Research on constitutive parameters of high-efficiency inverted metamorphic GaAs triple junction solar cell for space applications

-

摘要:

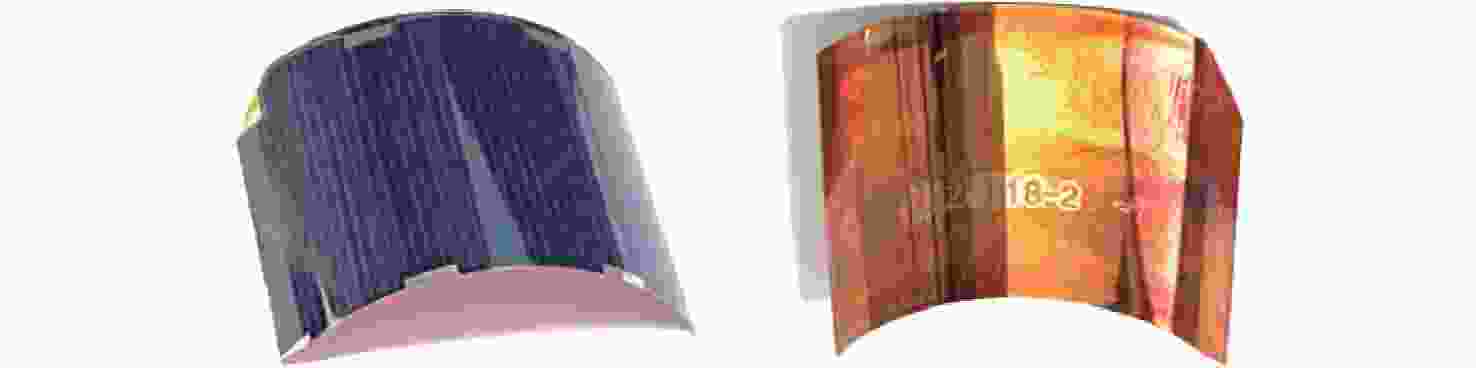

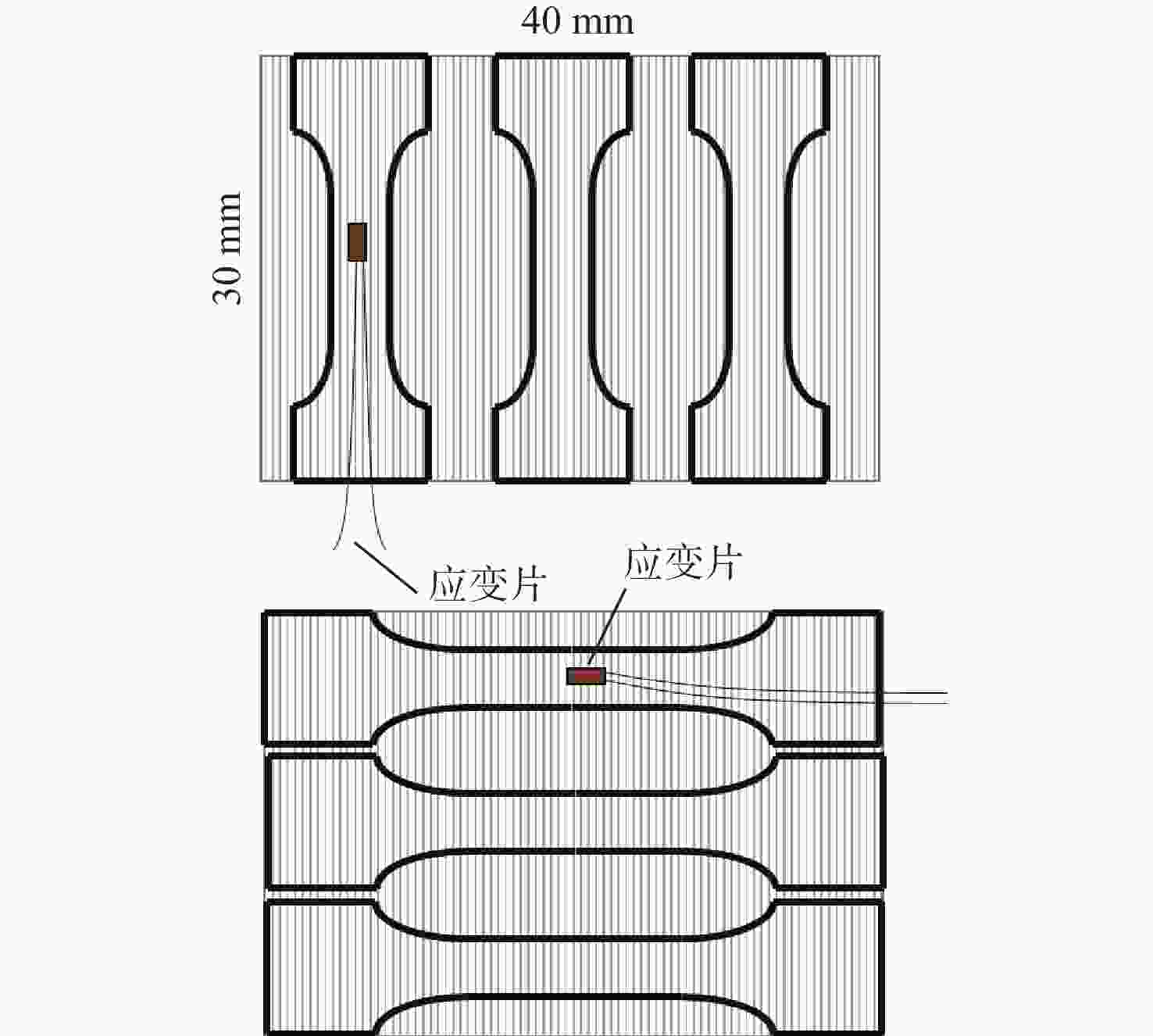

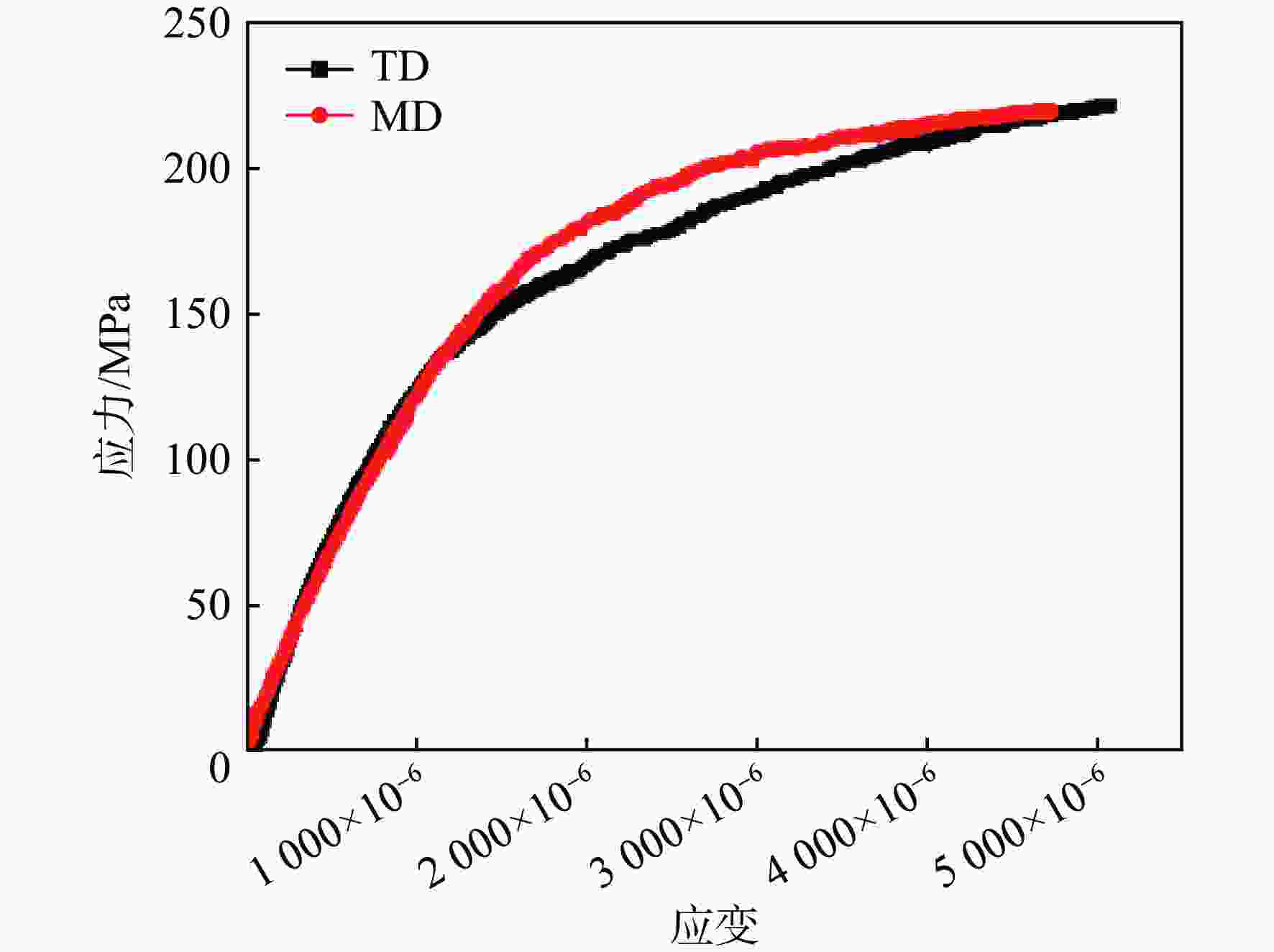

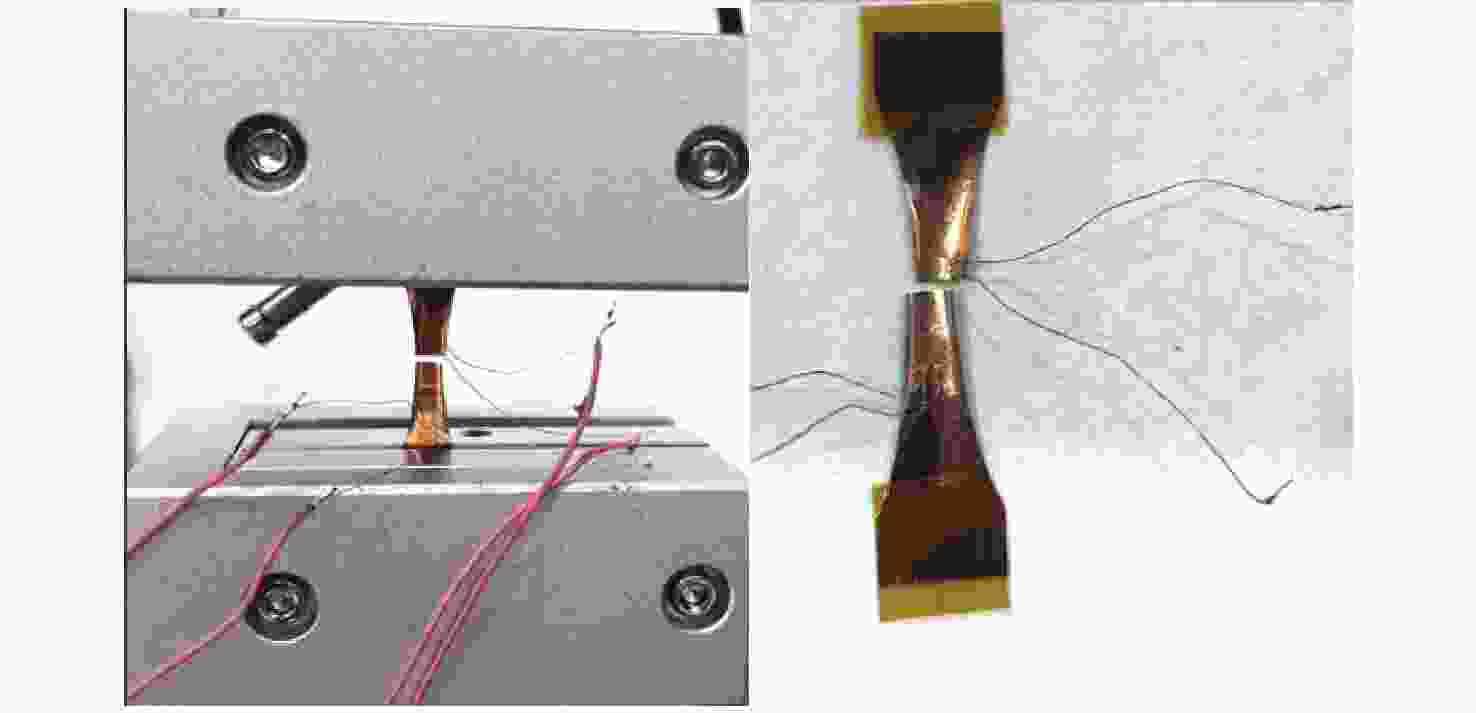

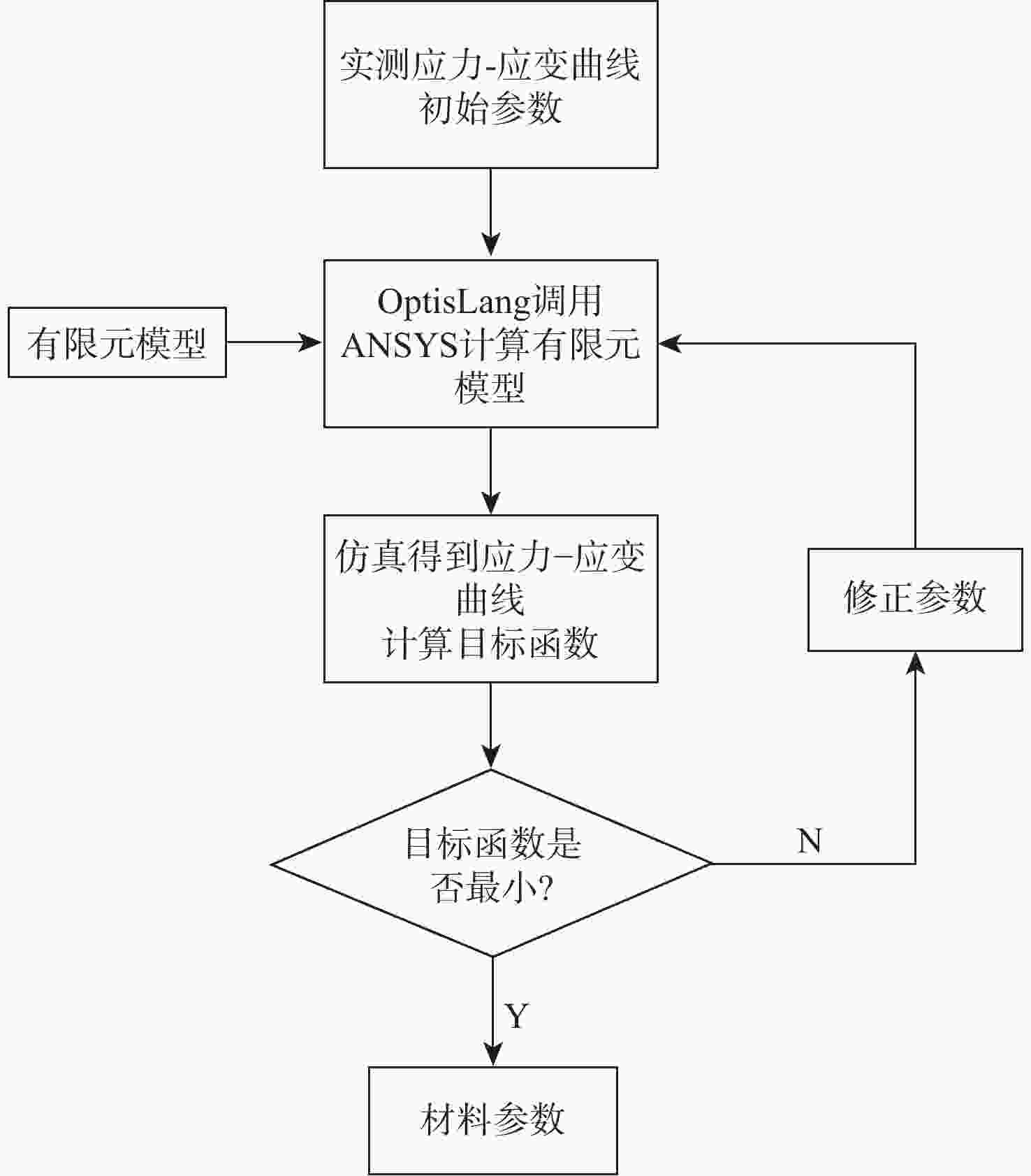

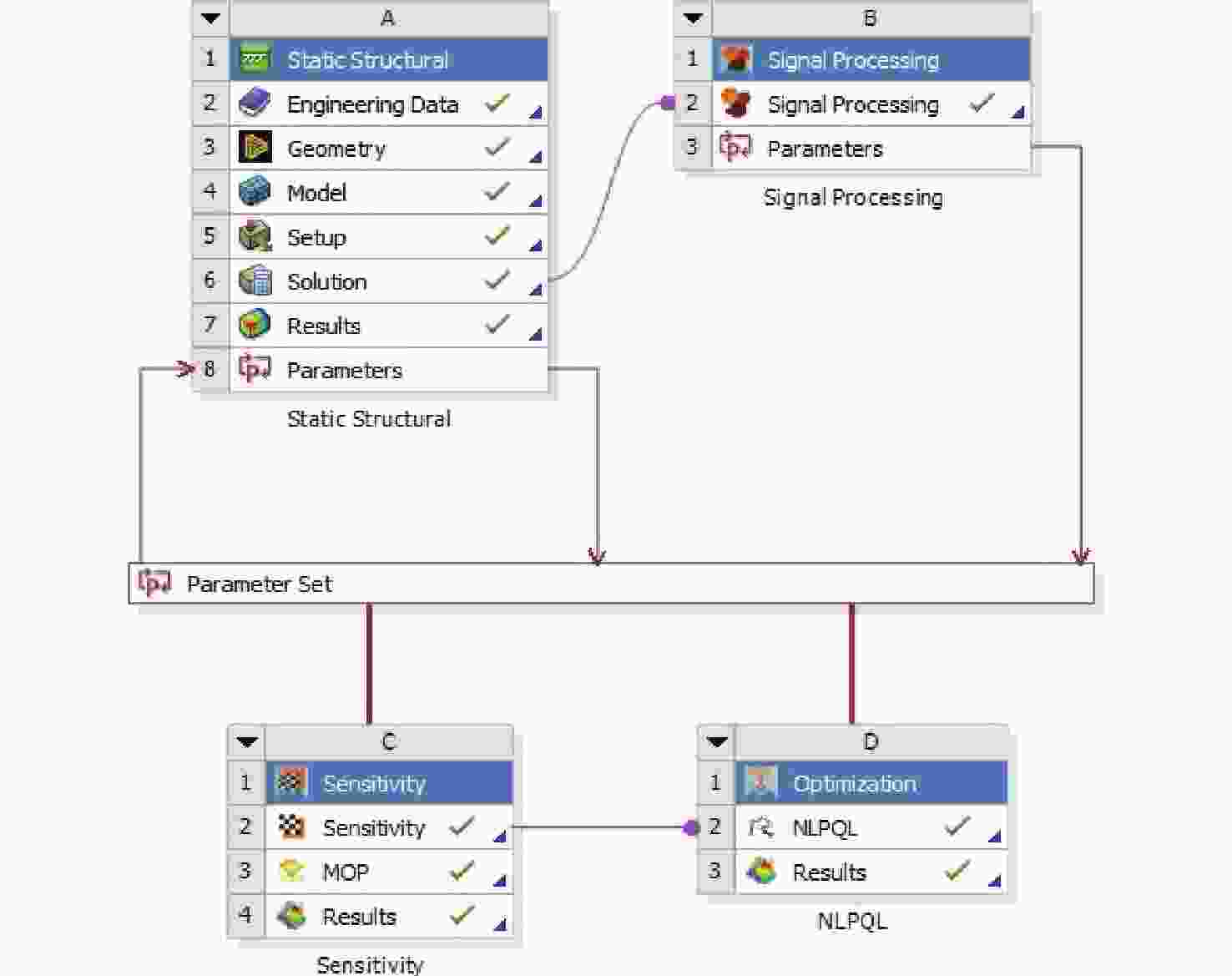

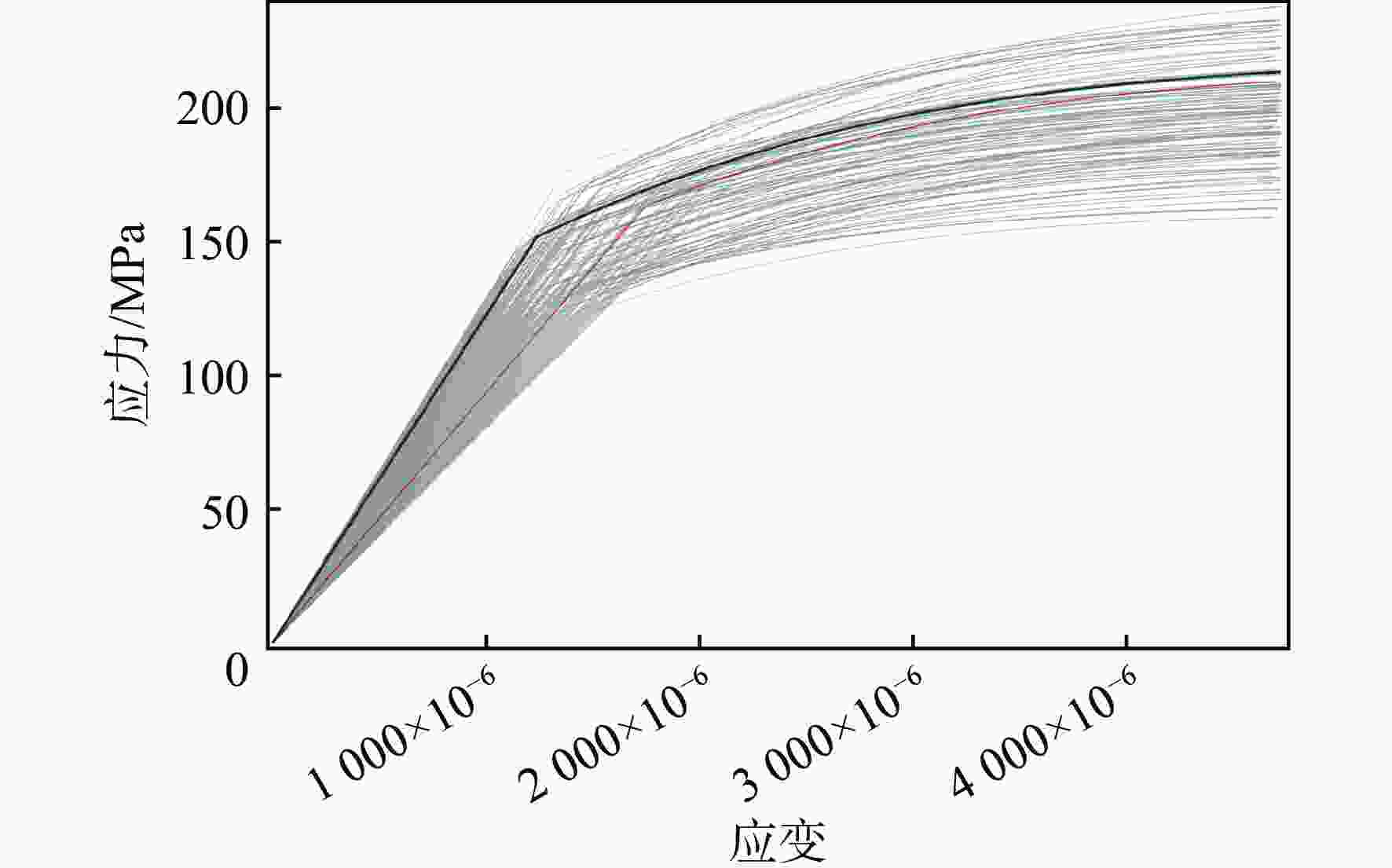

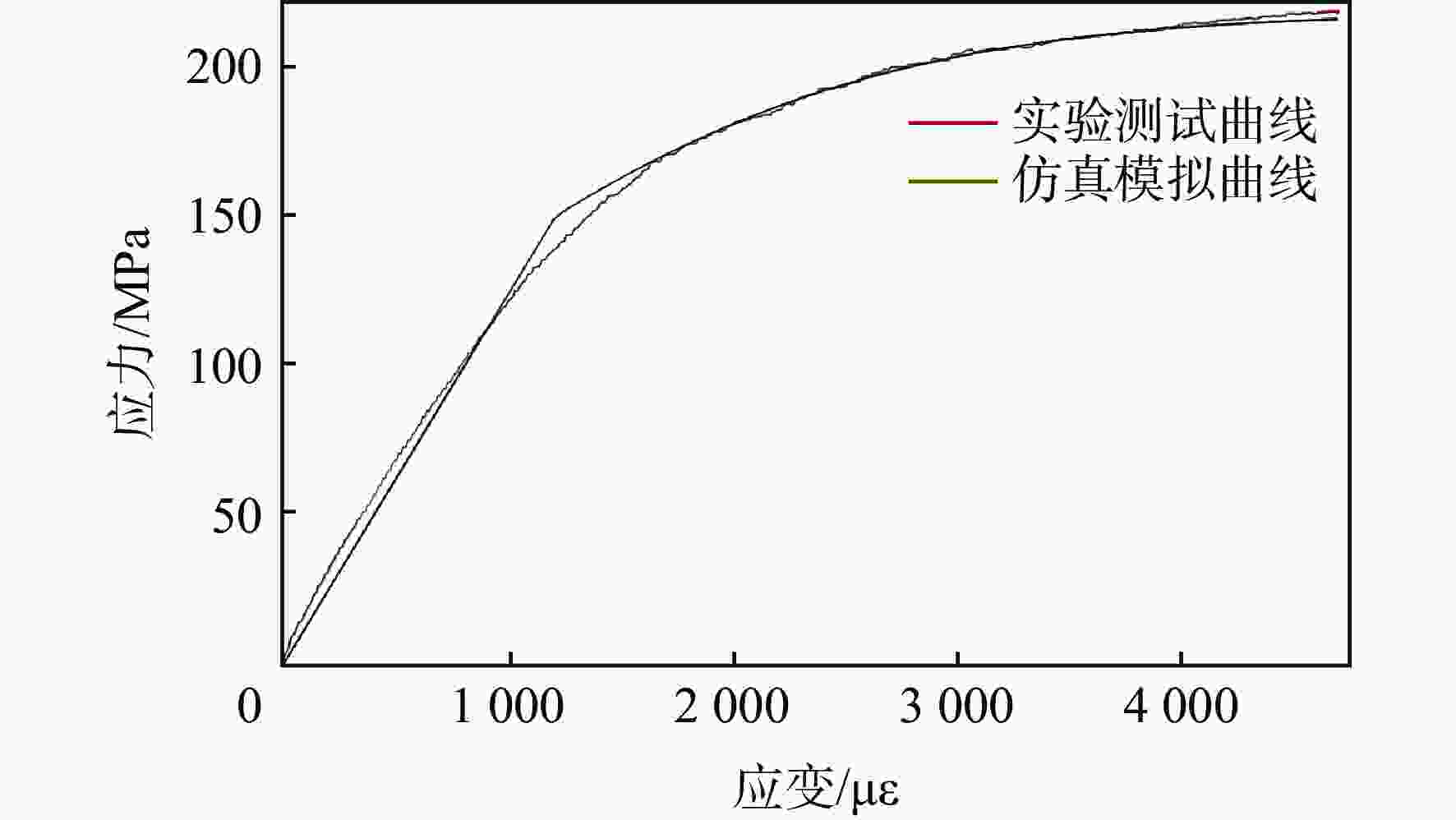

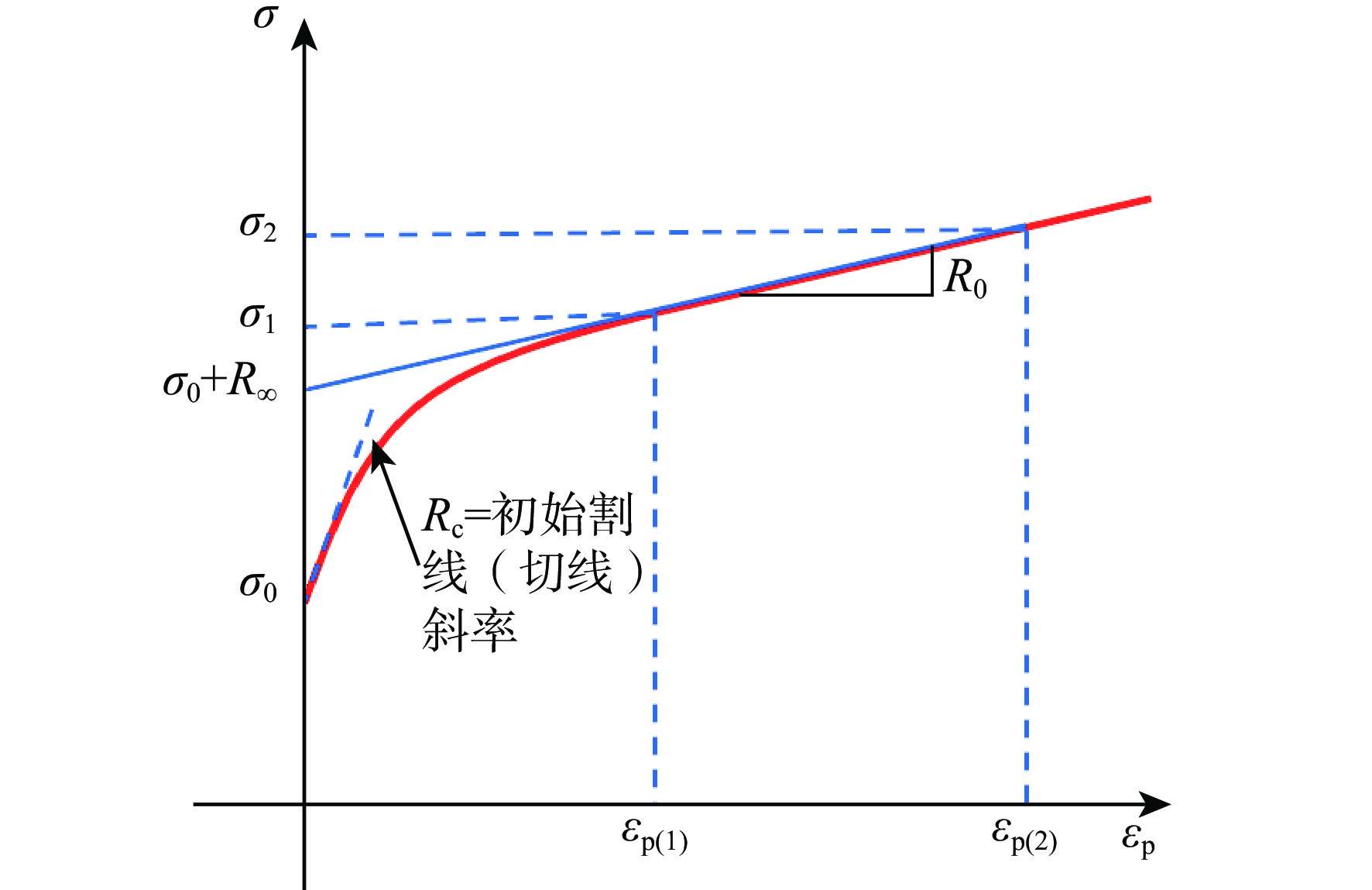

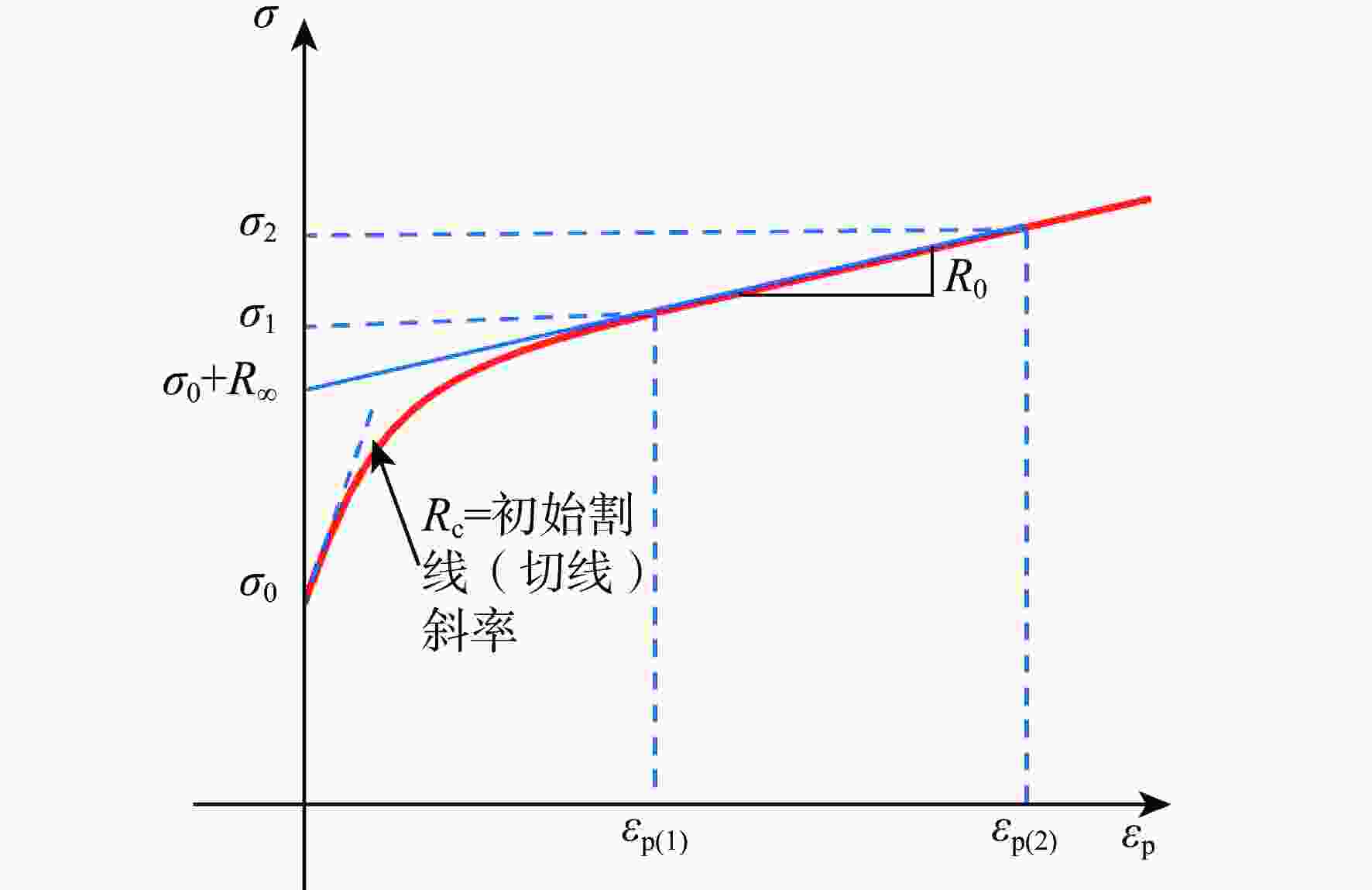

倒置结构三结砷化镓薄膜(IMM)太阳电池由于很好地解决了多结电池带隙不匹配的问题,因此获得更高的光电转换效率,为下一代空间用太阳电池提供了一种选择。IMM太阳电池具有塑性材料的力学特性,区别于传统三结砷化镓薄膜电池的脆性材料特性,所以IMM太阳电池本构模型的准确性是仿真其抗力学环境影响的关键因素。所提方法利用Voce本构模型对IMM太阳电池进行拉伸试验模拟,并在ANSYS-OptiSLang联合仿真平台上采用非线性二次规划算法优化本构模型参数。通过将数值模拟结果与实际试验数据进行比对,并将其差异作为目标函数进行最小化,成功获得了与试验测试结果非常接近的应力-应变曲线。结果表明:所提方法建立的IMM太阳电池本构模型可在后续其他力学仿真分析中使用。

-

关键词:

- 倒置结构三结砷化镓太阳电池 /

- Voce本构模型 /

- ANSYS-OptiSLang联合仿真 /

- 本构反演优化 /

- 非线性二次规划算法

Abstract:Another option for the next generation of solar cells for space applications is the inverted metamorphic (IMM) GaAs triple junction solar cell, which has a greater photoelectric conversion efficiency since it significantly addresses the current issue of subcell mismatch. IMM solar cells have the mechanical properties of ductile materials, which are different from the brittle materials properties of conventional GaAs triple junction solar cells; therefore, the accuracy of the constitutive model of IMM solar cells is a key factor in simulating its resistance to the mechanical environment. In this paper, the Voce constitutive model is used to simulate the tensile experimental process of IMM solar cells. On the basis of the ANSYS-OptiSlang co-simulation platform, the NLPQL optimization algorithm is used, and the tensile experimental validation is combined to form the objective function with the difference between the numerical simulation and experimental data. Then, the objective function is minimized to acquire the parameters of the constitutive model. The results indicate that the stress-strain curves calculated by the inverse optimization method are very similar to the experimental results. The ensuing mechanical simulation analysis can make use of the IMM solar cell constitutive model that was created using this technique.

-

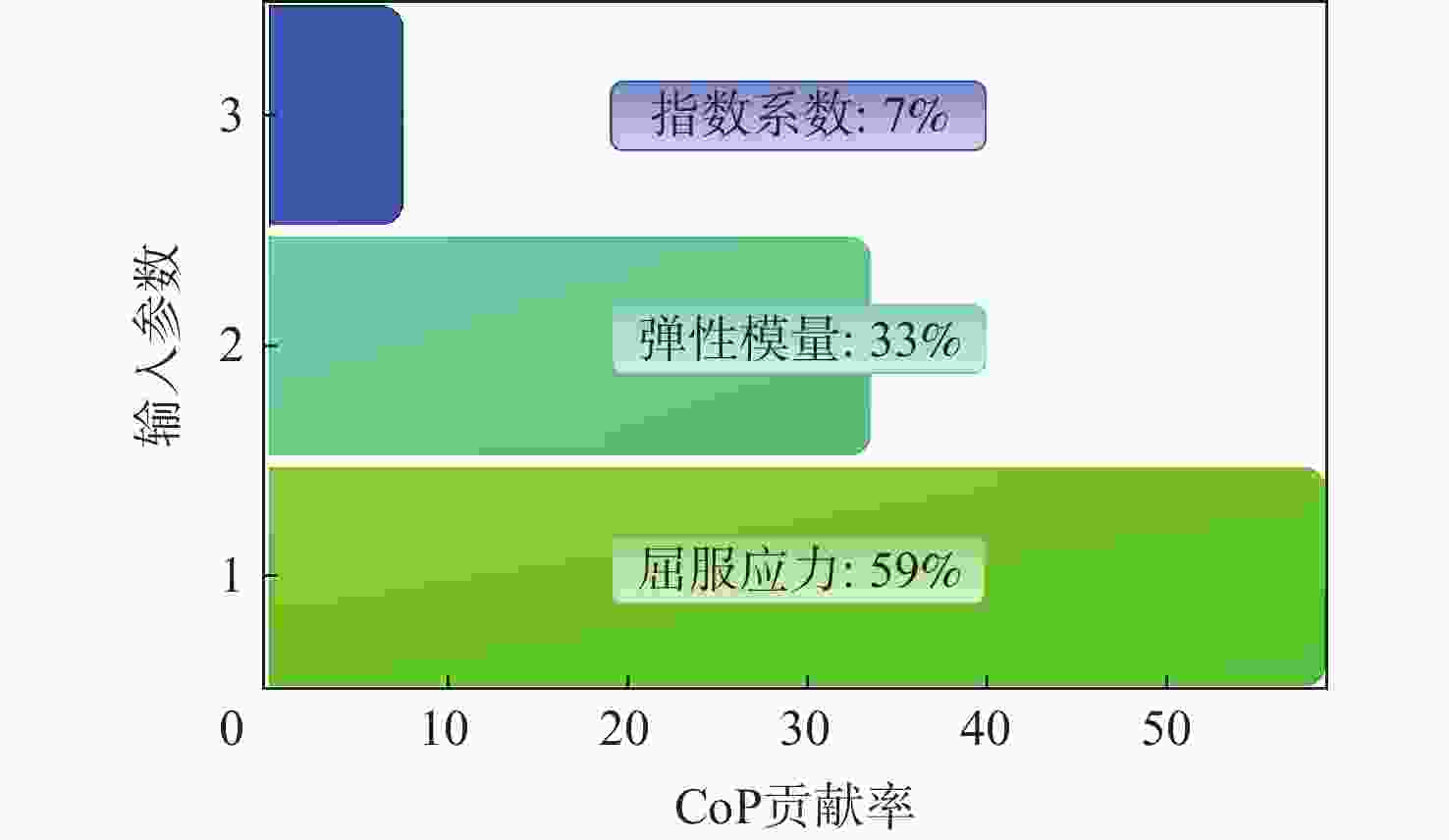

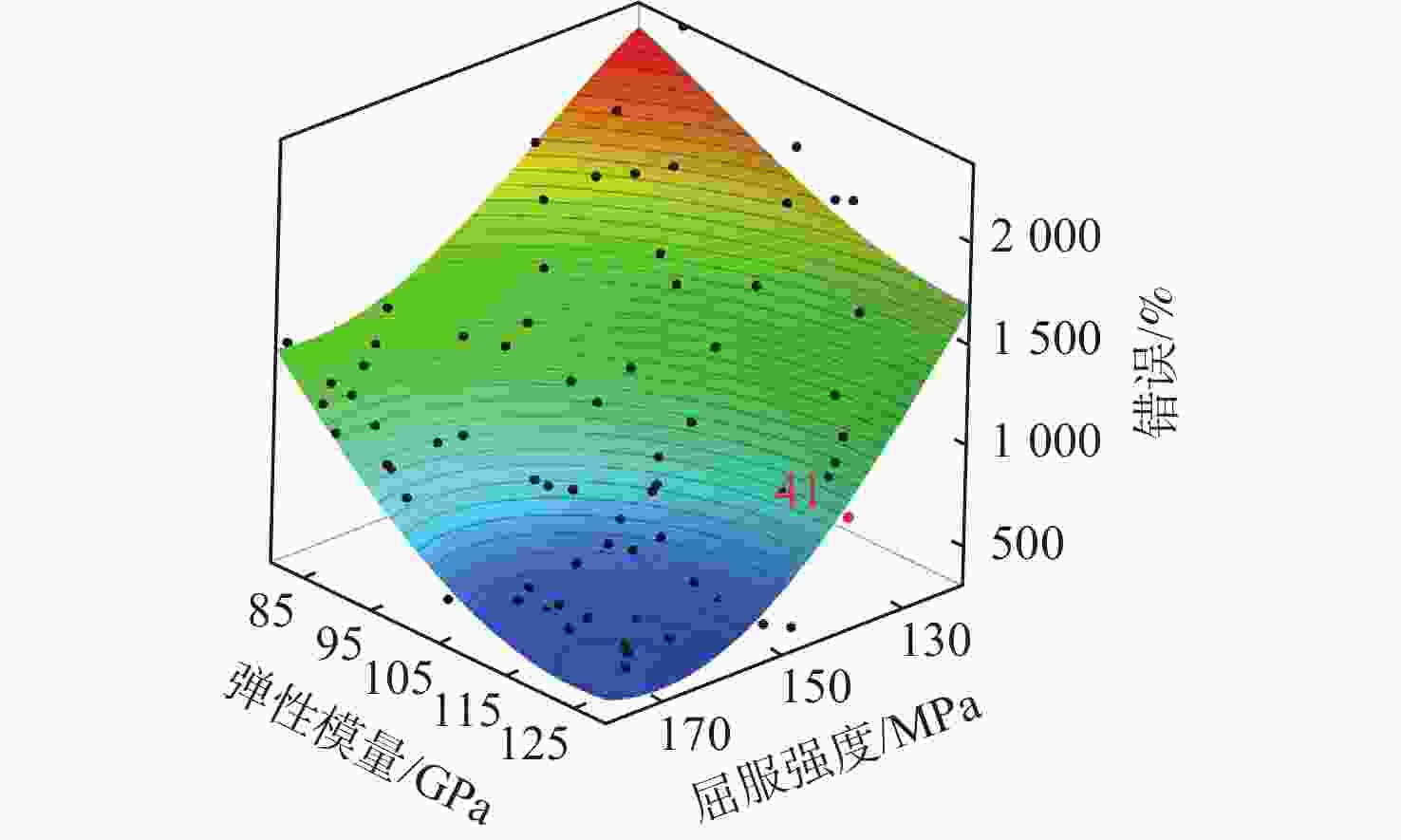

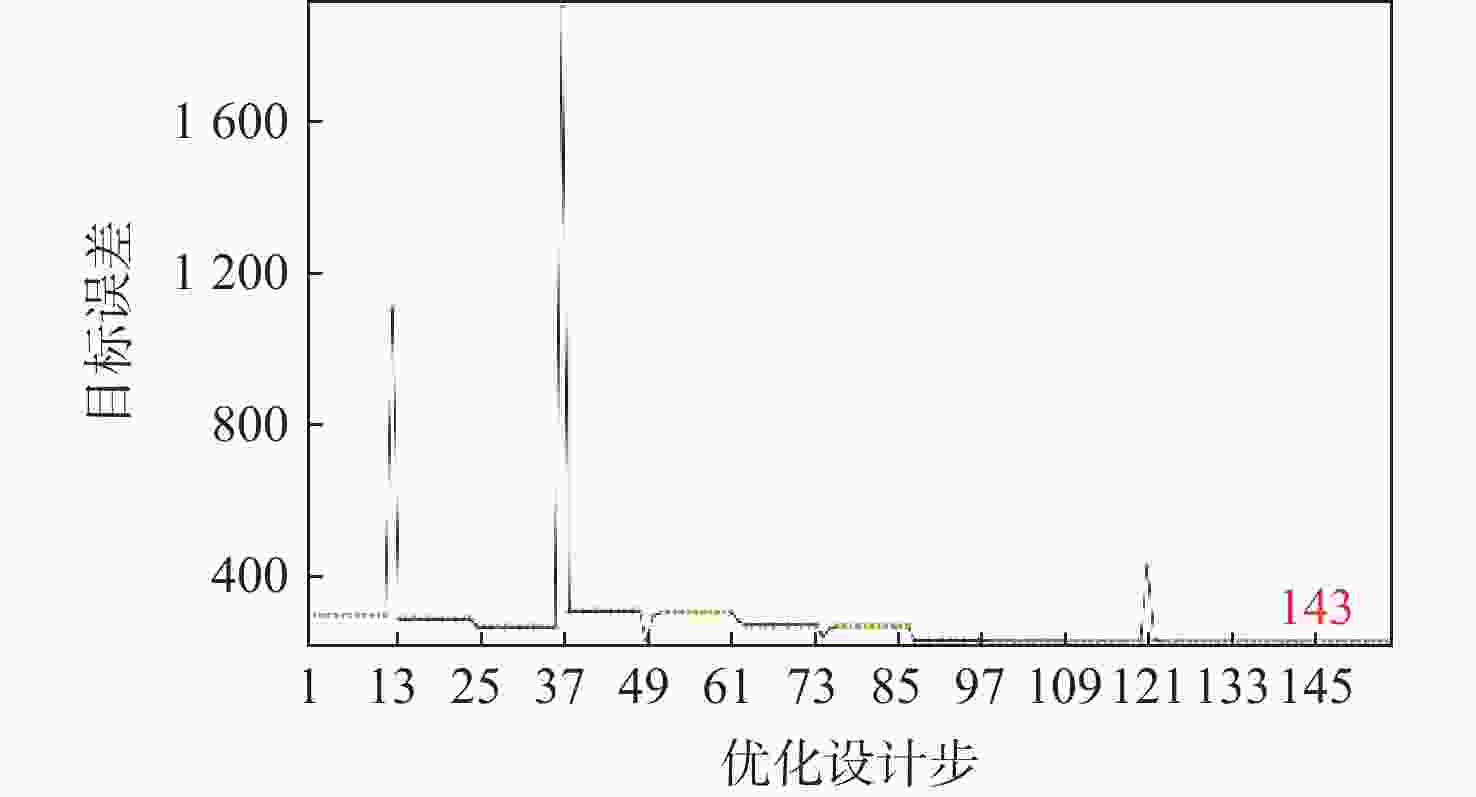

表 1 输入参数的设计空间

Table 1. Input Parameter Design Space

参数值 弹性模量/

GPa屈服应力/

MPa线性

系数指数

系数饱和应力/

MPa初始值 106 158 0 58 878 参数值范围 80~130 120~180 0~100 40~70 700~1 100 表 2 最佳设计点参数与初始参数对比

Table 2. Comparison of best design point parameters with initial parameters

参数值 弹性模量/

GPa屈服应力/

MPa线性

系数指数

系数饱和应力/

MPa$\sqrt{\displaystyle\sum _{i=1}^{150}{({y}_{i}^{*}-{y}_{i})}^{2}} $ 初始值 106 158 0 58 878 627.5 最佳值 124.14 150.98 8.68 70 1 100 276.6 -

[1] GUTER W, DUNZER F, EBEL L, et al. Space solar cells–3G30 and next generation radiation hard products[J]. E3S Web of Conferences, 2017, 16: 03005. doi: 10.1051/e3sconf/20171603005 [2] STAN M, AIKEN D, CHO B, et al. Very high efficiency triple junction solar cells grown by MOVPE[J]. Journal of Crystal Growth, 2008, 310(23): 5204-5208. doi: 10.1016/j.jcrysgro.2008.07.024 [3] LI J, AIERKEN A, ZHUANG Y, et al. 1 MeV electron and 10 MeV proton irradiation effects on inverted metamorphic GaInP/GaAs/InGaAs triple junction solar cell[J]. Solar Energy Materials and Solar Cells, 2021, 224: 111022. doi: 10.1016/j.solmat.2021.111022 [4] QIAN M, ZHANG Y, MAO X J, et al. Flexible photoelectronic material device and investigation method for space applications[J]. Progress in Aerospace Sciences, 2023, 139: 100901. doi: 10.1016/j.paerosci.2023.100901 [5] SONG M-H, WANG D-X, BI J-F, et al. Inverted metamorphic triple-junction solar cell and its radiation hardness for space applications[J]. Acta Physica Sinica, 2017, 66(18): 188801. doi: 10.7498/aps.66.188801 [6] 周南. 柔性薄膜太阳能电池力学性能及其在膜结构中的应用研究[D]. 杭州: 浙江大学, 2010: 18-21.ZHOU, N. Mechanical properties of flexible thin film solar cells and its applied research in membrane structure[D]. Hangzhou: Zhejiang University, 2010: 18-21(in Chinese). [7] WAKAYAMA S, MIZUTANI A. AE analysis of damage process in thin film solar cells under mechanical strain[C]//Proceedings of the 29th European Conference on Acoustic Emission Testing. Vienna: eTNDT, 2010: 62. [8] 汪冠宇, 马贵春, 吴建军. 2099-T83铝锂合金本构模型研究[J]. 塑性工程学报, 2019, 26(1): 174-181.WANG G Y, MA G C, WU J J. Research on constitutive model of 2099-T83 aluminum-lithium alloy[J]. Journal of Plasticity Engineering, 2019, 26(1): 174-181(in Chinese). [9] 董菲, GERMAIN G, LEBRUN J, 等. 有限元分析法确定Johson-Cook本构方程材料参数[J]. 上海交通大学学报, 2011, 45(11): 1657-1660,1667.DONG F, GERMAIN G, LEBRUN J, et al. Identification of Johnson-cook constitutive model by finite element analysis[J]. Journal of Shanghai Jiao Tong University, 2011, 45(11): 1657-1660,1667(in Chinese). [10] SAINATH G, CHOUDHARY B K, CHRISTOPHER J, et al. Applicability of voce equation for tensile flow and work hardening behaviour of P92 ferritic steel[J]. International Journal of Pressure Vessels and Piping, 2015, 132: 1-9. [11] ASTM International. Standard test methods of tension testing of metallic foil: ASTM E345-24a[S]. West Conshohocken: ASTM International, 2024: 1-8. [12] 李璐璐, 周蕊, 张建国, 等. 基于ABAQUS-MATLAB联合仿真反演优化确定金属粉末成形本构模型参数[J]. 中国有色金属学报, 2018, 28(7): 1387-1393.LI L L, ZHOU R, ZHANG J G, et al. Inversion optimization of constitutive model parameters of metal powder forming based on ABAQUS-MATLAB joint simulation[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(7): 1387-1393(in Chinese). [13] TINCA I E, AILINEI I I, DAVIDESCU A. Printed circuit board orthotropic material calibration for static and dynamic loading[C]//Proceedings of the 2022 IEEE 9th Electronics System-Integration Technology Conference. Piscataway: IEEE Press, 2022: 194-202. [14] 李洋, 桑建兵, 敖日汗, 等. 基于仿真和智能算法骨骼肌超弹性本构参数的反演方法研究[J]. 力学学报, 2021, 53(5): 1449-1456.LI Y, SANG J B, AO R H, et al. Research on inversion method of hyperelastic constitutive parameters of skeletal muscles based on simulation and intelligent algorithm[J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(5): 1449-1456(in Chinese). [15] KAŇÁKOVÁ S, KOTTNER R. Identification of material properties of foam used in motorcyclist protective equipment based on obtained experimental data and optimization algorithm[J]. Applied and Computational Mechanics, 2018, 12(2): 139-146. [16] 徐晓宏, 赵万忠, 王春燕, 等. 基于NLPQL算法的电动轮汽车差速助力转向参数优化[J]. 中南大学学报(自然科学版), 2012, 43(9): 3431-3436.XU X H, ZHAO W Z, WANG C Y, et al. Parameters optimization of differential assisted steering for electric vehicle with motorized wheels based on NLPQL algorithm[J]. Journal of Central South University (Science and Technology), 2012, 43(9): 3431-3436(in Chinese). [17] TAGHAVIFAR H, ANVARI S. Optimization of a DI diesel engine to reduce emission and boost power by exergy and NLPQL method[J]. Environmental Progress & Sustainable Energy, 2020, 39(2): e13338. [18] DUBEC B, MAŇAS P, ŠTOLLER J, et al. Numerical identification of material model parameters of UHPFRC slab under blast loading[J]. Applied Sciences, 2023, 13(1): 70. [19] CADA Z, HRADIL P, MROZEK M. Parametric study on dynamic behaviour of a multi-storey building including soil-structure interaction[C]//Proceedings of the 17th International Conference on Engineering Mechanics. Svratka: ACM, 2011: 91-94. -

下载:

下载: