-

摘要:

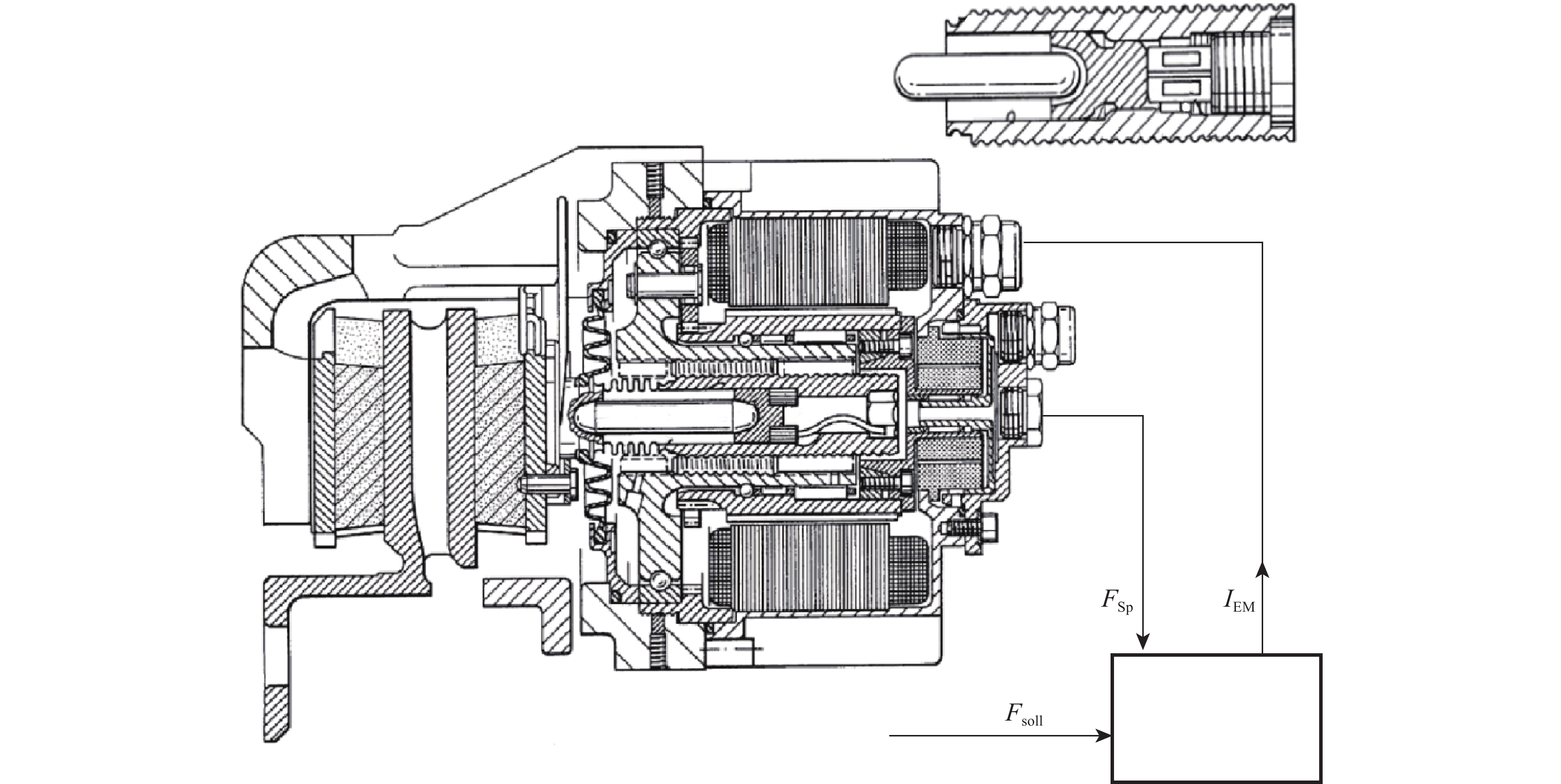

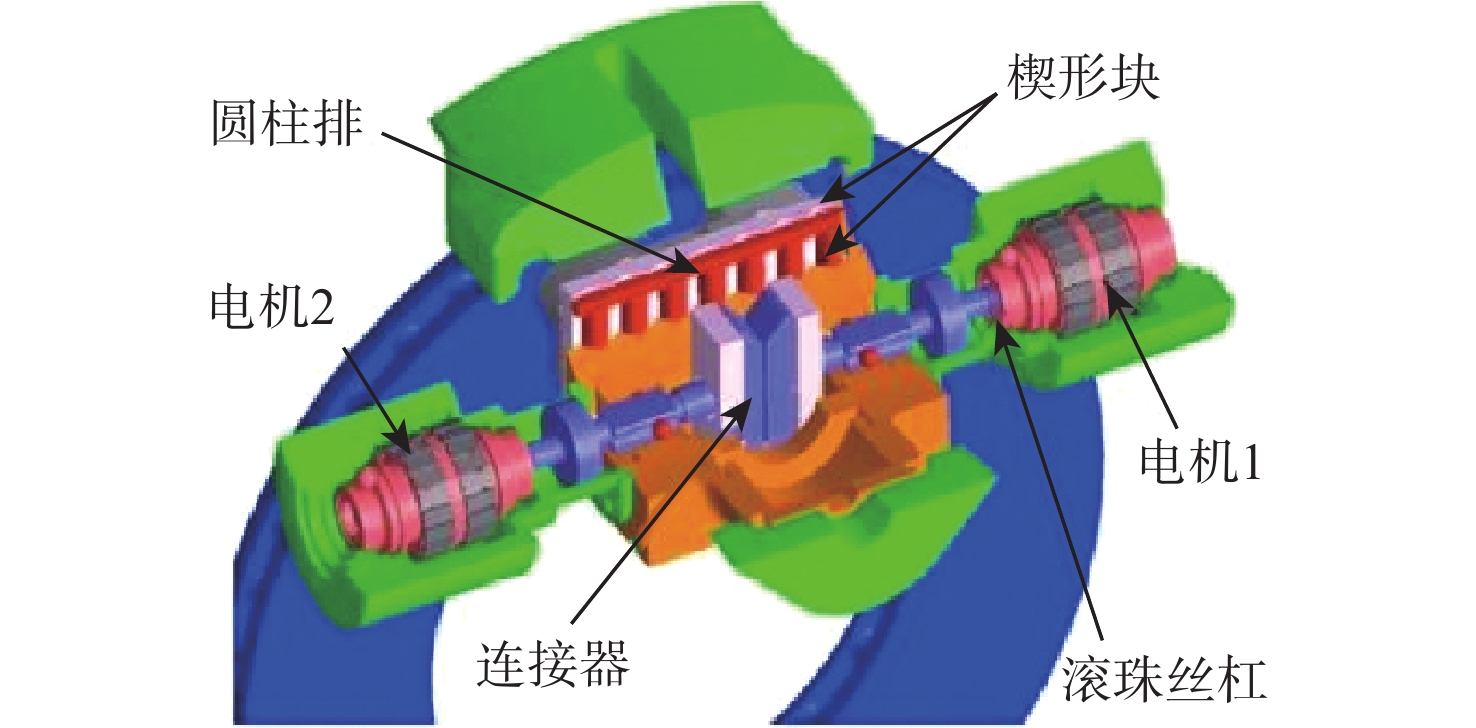

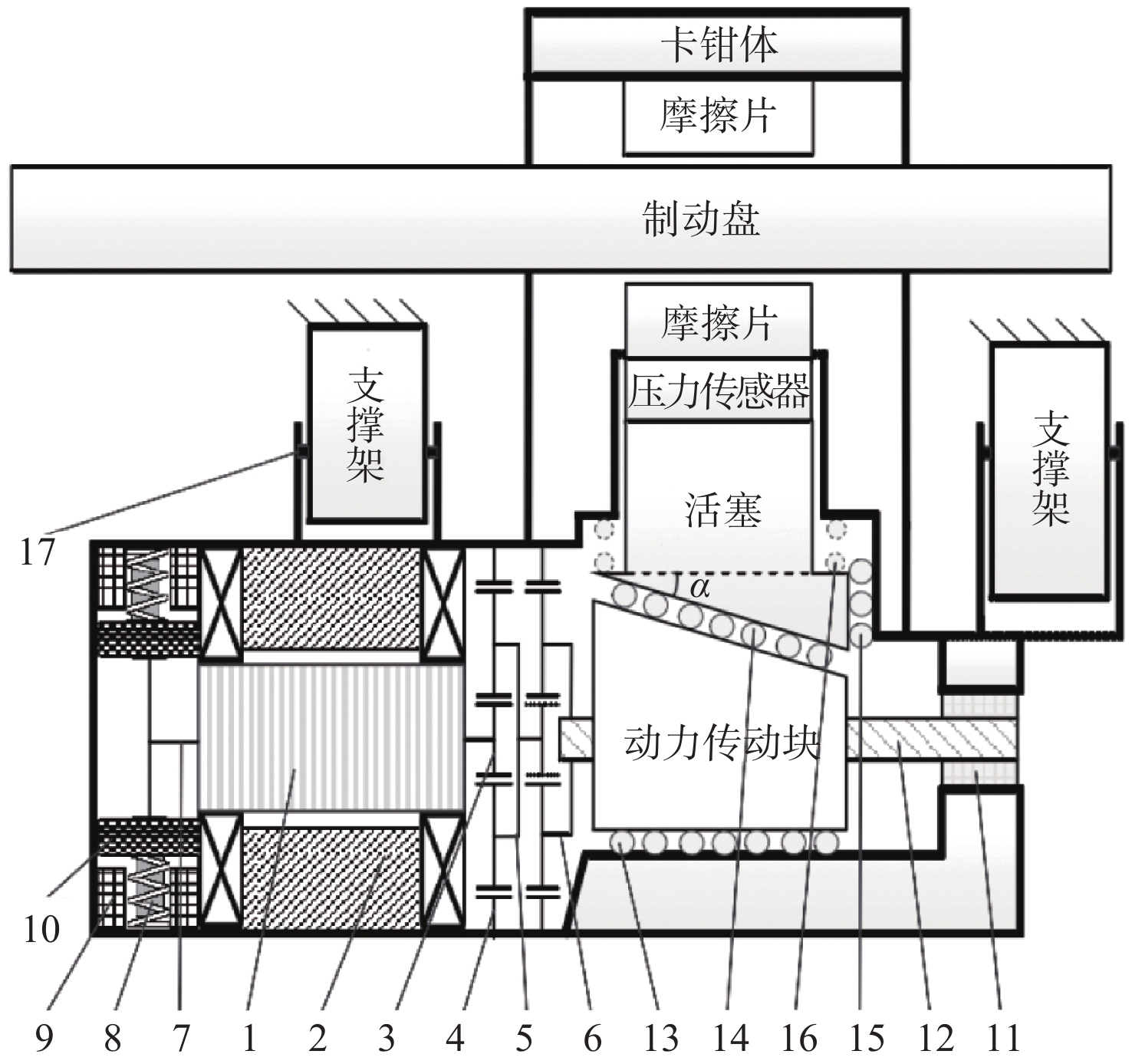

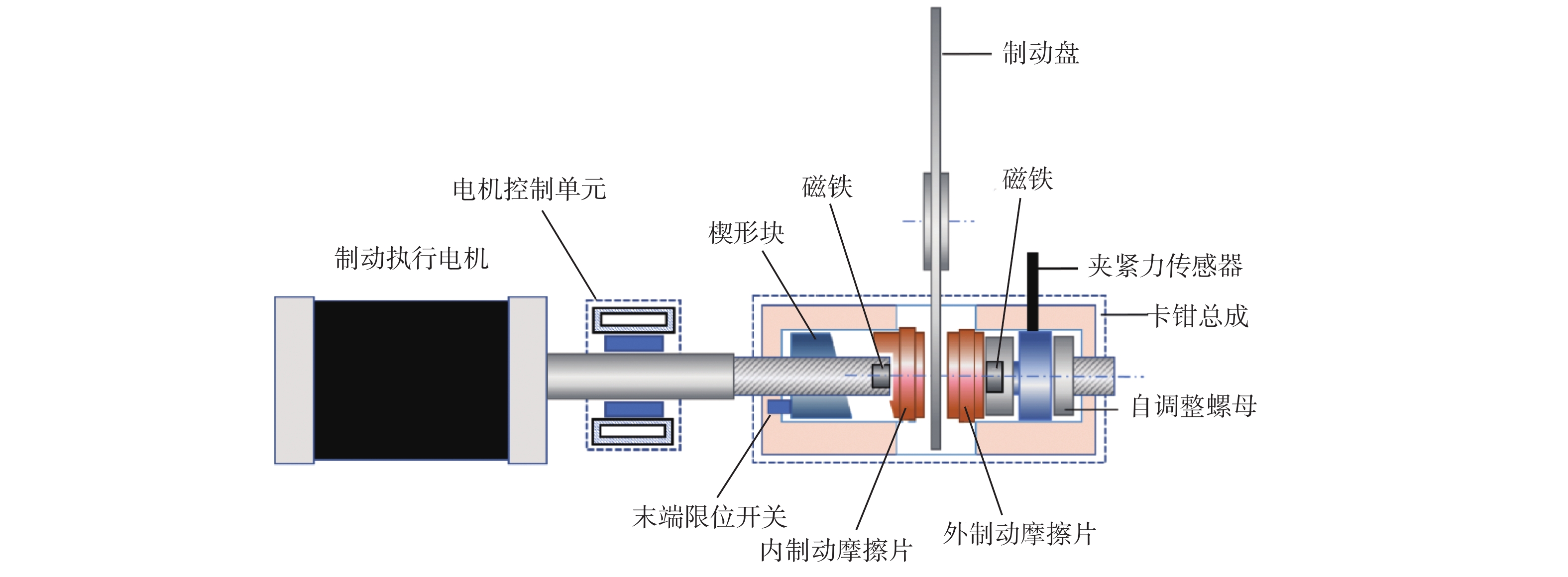

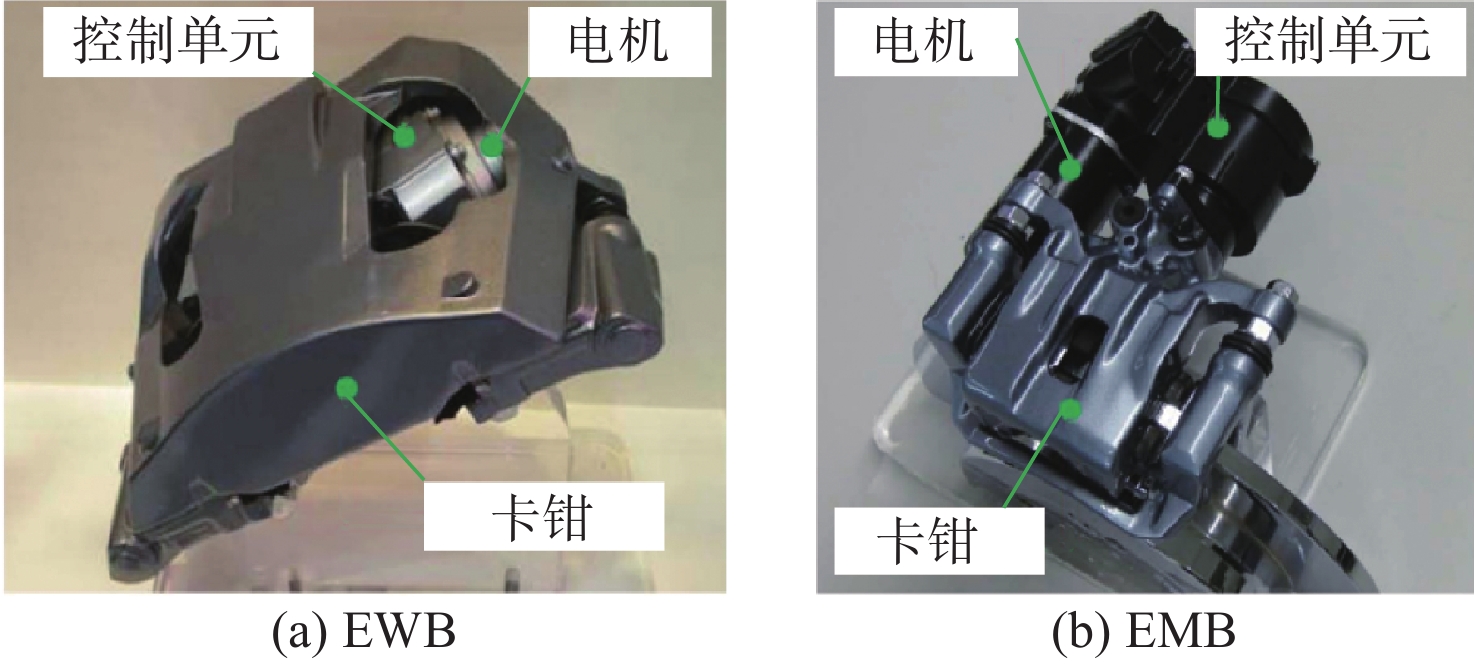

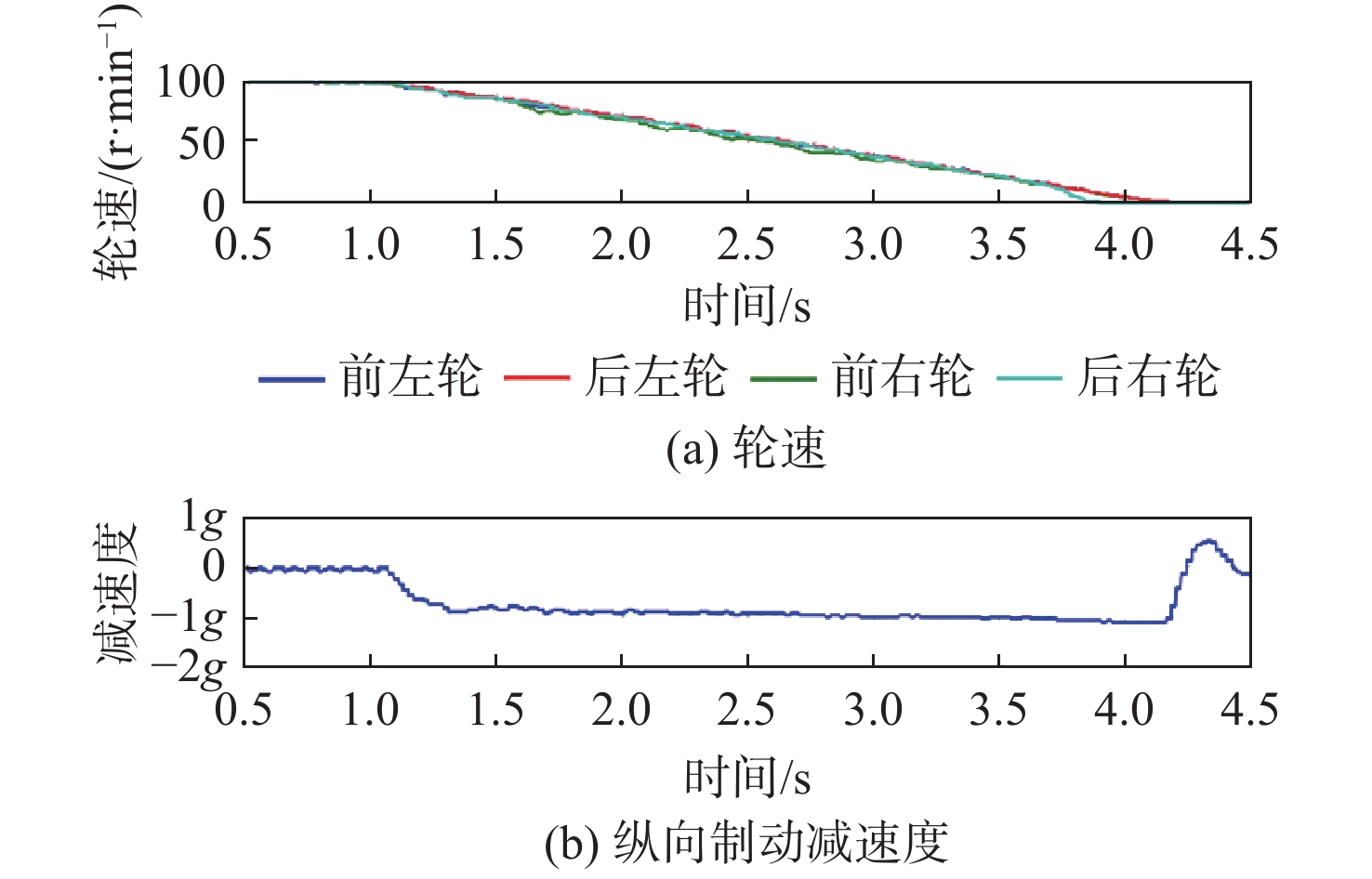

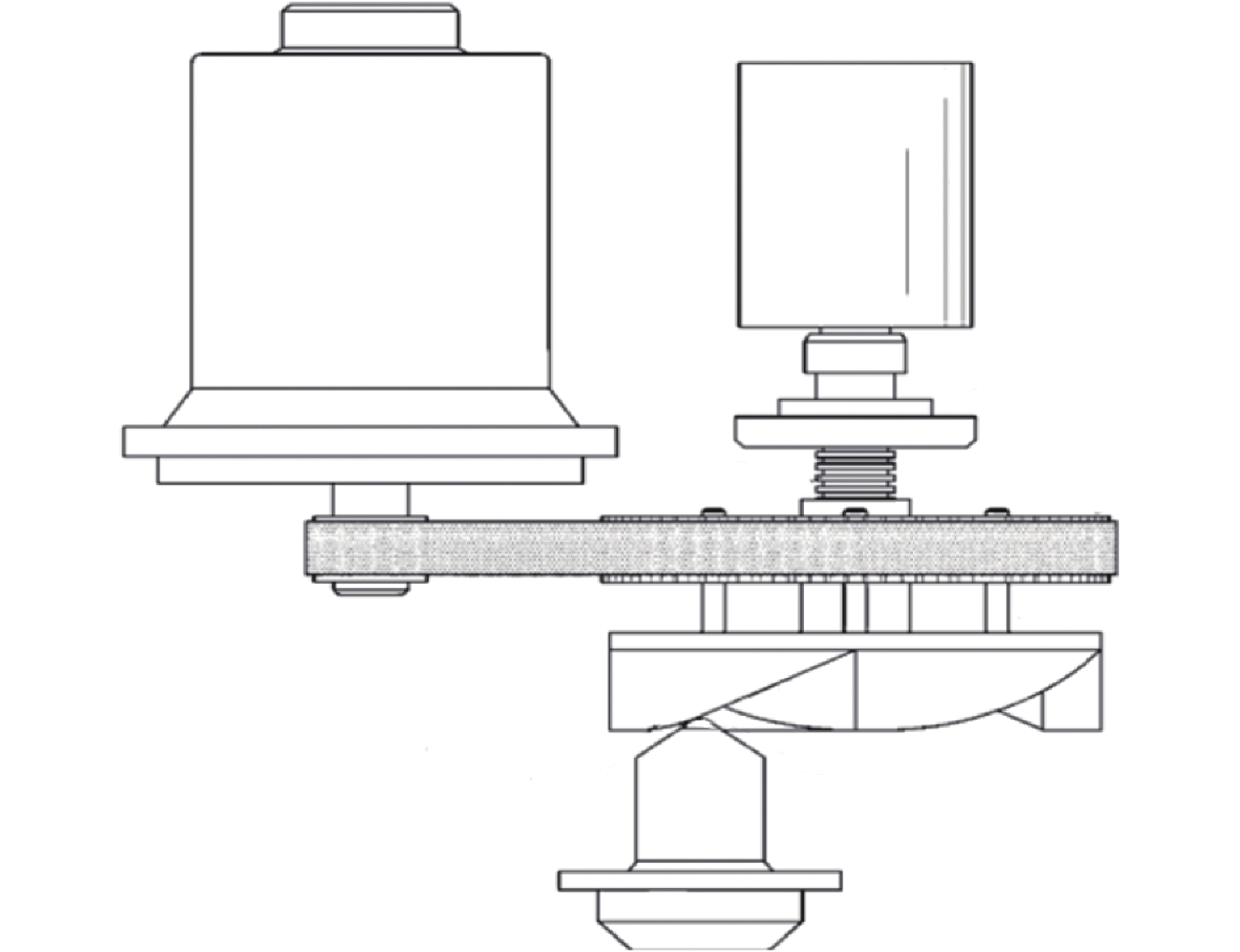

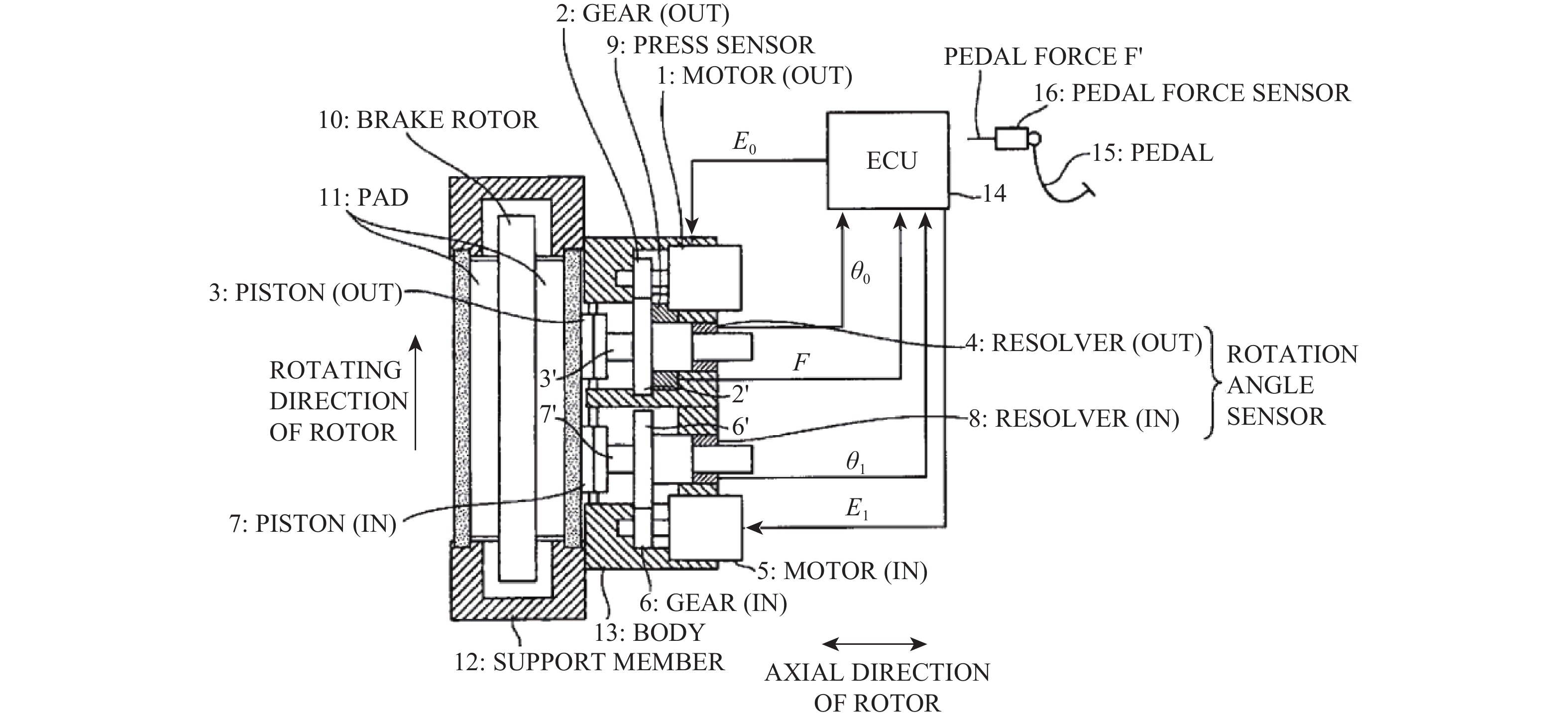

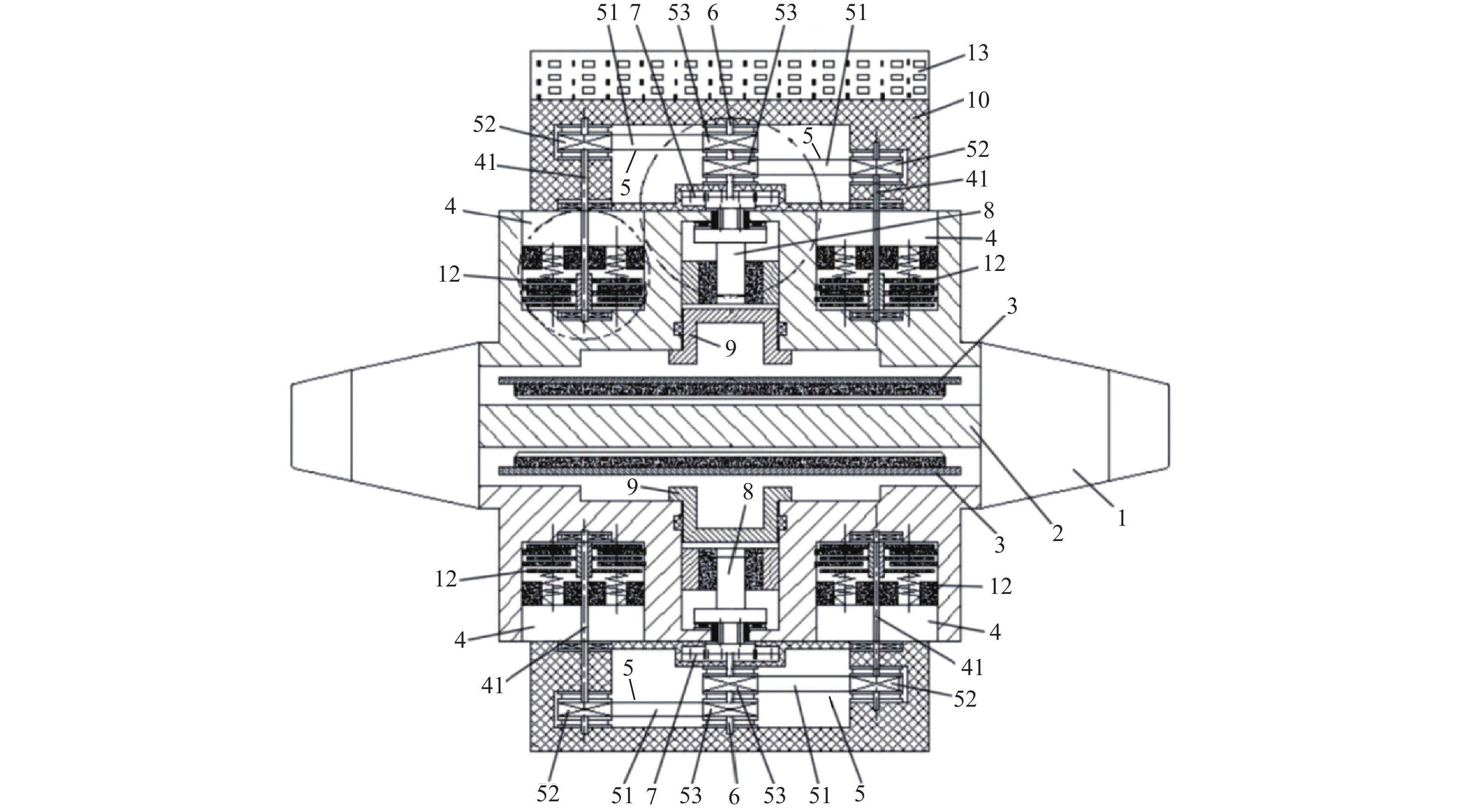

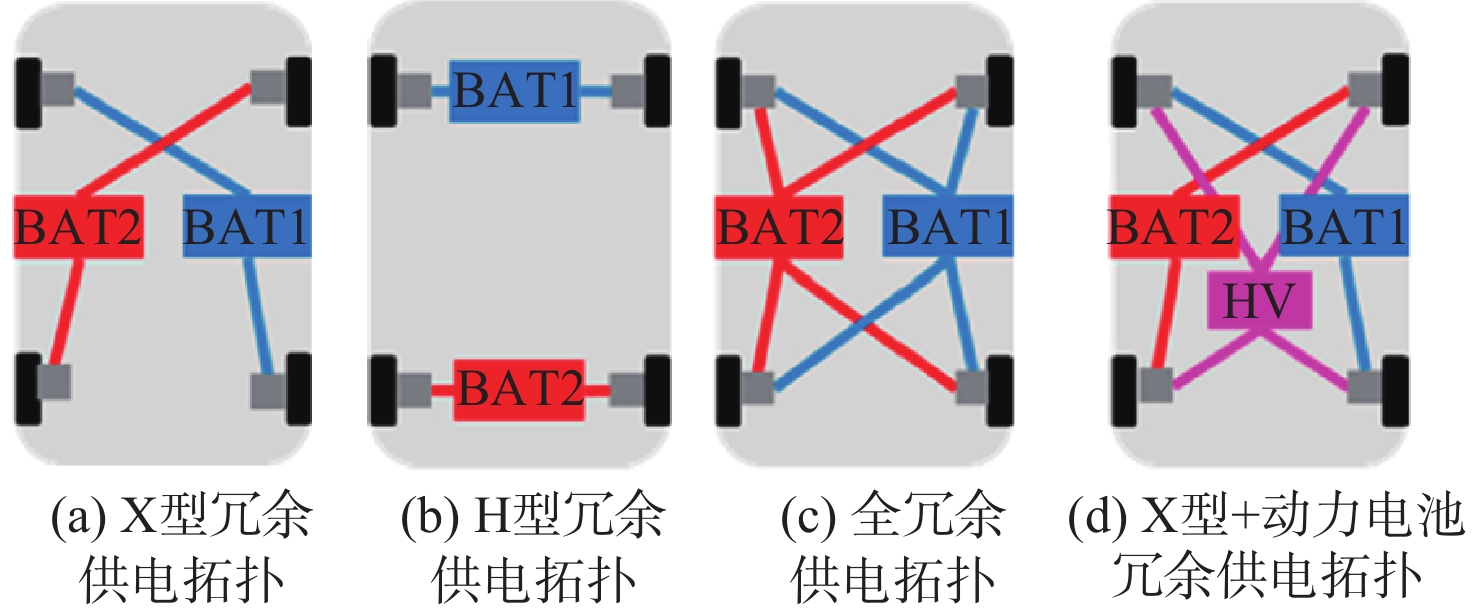

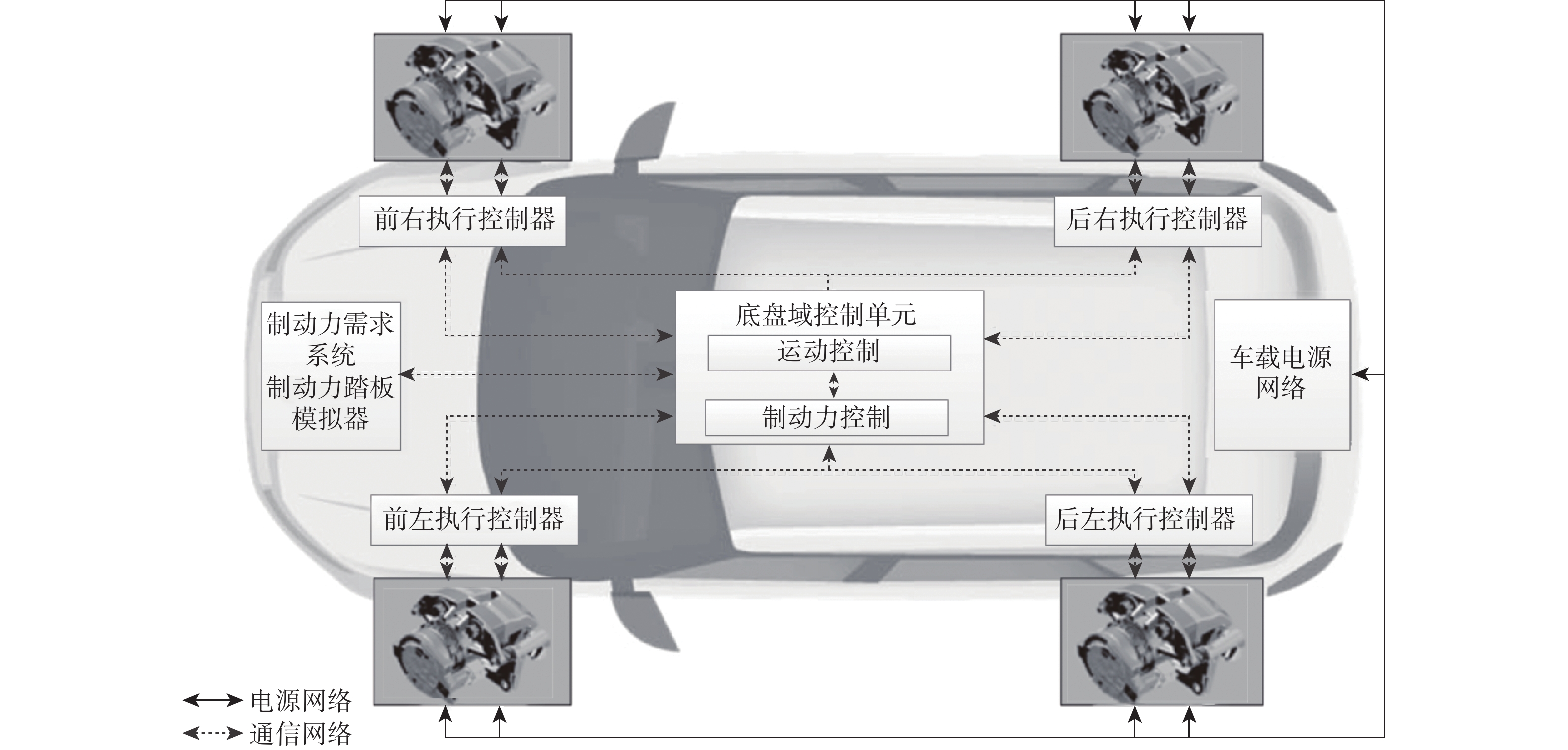

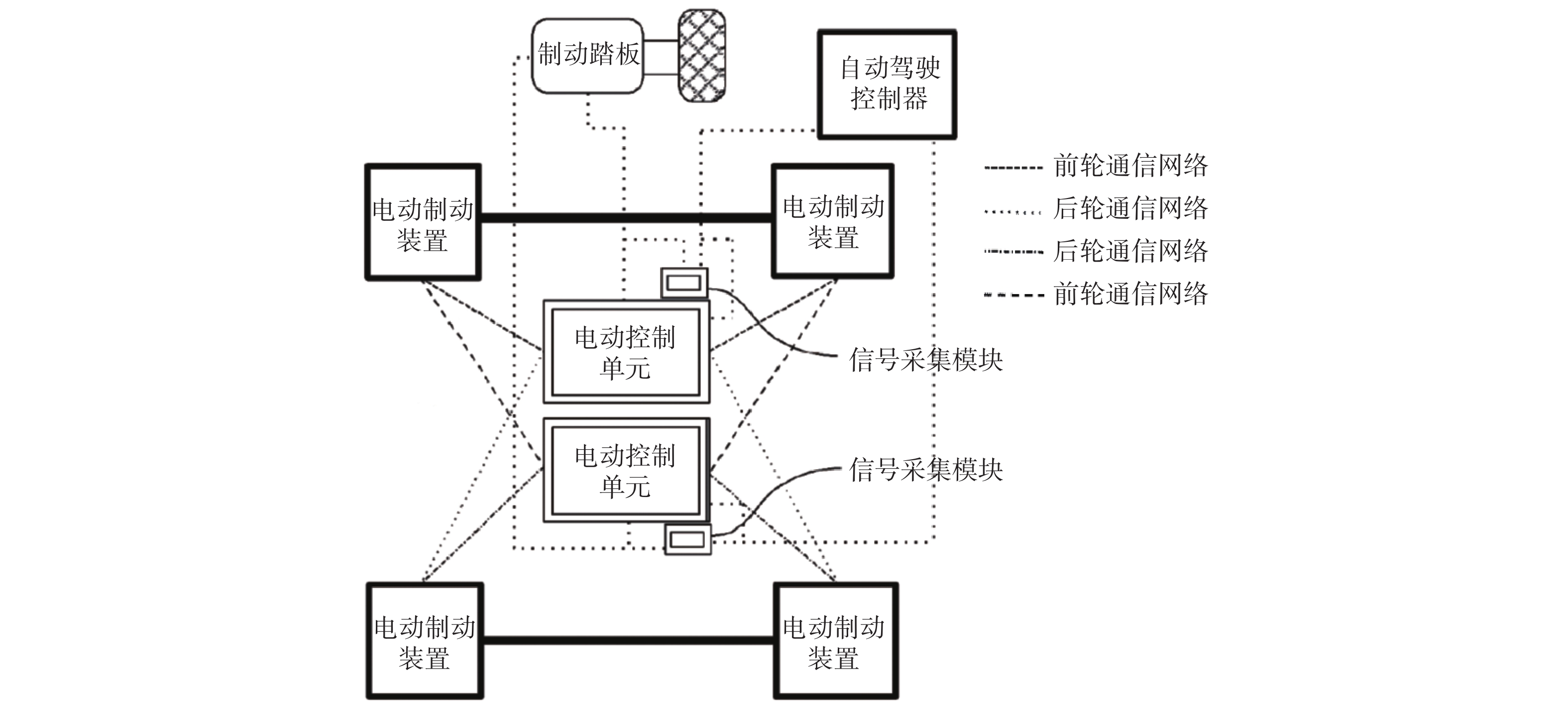

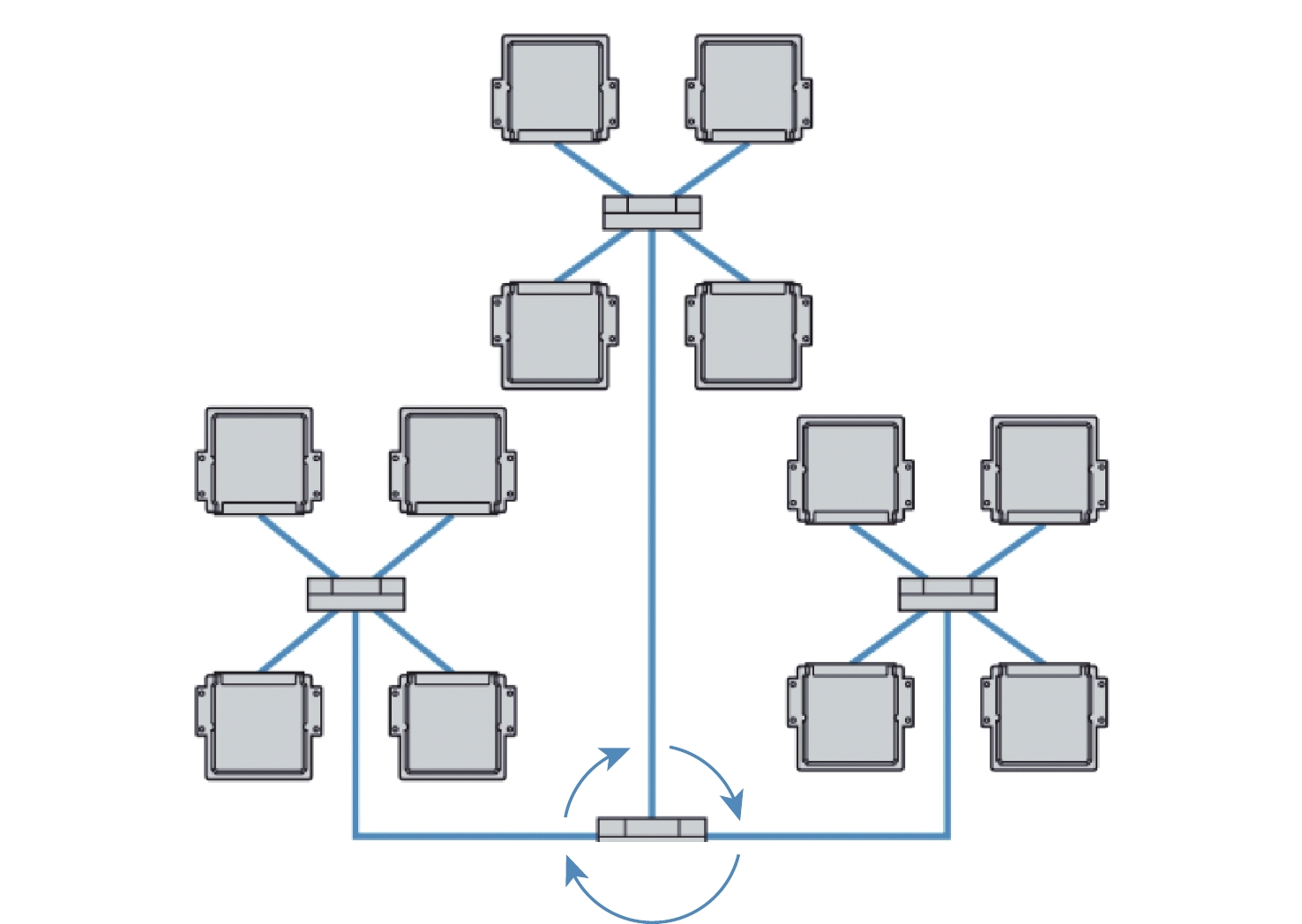

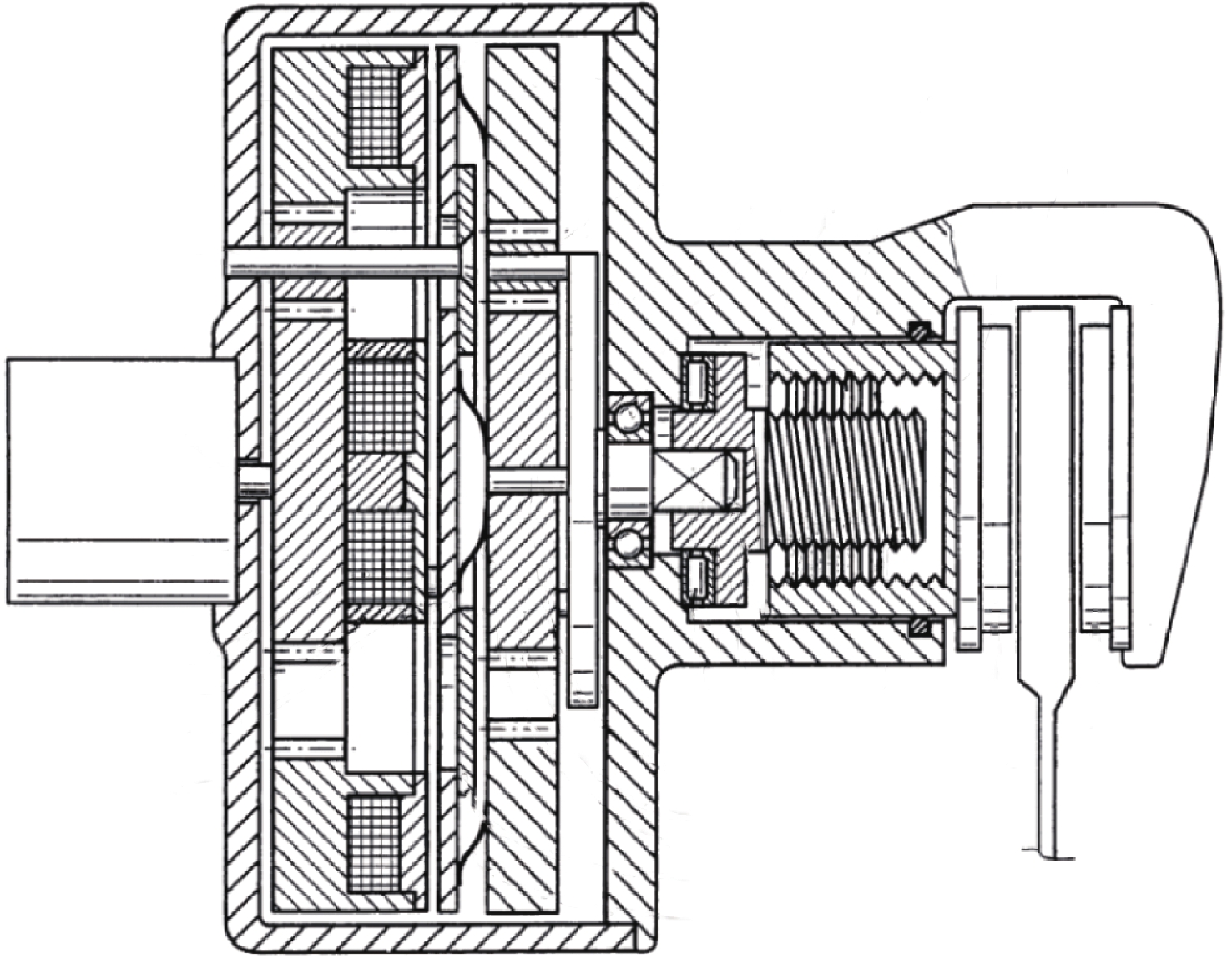

电子机械制动系统(electro-mechanical brake, EMB)是真正意义上的纯线控制动,完全摒弃液压/气压装置,实现人车解耦、更高的响应速度、更精准的制动力控制,是高级别自动驾驶技术的理想制动执行机构,然而由于系统可靠性、功能安全及成本等原因仍未规模量产应用。分析EMB的技术发展现状及典型系统结构,比较线性自增力式和非线性增力式两大技术路线,介绍基于楔形自增力结构的电子楔式制动器(electronic wedge brake,EWB)及混合EMB系统,并探讨其在自动驾驶环境下的适用性。针对EMB系统关键技术,重点研究了系统架构、电控单元、通信架构、失效模式等冗余设计方案,以及无传感器夹紧力估算方法的夹紧力控制技术,并对其后续产业化应用所面临的挑战进行了分析和后续研究展望。

Abstract:The electro-mechanical brake (EMB) is a true brake-by-wire system that completely eliminates hydraulic/pneumatic components, enabling decoupling between driver and vehicle, achieving higher response speed, and providing more precise braking force control. As an ideal braking actuator for high-level autonomous driving technology, EMB has not yet to be widely mass-produced due to challenges related to system reliability, functional safety, and cost.This paper analyzes the current technological development and typical system structures of EMB, comparing the two major technological approaches: linear self-amplifying and nonlinear force-amplifying methods. It introduces the electronic wedge brake (EWB) , as well as hybrid EMB systems, and discusses their applicability in autonomous driving environments. Second, this study focuses on the redundancy design solutions for system architecture, electronic control units (ECU), communication architecture, and failure modes. Additionally, it explores clamping force control technology based on a sensorless clamping force estimation method. Finally, the paper analyzes the challenges faced by EMB for future industrial applications and presents prospects for further research.

-

-

[1] 邓美俊, 孙仁云, 潘湘芸, 等. 汽车电子机械制动系统技术发展分析[J]. 汽车零部件, 2021(9): 103-109.DENG M J, SUN R Y, PAN X Y, et al. Research status analysis of automotive electro-mechanical brake system[J]. Automobile Parts, 2021(9): 103-109(in Chinese). [2] 雍健羽, 王洪亮, 董金聪, 等. 轻型车辆线控制动技术研究现状及发展趋势综述[J]. 中国汽车, 2022, 32(11): 16-22.YONG J Y, WANG H L, DONG J C, et al. Review on the research status and development trend of wire control technology[J]. China Auto, 2022, 32(11): 16-22(in Chinese). [3] 牟希东. 面向动力学控制的电子机械制动系统控制策略研究[D]. 长春: 吉林大学, 2021.MU X D. Research on control strategy of electro-mechanical braking system oriented to dynamic control[D]. Changchun: Jilin University, 2021(in Chinese). [4] 夏利红. 基于EMB的分布式复合制动系统研究[D]. 重庆: 重庆大学, 2019.XIA L H. The study on distributed hybrid braking system based on EMB[D]. Chongqing: Chongqing University, 2019(in Chinese). [5] 张奇祥, 靳立强, 靳博豪, 等. EMB夹紧力控制与传感器故障诊断研究进展[J]. 汽车工程, 2022, 44(5): 736-746.ZHANG Q X, JIN L Q, JIN B H, et al. Research progress of EMB clamping force control and sensor fault diagnosis[J]. Automotive Engineering, 2022, 44(5): 736-746(in Chinese). [6] NEZU T, INOUE Y, USUI T. Electronic control technology for chassis subsystems[J]. Hitachi Review, 2022, 71(1): 76-77. [7] BROWN S, HOLWEG E. Smart electro-mechanical actuation for drive-by-wire applications[C]//Proceedings of the SAE Technical Paper Series. Warrendale: SAE International, 2004. [8] 德尔福集团. 德尔福混合线控制动系统[J]. 汽车与配件, 2004(23): 48.Delphi. Delphi hybrid brake-by-wire[J]. Automobile & Parts, 2004(23): 48(in Chinese). [9] 高国伟. 面向线控底盘平台的弯道制动力分配控制策略研究[D]. 天津: 天津职业技术师范大学, 2022.GAO G W. Research on bend braking force distribution control strategy for wire controlled chassis platform[D]. Tianjin: Tianjin University of Technology and Education , 2022(in Chinese). [10] 杨岩松. 基于楔形传动的电子机械线控制动系统的研究与设计[D]. 广州: 华南理工大学, 2020.YANG Y S. Research and design of the electro-mechanical brake-by-wire system based on wedge transmission[D]. Guangzhou: South China University of Technology, 2020(in Chinese). [11] 宋瑞琦. 商用车电子机械制动系统设计与控制策略研究 [D]. 青岛: 青岛理工大学, 2022.SONG R Q. Research on design and control strategy of electro-mechanical braking system of commercial vehicle[D]. Qingdao: Qingdao University of Technology, 2022(in Chinese). [12] KELLER F. Electromagnetic wheel brake device: US6536561[P]. 2003-03-25. [13] CAO C T, BAUMANN D, HOFMANN D, et al. Self-reinforcing electromechanical disc brake: US8439170[P]. 2013-05-14. [14] NEWTON M. Siemens’ wedge brake hits the ice[J]. Automotive Engineering International, 2007, 115(7): 26-30. [15] XU F, CHO C. A novel electronic wedge brake based on active disturbance rejection control[J]. Energies, 2022, 15(14): 5096. doi: 10.3390/en15145096 [16] CHEON J S. Brake by wire system configuration and functions using front EWB (electric wedge brake) and rear EMB (electro-mechanical brake) actuators[C]//Proceedings of the SAE Technical Paper Series. Warrendale: SAE International, 2010. [17] CHEON J S, KIM J, JEON J. New brake by wire concept with mechanical backup[J]. SAE International Journal of Passenger Cars-Mechanical Systems, 2012, 5(4): 1194-1198. doi: 10.4271/2012-01-1800 [18] 姚兴娟, 李学佳, 张水清, 等. 一种电子机械制动器: CN218294260U[P]. 2023-01-13.YAO X J, LI X J, ZHANG S Q, et al. An electronic mechanical brake: CN218294260U[P]. 2023-01-13(in Chinese). [19] 郭锋亮, 叶乙兴, 朱元澄, 等. 一种制动钳总成: CN218063174U[P]. 2022-12-16.GUO F L, YE Y X, ZHU Y C, et al. Brake caliper assembly: CN218063174U[P]. 2022-12-16(in Chinese). [20] DE MORAIS A E, 许志, 李运动, 等. 多缸同步建压电控制动卡钳: CN217926862U[P]. 2022-11-29.DE MORAIS A E, XU Z, LI Y D, et al. Multi-cylinder synchronous built-in piezoelectric control caliper: CN217926862U[P]. 2022-11-29(in Chinese). [21] 郑祖雄, 刘磊, 邹佳航. 一种带传动制动钳、制动系统、汽车和设计方法 : CN115507141A[P]. 2022-12-23.ZHENG Z X, LIU L, ZOU J H. Belt transmission brake caliper, brake system, automobile and design method: CN115507141A[P]. 2022-12-23(in Chinese). [22] LIU H Z, DENG W W, HE R, et al. Fault-tolerant control of brake-by-wire systems based on control allocation[C]//Proceedings of the SAE Technical Paper Series. Warrendale: SAE International, 2016: 923-936. [23] SCHRADE S, NOWAK X, VERHAGEN A, et al. Short review of EMB systems related to safety concepts[J]. Actuators, 2022, 11(8): 214. doi: 10.3390/act11080214 [24] The United Nations Economic Commission for Europe. Uniform provisions concerning the approval of passenger cars with regard to braking: UNECE-R13H[S]. Geneva: The United Nations Economic Commission for Europe, 2015. [25] Transport Canada. Hydraulic and electric brake systems: technical standards document No. 105, revision 5[S]. Ottawa: Transport Canada, 2015. [26] 张晓坤, 于飞. 电子机械制动器和车辆: CN218177792U[P]. 2022-12-30.ZHANG X K, YU F. Electromechanical brake and vehicle: CN218177792U[P]. 2022-12-30(in Chinese). [27] 沈暻勋, 张在勋. 电动制动系统及其操作方法: CN115087814A[P]. 2022-09-20.SHEN J X, ZHANG Z X. Electric brake system and operating method thereof: CN115087814A[P]. 2022-09-20(in Chinese). [28] TAKAHASHI H, TAKAHASHI K. Electric brake: US11523500[P]. 2010-10-05. [29] KÖHLER A, BERTSCHE B. An approach of fail operational power supply for next generation vehicle powernet architectures[C]//Proceedings of the 30th European Safety and Reliability Conference and 15th Probabilistic Safety Assessment and Management Conference. Singapore: Research Publishing Services, 2020: 60-67. [30] REINHARD W. Electric brake system, particularly electro-mechanical brake system for motor vehicle, has brake circuit, and control unit for implementation of driver braking demand: DE102009046231[P]. 2011-05-11. [31] 刘强, 秦宬, 付永泉, 等. 车辆电子机械制动系统和具有其的车辆: CN112550189B[P]. 2021-02-10.LIU Q, QIN C, FU Y Q, et al. Vehicle electromechanical brake system and vehicle with same: CN112550189B[P]. 2021-02-10(in Chinese). [32] 孙冰. 线控转向系统冗余安全方案设计与测试研究[D]. 长春: 吉林大学, 2022.SUN B. Research on design and testing scheme for redundant security of steer-by-wire system[D]. Changchun: Jilin University, 2022(in Chinese). [33] PUTZ M H, SEIFERT H, ZACH M, et al. Functional safety (ASIL-D) for an electro mechanical brake[C]//Proceedings of the SAE Technical Paper Series. Warrendale: SAE International, 2016. [34] LEE K J, KI Y H, CHEON J S, et al. Approach to functional safety-compliant ECU design for electro-mechanical brake systems[J]. International Journal of Automotive Technology, 2014, 15(2): 325-332. doi: 10.1007/s12239-014-0033-7 [35] ANDERS N, ANDERS L, DONG X B. A brake system for a vehicle: WO2021139954A1[P]. 2021-07-01. [36] 尹荣彬, 陈博, 孔祥明. 智能网联汽车车载以太网技术应用研究[J]. 汽车文摘, 2019(11): 1-5.YIN R B, CHEN B, KONG X M. Research and application on Ethernet technologies for connected and intelligent vehicles[J]. Automotive Digest, 2019(11): 1-5(in Chinese). [37] Robert Bosch GmbH. Bosch automotive electrics and automotive electronics[M]. Wiesbaden: Springer Fachmedien Wiesbaden, 2014: 70-81. [38] 卢天义, 胡浩, 刘佳勇, 等. 一种电子机械制动EMB控制系统及汽车: CN115107722A[P]. 2022-09-27.LU T Y, HU H, LIU J Y, et al. Electromechanical braking (EMB) control system and automobile: CN115107722A[P]. 2022-09-27(in Chinese). [39] 张帅. 电子机械制动EMB控制策略研究 [D]. 西安: 长安大学, 2021.ZHANG S. Research on control strategy of electro-mechanical braking (EMB)[D]. Xi’an: Chang’an University, 2021(in Chinese). [40] LI Y J, SHIM T, SHIN D H, et al. Control system design for electromechanical brake system using novel clamping force model and estimator[J]. IEEE Transactions on Vehicular Technology, 2021, 70(9): 8653-8668. doi: 10.1109/TVT.2021.3095900 [41] WEI Z, XU J, HALIM D. Clamping force control of Sensor-less electro-mechanical brake actuator[C]//Proceedings of the IEEE International Conference on Mechatronics and Automation. Piscataway: IEEE Press, 2017: 764-769. [42] LINE C, MANZIE C, GOOD M C. Electromechanical brake modeling and control: from PI to MPC[J]. IEEE Transactions on Control Systems Technology, 2008, 16(3): 446-457. doi: 10.1109/TCST.2007.908200 [43] DE CASTRO R, TODESCHINI F, ARAÚJO R E, et al. Adaptive-robust friction compensation in a hybrid brake-by-wire actuator[J]. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2014, 228(10): 769-786. doi: 10.1177/0959651813507562 [44] LEE C F, MANZIE C. Active brake judder attenuation using an electromechanical brake-by-wire system[J]. IEEE/ASME Transactions on Mechatronics, 2016, 21(6): 2964-2976. doi: 10.1109/TMECH.2016.2571318 [45] 赵逸云, 林辉, 李兵强. 电子机械制动系统无压力传感器控制策略[J]. 北京航空航天大学学报, 2023, 49(10): 2711-2720.ZHAO Y Y, LIN H, LI B Q. Clamping force sensorless control strategies for electromechanical brake systems[J]. Journal of Beijing University of Aeronautics and Astronautics, 2023, 49(10): 2711-2720(in Chinese). [46] KWON S, LEE S, LEE J, et al. Accurate state estimation for electro-mechanical brake systems[J]. Journal of Electrical Engineering & Technology, 2019, 14(2): 889-896. [47] XU Z, GERADA C. Enhanced force estimation for electromechanical brake actuators in transportation vehicles[J]. IEEE Transactions on Power Electronics, 2021, 36(12): 14329-14339. doi: 10.1109/TPEL.2021.3085996 [48] FU Y F, HU X H, WANG W R, et al. Simulation and experimental study of a new electromechanical brake with automatic wear adjustment function[J]. International Journal of Automotive Technology, 2020, 21(1): 227-238. doi: 10.1007/s12239-020-0022-y [49] 张峻峰, 张俊智, 季园, 等. 一种夹紧力估计系统、夹紧力控制方法及汽车制动系统: CN115431938A[P]. 2022-12-06.ZHANG J F, ZAHNG J Z, JI Y, et al. Clamping force estimation system, clamping force control method and automobile braking system: CN115431938A[P]. 2022-12-06(in Chinese). [50] 林东焕. 电子机械制动器: CN115771488A[P]. 2023-03-10.LIN D H. Electro-hydraulic brake: CN115771488A[P]. 2023-03-10(in Chinese). [51] RIVA G, FORMENTIN S, SAVARESI S M. Force estimation in electro-mechanical systems: theory and experiments[C]//Proceedings of the IEEE Conference on Control Technology and Applications. Piscataway: IEEE Press, 2021: 992-997. [52] 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 乘用车制动系统技术要求及试验方法:GB 21670—2008[S]. 北京:中国标准出版社, 2008.General Administration of Quality Supervision, Inspectionand Quarantine, Standardization Administration of China. Technical requirements and testing methods for passenger car braking systems: GB 21670—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [53] 高惠民. 新能源汽车制动系统解析(三)[J]. 汽车维修与保养, 2022(5): 53-56.GAO H M. Analysis of new energy vehicle braking system (Ⅲ)[J]. Motor China, 2022(5): 53-56(in Chinese). [54] 陈韦纲. 线控液压制动系统制动力分配与控制策略研究[D]. 长春: 吉林大学, 2022.CHEN W G. Research on braking force distribution and control of hydraulic brake-by-wire system[D]. Changchun: Jilin University, 2022(in Chinese). -

下载:

下载: