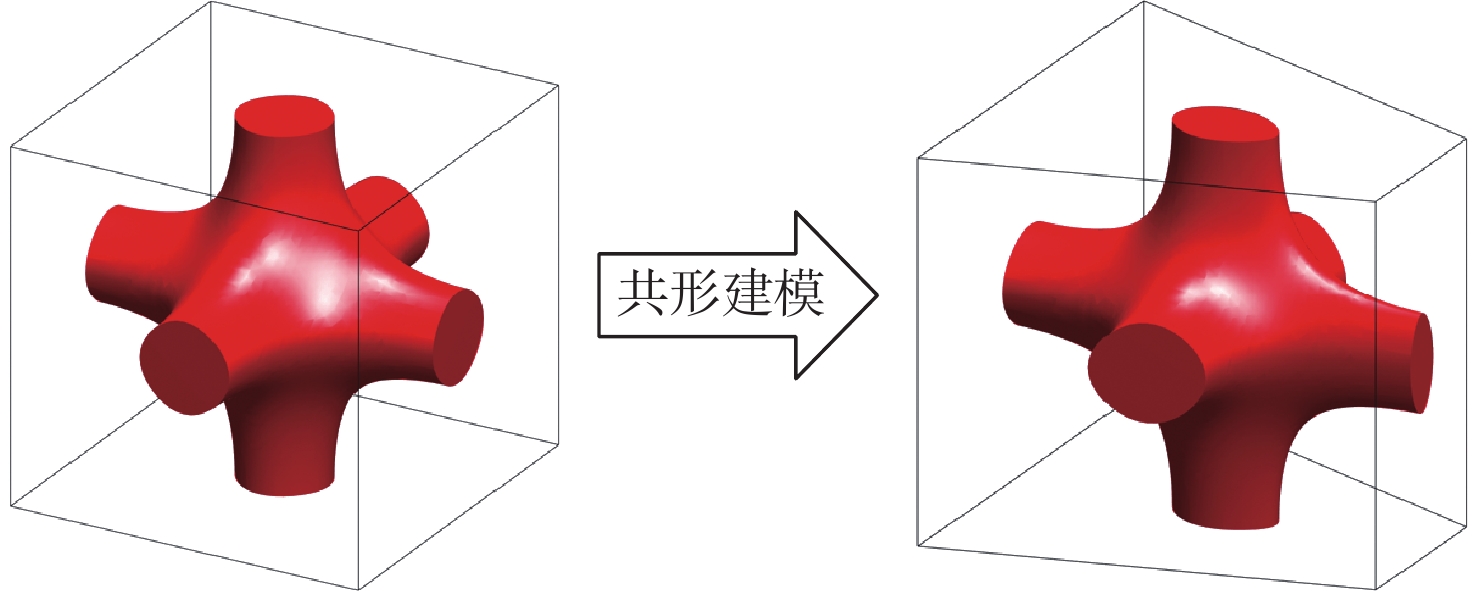

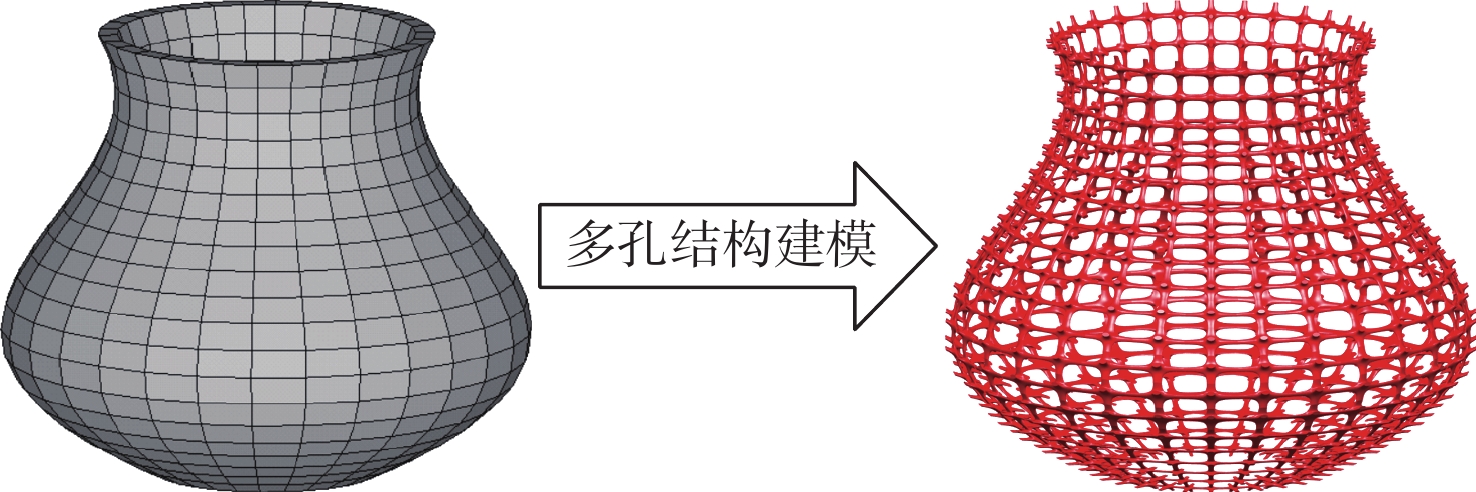

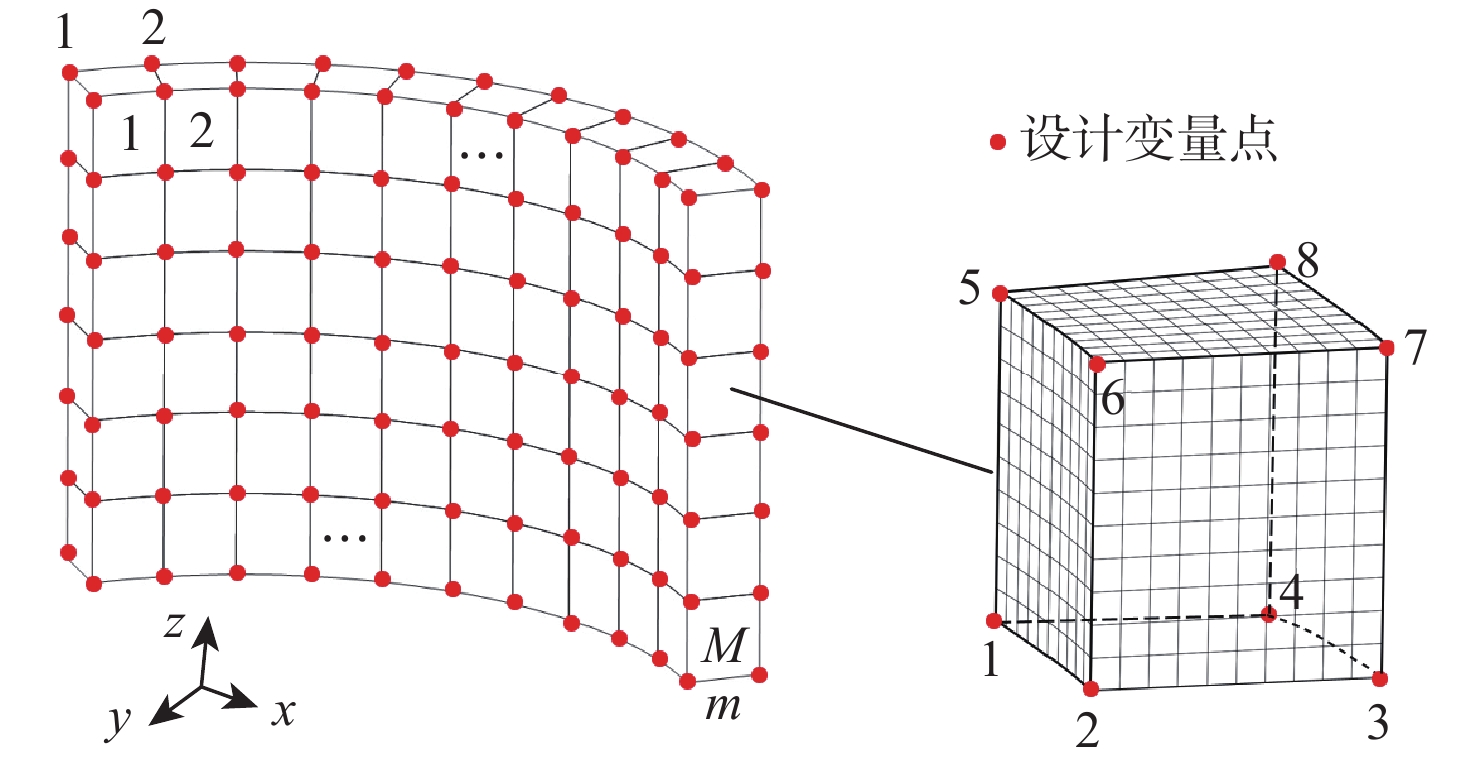

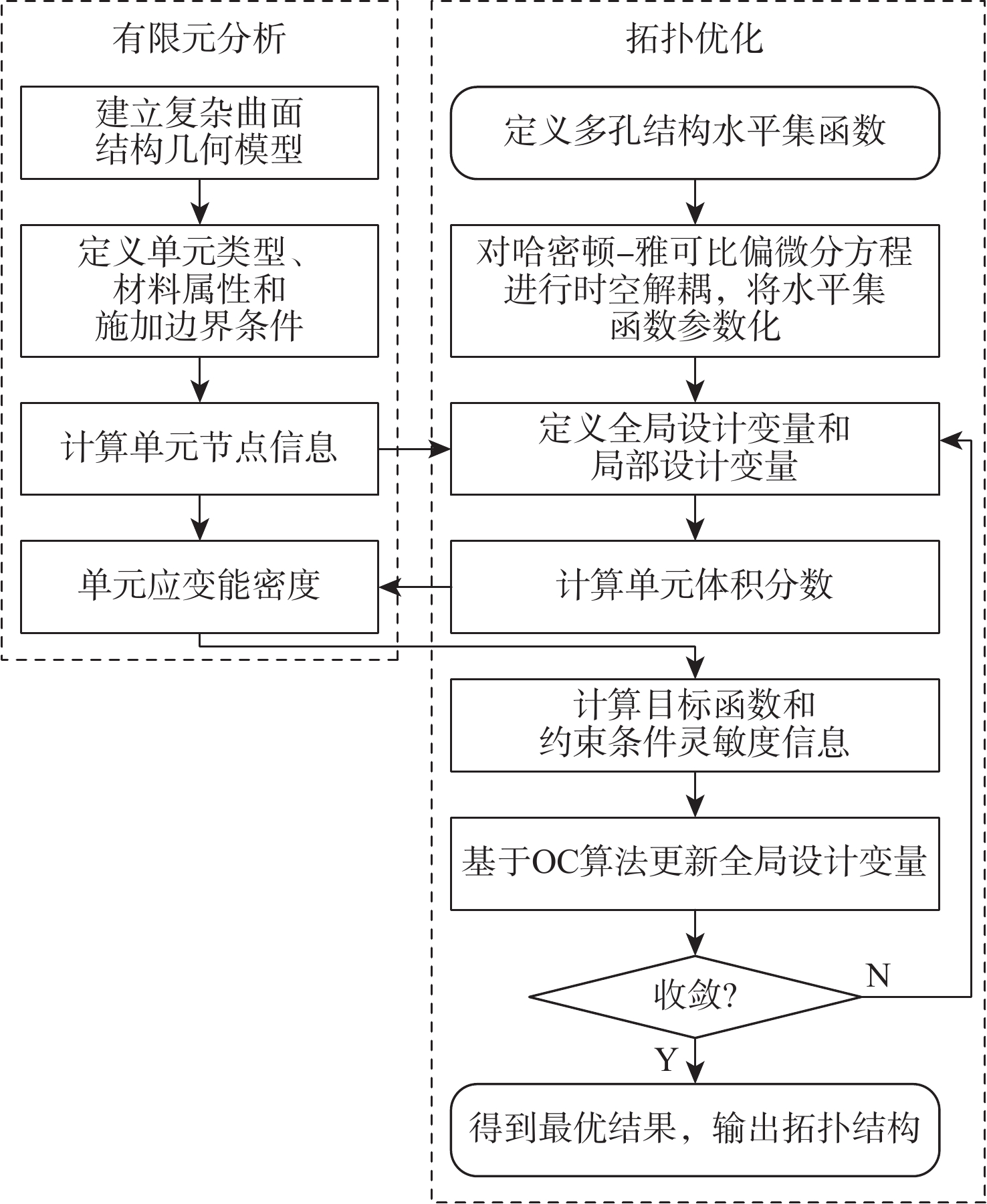

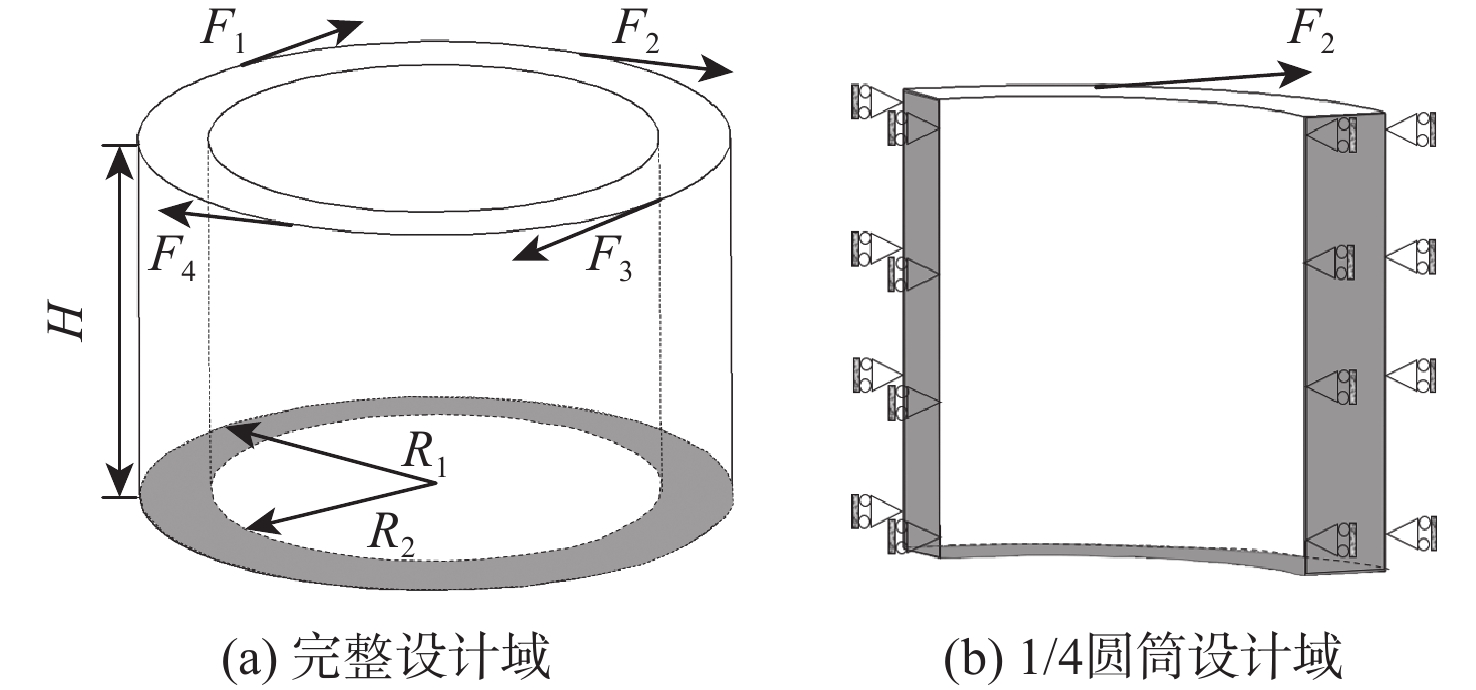

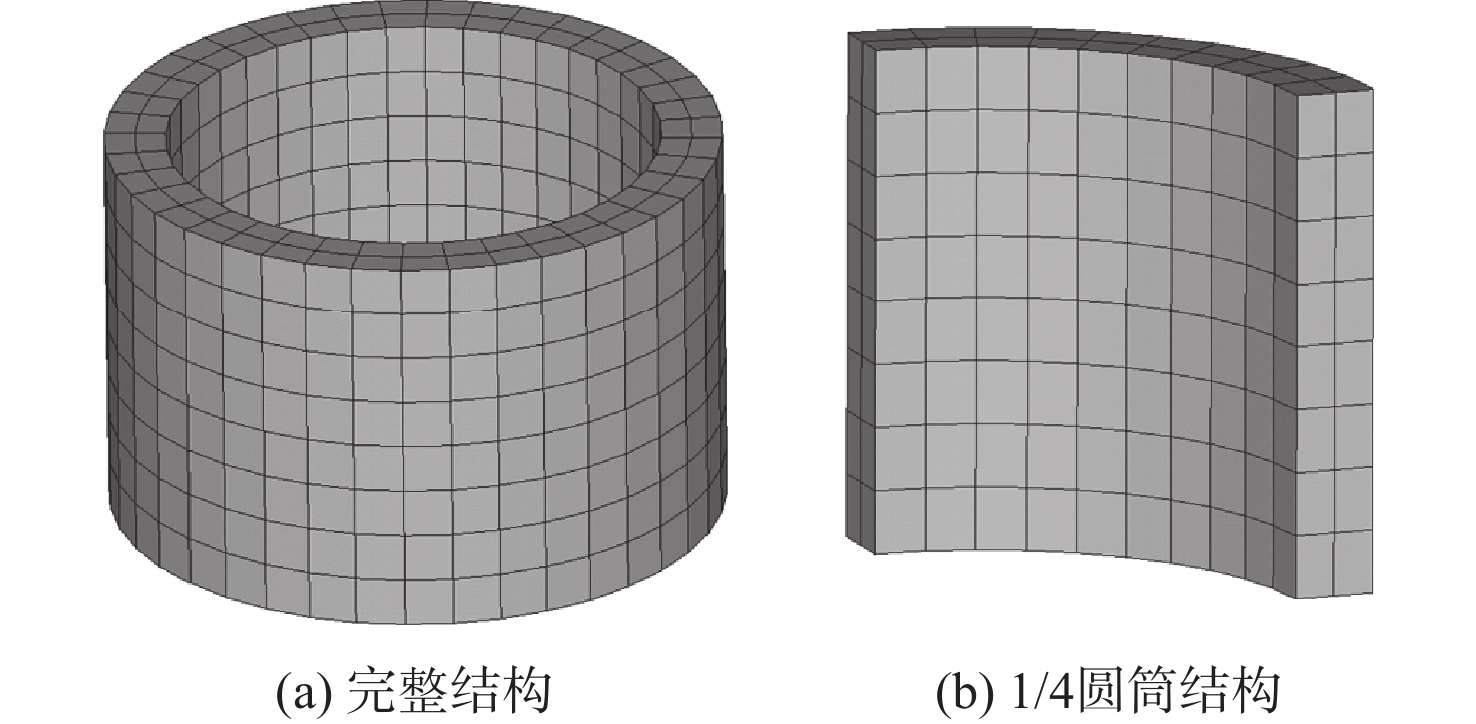

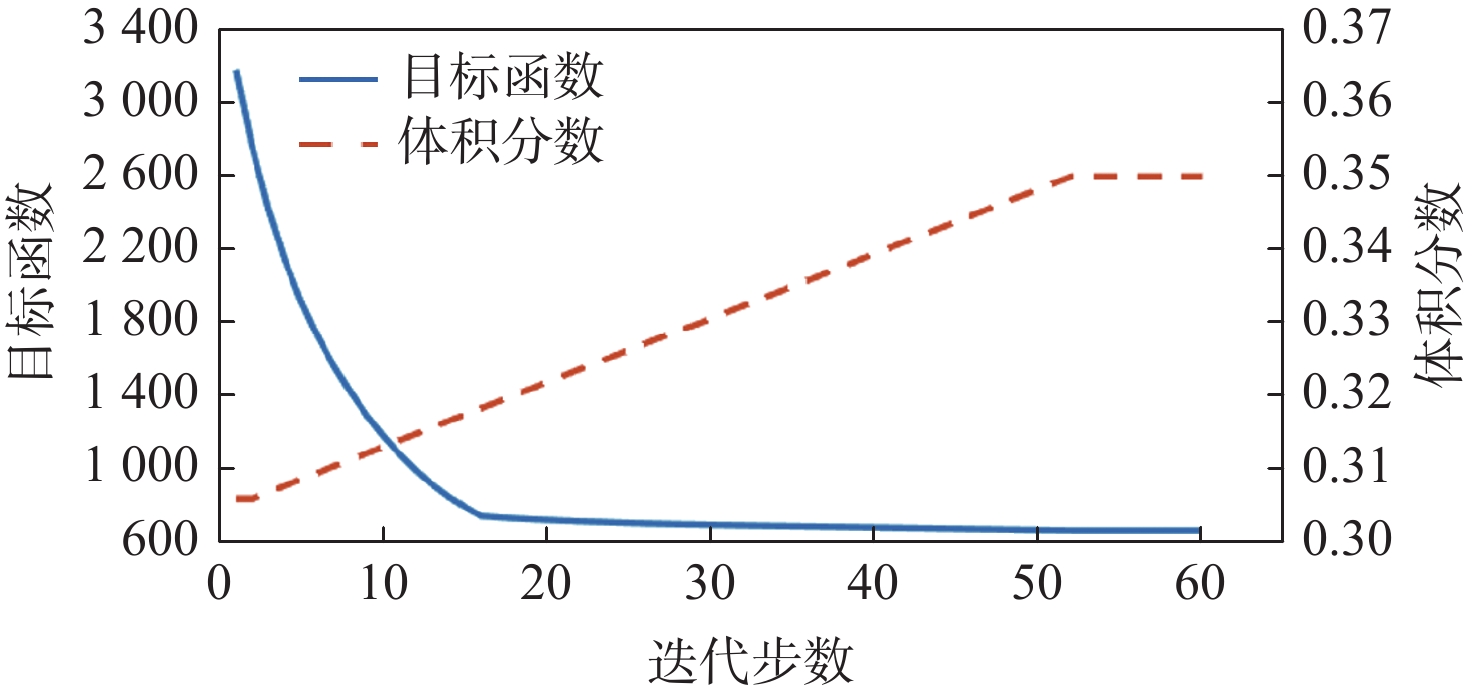

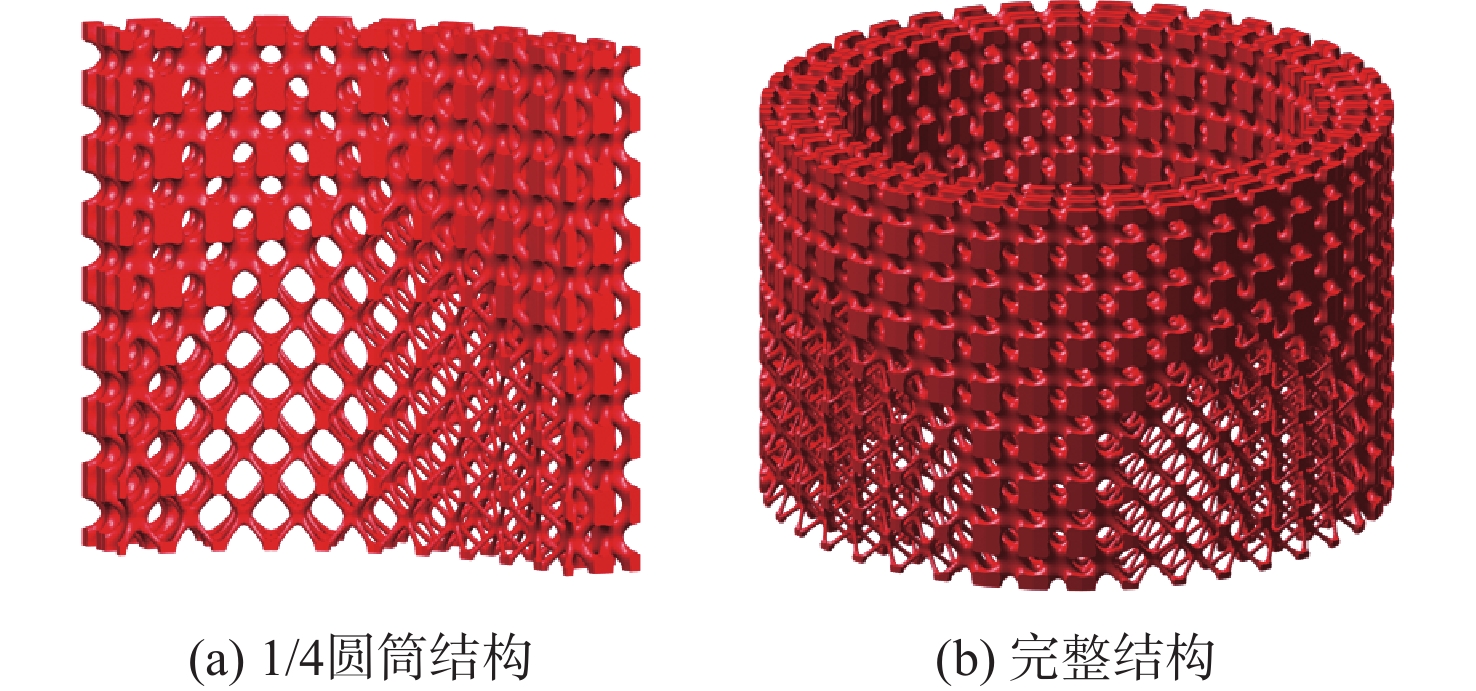

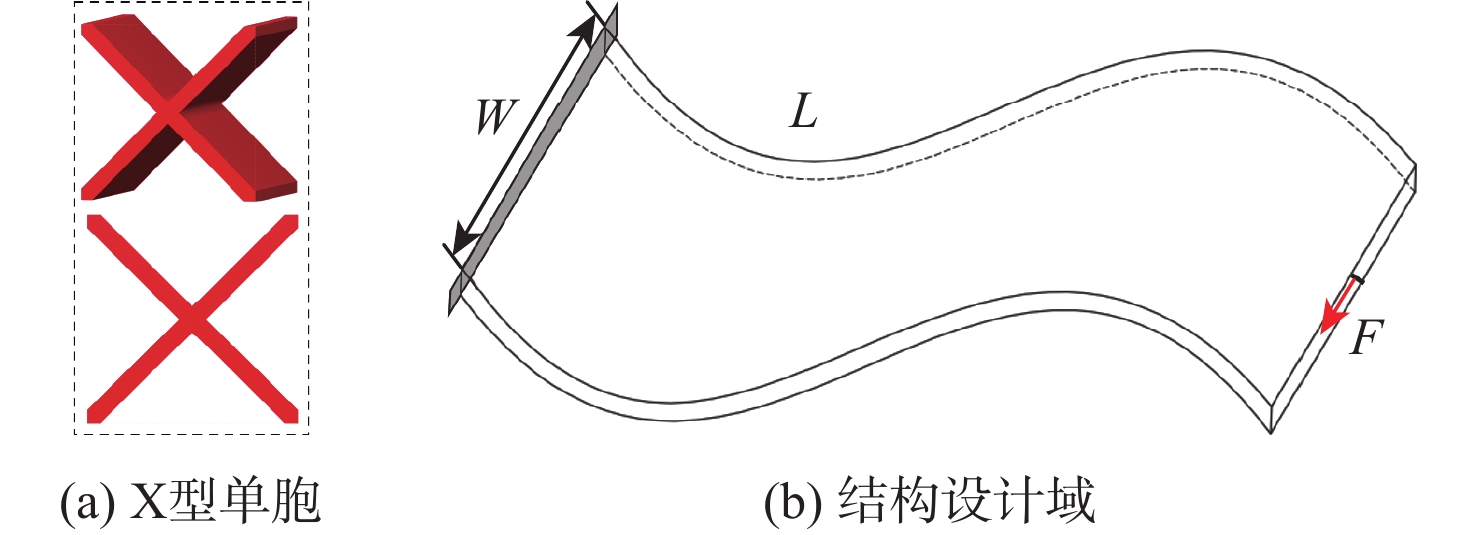

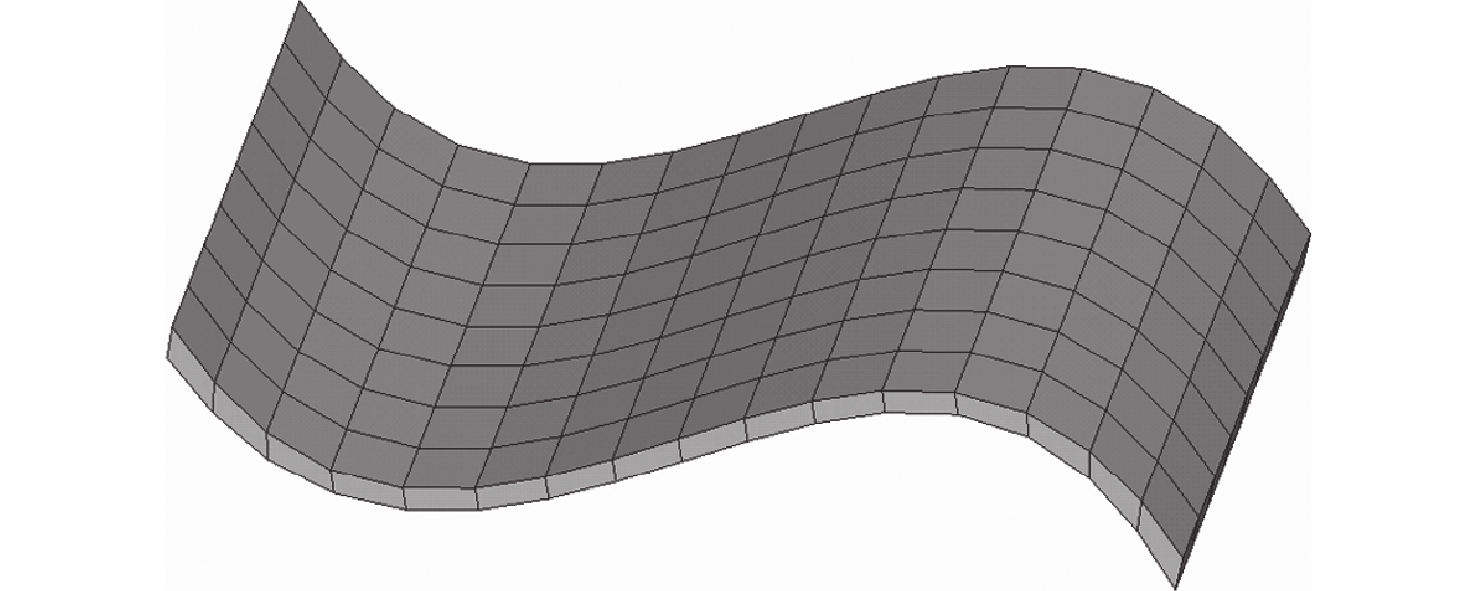

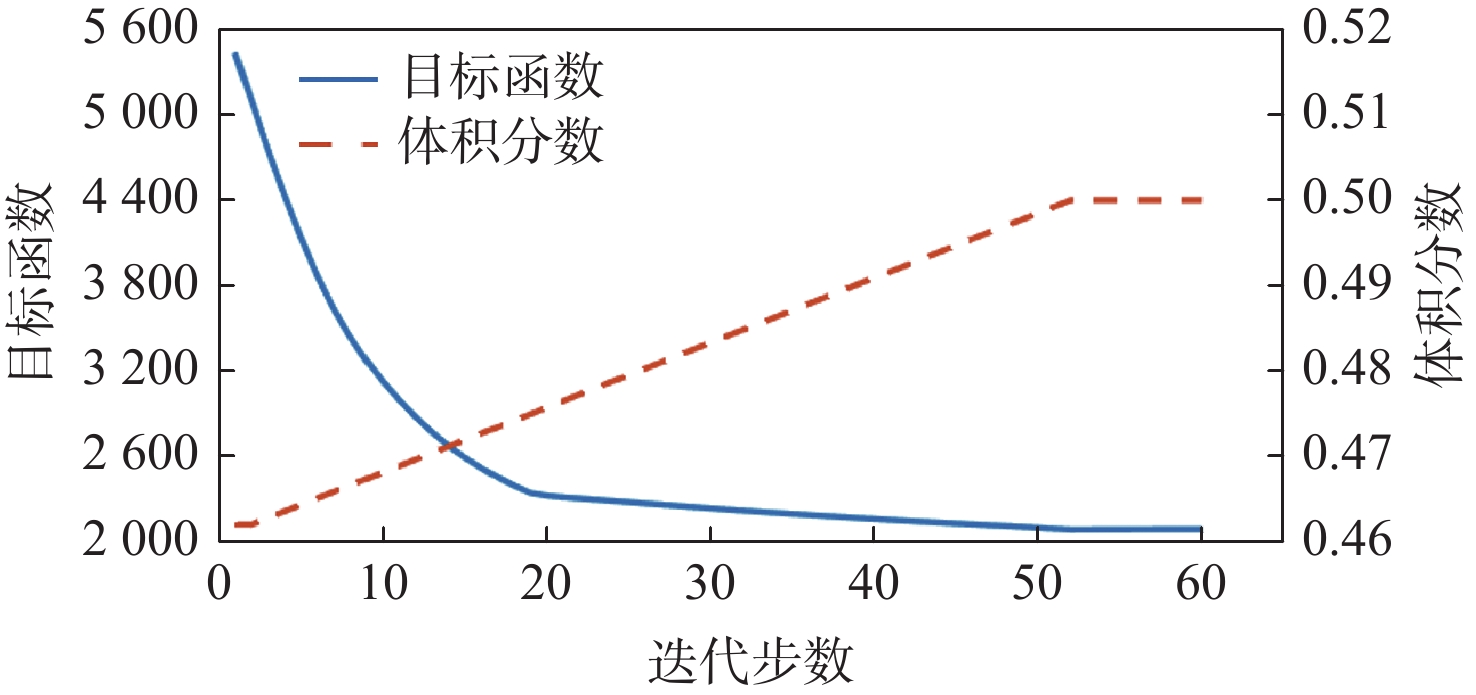

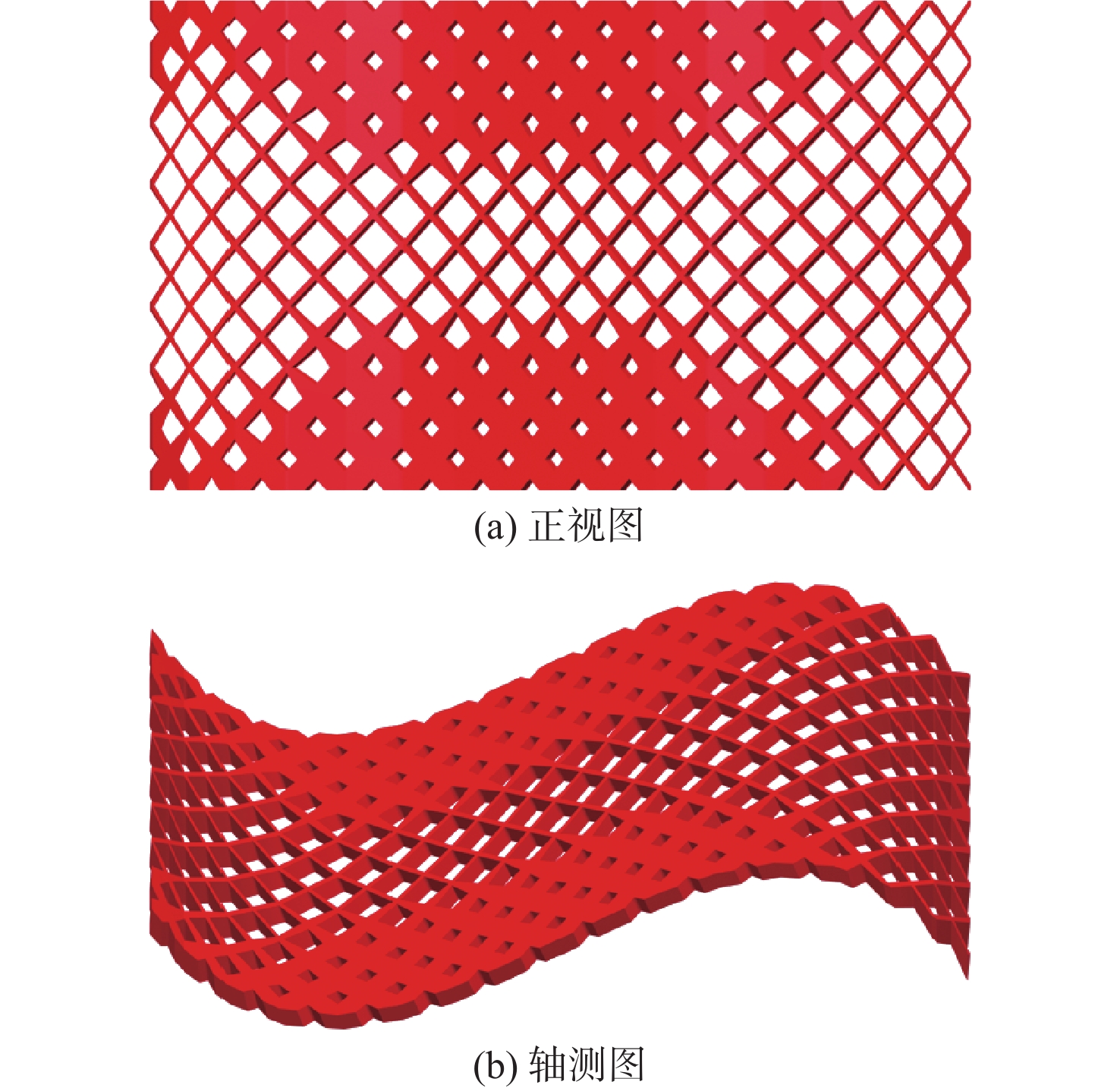

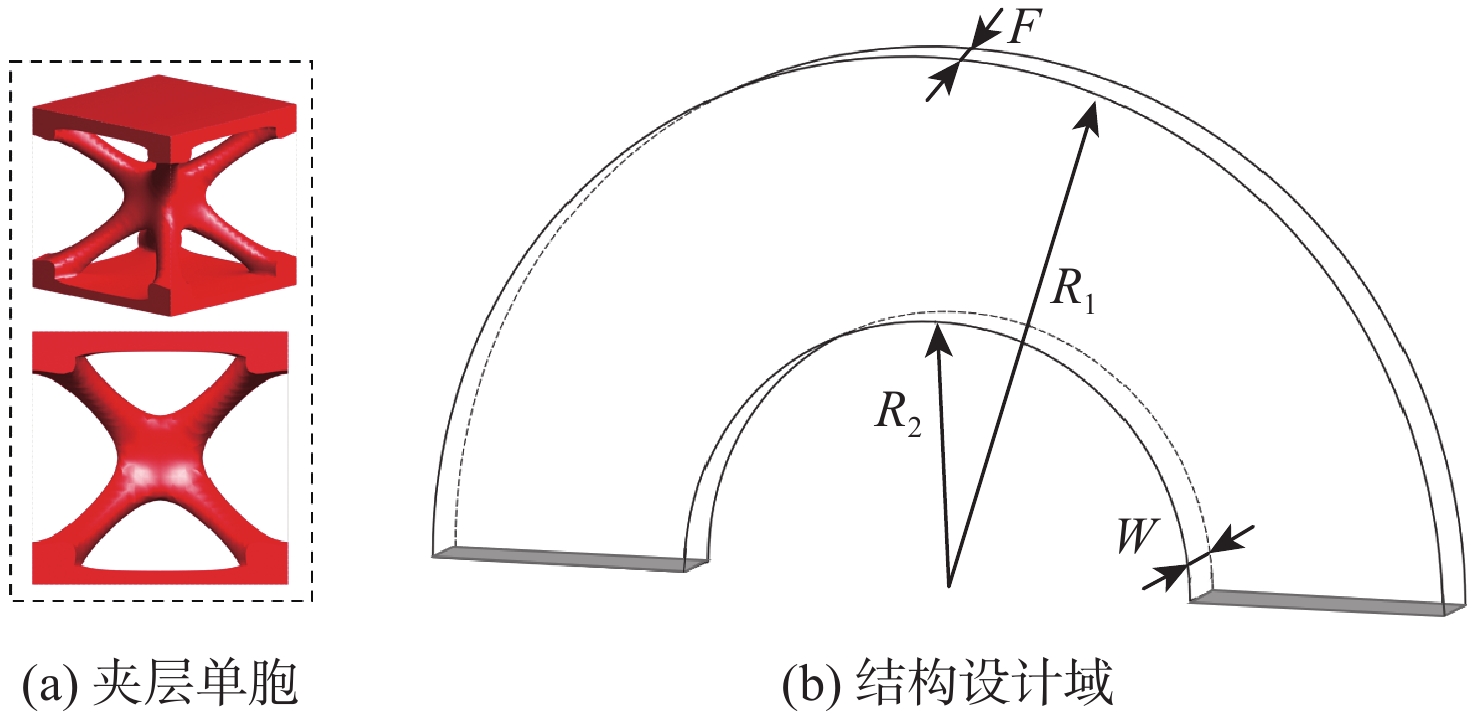

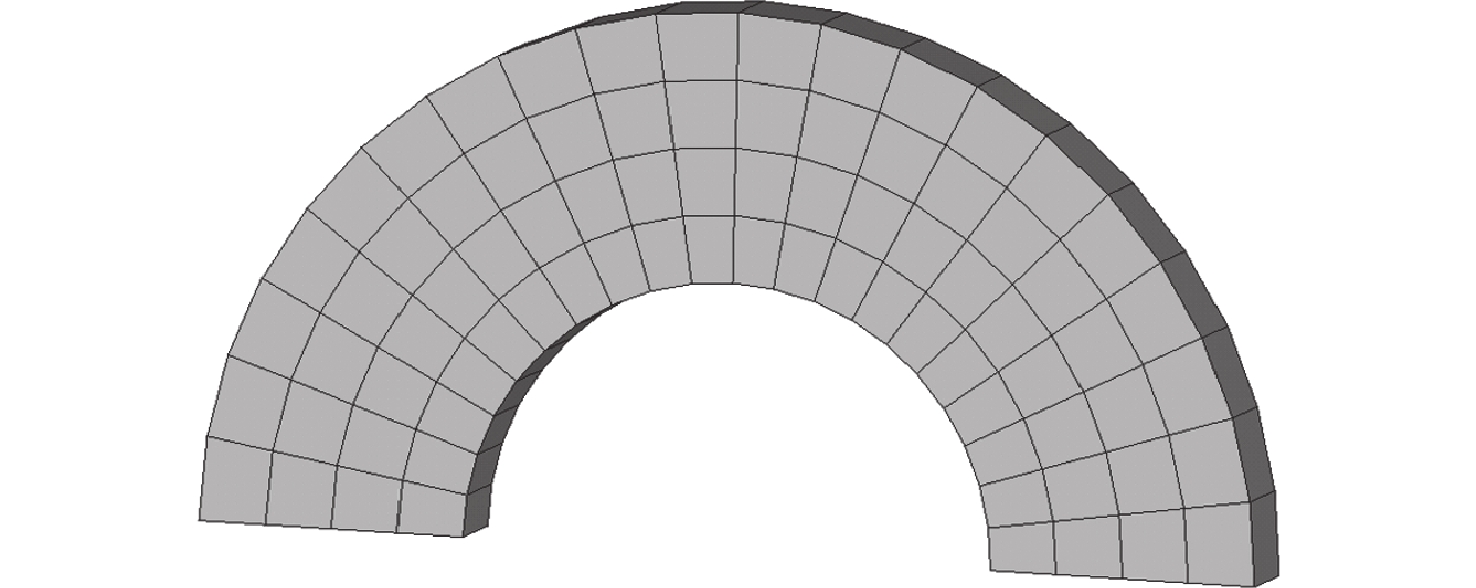

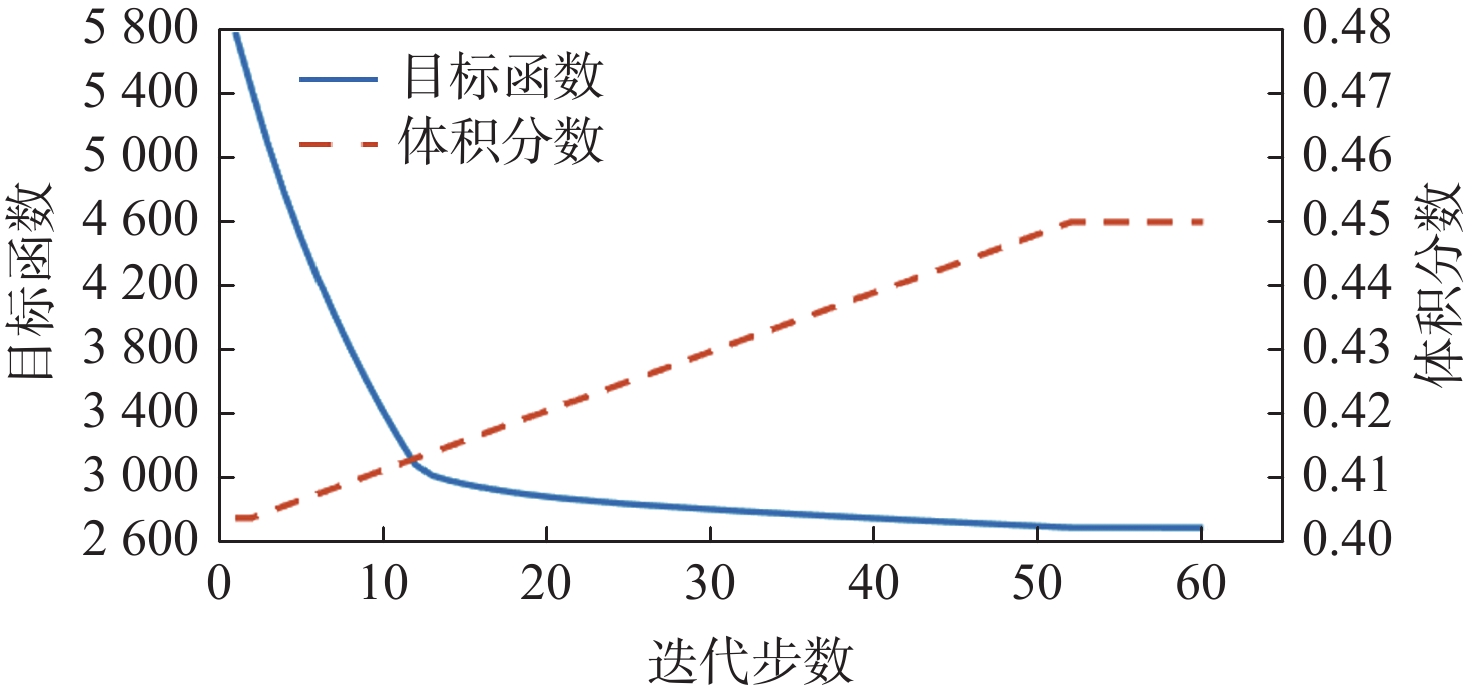

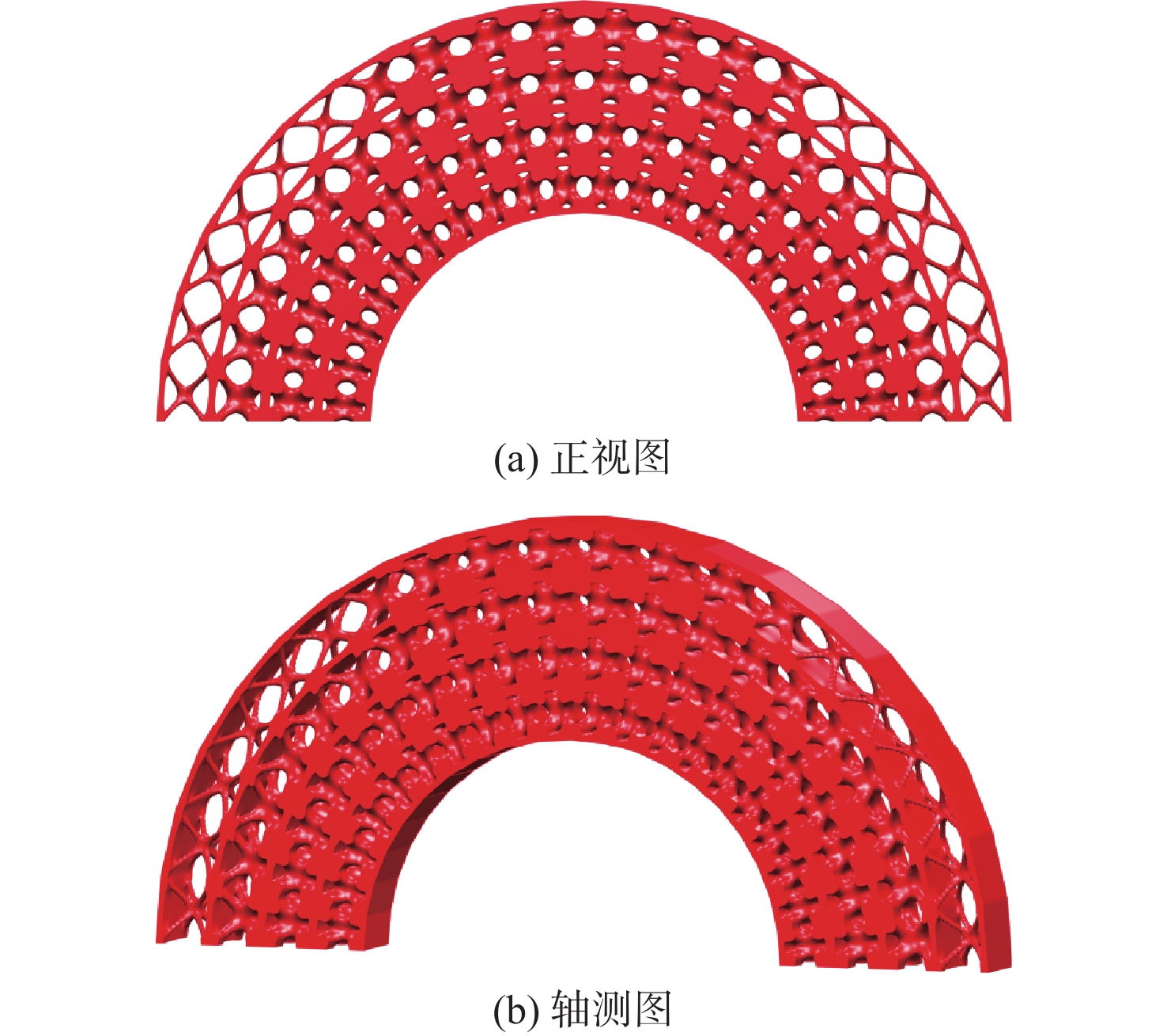

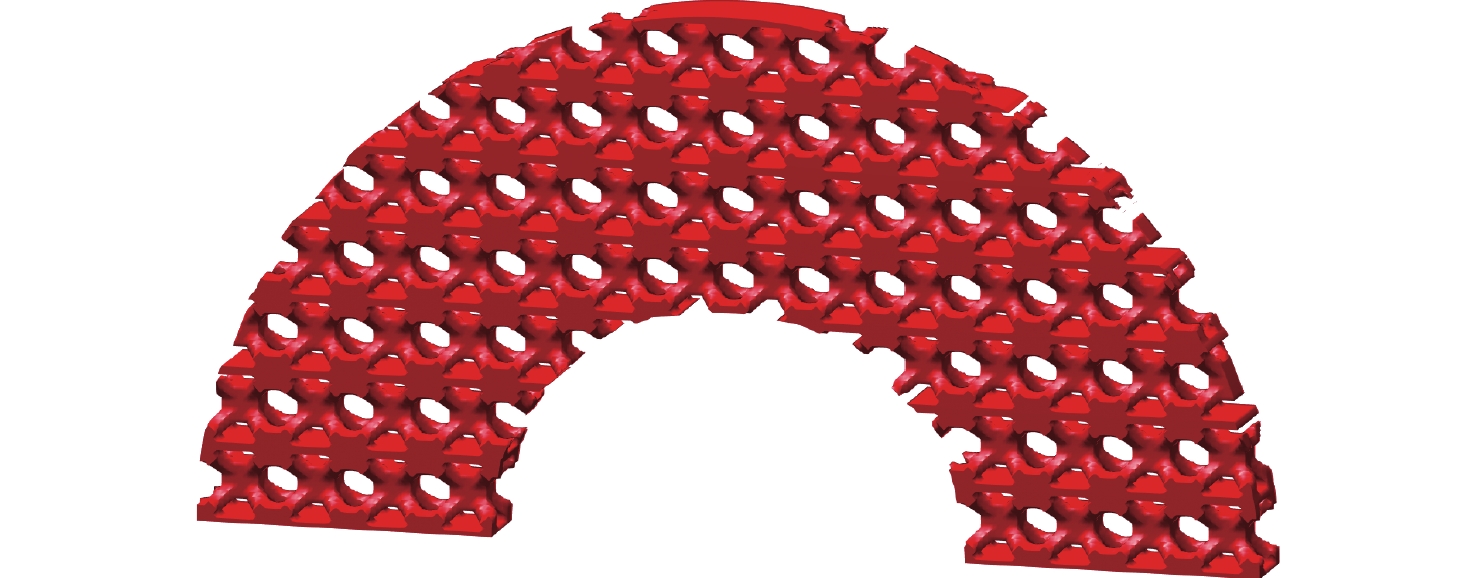

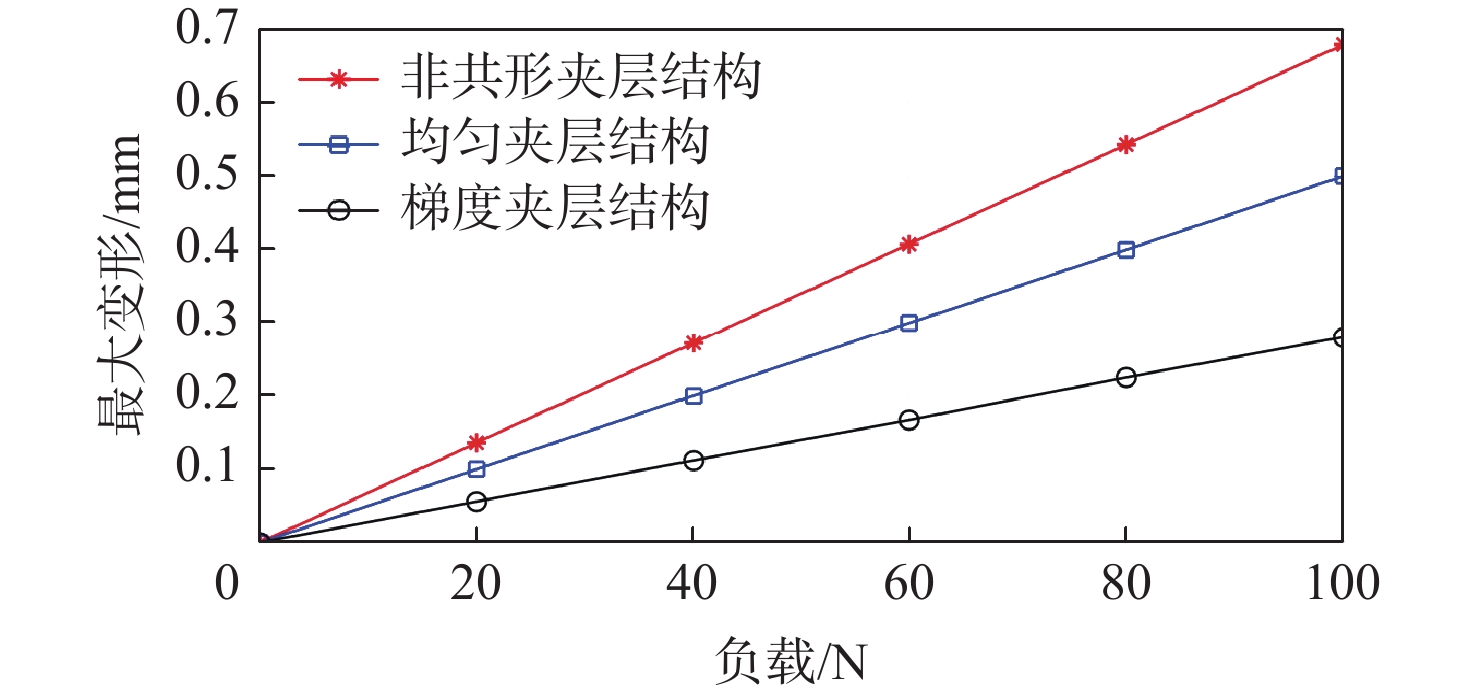

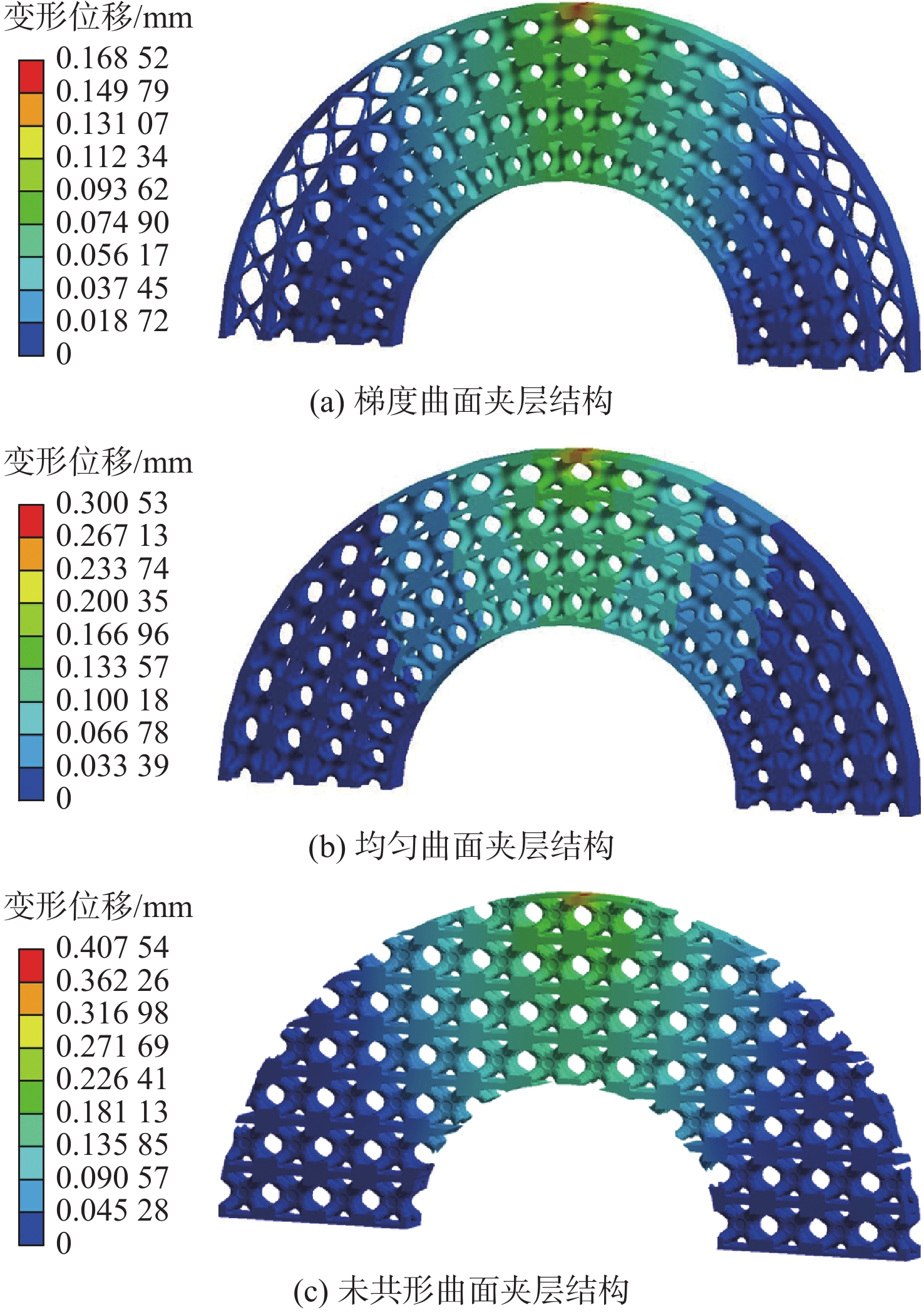

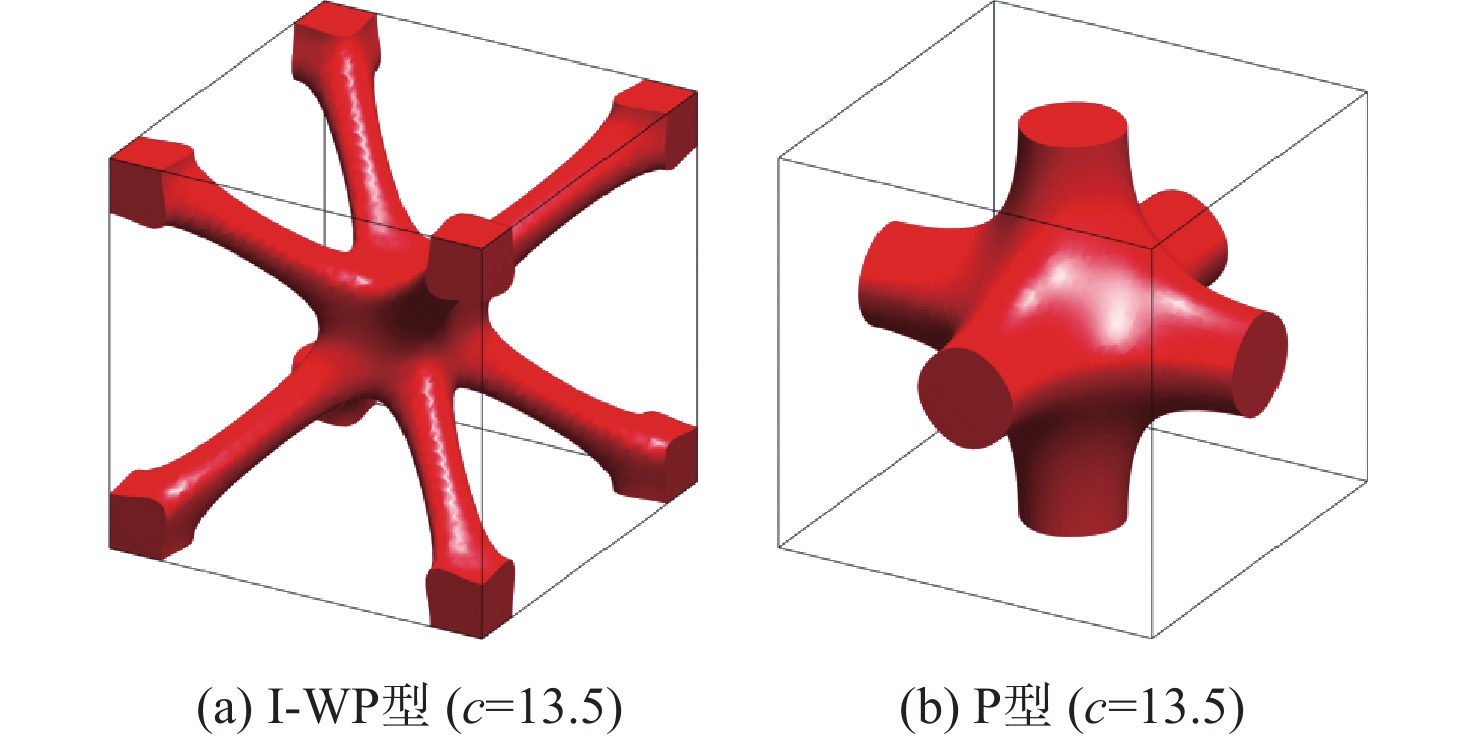

针对宏观曲面结构上多孔结构单胞构型与设计域外形不匹配,导致曲面结构优化困难的问题,提出一种基于联合仿真的曲面共形多孔结构拓扑优化方法。基于三周期极小曲面隐式水平集函数,实现多孔结构的参数化建模。采用等参单元法理论,建立自然坐标系到笛卡儿坐标系的映射关系,实现曲面多孔结构的共形建模。构造线性插值函数,保证多孔结构单胞之间的C0连续。引入可变切割水平集函数,建立MATLAB与ANSYS联合仿真的多孔结构拓扑优化框架。数值算例表明:所提方法可有效实现曲面多孔结构的拓扑优化设计,确保多孔结构单胞与设计域外形的匹配,提升多孔结构的力学性能。

Abstract:The optimization design for structures with surface is challenging due to the mismatch between cellular unit cell configuration and the design domain shape. Thus, a topological optimization design method for conformal cellular structures on surfaces based on co-simulation is proposed. The parametric modelling of cellular structures is achieved by utilising the implicit level set functions derived from triply periodic minimal surfaces. By using the isoparametric element method, the mapping relationship between the natural coordinate system and the cartesian coordinate is established to realize the conformal modeling of the cellular structures on surfaces. A linear interpolation function is constructed to ensure the C0 continuity of the cellular unit cell. An optimization framework for cellular structures is built by combining MATLAB and ANSYS with the use of variable cutting level set functions.Numerical examples show that this method can effectively realize the topological optimization design of cellular structures on surfaces. The method also ensures the matching of the cellular structures unit cell with the shape of the design domain, and improves the mechanical properties of the cellular structures.

-

[1] 王向明, 苏亚东, 吴斌, 等. 微桁架点阵结构在飞机结构/功能一体化中的应用[J]. 航空制造技术, 2018, 61(10): 16-25.WANG X M, SU Y D, WU B, et al. Application for additive manufacturing of lattice materials on integrated aircraft structures and functions[J]. Aeronautical Manufacturing Technology, 2018, 61(10): 16-25(in Chinese). [2] 邓昊宇, 王春洁. 三维点阵结构等效热分析与优化方法[J]. 北京航空航天大学学报, 2019, 45(6): 1122-1128.DENG H Y, WANG C J. Equivalent thermal analysis and optimization method for three-dimensional lattice structure[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(6): 1122-1128(in Chinese). [3] WANG B, YANG M S, ZHANG D Y, et al. Alternative approach for imperfection-tolerant design optimization of stiffened cylindrical shells via energy barrier method[J]. Thin-Walled Structures, 2022, 172: 108838. doi: 10.1016/j.tws.2021.108838 [4] 张壮雅, 赵珂, 杨晓峰, 等. 基于三周期极小曲面和等参单元法的骨支架建模方法研究[J]. 机械设计与制造, 2017(11): 234-237. doi: 10.3969/j.issn.1001-3997.2017.11.060ZHANG Z Y, ZHAO K, YANG X F, et al. Reseachon bone scaffold modeling method basedon triply periodic minimaland isoperimetric element method[J]. Machinery Design & Manufacture, 2017(11): 234-237(in Chinese). doi: 10.3969/j.issn.1001-3997.2017.11.060 [5] 王清辉, 夏刚, 徐志佳, 等. 面向组织工程的松质骨微观结构TPMS建模方法[J]. 计算机辅助设计与图形学学报, 2016, 28(11): 1949-1956. doi: 10.3969/j.issn.1003-9775.2016.11.017WANG Q H, XIA G, XU Z J, et al. Modelling the microstructures of cancellous bone based on triply periodic minimal surface for tissue engineering[J]. Journal of Computer-Aided Design & Computer Graphics, 2016, 28(11): 1949-1956(in Chinese). doi: 10.3969/j.issn.1003-9775.2016.11.017 [6] YOO D J. Porous scaffold design using the distance field and triply periodic minimal surface models[J]. Biomaterials, 2011, 32(31): 7741-7754. doi: 10.1016/j.biomaterials.2011.07.019 [7] 余学伟, 李琳慧, 张涛, 等. 基于三周期极小曲面和体素距离场的复杂轮廓点阵结构建模[J]. 重庆大学学报, 2022, 45(6): 75-84. doi: 10.11835/j.issn.1000-582X.2021.115YU X W, LI L H, ZHANG T, et al. Modeling of complex contour lattice structure based on triply periodic minimal surface and voxel distance field[J]. Journal of Chongqing University, 2022, 45(6): 75-84(in Chinese). doi: 10.11835/j.issn.1000-582X.2021.115 [8] 任毅如, 向剑辉, 何杰, 等. 基于导重法的自重载荷下悬臂梁结构拓扑优化[J]. 北京航空航天大学学报, 2021, 47(7): 1338-1344.REN Y R, XIANG J H, HE J, et al. Topology optimization of cantilever structure with self-weight load based on guide-weight method[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(7): 1338-1344(in Chinese). [9] 付君健, 舒正涛, 田启华, 等. 功能梯度多孔结构拓扑优化的混合水平集方法[J]. 机械工程学报, 2022, 58(17): 249-260. doi: 10.3901/JME.2022.17.249FU J J, SHU Z T, TIAN Q H, et al. A hybrid level set method for topology optimization of functionally graded cellular structures[J]. Journal of Mechanical Engineering, 2022, 58(17): 249-260(in Chinese). doi: 10.3901/JME.2022.17.249 [10] 孙鹏飞, 张跃, 尹鹏, 等. 隐式曲面梯度多孔结构拓扑优化设计方法[J]. 西安交通大学学报, 2022, 56(1): 85-95. doi: 10.7652/xjtuxb202201010SUN P F, ZHANG Y, YIN P, et al. A topology optimization design method of graded cellular structures with implicit surfaces[J]. Journal of Xi’an Jiaotong University, 2022, 56(1): 85-95(in Chinese). doi: 10.7652/xjtuxb202201010 [11] NIKNAM H, AKBARZADEH A H, RODRIGUE D, et al. Architected multi-directional functionally graded cellular plates[J]. Materials & Design, 2018, 148: 188-202. [12] QI D X, LU Q Y, HE C W, et al. Impact energy absorption of functionally graded chiral honeycomb structures[J]. Extreme Mechanics Letters, 2019, 32: 100568. doi: 10.1016/j.eml.2019.100568 [13] 赵芳垒, 敬石开, 刘晨燕. 基于局部相对密度映射的变密度多孔结构设计方法[J]. 机械工程学报, 2018, 54(19): 121-128. doi: 10.3901/JME.2018.19.121ZHAO F L, JING S K, LIU C Y. Variable density cellular structure design method base on local relative density mapping[J]. Journal of Mechanical Engineering, 2018, 54(19): 121-128(in Chinese). doi: 10.3901/JME.2018.19.121 [14] 蔡金虎, 王春洁. 基于映射的梯度点阵结构设计方法[J]. 振动与冲击, 2020, 39(20): 74-81.CAI J H, WANG C J. A graded lattice structure design method based on mapping process[J]. Journal of Vibration and Shock, 2020, 39(20): 74-81(in Chinese). [15] TOWNSEND S, KIM H A. A level set topology optimization method for the buckling of shell structures[J]. Structural and Multidisciplinary Optimization, 2019, 60(5): 1783-1800. doi: 10.1007/s00158-019-02374-9 [16] VOGIATZIS P, MA M, CHEN S K, et al. Computational design and additive manufacturing of periodic conformal metasurfaces by synthesizing topology optimization with conformal mapping[J]. Computer Methods in Applied Mechanics and Engineering, 2018, 328: 477-497. doi: 10.1016/j.cma.2017.09.012 [17] YE Q, GUO Y, CHEN S K, et al. Topology optimization of conformal structures on manifolds using extended level set methods (X-LSM) and conformal geometry theory[J]. Computer Methods in Applied Mechanics and Engineering, 2019, 344: 164-185. doi: 10.1016/j.cma.2018.08.045 [18] ZHOU Y, GAO L, LI H. Graded infill design within free-form surfaces by conformal mapping[J]. International Journal of Mechanical Sciences, 2022, 224: 107307. doi: 10.1016/j.ijmecsci.2022.107307 [19] HUO W D, LIU C, DU Z L, et al. Topology optimization on complex surfaces based on the moving morphable component method and computational conformal mapping[J]. Journal of Applied Mechanics, 2022, 89(5): 051008. doi: 10.1115/1.4053727 [20] ZONG H M, LIU H, MA Q P, et al. VCUT level set method for topology optimization of functionally graded cellular structures[J]. Computer Methods in Applied Mechanics and Engineering, 2019, 354: 487-505. doi: 10.1016/j.cma.2019.05.029 [21] WANG L, LI Z S, NI B W, et al. A robust topology optimization method considering bounded field parameters with uncertainties based on the variable time step parametric level-set method[J]. Applied Mathematical Modelling, 2022, 107: 441-463. doi: 10.1016/j.apm.2022.03.008 [22] LI D W, DAI N, TANG Y L, et al. Design and optimization of graded cellular structures with triply periodic level surface-based topological shapes[J]. Journal of Mechanical Design, 2019, 141(7): 071402. doi: 10.1115/1.4042617 [23] 蔡升勇, 习俊通. 基于形函数控制的组织工程骨架孔隙结构实体建模方法[J]. 机械工程学报, 2009, 45(7): 297-304. doi: 10.3901/JME.2009.07.297CAI S Y, XI J T. Computer modeling approach for a porous scaffold structure in tissue engineering based on the shape function control[J]. Journal of Mechanical Engineering, 2009, 45(7): 297-304(in Chinese). doi: 10.3901/JME.2009.07.297 [24] WANG Y Q, CHEN F F, WANG M Y. Concurrent design with connectable graded microstructures[J]. Computer Methods in Applied Mechanics and Engineering, 2017, 317: 84-101. doi: 10.1016/j.cma.2016.12.007 [25] CRAMER A D, CHALLIS V J, ROBERTS A P. Microstructure interpolation for macroscopic design[J]. Structural and Multidisciplinary Optimization, 2016, 53(3): 489-500. doi: 10.1007/s00158-015-1344-7 [26] 杜义贤, 张跃, 付君健, 等. 承载散热一体化的功能梯度多孔结构拓扑优化设计[J]. 计算机辅助设计与图形学学报, 2021, 33(7): 1141-1150.DU Y X, ZHANG Y, FU J J, et al. Topology optimization design of functionally graded cellular structure with integrated load bearing and heat dissipation[J]. Journal of Computer-Aided Design & Computer Graphics, 2021, 33(7): 1141-1150(in Chinese). [27] LIU H, ZONG H M, SHI T L, et al. M-VCUT level set method for optimizing cellular structures[J]. Computer Methods in Applied Mechanics and Engineering, 2020, 367: 113154. doi: 10.1016/j.cma.2020.113154 [28] ALLAIRE G, JOUVE F, TOADER A M. Structural optimization using sensitivity analysis and a level-set method[J]. Journal of Computational Physics, 2004, 194(1): 363-393. doi: 10.1016/j.jcp.2003.09.032 [29] 龙凯, 左正兴. 基于拓扑优化和形状优化方法的主轴承盖结构设计[J]. 农业机械学报, 2008, 39(4): 152-156.LONG K, ZUO Z X. Structural design of main bearing cap based on topological optimization and shape optimization[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(4): 152-156(in Chinese). [30] 范文杰, 徐进永, 张子达. 基于双向渐进结构优化法的装载机动臂拓扑优化[J]. 农业机械学报, 2006, 37(11): 24-27. doi: 10.3969/j.issn.1000-1298.2006.11.007FAN W J, XU J Y, ZHANG Z D. Topology optimization on arm of loader based on BESO[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(11): 24-27(in Chinese). doi: 10.3969/j.issn.1000-1298.2006.11.007 [31] ZHOU M, ROZVANY G. The COC algorithm, Part II: Topological, geometrical and generalized shape optimization[J]. Computer Methods in Applied Mechanics and Engineering, 1991, 89(1-3): 309-336. doi: 10.1016/0045-7825(91)90046-9 [32] XIE Y M, ZUO Z H, HUANG X D, et al. Convergence of topological patterns of optimal periodic structures under multiple scales[J]. Structural and Multidisciplinary Optimization, 2012, 46(1): 41-50. doi: 10.1007/s00158-011-0750-8 -

下载:

下载: