Study on global stability of aluminum alloy honeycomb cylinder under axial compression

-

摘要:

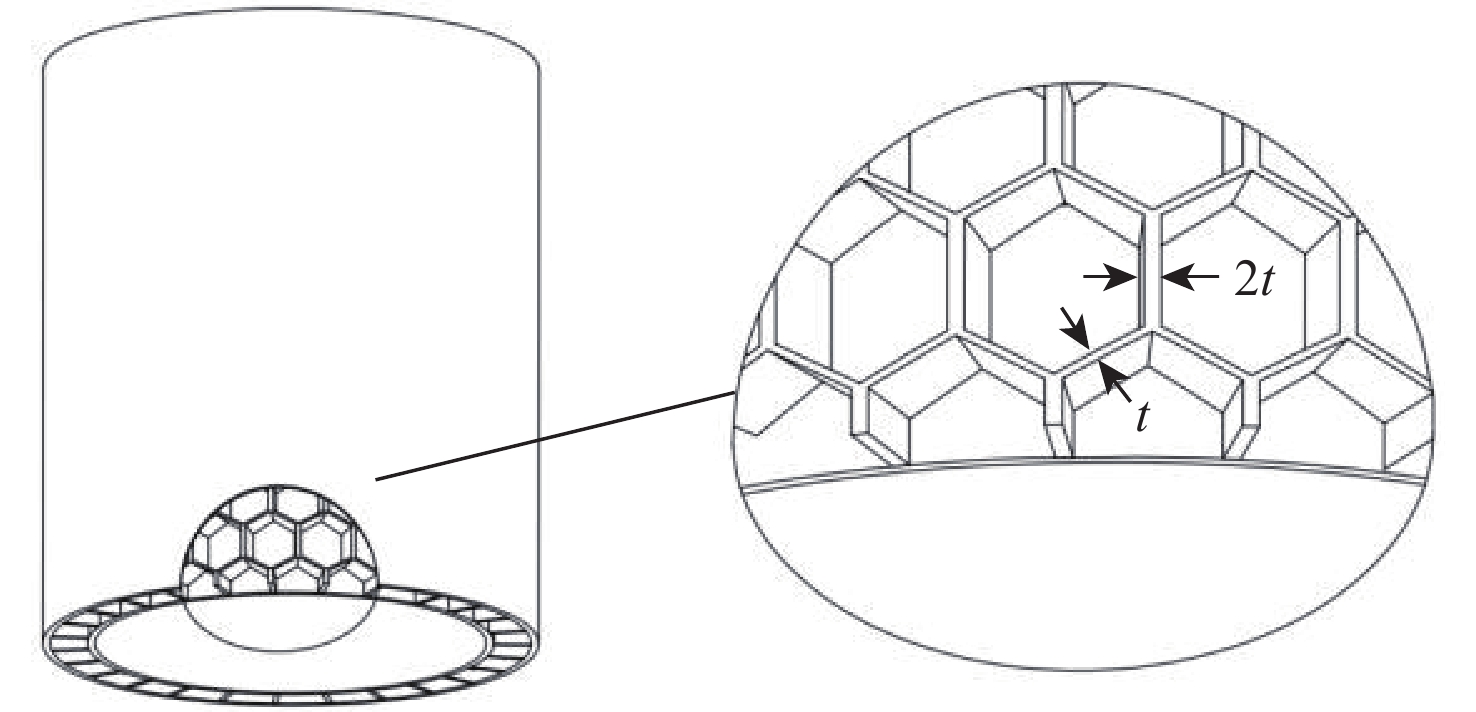

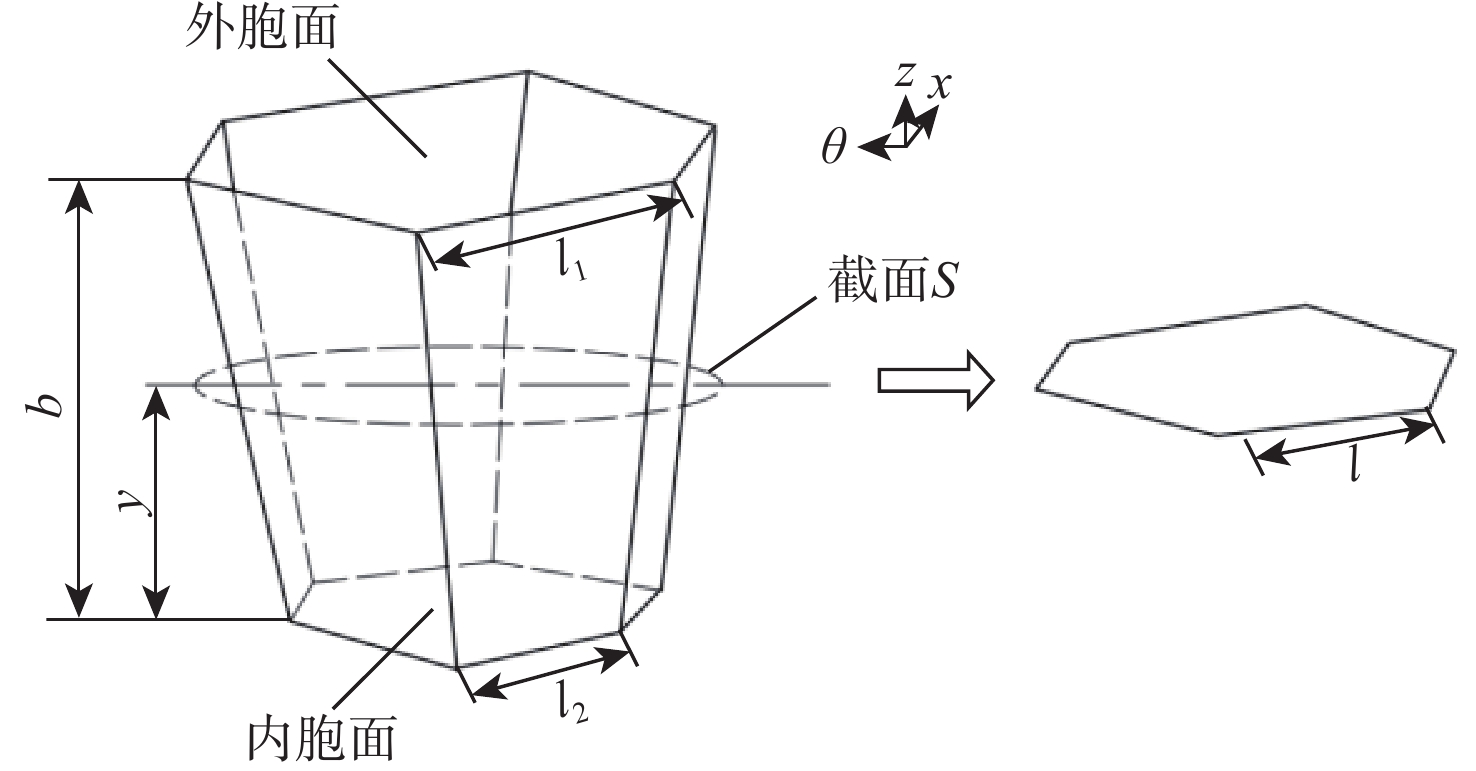

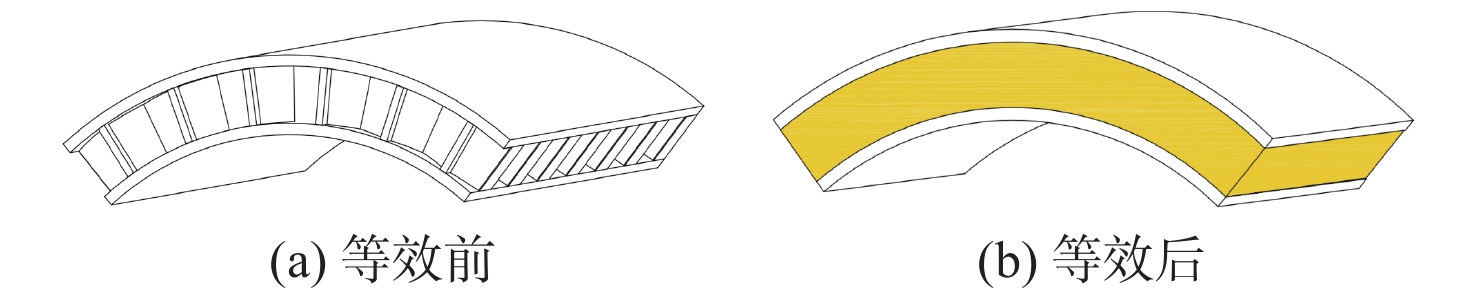

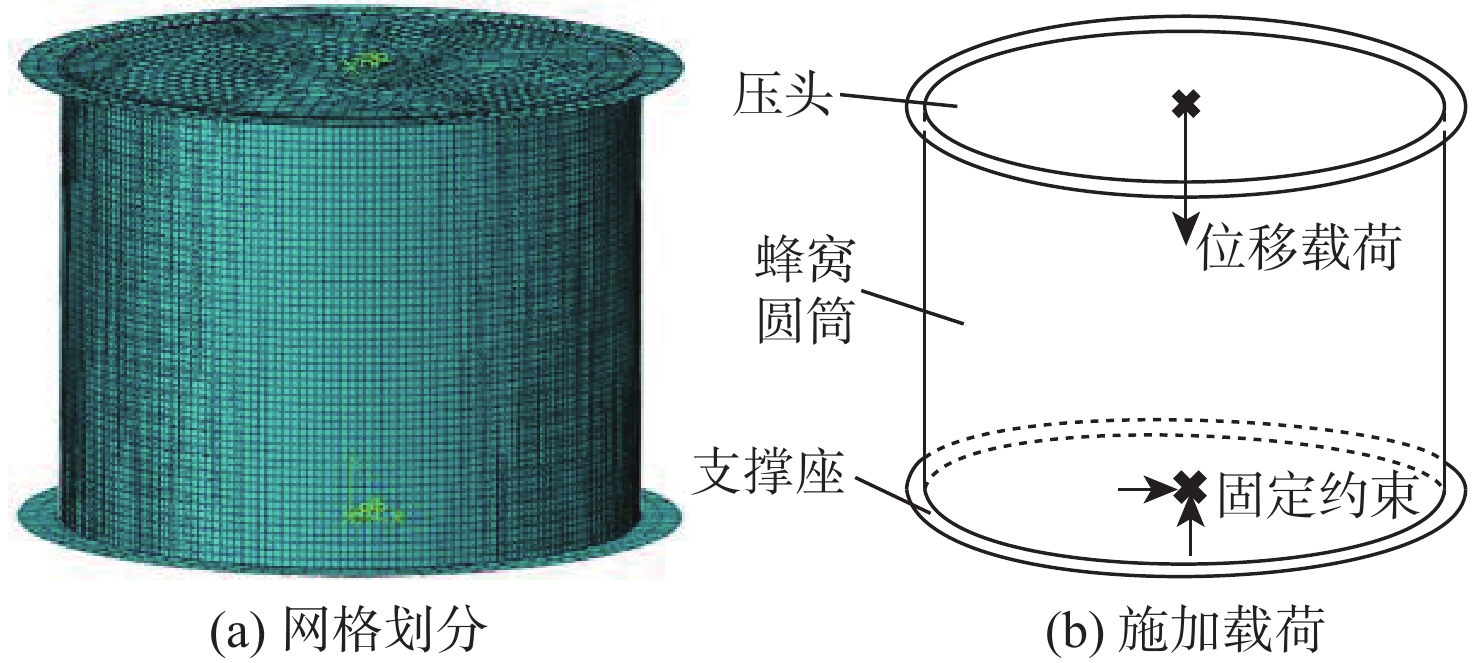

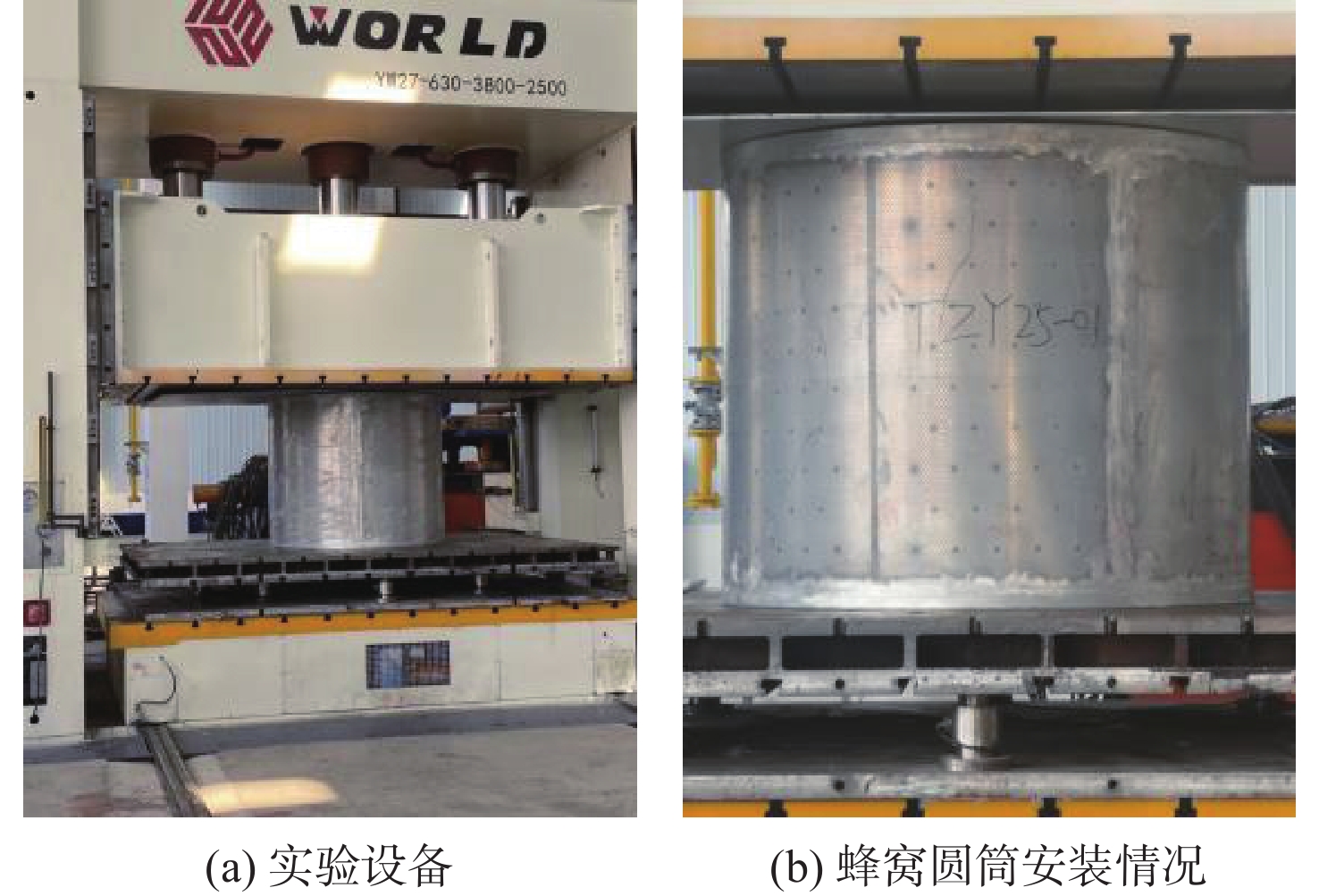

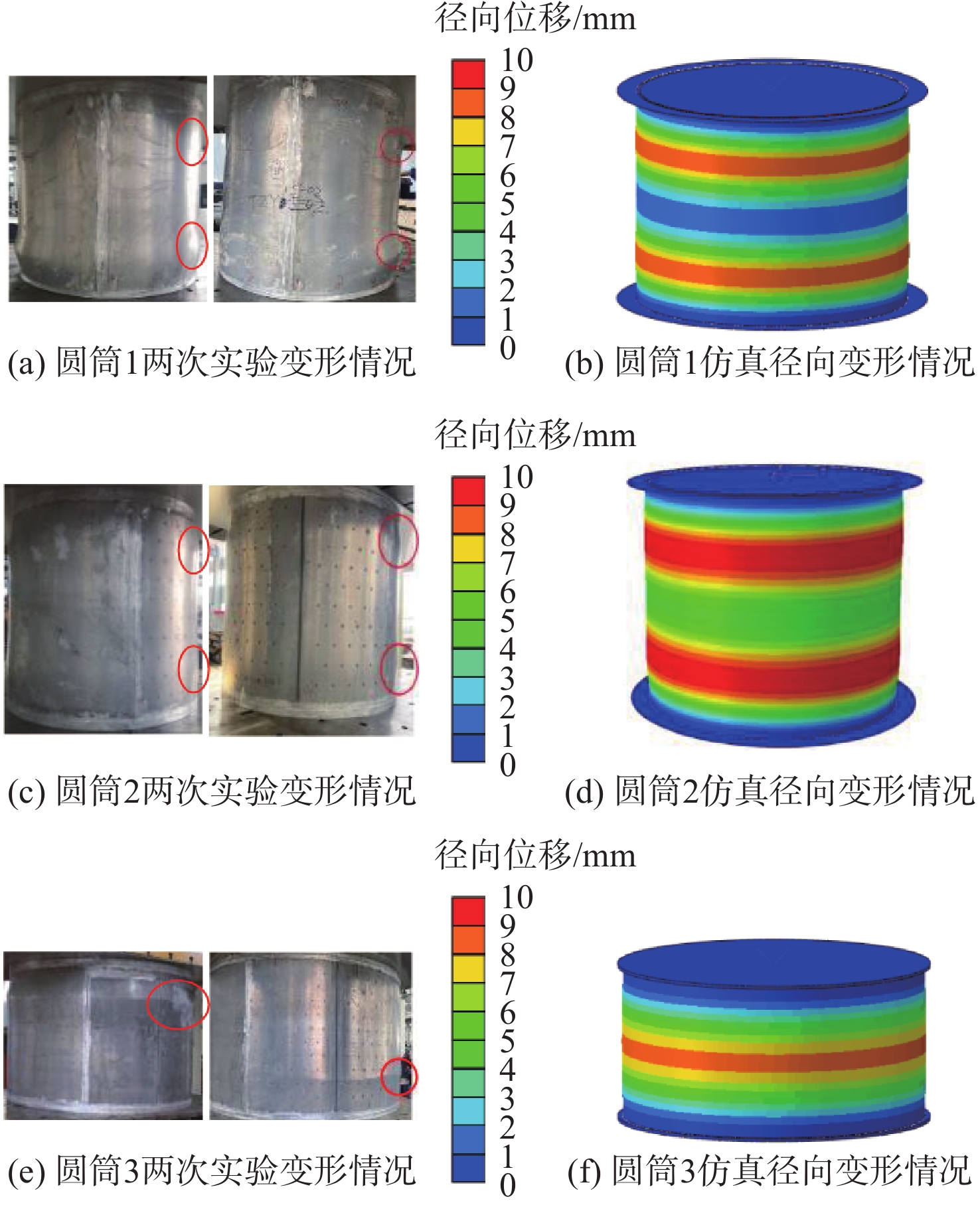

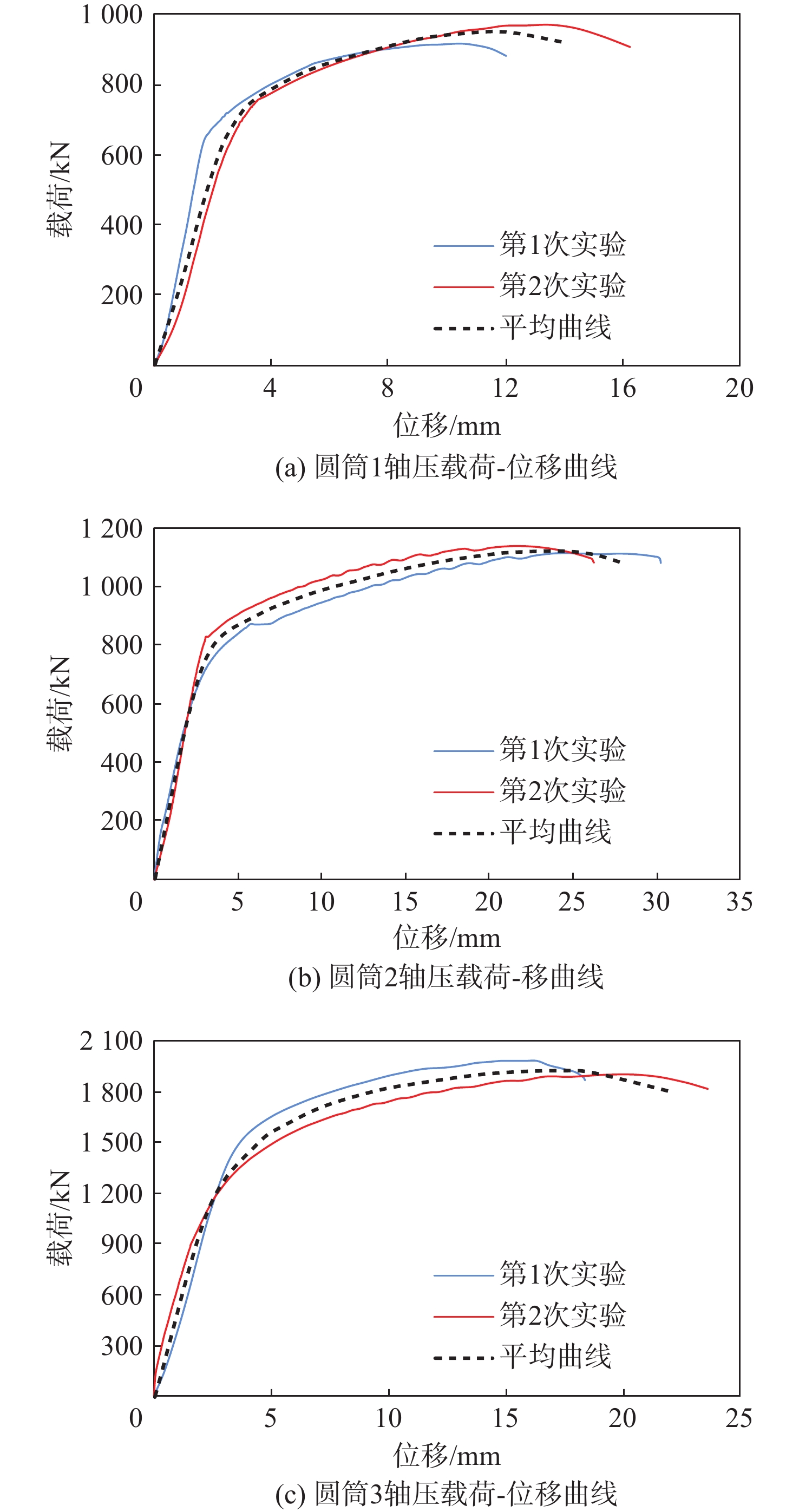

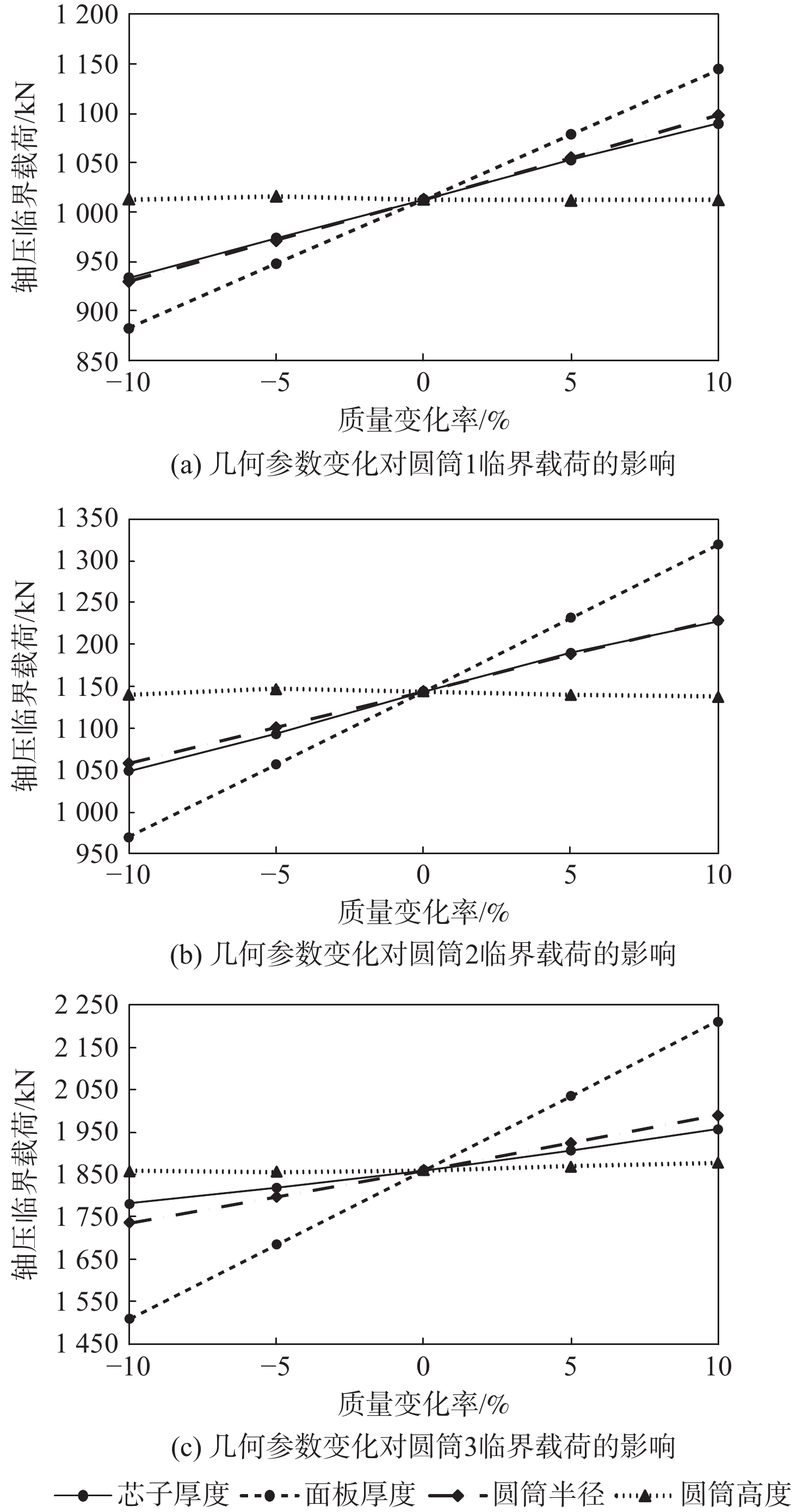

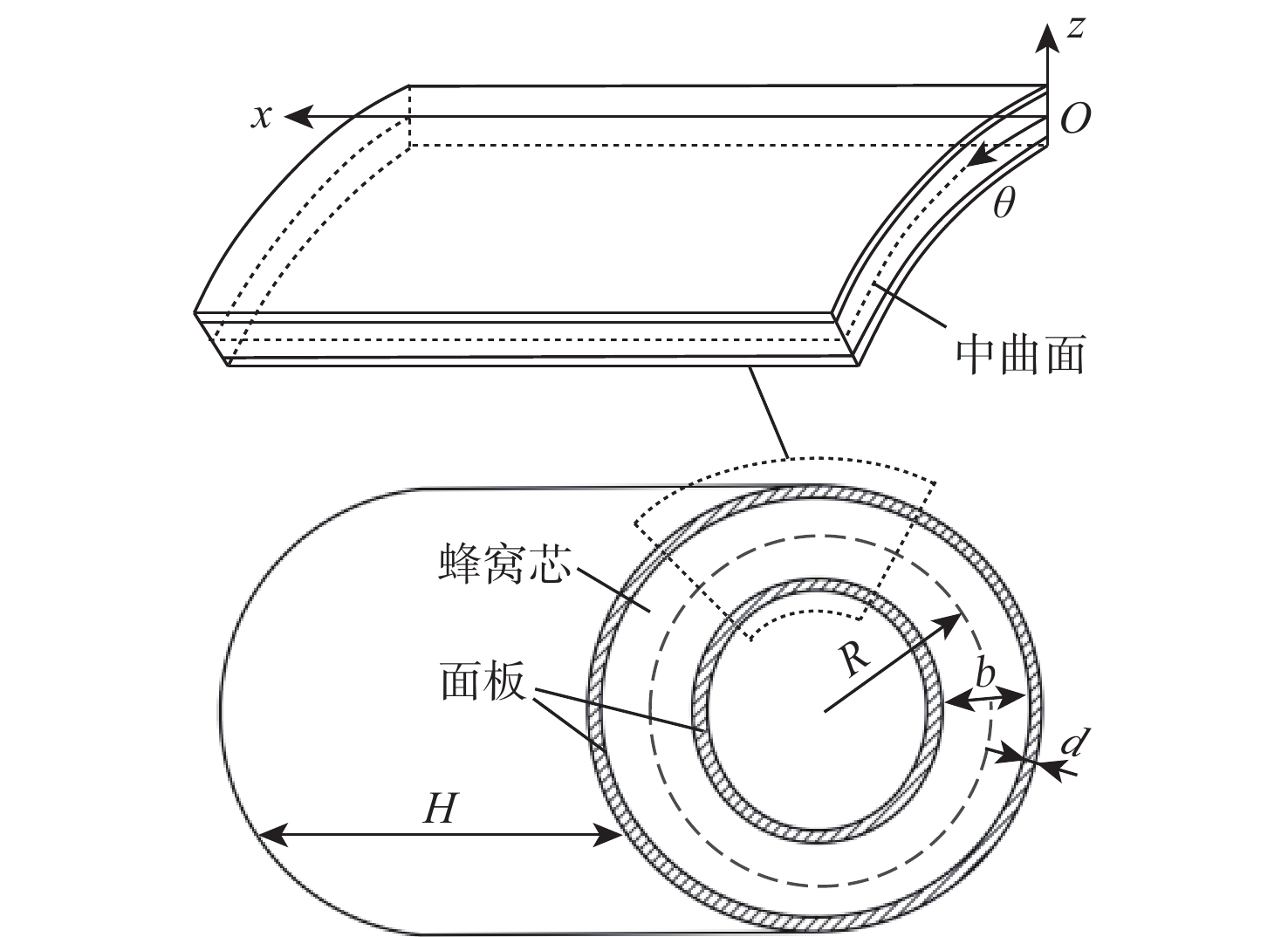

金属蜂窝圆筒结构常因轴压整体屈曲导致承载能力下降,对于其弹性屈曲问题目前已有大量研究,但在塑性屈曲问题方面的理论研究工作较少。为解决上述问题,基于蜂窝圆筒等效模型和Hamilton原理,推导了铝合金蜂窝圆筒承受轴压载荷作用时弹、塑性屈曲临界载荷的理论计算公式,并进行了轴压仿真分析和实验验证,利用理论公式讨论了蜂窝圆筒各尺寸参数对临界载荷的影响。结果表明:所提理论公式和仿真模型均能准确预测铝合金蜂窝圆筒的临界载荷,理论公式计算效率更高;圆筒质量变化±10%时,影响临界载荷的因素依次为面板厚度、圆筒半径、芯子厚度、圆筒高度;蜂窝圆筒的临界载荷与芯子厚度、面板厚度、圆筒半径近似呈线性正相关,与圆筒高度关系较弱。

Abstract:Metal honeycomb cylinder structures frequently encounter a decrease in load-carrying capacity due to axial compression buckling. Extensive research has been conducted on their elastic buckling behavior. However, there are few theoretical studies on their plastic buckling behavior. To address this issue, a theoretical formula was derived for the elastic and plastic buckling critical load of the aluminum alloy honeycomb cylinder under axial compression, drawing upon the equivalent model of the honeycomb cylinder and the Hamilton principle. The simulation analysis and experimentations on the above problem were carried out. Finally, the influence of the honeycomb cylinder dimensional parameters on the critical load was discussed using the theoretical formula. The results show that both the theoretical formula and the simulation model can accurately predict the critical load of the aluminum alloy honeycomb cylinder. In comparison, the theoretical formula is calculated faster. When the cylinder mass changes within the range of ±10%, the influence degree of panel thickness, cylinder radius, core thickness and cylinder height on the critical load decreases successively. The honeycomb cylinder’s critical load exhibits a minor association with the cylinder height, but it exhibits an approximately linear positive correlation with the cylinder radius, core thickness, and panel thickness.

-

Key words:

- honeycomb cylinder /

- global stability /

- critical load /

- elasto-plastic /

- Hamilton principle /

- finite element

-

表 1 3种铝合金蜂窝圆筒的尺寸参数

Table 1. Dimensional parameters of three aluminum alloy honeycomb cylinders

圆筒编号 b/mm d/mm R/mm H/mm t/mm l0/mm 圆筒1 12.6 1.2 692.5 1100 0.2 6 圆筒2 22.6 1.2 687.5 1100 0.2 6 圆筒3 37.6 1.2 1140 1100 0.2 6 表 2 面板和蜂窝芯材料的弹性参数

Table 2. Elastic parameters of panel and honeycomb core materials

材料名称 弹性模量/MPa 泊松比 密度/(kg·m−3) 6A02 63000 0.33 2700 3003 69000 0.33 2730 表 3 蜂窝圆筒的蜂窝芯等效参数

Table 3. Equivalent parameters of honeycomb core of honeycomb cylinder

等效参数 圆筒1 圆筒2 圆筒3 Eex/MPa 5.6926 5.5361 5.5350 Eeθ/MPa 5.8955 5.9062 5.9062 Eez/MPa 3533.1 3526.6 3526.6 Gexθ /MPa 3.4896 3.4482 3.4479 Gexz/MPa 984.811 973.845 973.763 Geθz/MPa 500.343 501.247 501.254 μexθ 0.997 0.997 0.997 μexz 5.32×10−4 5.18×10−4 5.18×10−4 μeθz 5.51×10−4 5.53×10−4 5.53×10−4 ρe/(kg·m−3) 139.31 138.67 138.66 表 4 质量变化率由−10%~+10%时临界载荷的变化率

Table 4. Critical load change rate when mass change rate is from −10% to +10%

参数 临界载荷变化率/% 平均值/% 圆筒1 圆筒2 圆筒3 芯子厚度 +16.7 +17.1 +9.88 +14.6 面板厚度 +29.8 +36.1 +46.6 +37.5 圆筒半径 +18.1 +16.1 +14.6 +16.3 圆筒高度 −0.06 −0.25 +1.12 +0.27 表 5 蜂窝圆筒尺寸参数与临界载荷的相关系数

Table 5. Correlation coefficient between dimension parameters and critical load of honeycomb cylinder

参数 相关系数 平均值 圆筒1 圆筒2 圆筒3 芯子厚度 0.999 9 0.999 0 0.998 6 0.999 2 面板厚度 0.999 9 0.999 9 0.999 9 0.999 9 圆筒半径 0.999 9 0.999 9 0.999 9 0.999 9 圆筒高度 −0.545 7 0.648 5 0.926 8 0.343 2 -

[1] HUANG S Z, JIN Z Y, CHEN Y. Underwater blast resistance of double cylindrical shells with circular tube stiffeners[J]. Ocean Engineering, 2021, 238: 109691. doi: 10.1016/j.oceaneng.2021.109691 [2] TENG J G, HU Y M. Behaviour of FRP-jacketed circular steel tubes and cylindrical shells under axial compression[J]. Construction and Building Materials, 2007, 21(4): 827-838. doi: 10.1016/j.conbuildmat.2006.06.016 [3] LAN X K, FENG S S, HUANG Q, et al. A comparative study of blast resistance of cylindrical sandwich panels with aluminum foam and auxetic honeycomb cores[J]. Aerospace Science and Technology, 2019, 87: 37-47. doi: 10.1016/j.ast.2019.01.031 [4] CAI L C, ZHANG D Y, ZHOU S H, et al. Investigation on mechanical properties and equivalent model of aluminum honeycomb sandwich panels[J]. Journal of Materials Engineering and Performance, 2018, 27(12): 6585-6596. doi: 10.1007/s11665-018-3771-2 [5] 骆洪志, 郭彦明, 吴会强. 直径五米大型箭体结构设计与优化[J]. 深空探测学报(中英文), 2021, 8(4): 380-388.LUO H Z, GUO Y M, WU H Q. Structural design and optimization of Φ5 m diameter large arrow body[J]. Journal of Deep Space Exploration, 2021, 8(4): 380-388(in Chinese). [6] LI Q, YANG D Q, MAO X. Pressure-resistant cylindrical shell structures comprising graded hybrid zero Poisson’s ratio metamaterials with designated band gap characteristics[J]. Marine Structures, 2022, 84: 103221. doi: 10.1016/j.marstruc.2022.103221 [7] TIWARI G, KHAIRE N. Ballistic performance and energy dissipation characteristics of cylindrical honeycomb sandwich structure[J]. International Journal of Impact Engineering, 2022, 160: 104065. doi: 10.1016/j.ijimpeng.2021.104065 [8] ALMROTH B O, BURNS A B, PITTNER E V. Design criteria for axially loaded cylindrical shells[J]. Journal of Spacecraft and Rockets, 1970, 7(6): 714-720. doi: 10.2514/3.30025 [9] 祝恩淳, MANDAL P, CALLADINE C R. 轴压圆柱薄壳的屈曲分析[J]. 土木工程学报, 2001, 34(3): 18-22. doi: 10.3321/j.issn:1000-131X.2001.03.004ZHU E C, MANDAL P, CALLADINE C R. Analysis of buckling of thin cylindrical shells under axial compression[J]. China Civil Engineering Journal, 2001, 34(3): 18-22(in Chinese). doi: 10.3321/j.issn:1000-131X.2001.03.004 [10] ANSARI Q M, TRINH L C, ZUCCO G, et al. Effect of elastic support on the linear buckling response of quasi-isotropic cylindrical shells under axial compression[J]. Engineering Structures, 2021, 244: 112796. doi: 10.1016/j.engstruct.2021.112796 [11] LAI A D, JIA J F, ZHOU Z H, et al. Homotopic analysis for post-buckling of cylindrical shells with local thickness defects[J]. Acta Astronautica, 2022, 193: 44-55. doi: 10.1016/j.actaastro.2022.01.005 [12] SHAMASS R, ALFANO G, GUARRACINO F. A numerical investigation into the plastic buckling paradox for circular cylindrical shells under axial compression[J]. Engineering Structures, 2014, 75: 429-447. doi: 10.1016/j.engstruct.2014.05.050 [13] LEGENDRE J, LE GROGNEC P, DOUDARD C, et al. Analytical, numerical and experimental study of the plastic buckling behavior of thick cylindrical tubes under axial compression[J]. International Journal of Mechanical Sciences, 2019, 156: 494-505. doi: 10.1016/j.ijmecsci.2019.03.002 [14] EVKIN A, LYKHACHOVA O. Energy barrier method for estimation of design buckling load of axially compressed elasto-plastic cylindrical shells[J]. Thin-Walled Structures, 2021, 161: 107454. doi: 10.1016/j.tws.2021.107454 [15] RAJABIEHFARD R, DARVIZEH A, ALITAVOLI M, et al. Experimental and numerical investigation of dynamic plastic behavior of tube with different thickness distribution under axial impact[J]. Thin-Walled Structures, 2016, 109: 174-184. doi: 10.1016/j.tws.2016.08.017 [16] 张靖华, 郑武. 功能梯度圆柱壳的弹塑性屈曲[J]. 兰州理工大学学报, 2021, 47(5): 167-172. doi: 10.3969/j.issn.1673-5196.2021.05.025ZHANG J H, ZHENG W. Elastoplastic buckling of functionally graded cylindrical shells[J]. Journal of Lanzhou University of Technology, 2021, 47(5): 167-172(in Chinese). doi: 10.3969/j.issn.1673-5196.2021.05.025 [17] HOU X H, ZHOU S Q, CHENG Z W, et al. Buckling of regular and auxetic honeycombs under a general macroscopic stress state in symplectic system[J]. Applied Mathematical Modelling, 2022, 109: 318-340. doi: 10.1016/j.apm.2022.04.033 [18] ZHANG C W, EYVAZIAN A, ALKHEDHER M, et al. Modified couple stress theory application to analyze mechanical buckling behavior of three-layer rectangular microplates with honeycomb core and piezoelectric face sheets[J]. Composite Structures, 2022, 292: 115582. doi: 10.1016/j.compstruct.2022.115582 [19] 赵杰, 张娟, 蒋晓琴, 等. 不同压缩工况下焊接缺陷对钎焊铝蜂窝板承载能力的影响[J]. 机械工程材料, 2020, 44(12): 97-102.ZHAO J, ZHANG J, JIANG X Q, et al. Influence of welding defects on bearing capacity of brazed aluminum honeycomb panel under different compression conditions[J]. Materials for Mechanical Engineering, 2020, 44(12): 97-102(in Chinese). [20] 王宝芹, 王沫楠, 刘长喜. 基于多尺度方法的蜂窝夹层复合材料结构轴向压缩稳定性[J]. 复合材料学报, 2020, 37(3): 601-608.WANG B Q, WANG M N, LIU C X. Stability of honeycomb sandwich composite structure under axial compression based on multi-scale method[J]. Acta Materiae Compositae Sinica, 2020, 37(3): 601-608(in Chinese). [21] ZHANG Z J, WANG Y J, HUANG L, et al. Mechanical behaviors and failure modes of sandwich cylinders with square honeycomb cores under axial compression[J]. Thin-Walled Structures, 2022, 172: 108868. doi: 10.1016/j.tws.2021.108868 [22] PAN D R, CHEN L, ZHAO Q L, et al. Local buckling theoretical calculation method of the FRP foam sandwich cylinder under axial compression[J]. Composite Structures, 2020, 246: 112371. doi: 10.1016/j.compstruct.2020.112371 [23] 王颖坚, 徐颖. 复合材料夹层板的塑性屈曲[J]. 北京大学学报(自然科学版), 1993, 29(1): 48-56.WANG Y J, XU Y. Plastic buckling of composite sandwich plates[J]. Acta Scicentiarum Naturalum Universitis Pekinesis, 1993, 29(1): 48-56(in Chinese). [24] 刘强, 黄争呜. 金属蜂窝材料的弹塑性屈曲临界应力值[J]. 力学季刊, 2008, 29(4): 515-520.LIU Q, HUANG Z W. Elasto-plastic buckling critical stress of metal honeycomb[J]. Chinese Quarterly of Mechanics, 2008, 29(4): 515-520(in Chinese). [25] 李贤冰, 温激鸿, 郁殿龙, 等. 蜂窝夹层板力学等效方法对比研究[J]. 玻璃钢/复合材料, 2012(增刊1): 11-15.LI X B, WEN J H, YU D L, et al. The comparative study of equivalent mechanical methods on honeycomb sandwich plate[J]. Composites Science and Engineering, 2012(Sup 1): 11-15(in Chinese). [26] 沈元星, 侯文彬. 基于双曲面蜂窝夹层结构等效模型的研究及数值分析[J]. 计算力学学报, 2022, 39(2): 209-215.SHEN Y X, HOU W B. Equivalent models research and numerical analysis based on double curved honeycomb sandwich structure[J]. Chinese Journal of Computational Mechanics, 2022, 39(2): 209-215(in Chinese). [27] 陈明祥. 弹塑性力学[M]. 北京: 科学出版社, 2007: 278-281.CHEN M X. Elasticity and plasticity[M]. Beijing: Science Press, 2007: 278-281(in Chinese). [28] 闻邦椿. 机械设计手册(第1卷)[M]. 5版. 北京: 机械工业出版社, 2010: 25-26.WEN B C. Machine design handbook (Vol. 1)[M]. 5th ed. Beijing: China Machine Press, 2010: 25-26(in Chinese). -

下载:

下载: