Orientation effect on sealing characteristics of rectangular micro-textured floating ring gas film

-

摘要:

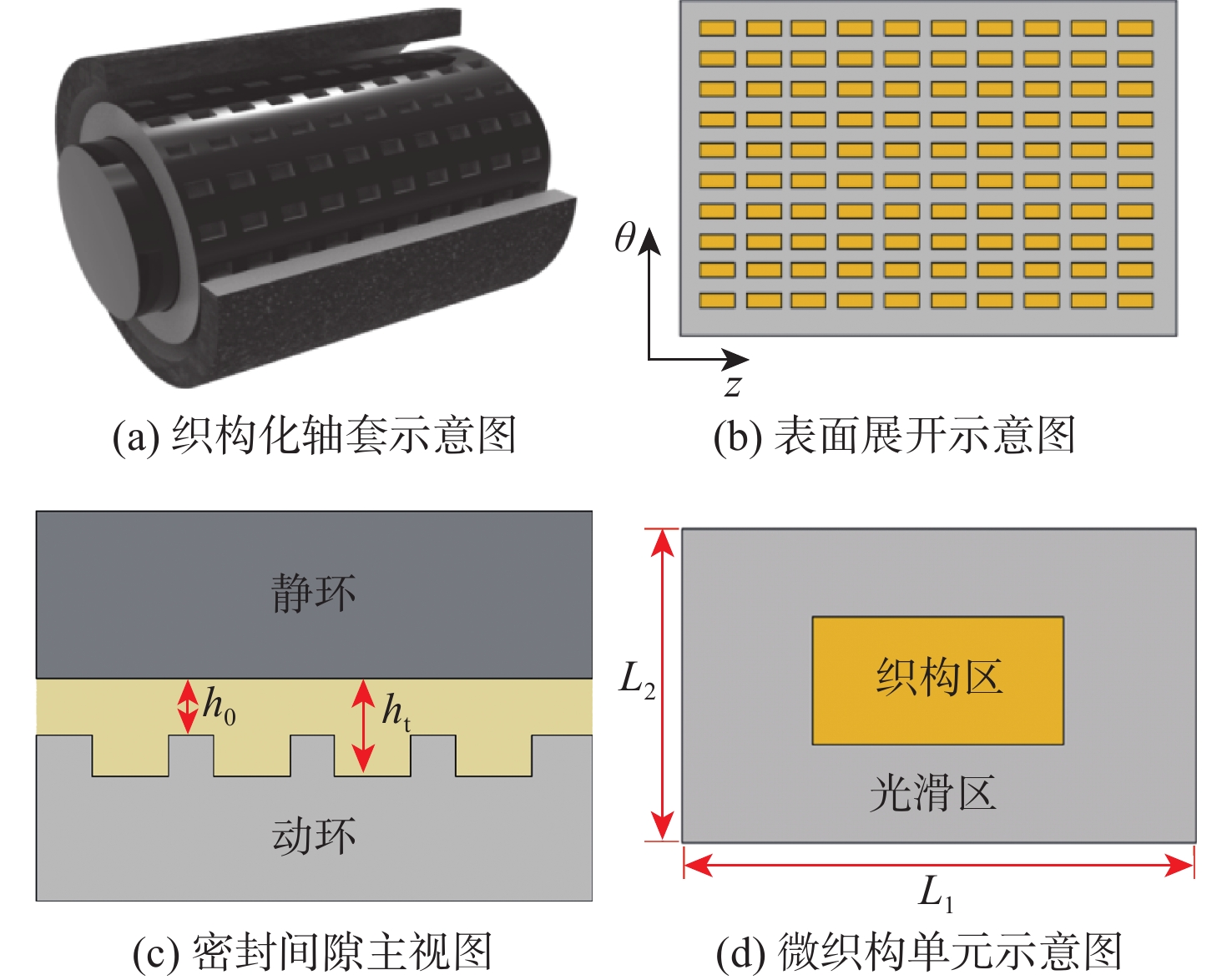

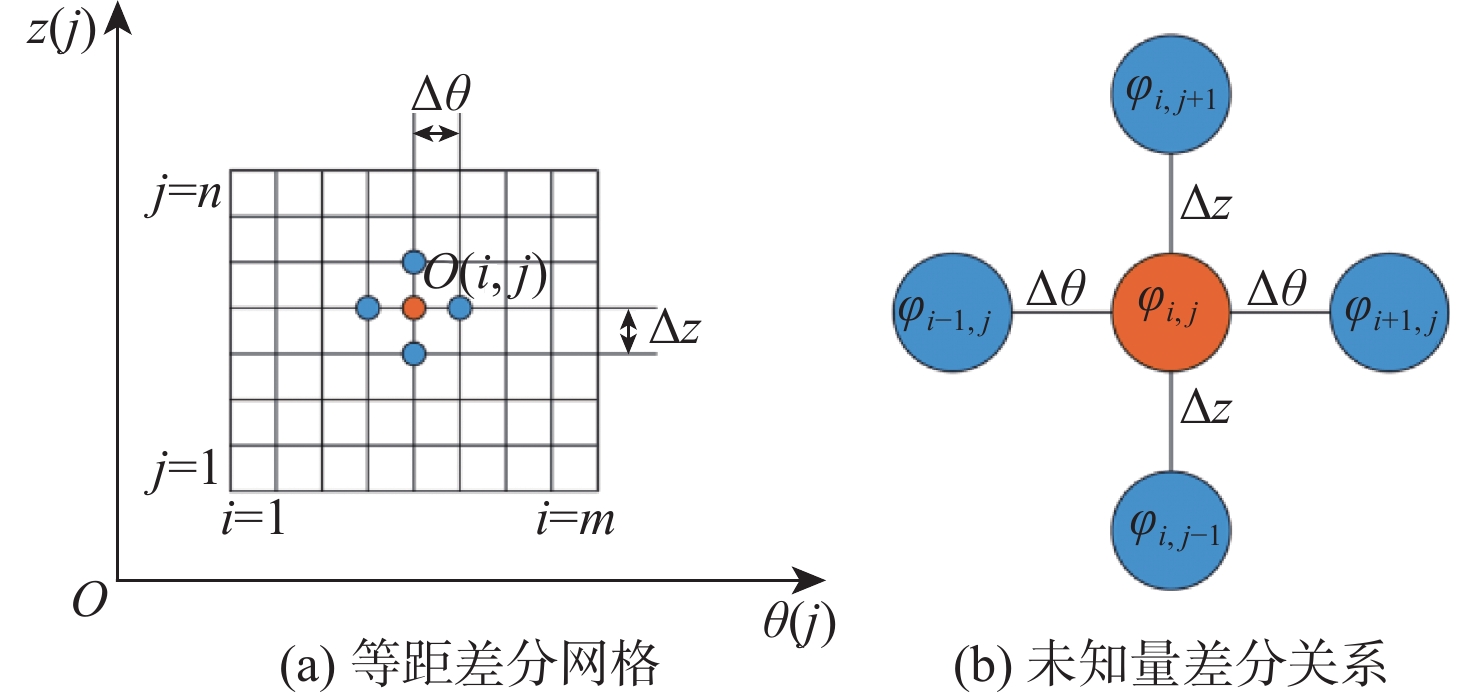

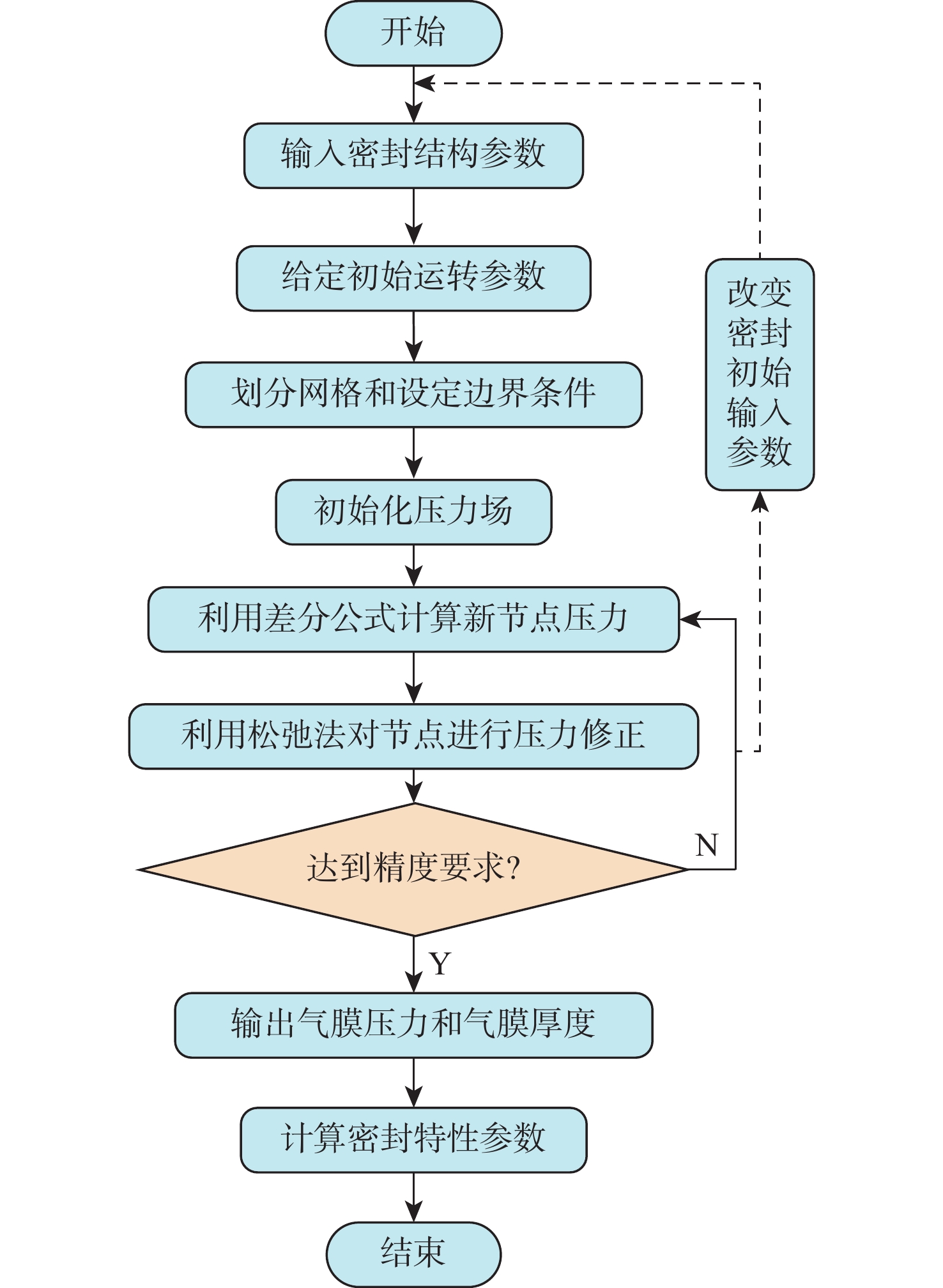

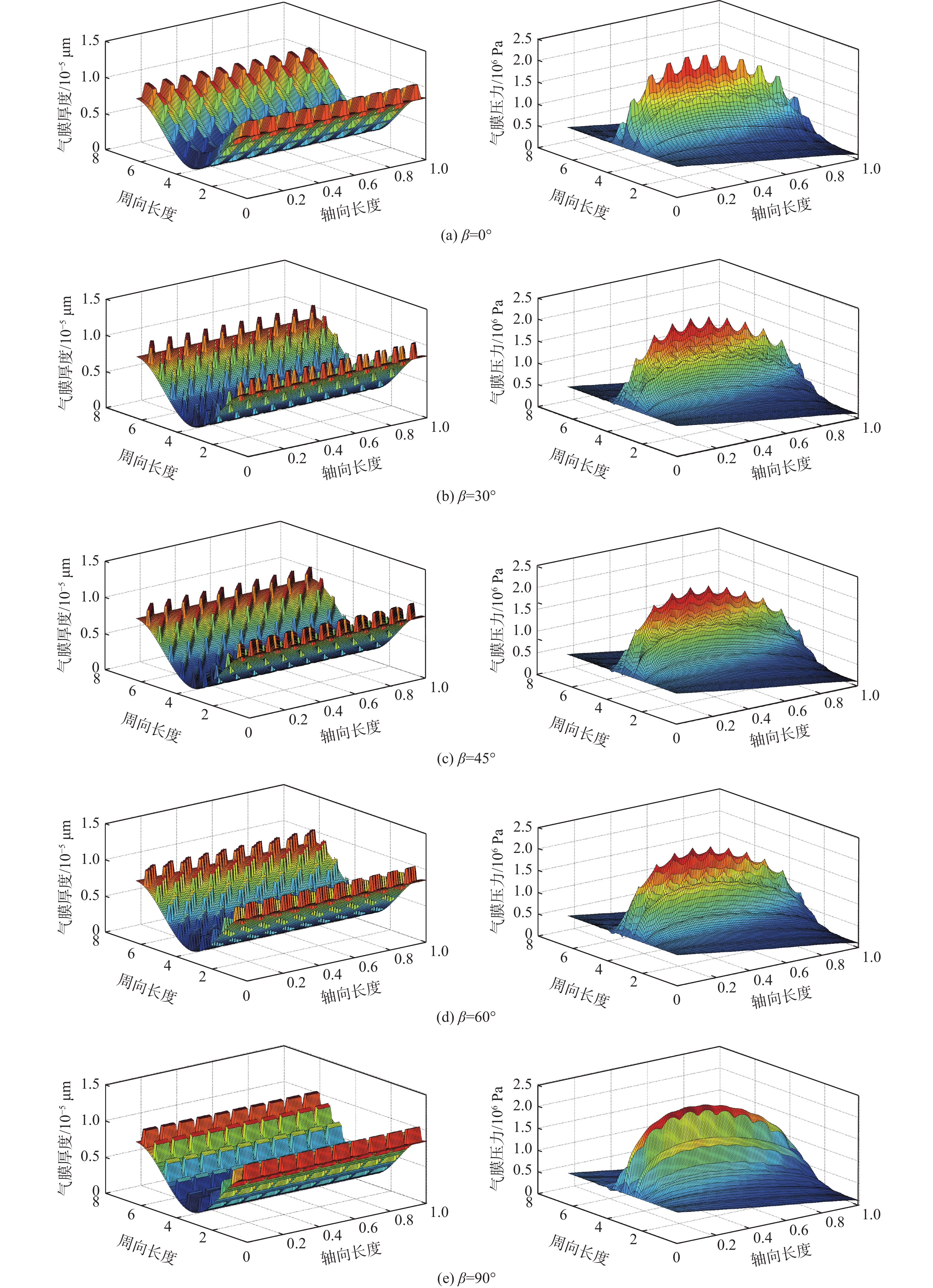

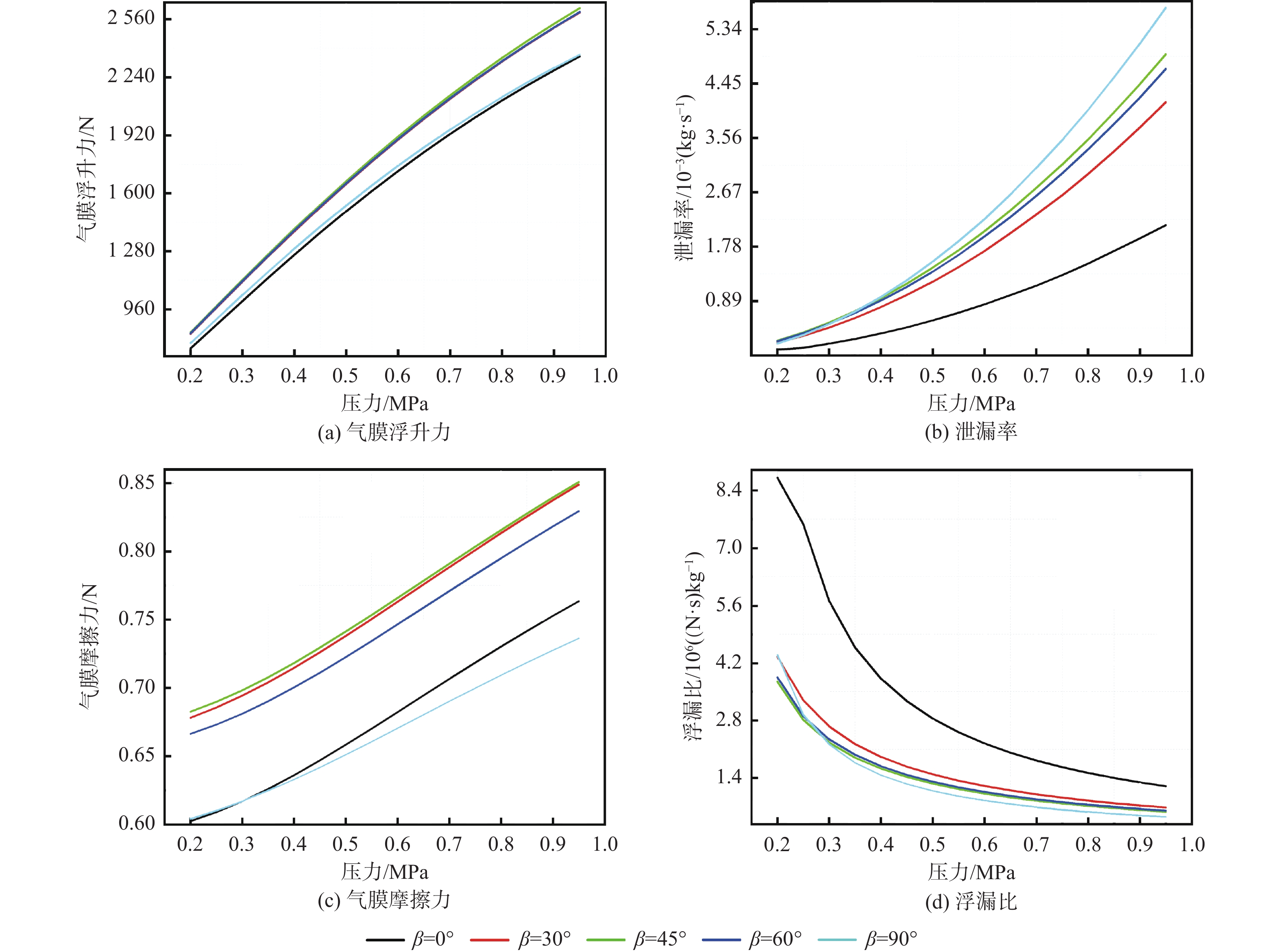

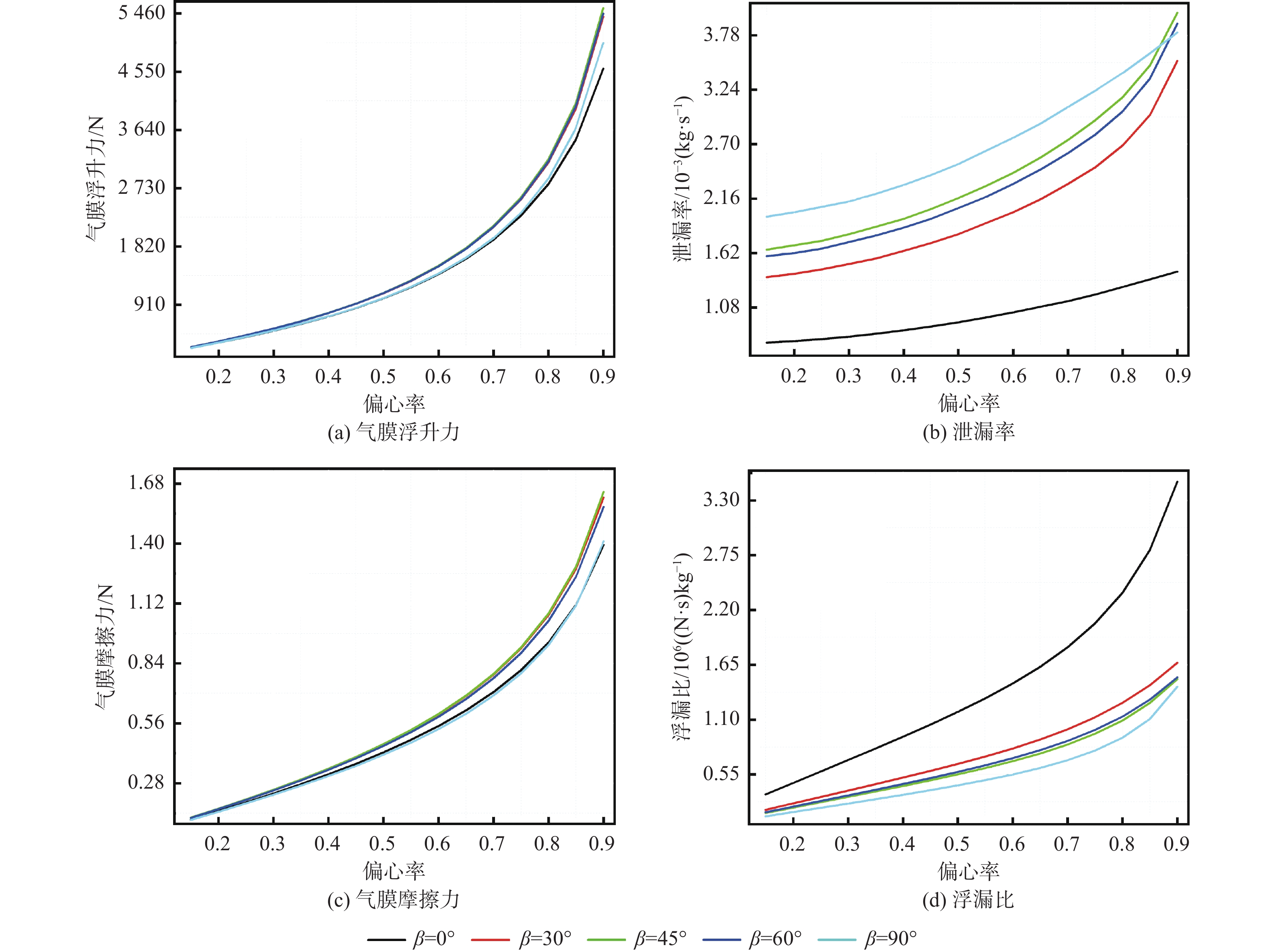

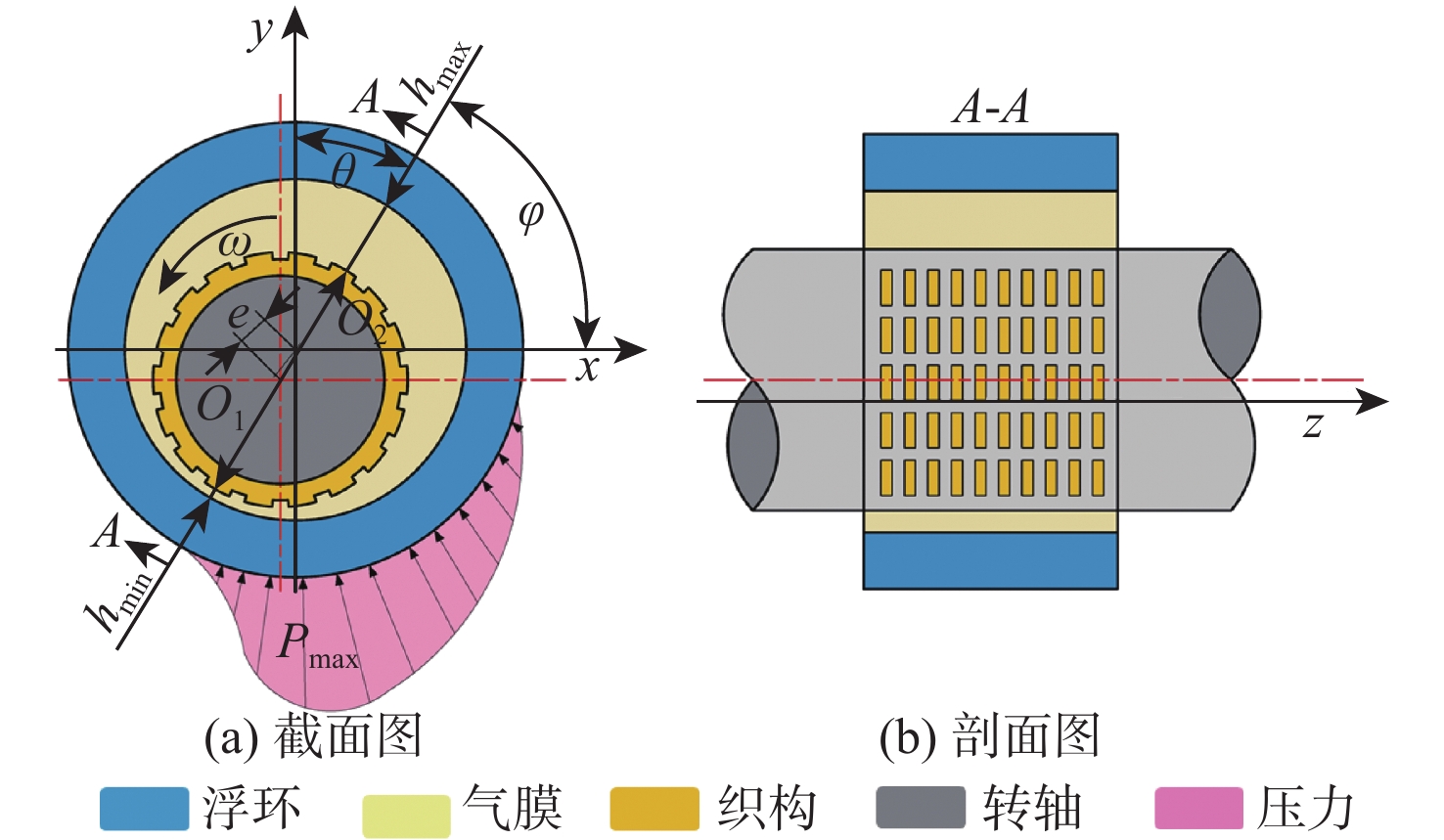

为研究微织构的方向效应对浮环气膜密封性能参数的影响,选取矩形微织构孔为研究对象,基于气体润滑理论,建立该织构化流体动压润滑控制的理论分析模型并采用有限差分法对其进行求解,获得了密封间隙气膜的压力分布,以转速、压力、偏心率、织构深度为自变量,重点研究织构方向角对其密封性能参数影响的规律。结果表明:开设微织构的浮环密封浮升力随着转速、压力和偏心率的增大均可提高,但微织构孔深度的增大会导致浮升力下降。泄漏率随着转速、压力、偏心率和织构深度的增加而提高;但转速的升高对其泄漏率数值影响不大。气膜摩擦力随转速、压力和偏心率的变大而升高,随织构深度的增大而降低。矩形微织构在改善密封性能参数方面起着重要的作用,合理的选择微织构方向角,可有效地提高浮环气膜密封的密封性能。研究结果为提高织构化表面浮环密封性能设计提供了新思路。

Abstract:To investigate the orientation effect of micro-texture on the sealing performance parameters of the floating ring gas film, a rectangular micro-textured hole was selected as the study object. A theoretical analysis model of textured hydrodynamic lubrication control was developed based on gas lubrication theory, and the finite difference method was used to solve the model. The gas film pressure distribution in the sealing gap was obtained. With rotational speed, pressure, eccentricity, and texture depth as independent variables, this study primarily investigated the influence of texture direction angle on sealing performance parameters. The results indicate that the sealing uplift of the micro-textured floating ring increases with rotational speed, pressure, and eccentricity, while increasing micro-textured hole depth results in a decrease in the uplift. Furthermore, the leakage rate increases as rotational speed, pressure, eccentricity, and texture depth increase. However, an increase in rotational speed has little effect on the leakage rate value. The gas film friction also increases with the increase in rotational speed, pressure, and eccentricity and decreases as the texture depth improves. Rectangular micro-texture plays a crucial role in improving the sealing performance parameters. The rational selection of micro-texture direction angle can effectively enhance the sealing performance of the floating ring gas film. These study outcomes provide a novel idea for enhancing the sealing performance of the textured surface floating ring.

-

表 1 织构化浮环气密封的工况参数和几何参数

Table 1. Operating conditions and geometric parameters of textured floating ring gas seal

参数 数值 轴套外半径/mm 25 平均气膜厚度/μm 5 介质气体黏度/(Pa·s) 1.8×10−5 偏心率 0.7 轴套长度/mm 52 出口压力/MPa 0.101325 入口压力/MPa 0.7 转速/(r·min−1) 16000 介质气体密度/(kg·m−3) 1.1452 轴向织构间距/mm 3.36 周向织构间距/mm 2.9 织构长度/mm 12 织构宽度/mm 2 织构深度/μm 2 轴向织构个数 10 周向织构个数 10 -

[1] XIA P, ZHANG G H, ZHAO J M, et al. Investigations on rotordynamic characteristics of a floating ring seal considering structural elasticity[C]//ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition. New York: ASME, 2017. [2] XIA P, CHEN H, LIU Z S, et al. Analysis of whirling motion for the dynamic system of floating ring seal and rotor[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2019, 233(8): 1221-1235. doi: 10.1177/1350650119829374 [3] LI G Q, ZHANG Q, HUANG E L, et al. Leakage performance of floating ring seal in cold/hot state for aero-engine[J]. Chinese Journal of Aeronautics, 2019, 32(9): 2085-2094. doi: 10.1016/j.cja.2019.03.004 [4] NAGAI K, KANEKO S, TAURA H, et al. Numerical and experimental analyses of dynamic characteristics for liquid annular seals with helical grooves in seal stator[J]. Journal of Tribology, 2018, 140(5): 052201. doi: 10.1115/1.4039428 [5] LU X L, ANDRÉS L S. Leakage and rotordynamic force coefficients of a three-wave (air in oil) wet annular seal: measurements and predictions[J]. Journal of Engineering for Gas Turbines and Power, 2019, 141(3): 032503. doi: 10.1115/1.4041270 [6] SINGH N, AWASTHI R K. Influence of dimple location and depth on the performance characteristics of the hydrodynamic journal bearing system[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2020, 234(9): 1500-1513. doi: 10.1177/1350650120901979 [7] SHI L P, ZHANG Y C, CHEN S, et al. Comparative research on gas seal performance textured with microgrooves and microdimples[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2019, 41(7): 280. doi: 10.1007/s40430-019-1786-8 [8] SHI L P, WANG X Y, SU X, et al. Comparison of the load-carrying performance of mechanical gas seals textured with microgrooves and microdimples[J]. Journal of Tribology, 2016, 138(2): 021701. doi: 10.1115/1.4031435 [9] YANG X, PENG X D, MENG X K, et al. Thermo-elasto-hydrodynamic analysis of triangular textured mechanical face seals[J]. Journal of Zhejiang University: Science A, 2019, 20(11): 864-881. doi: 10.1631/jzus.A1900163 [10] ADJEMOUT M, BRUNETIERE N, BOUYER J. Numerical analysis of the texture effect on the hydrodynamic performance of a mechanical seal[J]. Surface Topography: Metrology and Properties, 2015, 4(1): 014002. doi: 10.1088/2051-672X/4/1/014002 [11] ADJEMOUT M, BRUNETIERE N, BOUYER J. Optimization of mesh density for numerical simulations of hydrodynamic lubrication considering textured surfaces[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2015, 229(9): 1132-1144. doi: 10.1177/1350650115574535 [12] 陈传刚, 丁雪兴, 陆俊杰, 等. 摩擦副界面微造型序列对气体密封性能的影响[J]. 化工学报, 2019, 70(3): 1016-1026.CHEN C G, DING X X, LU J J, et al. Effect of friction pair interface micro-texture sequence on gas sealing performance[J]. CIESC Journal, 2019, 70(3): 1016-1026(in Chinese). [13] 程香平, 孟祥铠, 彭旭东. 大菱形孔端面密封力变形及密封性能分析[J]. 化工学报, 2014, 65(8): 3089-3097.CHENG X P, MENG X K, PENG X D. Analysis of surface deformation and seal performance of mechanical face seal with diamond macro-pores[J]. CIESC Journal, 2014, 65(8): 3089-3097(in Chinese). [14] 程香平, 孟祥铠, 彭旭东, 等. 端面锥形参数对锥-孔组合型机械密封性能的影响[J]. 化工学报, 2016, 67(11): 4762-4770.CHENG X P, MENG X K, PENG X D, et al. Effect of tapered face parameters on performance of cone-pore-combined mechanical seal[J]. CIESC Journal, 2016, 67(11): 4762-4770(in Chinese). [15] 程香平, 张友亮, 康林萍, 等. 双向菱形孔织构端面密封性能研究[J]. 润滑与密封, 2020, 45(12): 73-80. doi: 10.3969/j.issn.0254-0150.2020.12.011CHENG X P, ZHANG Y L, KANG L P, et al. Study on the performance of end face seal with bidirectional and double row diamond pores textured[J]. Lubrication Engineering, 2020, 45(12): 73-80(in Chinese). doi: 10.3969/j.issn.0254-0150.2020.12.011 [16] 魏伟, 陈思, 章亦聪, 等. 三角形-椭圆复合微孔织构化机械端面密封性能的数值研究[J]. 流体机械, 2020, 48(8): 25-31.WEI W, CHEN S, ZHANG Y C, et al. Numerical study on the sealing performance textured with multi-shape texture pattern combined with triangular and elliptical dimples[J]. Fluid Machinery, 2020, 48(8): 25-31(in Chinese). [17] 魏伟, 时礼平, 俞凤桥, 等. 复合槽孔织构化端面机械密封性能的研究[J]. 安徽工业大学学报(自然科学版), 2020, 37(1): 32-39.WEI W, SHI L P, YU F Q, et al. A study of mechanical seal performance of textured end face with compound grooves and dimples[J]. Journal of Anhui University of Technology (Natural Science), 2020, 37(1): 32-39(in Chinese). [18] 吉华, 王彦镐, 战琳月, 等. 等边三角形微孔端面机械密封多楔现象对性能的影响[J]. 工程科学与技术, 2019, 51(2): 168-175.JI H, WANG Y H, ZHAN L Y, et al. Effect of multi-wedge on sealing performance in mechanical seal with equilateral triangular dimples[J]. Advanced Engineering Sciences, 2019, 51(2): 168-175(in Chinese). [19] 张然, 赵欢, 孙丹, 等. 螺旋槽对柱面气膜密封静力与动力特性影响机理研究[J]. 推进技术, 2023, 44(3): 87-96.ZHANG R, ZHAO H, SUN D, et al. Influence mechanism of spiral groove on static and dynamic characteristics of cylinder gas film seal[J]. Journal of Propulsion Technology, 2023, 44(3): 87-96(in Chinese). [20] LI Z G, FANG Z, LI J. Numerical investigation on the leakage and rotordynamic characteristics for three types of annular gas seals in wet gas conditions[J]. Journal of Engineering for Gas Turbines and Power, 2019, 141(3): 032504. doi: 10.1115/1.4041313 [21] WU D Z, JIANG X K, CHU N, et al. Numerical simulation on rotordynamic characteristics of annular seal under uniform and non-uniform flows[J]. Journal of Central South University, 2017, 24(8): 1889-1897. doi: 10.1007/s11771-017-3596-4 [22] WANG X L, LIU M H, KAO-WALTER S, et al. Numerical evaluation of rotordynamic coefficients for compliant foil gas seal[J]. Applied Sciences, 2020, 10(11): 3828. doi: 10.3390/app10113828 [23] KATSAROS K P, NIKOLAKOPOULOS P G. On the tilting-pad thrust bearings hydrodynamic lubrication under combined numerical and machine learning techniques[J]. Lubrication Science, 2021, 33(3): 153-170. doi: 10.1002/ls.1535 [24] 王国荣, 廖代胜, 钟林, 等. 沟槽形表面织构对柱塞密封副摩擦性能的影响[J]. 表面技术, 2019, 48(12): 165-173.WANG G R, LIAO D S, ZHONG L, et al. Effect of groove-like surface texture on friction performance of plunger seal pair[J]. Surface Technology, 2019, 48(12): 165-173(in Chinese). [25] 马彬鈃, 颜培, 余建杭, 等. 高压静密封表面微织构设计及其密封性能的有限元分析[J]. 表面技术, 2021, 50(8): 237-246.MA B X, YAN P, YU J H, et al. Micro-texture design of high-pressure static sealing surface and finite element analysis of its sealing performance[J]. Surface Technology, 2021, 50(8): 237-246(in Chinese). [26] 陆俊杰, 张炜, 谢方民, 等. 一种自适应柱状密封气膜特性分析[J]. 化工学报, 2020, 71(S1): 346-354.LU J J, ZHANG W, XIE F M, et al. Analysis of gas film characteristics of an adaptive cylindrical seal[J]. CIESC Journal, 2020, 71(S1): 346-354(in Chinese). [27] 纪敬虎, 邓智文, 陈天阳, 等. 局部织构无限长可倾瓦推力轴承流体动压润滑分析[J]. 表面技术, 2021, 50(2): 246-253.JI J H, DENG Z W, CHEN T Y, et al. Analysis of hydrodynamic lubrication of partially textured infinitely long tilting pad thrust bearing[J]. Surface Technology, 2021, 50(2): 246-253(in Chinese). [28] 王娟, 王隽, 田佳彬, 等. 表面织构水润滑聚合物轴承承载性能有限元分析[J]. 润滑与密封, 2021, 46(6): 90-96.WANG J, WANG J, TIAN J B, et al. Finite element analysis of load-carrying property of surface texture water-lubricated polymer bearings[J]. Lubrication Engineering, 2021, 46(6): 90-96(in Chinese). [29] 陈强. 表面微织构气体箔片轴承弹流润滑机理及特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.CHEN Q. Study on EHL mechanism and characteristics of surface micro-textured gas foil bearing[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [30] 于海武, 王晓雷, 孙造, 等. 圆柱形微凹坑表面织构对流体动压润滑性能的影响[J]. 南京航空航天大学学报, 2010, 42(2): 209-213. doi: 10.3969/j.issn.1005-2615.2010.02.015YU H W, WANG X L, SUN Z, et al. Theoretical analysis on hydrodynamic lubrication of cylinder micro-dimple surface texture[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2010, 42(2): 209-213(in Chinese). doi: 10.3969/j.issn.1005-2615.2010.02.015 [31] 王学良, 刘美红, 熊忠汾, 等. 考虑表面粗糙度的柔性箔柱面气膜密封紊流特性分析[J]. 化工学报, 2022, 73(4): 1683-1694. doi: 10.11949/0438-1157.20211721WANG X L, LIU M H, XIONG Z F, et al. Turbulence characteristics of compliant foil gas seal considering surface roughness[J]. CIESC Journal, 2022, 73(4): 1683-1694(in Chinese). doi: 10.11949/0438-1157.20211721 -

下载:

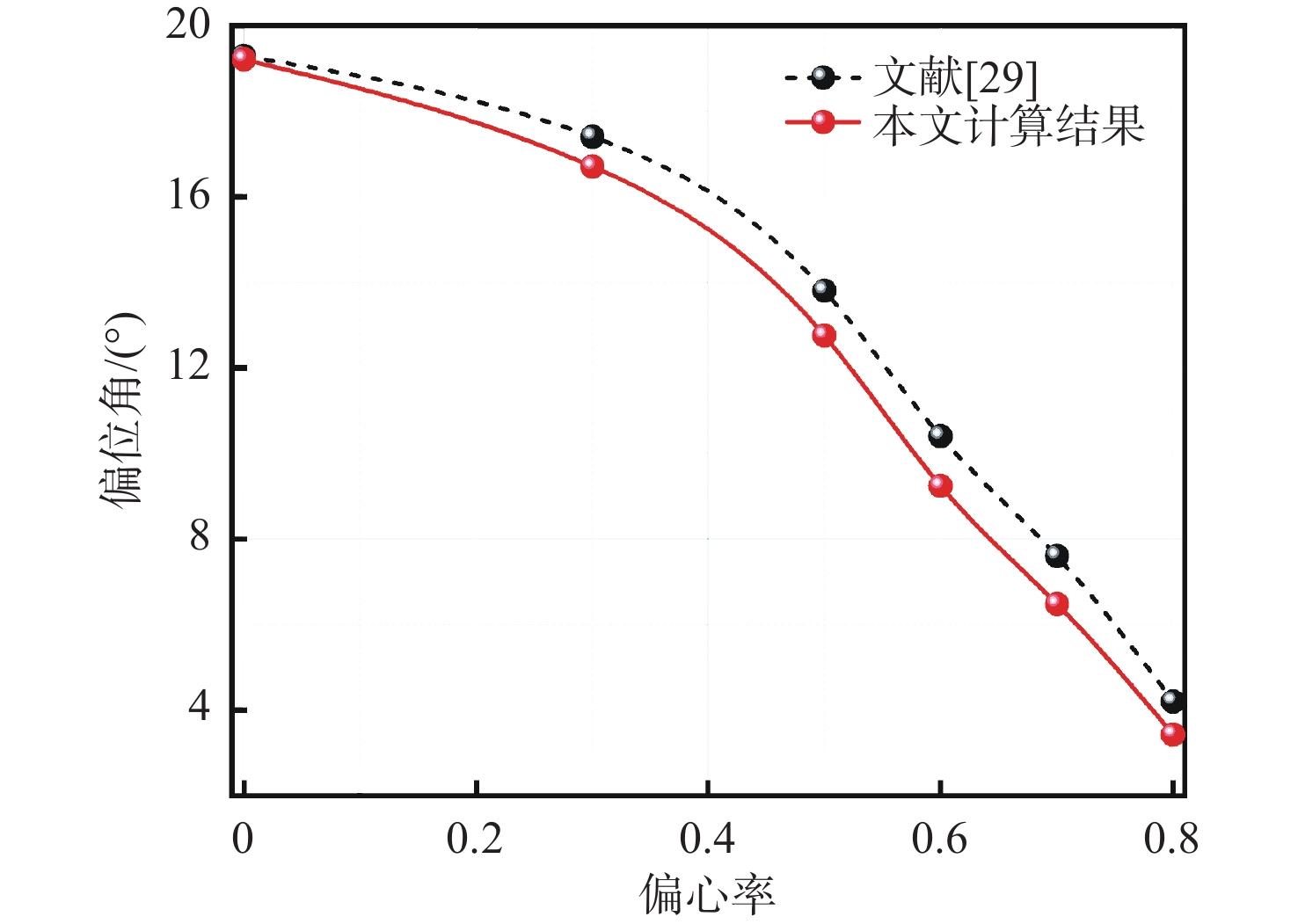

下载: