-

摘要:

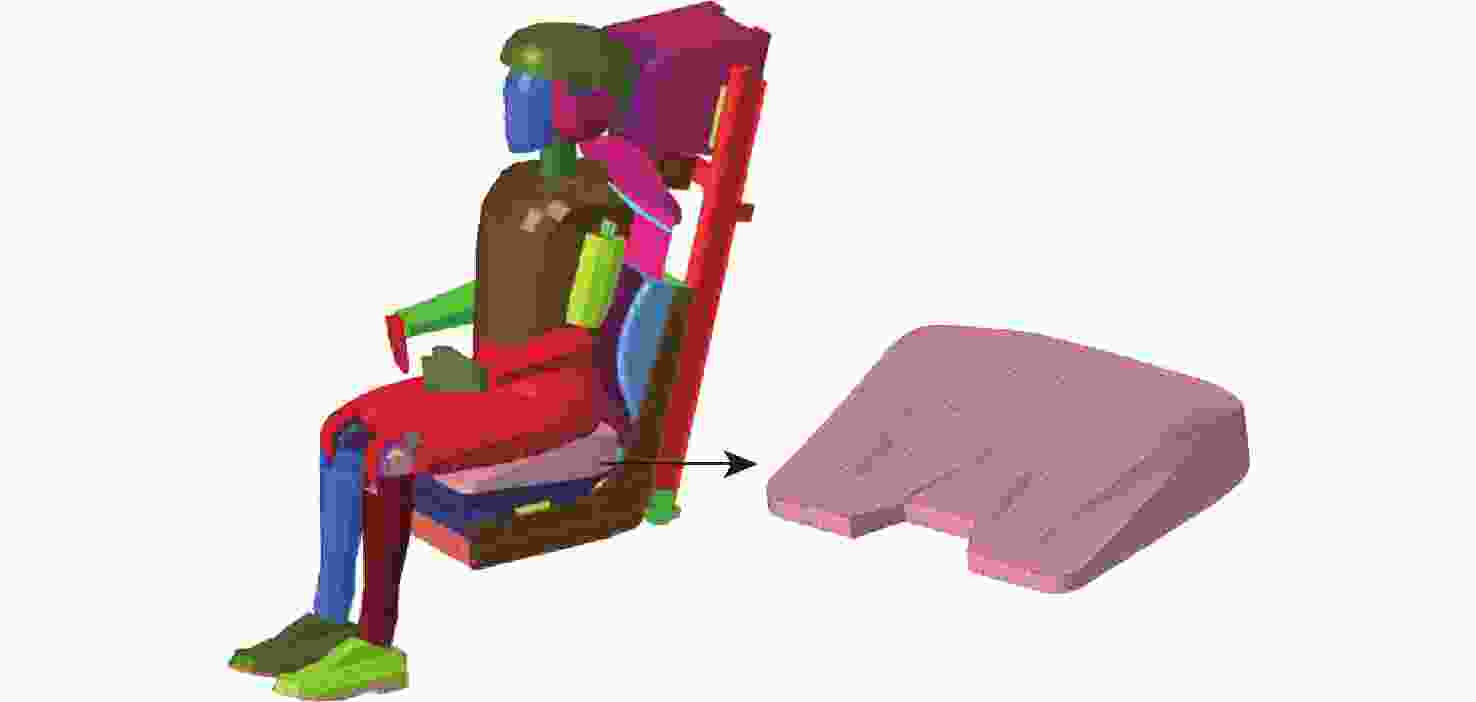

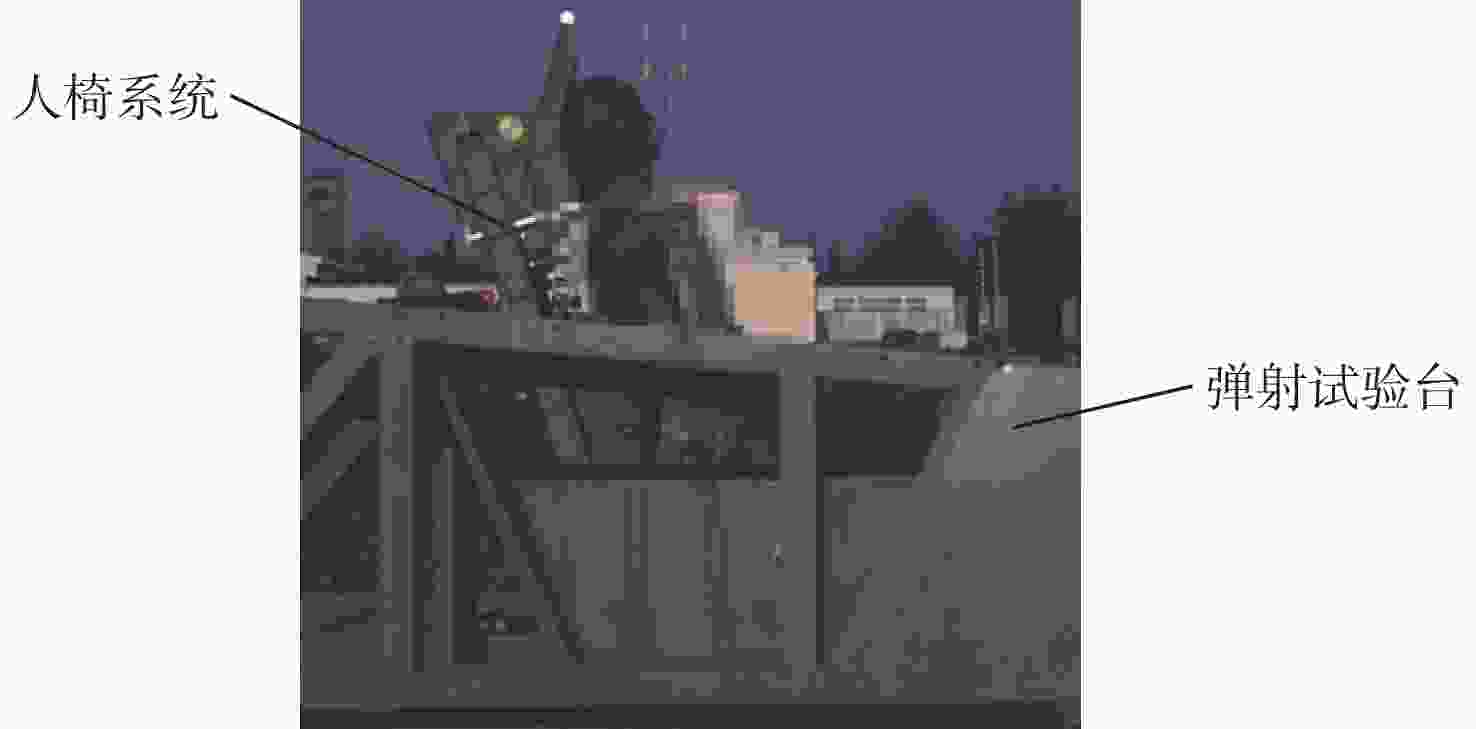

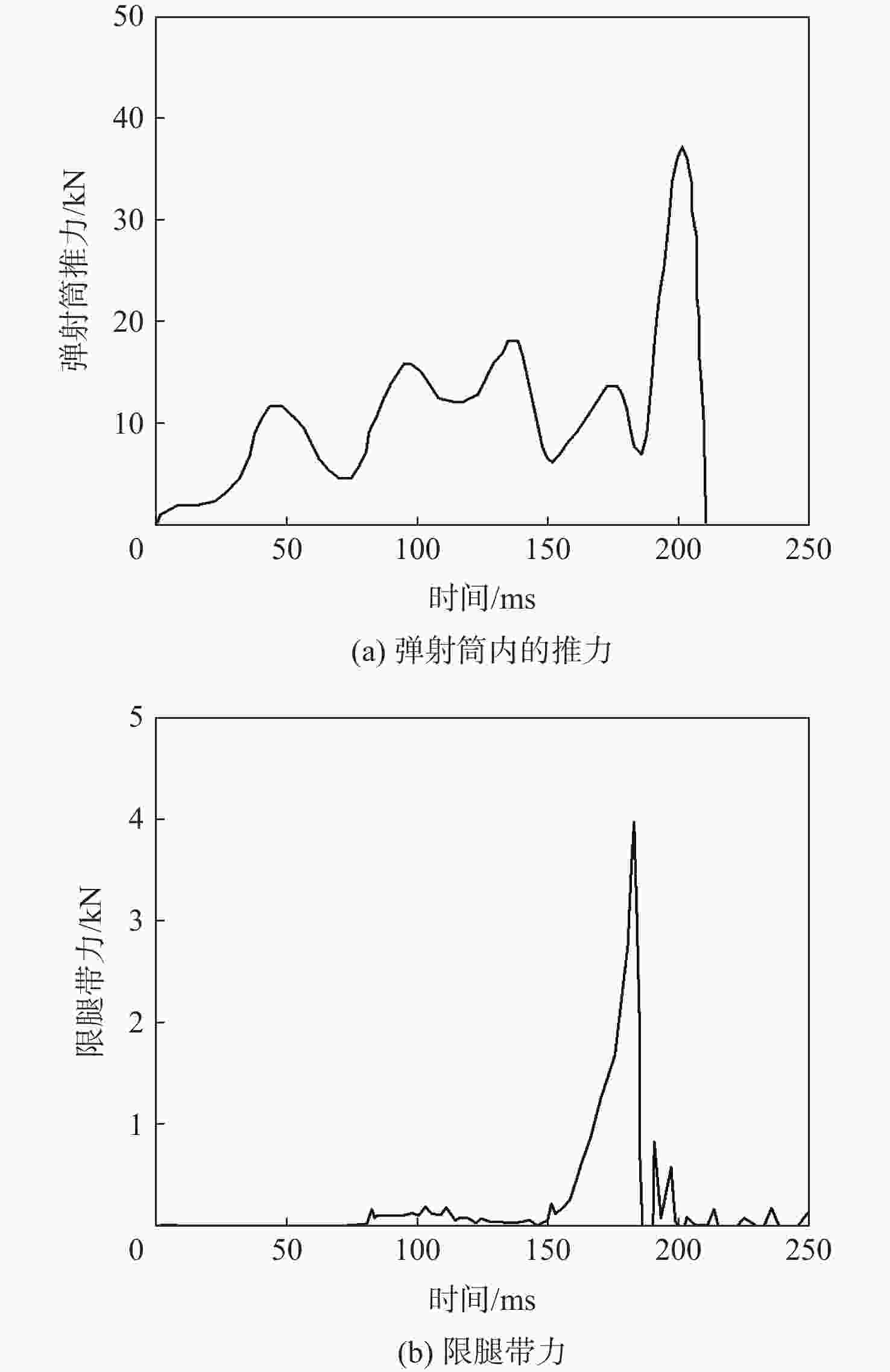

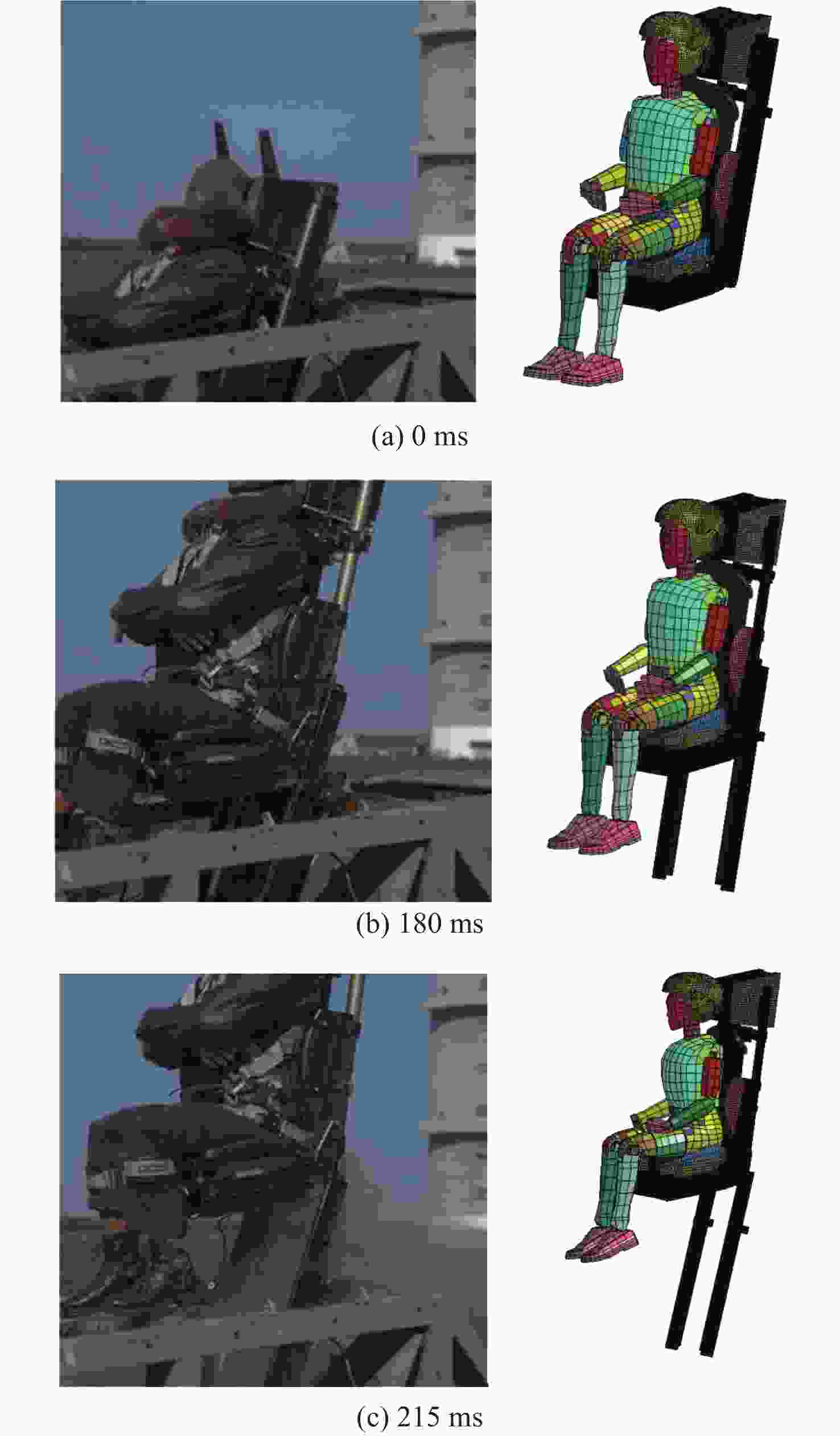

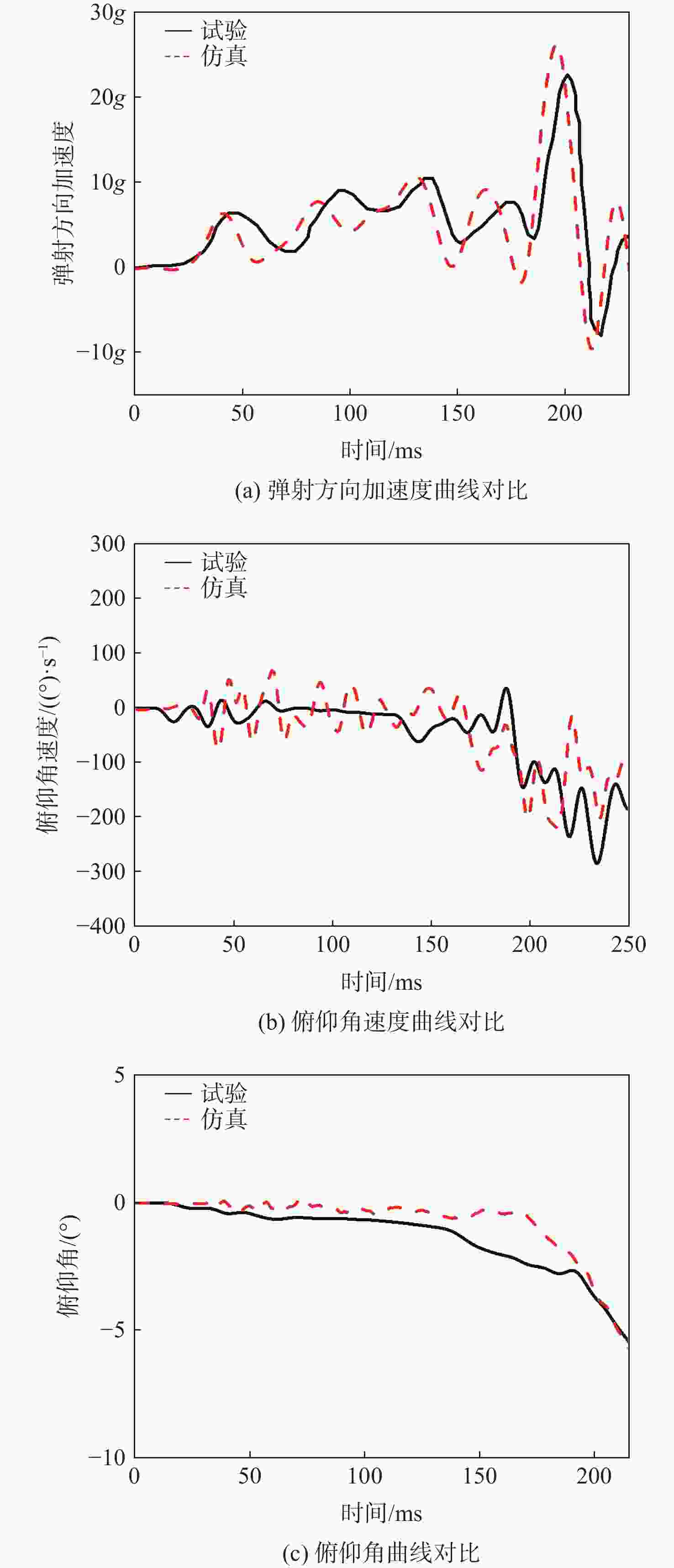

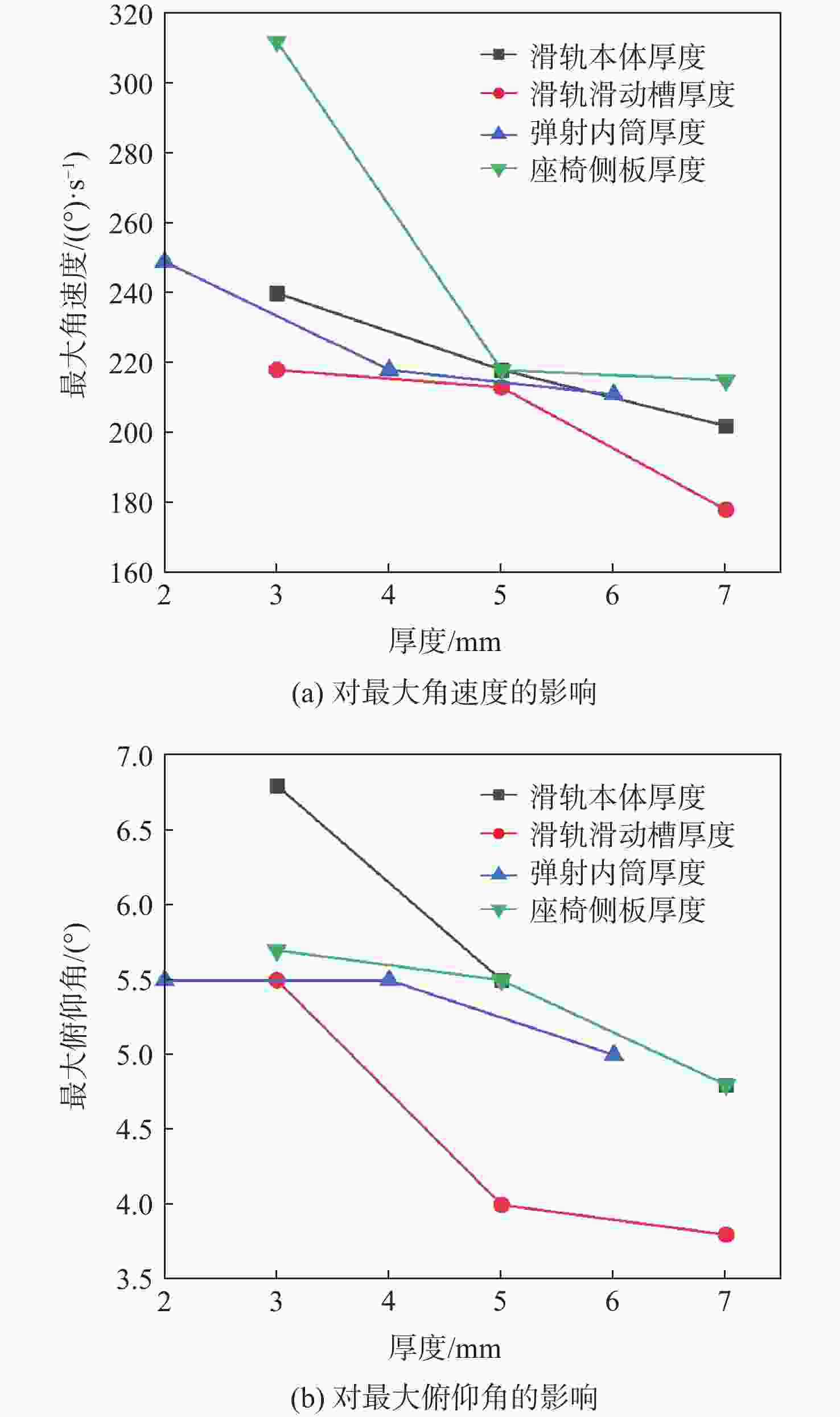

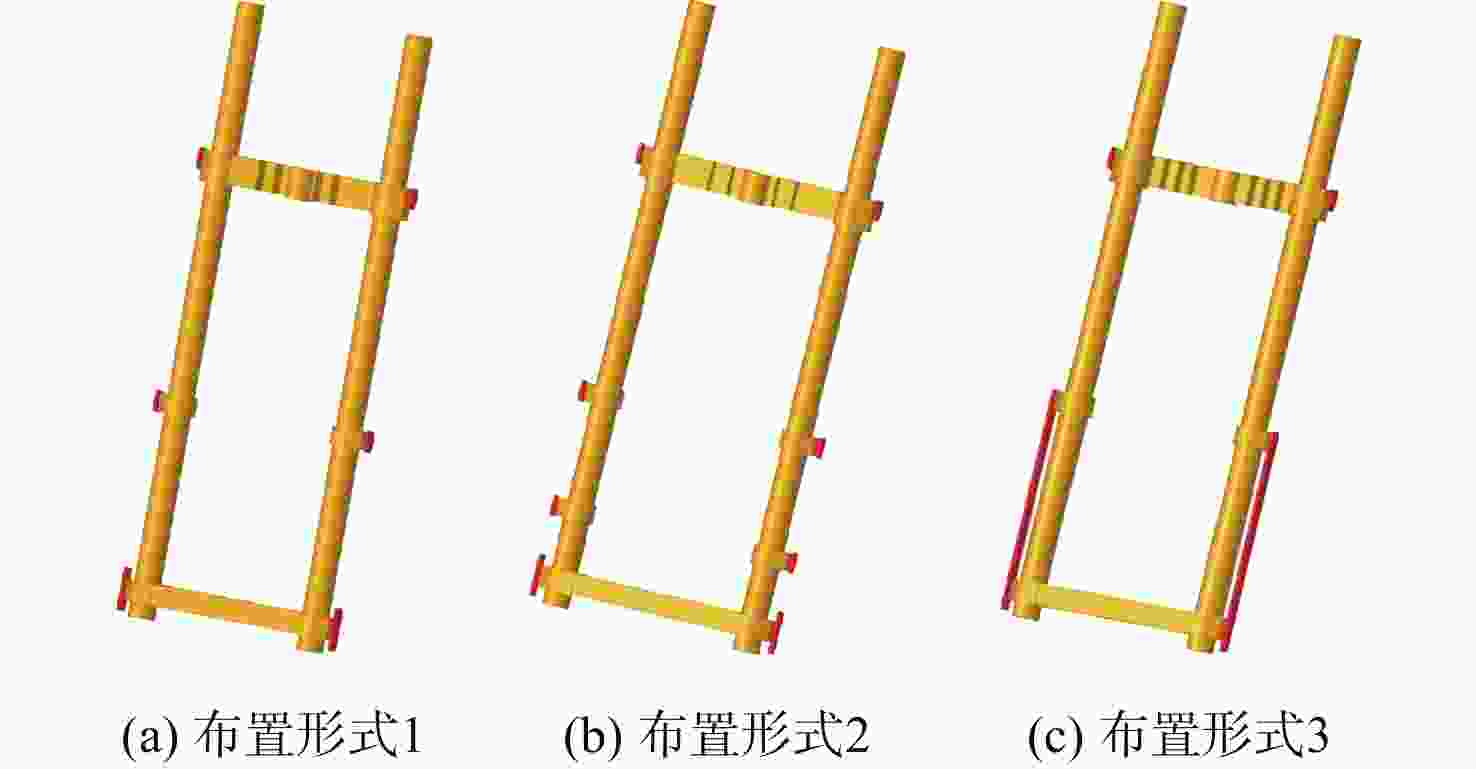

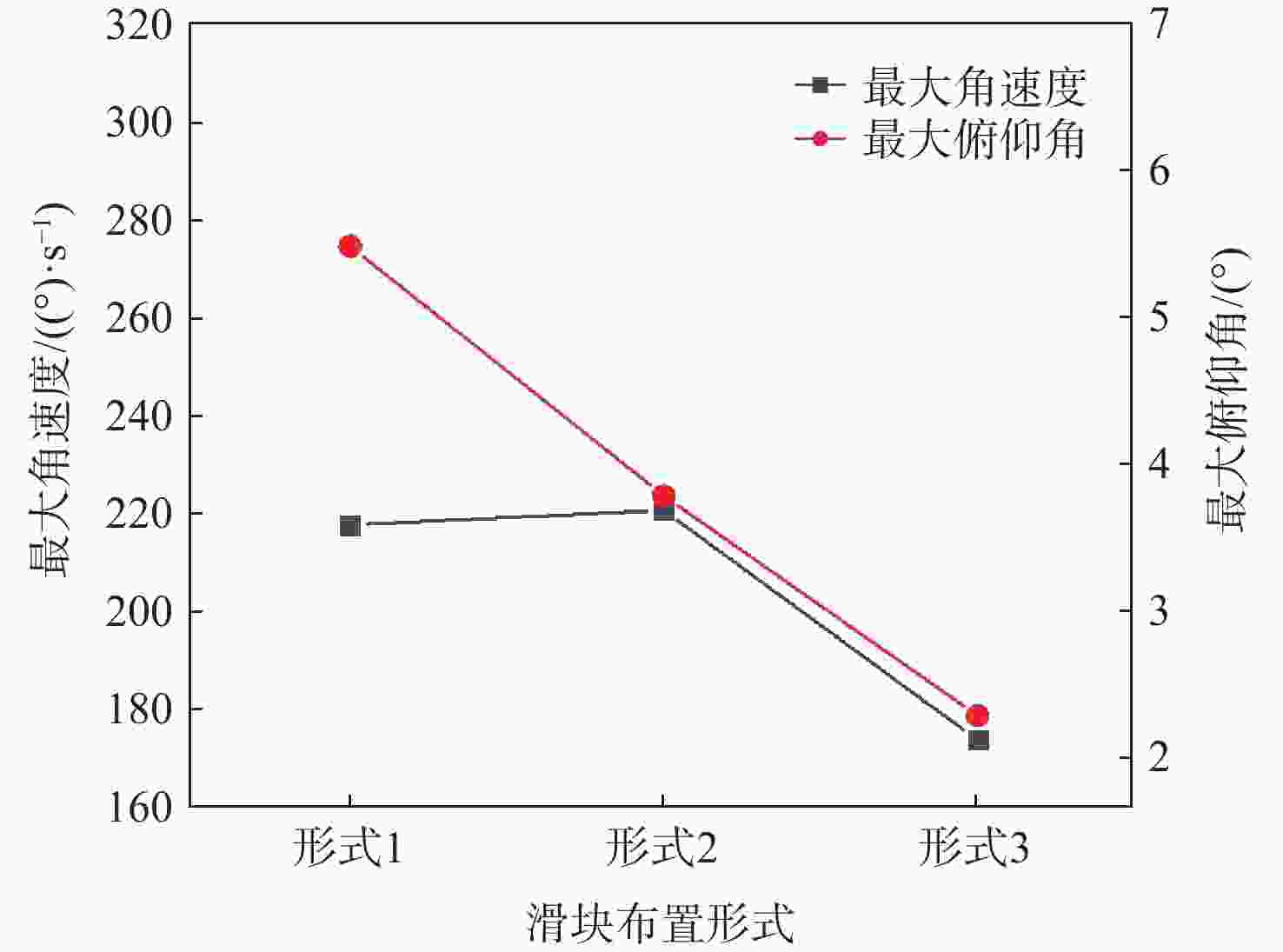

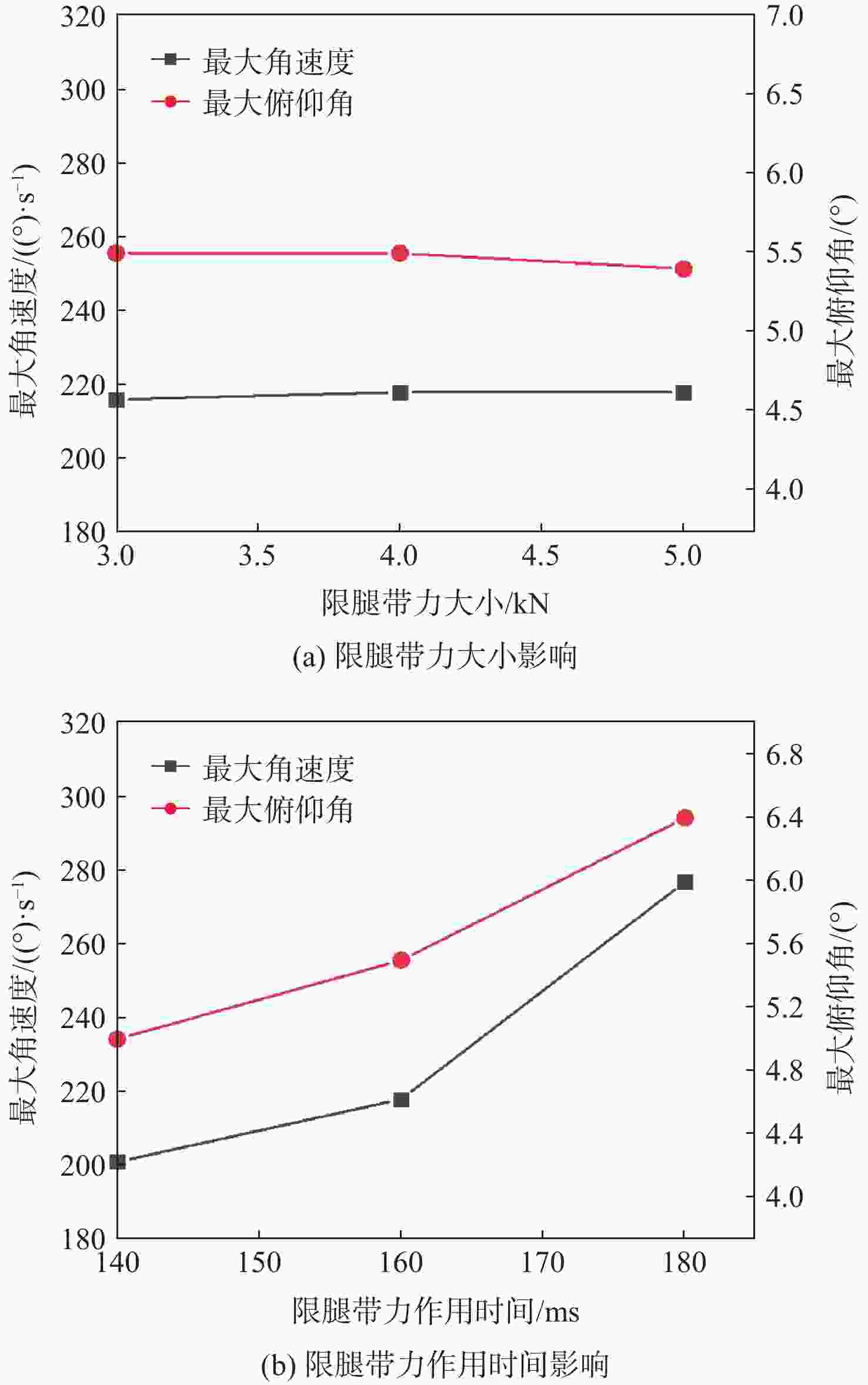

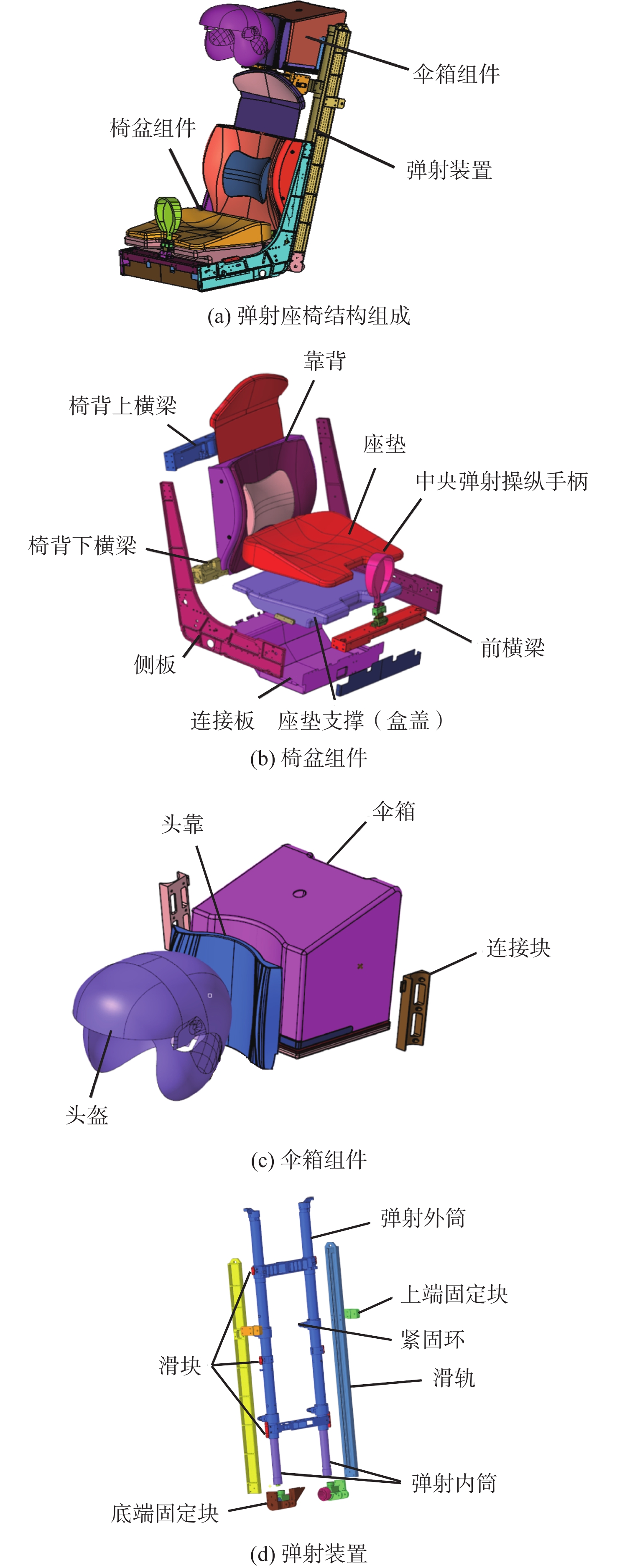

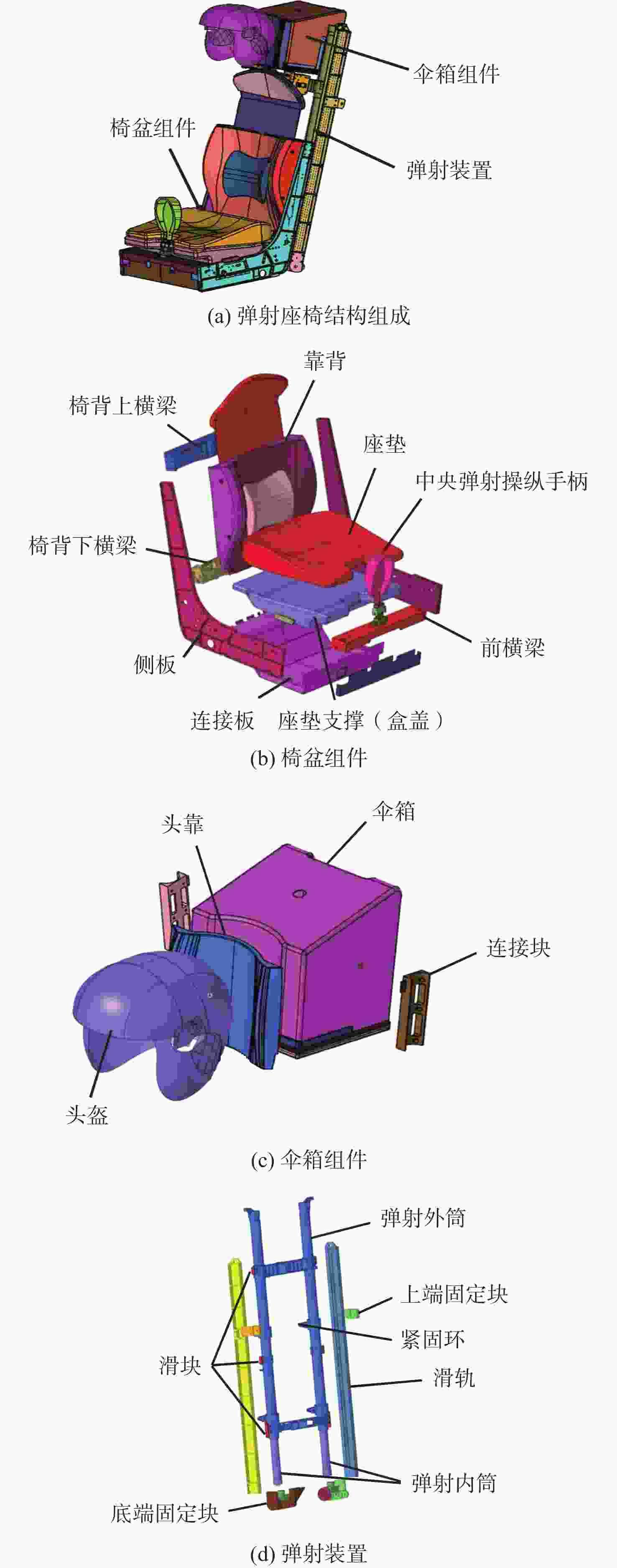

为了研究弹射座椅的出舱稳定性,以某弹射座椅为对象,建立包括椅盆组件、伞箱组件及弹射装置的弹射座椅的细致有限元模型,并通过耦合假人模型建立人椅系统模型;开展人椅系统的弹射出舱试验,得到弹射姿态、座椅加速度、座椅角速度及俯仰角等试验结果,基于这些数据对人椅系统仿真模型进行试验验证,结果表明,模型具有较高的精度;进一步从座椅关键组件的厚度、滑块的布置形式及限腿带力3个方面进行人椅系统出舱稳定性的影响因素分析,结果表明,滑轨滑动槽的厚度、滑轨本体厚度、座椅侧板厚度、滑块布置形式、限腿带力作用时间对出舱稳定性影响较明显,而弹射内筒的厚度和限腿带力的大小对出舱稳定性影响较小。研究结果为高稳定性弹射座椅的设计提供了依据。

Abstract:To study the tip-off stability of ejection seat, a finite element model was constructed based on an ejection seat, which includes the components of the seat basin, umbrella box, and ejection device, and then the seat-dummy system model was obtained by combining the seat model with a dummy model. The ejection experiment was carried out and the movement process, acceleration, angular velocity, and pitch angle were collected. The established ejection seat-dummy model has a rather high accuracy, as demonstrated by the simulation results of the seat-dummy model that were verified using these data. Sensitive analysis on the seat tip-off stability was carried out using the validated seat-dummy model. Three aspects were explored, including the thickness of the seat components, the configuration of the slider, and the force of the leg-limiting belt. The results show that seat tip-off stability is sensitive to the thicknesses of the rail groove, rail itself, and seat side plate, and the configuration of the slider, as well as the starting time of the leg-limiting force. Nonetheless, there is very little impact on the seat tip-off stability from the force of the limited leg belt and the thickness of the ejection inner cylinder.

-

Key words:

- ejection seat /

- seat-dummy system /

- seat tip-off stability /

- angular velocity /

- pitch angle

-

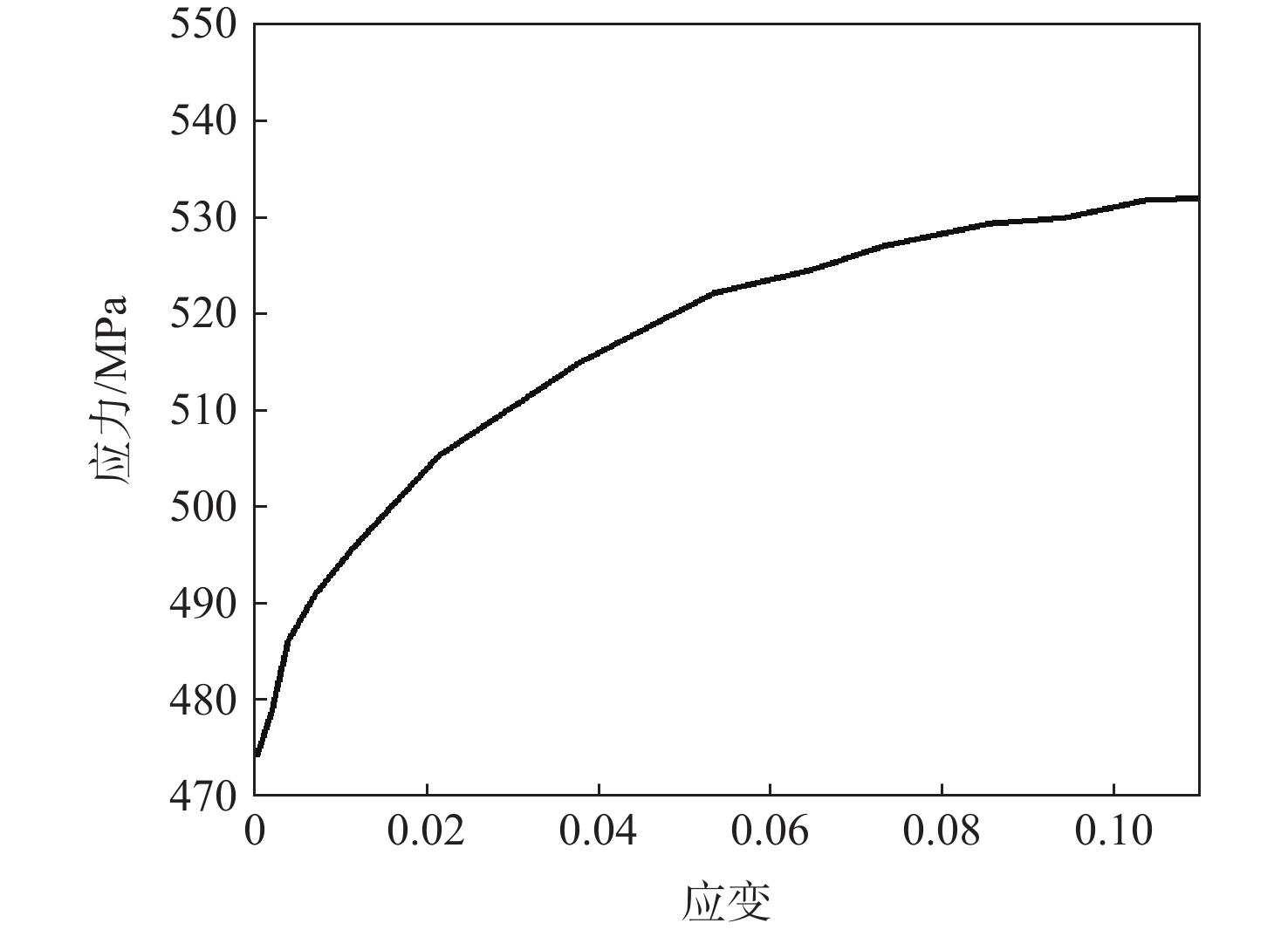

表 1 铝合金材料参数

Table 1. The material parameters of aluminum alloy

参数 数值 密度/(g·cm−3) 2.8 弹性模量/GPa 70 泊松比 0.3 屈服强度/MPa 474 抗拉强度/MPa 530 表 2 各个因素的取值及水平

Table 2. The value and level of each factor

水平 滑轨滑动槽

厚度/mm滑轨本体

厚度/mm弹射内筒

厚度/mm座椅侧板

厚度/mm滑块布置

形式限腿带力

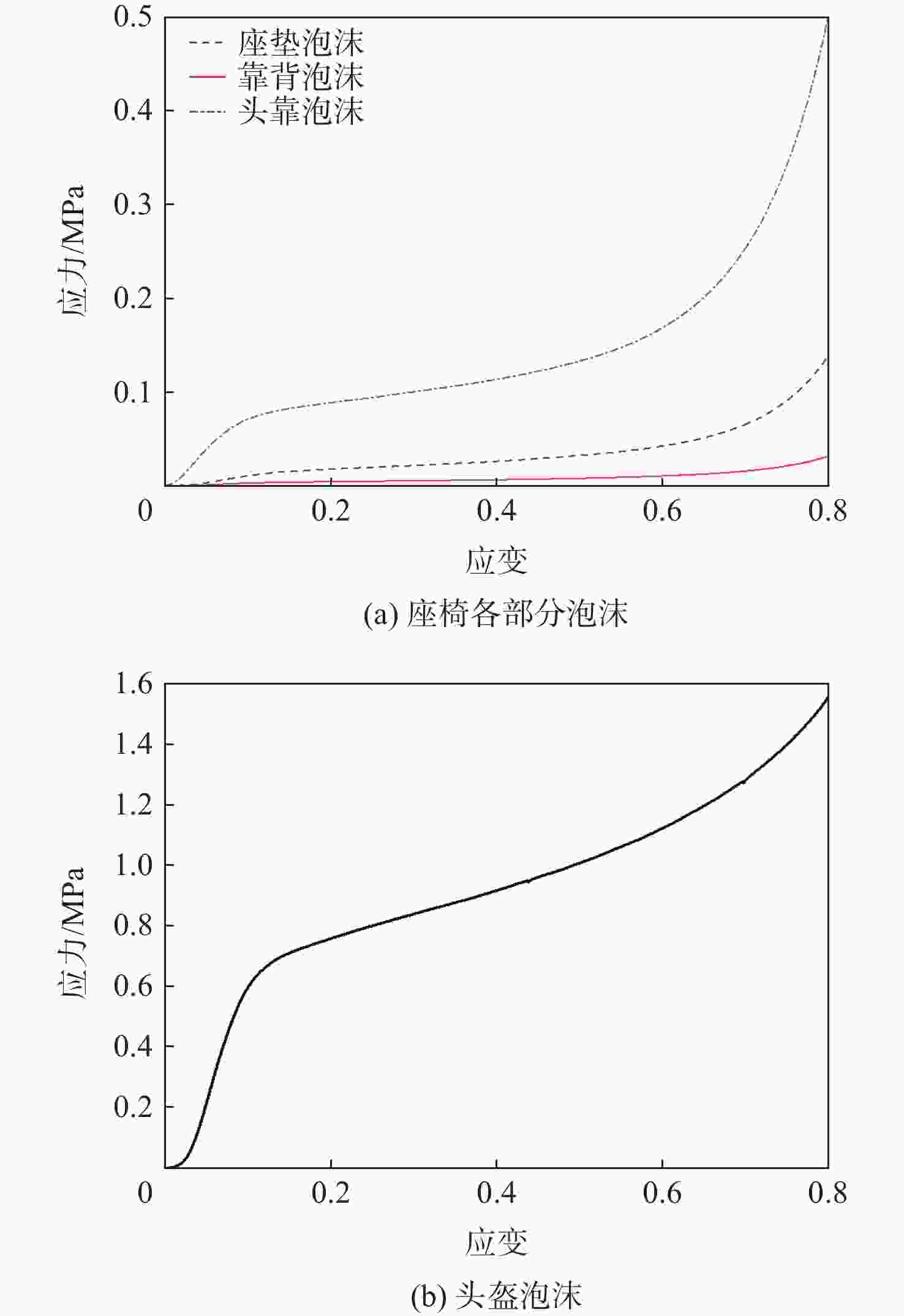

大小/kN限腿带力

作用时间/ms1 3 3 2 3 形式1 3 140 2 5 5 4 5 形式2 4 160 3 7 7 6 7 形式3 5 180 -

[1] EPSTEIN D, MARKOVITZ E, NAKDIMON I, et al. Injuries associated with the use of ejection seats: a systematic review, meta-analysis and the experience of the Israeli Air Force, 1990-2019[J]. Injury, 2020, 51(7): 1489-1496. doi: 10.1016/j.injury.2020.04.048 [2] 魏东, 李伟, 刘书岩. 基于AR技术的弹射救生模拟训练系统[J]. 测控技术, 2021, 40(1): 27-33.WEI D, LI W, LIU S Y. Simulation training system of ejection rescue based on AR technology[J]. Measurement & Control Technology, 2021, 40(1): 27-33(in Chinese). [3] 李慧. 航空弹射救生发射过程视景仿真技术研究[D]. 太原: 中北大学, 2015.LI H. Visual simulation of ejection escapes lifesaving system on launch process[D]. Taiyuan: North University of China, 2015(in Chinese). [4] KOWALECZKO G, DŁUGOŁĘCKI A, SOSNOWSKI M. The mathematical model of the pilot’s ejection process by using the K-36DM ejection seat[J]. Journal of KONBiN, 2018, 48(1): 515-541. doi: 10.2478/jok-2018-0069 [5] 韩冰, 刘更, 吴立言, 等. 弹射座椅冲击特性试验及仿真研究[J]. 中国机械工程, 2016, 27(9): 1165-1168.HAN B, LIU G, WU L Y, et al. Experiments and simulation of ejection seat impact dynamics[J]. China Mechanical Engineering, 2016, 27(9): 1165-1168(in Chinese). [6] 李宝峰. 战斗机弹射救生人椅系统的数字仿真研究[D]. 西安: 西北工业大学, 2005.LI B F. Simulation research of the ejection seats[D]. Xi’an: Northwestern Polytechnical University, 2005(in Chinese). [7] 郁嘉, 林贵平, 毛晓东. 弹射救生数值仿真及不利姿态下救生性能分析[J]. 航空学报, 2010, 31(10): 1927-1932.YU J, LIN G P, MAO X D. Numerical simulation of ejection seat and analysis of performance under adverse attitudes[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(10): 1927-1932(in Chinese). [8] 田佳林. 航空弹射座椅结构设计与仿真分析研究[D]. 长春: 长春理工大学, 2011.TIAN J L. Research on structural design and simulation analysis of aviation ejection seat[D]. Changchun: Changchun University of Science and Technology, 2011(in Chinese). [9] 雷森. 火箭弹射座椅高速稳定系统选型研究[D]. 西安: 西北工业大学, 2007.LEI S. Research on the lectotype of high speed stabilization system of ejection seat[D]. Xi’an: Northwestern Polytechnical University, 2007(in Chinese). [10] 吴亮, 吴铭. 火箭弹射座椅运动稳定性能数值仿真研究[J]. 科技资讯, 2015, 13(10): 4.WU L, WU M. Numerical simulation research on motion stability of rocket ejection seat[J]. Science & Technology Information, 2015, 13(10): 4(in Chinese). [11] 闵婕. 基于Adams的弹射座椅运动仿真分析[J]. 科技创新导报, 2013, 10(26): 61-65.MIN J. Motion simulation analysis of ejection seat based on Adams[J]. Science and Technology Innovation Herald, 2013, 10(26): 61-65(in Chinese). [12] 吴晓君, 冯光辉, 张岩. 基于姿态火箭的弹射座椅轨迹控制技术研究[J]. 舰船电子工程, 2015, 35(11): 133-136.WU X J, FENG G H, ZHANG Y. Ejection seat trajectory amendment based on attitude rocket[J]. Ship Electronic Engineering, 2015, 35(11): 133-136(in Chinese). [13] BIELAT R P. A transonic wind-tunnel investigation of the performance and of the static stability and control characteristics of a model of a fighter-type airplane which embodies partial body indentation: NACA RM L59F21a[R]. Washington, D. C.: National Advisory Committee for Aeronautics, 1959. [14] HABCHI S D, PRZEKWAS A J, MARQUETTE T, et al. CFD analysis of ejection seat escape systems[J]. SAE Transactions, 1992, 101: 1566-1579. [15] 罗经纬, 冯光辉, 张大林, 等. 密闭式弹射座椅稳定减速技术研究[J]. 航空科学技术, 2018, 29(12): 62-66.LUO J W, FENG G H, ZHANG D L, et al. Research on the stabilization and deceleration technology of closed ejection seat[J]. Aeronautical Science & Technology, 2018, 29(12): 62-66(in Chinese). [16] 刘愿, 陈川, 钱战森. 空天飞行器整体式救生座舱的稳定减速与分离特性数值模拟[J]. 航空学报, 2020, 41(12): 124059.LIU Y, CHEN C, QIAN Z S. Numerical simulation of stable deceleration and safe separation of integral escape module for aerospace vehicles[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(12): 124059(in Chinese). [17] 刘富, 童明波, 宋杰, 等. 带稳定板装置弹射座椅偏航稳定性能研究[J]. 空气动力学学报, 2010, 28(2): 203-208.LIU F, TONG M B, SONG J, et al. Research of yaw-stabilization performance of ejection seat with stabilization fins[J]. Acta Aerodynamica Sinica, 2010, 28(2): 203-208(in Chinese). [18] 郁嘉, 林贵平, 吴铭. 弹射座椅减速性能的数值仿真计算[J]. 航空学报, 2006, 27(6): 1033-1038.YU J, LIN G P, WU M. Numerical simulation of deceleration performance of ejection seat[J]. Acta Aeronautica et Astronautica Sinica, 2006, 27(6): 1033-1038(in Chinese). [19] 冯星, 谭率. 两级弹射筒与三级弹射筒座椅性能的对比分析[J]. 航空科学技术, 2018, 29(12): 1-7.FENG X, TAN S. Comparative analyzing performance between the two-stage ejection gun and three-stage ejection seat[J]. Aeronautical Science & Technology, 2018, 29(12): 1-7(in Chinese). [20] 周昊, 宋亚丽, 冯志杰, 等. 基于ADAMS的弹射座椅弹射出舱姿态研究[J]. 航空科学技术, 2021, 32(2): 66-73.ZHOU H, SONG Y L, FENG Z J, et al. Research on ejection attitude of ejection seat based on ADAMS[J]. Aeronautical Science & Technology, 2021, 32(2): 66-73(in Chinese). [21] DUFOUR P, MCGILLIVARY S. Explicit dynamics simulation of ejection sequence and analysis of seat support structure for F-15 aircraft[C]//Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Reston: AIAA, 2007: 2213. [22] ASTM International. Standard test methods for flexible cellular materials—slab, bonded, and molded urethane foams: ASTM D3574—17[S]. West Conshohocken: ASTM International, 2017. -

下载:

下载: