-

摘要:

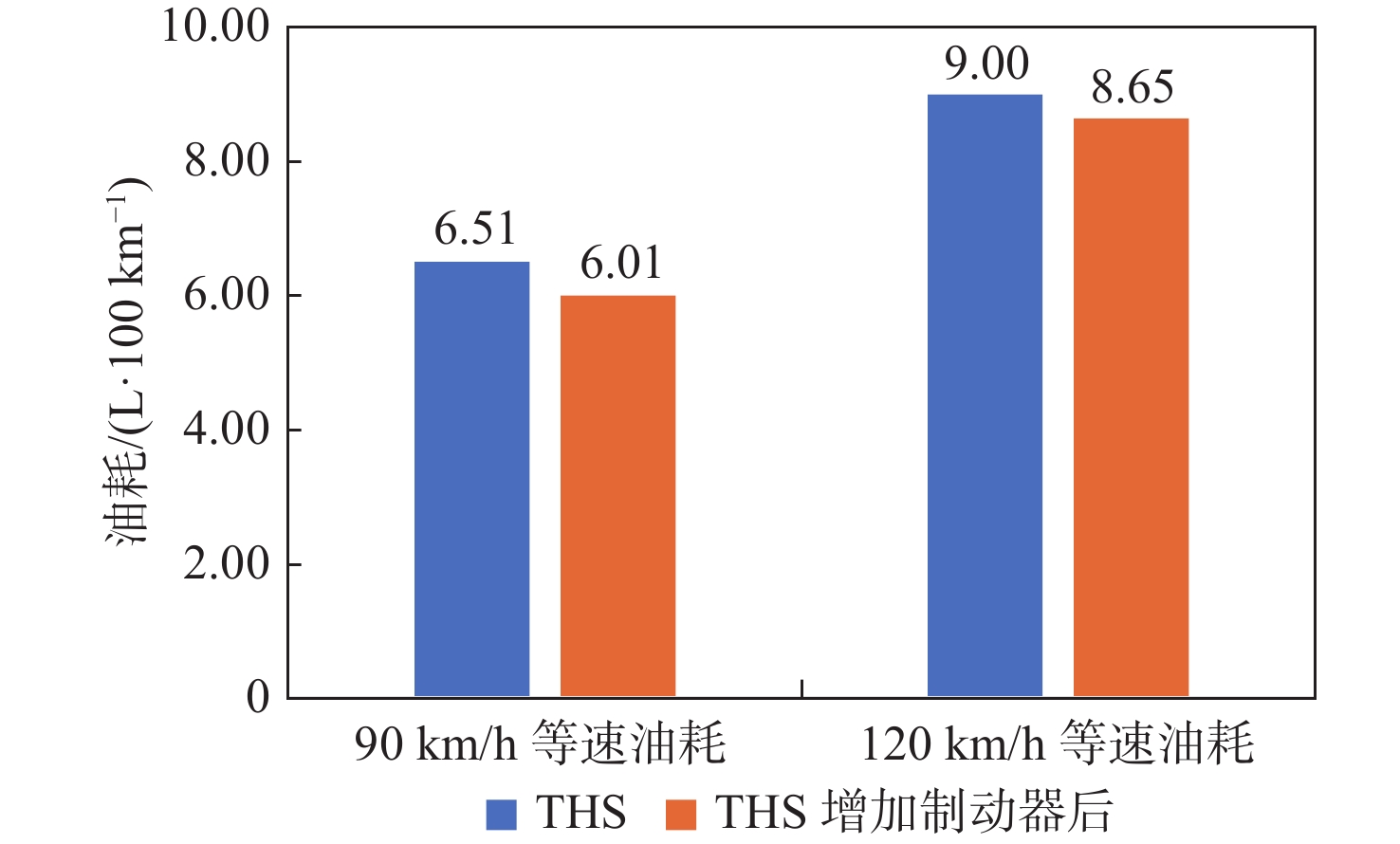

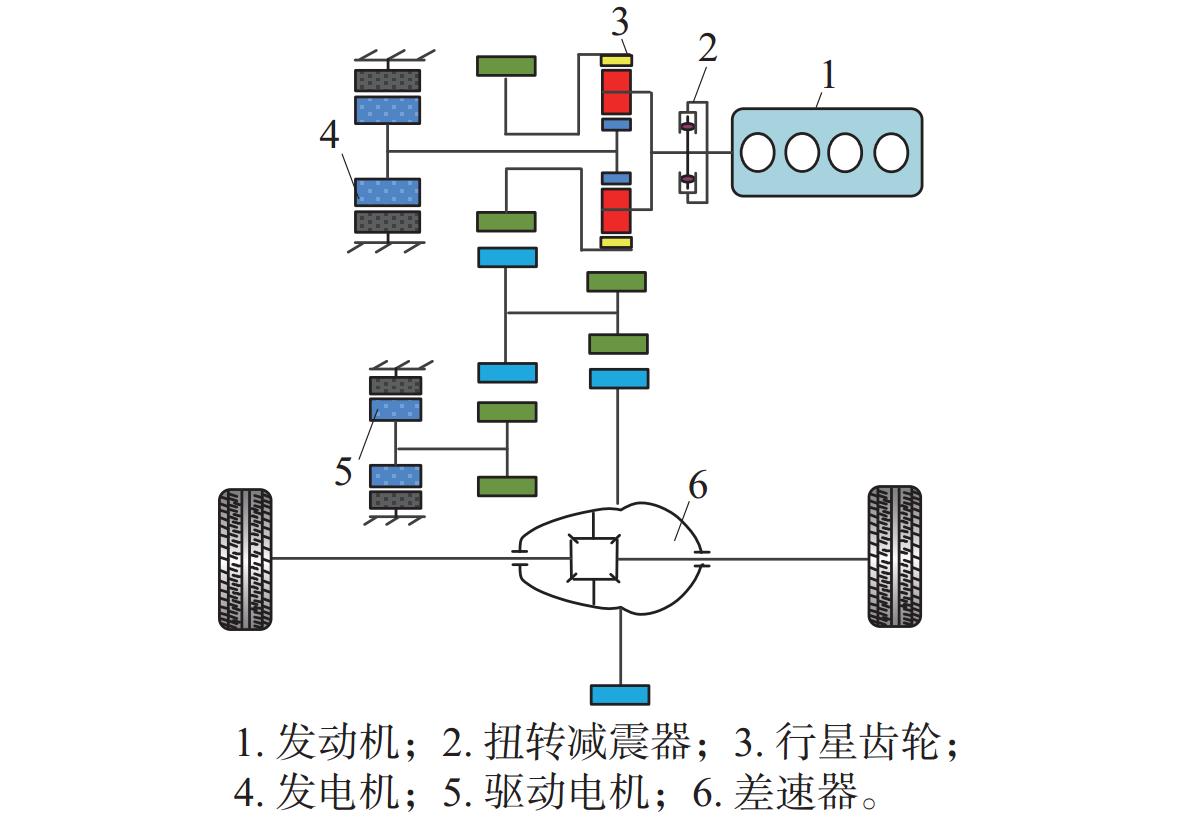

分析丰田混合动力系统(THS)在高速工况存在的功率回流现象及其原因,提出一种解决其功率回流问题的混合动力机电耦合系统方案,即在THS的基础上增加一个制动器,不仅消除了功率分流现象,而且增加了一个发动机直驱模式,降低了燃油消耗。仿真对比2种系统在定速工况的油耗,发现增加制动器后,系统的90 km/h等速油耗改善了7.7%,120 km/h等速油耗改善了3.9%。此外,对2种系统分别在2个等速工况下的控制策略进行分析。结果表明:改进后的系统在采用发动机直驱模式时,避免了THS的功率回流问题,提高了系统效率,改善了整车油耗。

Abstract:After analyzing the occurrence and the reason behind the power reflux in toyota hybrid system (THS) at high speeds, a novel hybrid electromechanical coupling system scheme that can address the power reflux issue is put forth. The system not only solves the power reflux problem, but also adds an engine direct drive mode and reduces fuel consumption by adding a brake based on THS. By comparing the fuel consumption of the two systems under constant speed conditions, it is found through simulation that the fuel consumption at 90 km/h and 120 km/h can improve by 7.7% and 3.9% after adding brakes. Furthermore, an analysis is conducted on the control strategies employed by the two systems under the two constant speed conditions. The findings indicate that the enhanced system circumvents THS’s power return issue, enhances system efficiency, and optimizes the vehicle's fuel consumption when it employs the engine direct drive mode.

-

表 1 混动系统模式控制逻辑

Table 1. Hybrid system mode control logic

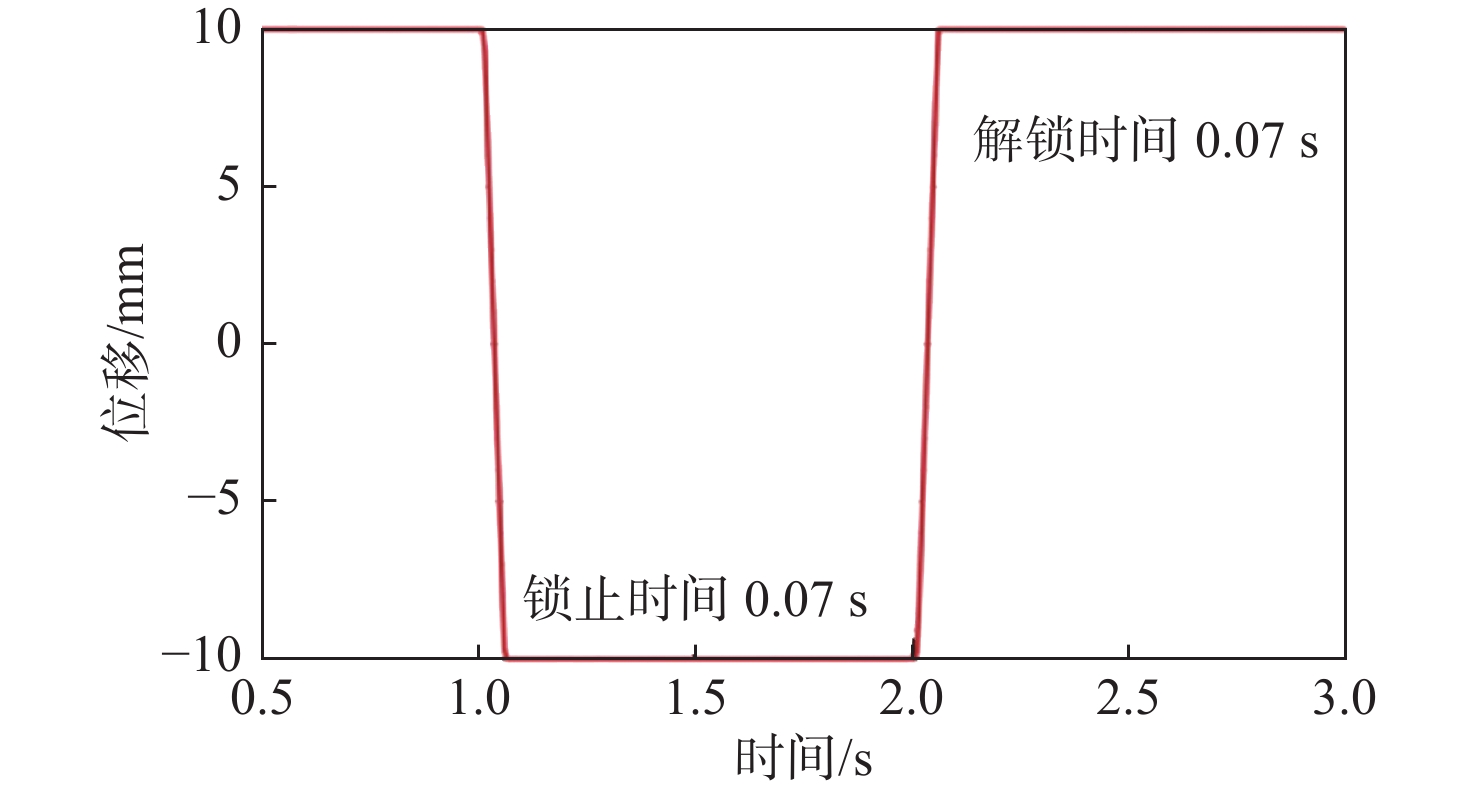

驱动模式 ICE EM1 EM2 B 纯电动 停机 空转 驱动 功率分流 驱动 发电 驱动 发动机直驱 驱动 停机 空转 制动 制动回收 停机 空转 发电 驻车发电 驱动 发电 停机 表 2 整车参数

Table 2. Vehicle parameters

整车

整备

质量/kg半载

质量/kg轴距/

mm车胎

滚动

半径/m迎风

面积/m2风阻

系数阻力

曲线/N发动机 2081.5 2900 +300 0.37 2.88 0.355 166.5+1.063v+

0.047v22.0TM 表 3 功率分流控制策略分析

Table 3. Power shunt control strategy analysis

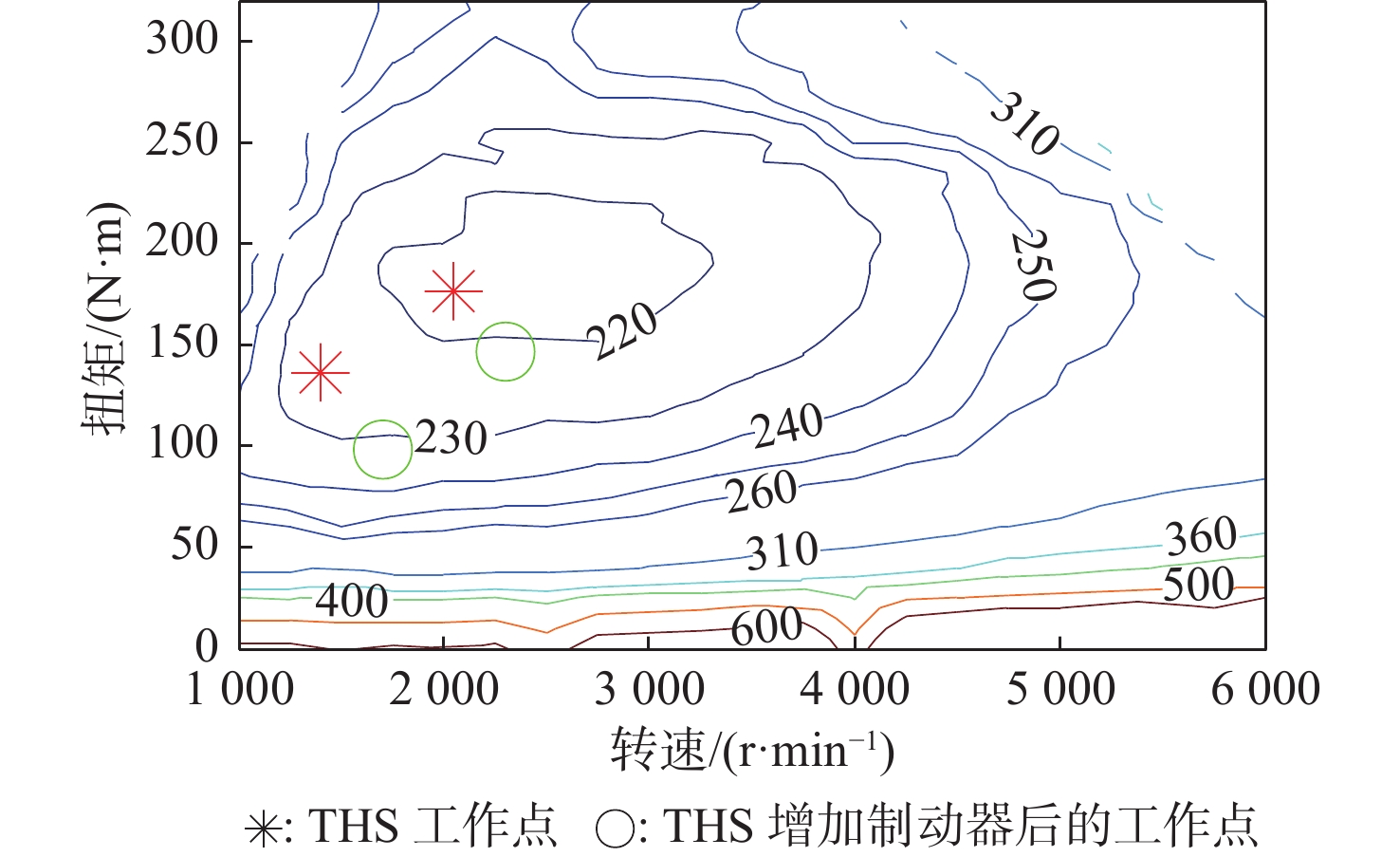

工况 动力源 工况点 备注 90 km/h等速 ICE 136 N·m 1400 r/min

效率37.4%EM1 −37 N·m

−1100 r/min“电驱动路径”能量占比约20% EM2 −6 N·m 7700 r/min120 km/h等速 ICE 176 N·m

2 050 r/min

效率39.2%EM1 −49 N·m

−700 r/min“电驱动路径”能量占比约10% EM2 −6 N·m

−10300 r/min表 4 发动机直驱模式控制策略分析

Table 4. Analysis of engine direct drive mode control strategy

工况 动力源 工况点 备注 90 km/h等速 ICE 98 N·m 1700 r/min

效率36.5%热效率差2.4% EM1 停机 “电驱动路径”能量占比由20%变为0 EM2 停机 120 km/h等速 ICE 147 N·m 2300 r/min

效率37.9%热效率差3.3% EM1 停机 “电驱动路径”能量占比由10%变为0 EM2 停机 -

[1] 赵江灵, 尚阳, 祖国强, 等. 单行星排式功率分流机电耦合传动方案[J]. 重庆理工大学学报(自然科学), 2019, 33(12): 38-44.ZHAO J L, SHANG Y, ZU G Q, et al. Single planetary gear set type of power split transmission concept analysis[J]. Journal of Chongqing University of Technology (Natural Science), 2019, 33(12): 38-44(in Chinese). [2] 张安伟, 祁宏钟, 赵江灵, 等. 混合动力机电耦合系统效率优化分析[J]. 汽车零部件, 2021(11): 1-8.ZHANG A W, QI H Z, ZHAO J L, et al. Efficiency optimization analysis of hybrid electromechanical coupling system[J]. Automobile Parts, 2021(11): 1-8(in Chinese). [3] 王振, 崔亚辉, 许宝卉, 等. 双模式功率分流无级变速器的分析与设计[J]. 机械传动, 2020, 44(5): 49-58.WANG Z, CUI Y H, XU B H, et al. Analysis and design of dual mode power split continuously variable transmission[J]. Journal of Mechanical Transmission, 2020, 44(5): 49-58(in Chinese). [4] 李冲. 新型功率分流式动力系统能量管理研究[D]. 重庆: 重庆大学, 2015: 17-22.LI C. Research on energy management of new power split power system[D]. Chongqing: Chongqing University, 2015: 17-22(in Chinese). [5] 步曦, 杜爱民, 薛锋. 混合动力汽车用行星齿轮机构的理论研究与仿真分析[J]. 汽车工程, 2006, 28(9): 834-838.BU X, DU A M, XUE F. Theoretical study and simulation on planetary gear set for hybrid electric vehicle[J]. Automotive Engineering, 2006, 28(9): 834-838(in Chinese). [6] 伍国强, 秦大同, 胡建军, 等. 混合动力行星齿轮动力传动系统方案及参数匹配研究[J]. 机械设计, 2009, 26(6): 60-65.WU G Q, QIN D T, HU J J, et al. Research on power transmission systematic scheme and matching of parameters of the hybrid power planetary gear train[J]. Journal of Machine Design, 2009, 26(6): 60-65(in Chinese). [7] 朱元, 田光宇, 陈全世, 等. 行星齿轮结构的混合动力汽车的系统效率[J]. 汽车工程, 2004, 26(3): 260-265. doi: 10.3321/j.issn:1000-680X.2004.03.004ZHU Y, TIAN G Y, CHEN Q S, et al. A research on the system efficiency of a hybrid electric vehicle with power-split powertrain[J]. Automotive Engineering, 2004, 26(3): 260-265(in Chinese). doi: 10.3321/j.issn:1000-680X.2004.03.004 [8] 蒋科军, 何仁, 束驰, 等. 混合动力汽车动力耦合技术综述[J]. 机械传动, 2015, 39(4): 175-181.JIANG K J, HE R, SHU C, et al. Review of the power coupling technology for hybrid vehicle[J]. Journal of Mechanical Transmission, 2015, 39(4): 175-181(in Chinese). [9] 杨亚联, 米娇, 胡晓松, 等. 混合动力汽车行星耦合传动系统的图论建模及动力学分析[J]. 汽车工程, 2015, 37(1): 9-15.YANG Y L, MI J, HU X S, et al. Graph theory modeling and dynamics analysis on the coupled planetary transmission system of HEV[J]. Automotive Engineering, 2015, 37(1): 9-15(in Chinese). [10] 张亿. 插电式混合动力汽车动力耦合系统设计与性能研究[D]. 重庆: 重庆大学, 2014: 13-26.ZHANG Y. Design and performance research of power coupling system for plug-in hybrid electric vehicle[D]. Chongqing: Chongqing University, 2014: 13-26(in Chinese). [11] 汤鹏翔, 刘艳芳, 王书翰, 等. 多片湿式离合器优化设计[J]. 北京航空航天大学学报, 2010, 36(3): 291-294.TANG P X, LIU Y F, WANG S H, et al. Optimal design of clutch in automatic transmission[J]. Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(3): 291-294(in Chinese). [12] 高炳钊, 洪金龙, 陈虹. 汽车传动系统平顺性驾驶品质控制[J]. 控制理论与应用, 2017, 34(7): 849-866.GAO B Z, HONG J L, CHEN H. Drivability control of automotive drivetrain[J]. Control Theory & Applications, 2017, 34(7): 849-866(in Chinese). [13] 侯祥颖, 张钰哲, 张红, 等. 超越离合器研究现状及发展趋势分析[J]. 机械传动, 2021, 45(12): 162-169.HOU X Y, ZHANG Y Z, ZHANG H, et al. Research status and development tendency analysis of overrunning clutch[J]. Journal of Mechanical Transmission, 2021, 45(12): 162-169(in Chinese). [14] 王成, 秦大同, 吴邦治, 等. 湿式离合器接合特性仿真与分析[J]. 重庆大学学报, 2020, 43(10): 38-51. doi: 10.11835/j.issn.1000-582X.2020.110WANG C, QIN D T, WU B Z, et al. Simulation and analysis of wet clutch engagement characteristics[J]. Journal of Chongqing University, 2020, 43(10): 38-51(in Chinese). doi: 10.11835/j.issn.1000-582X.2020.110 [15] 张恒, 李和言, 昌和, 等. 湿式多片离合器摩擦转矩衰减特性分析[J]. 哈尔滨工业大学学报, 2018, 50(7): 94-102. doi: 10.11918/j.issn.0367-6234.201709141ZHANG H, LI H Y, CHANG H, et al. Experimental study on attenuation characteristics of friction torque transferred by the wet multi-disc clutch[J]. Journal of Harbin Institute of Technology, 2018, 50(7): 94-102(in Chinese). doi: 10.11918/j.issn.0367-6234.201709141 -

下载:

下载: