A Prediction method of rolling bearing performance degradation trends based on digital twin models

-

摘要:

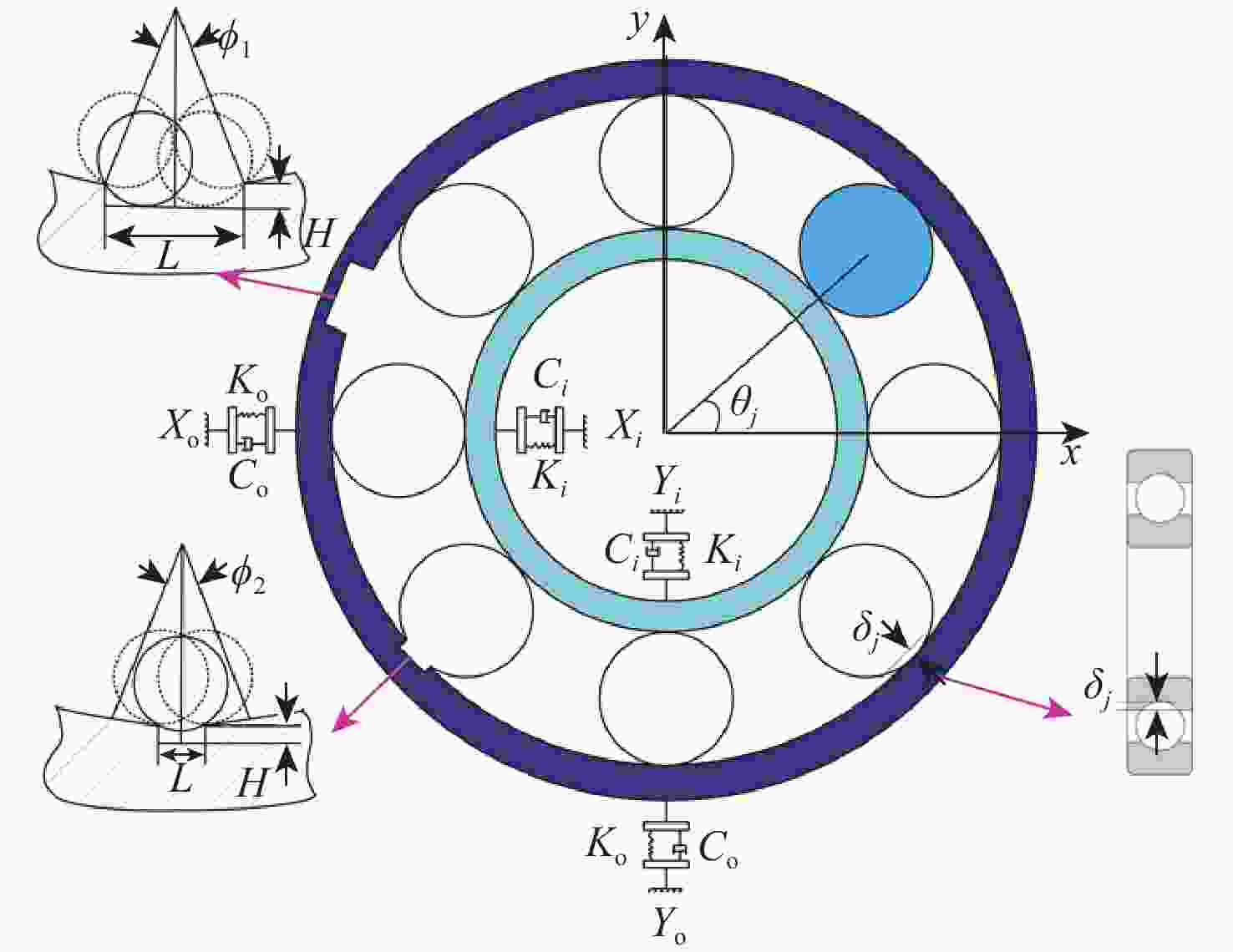

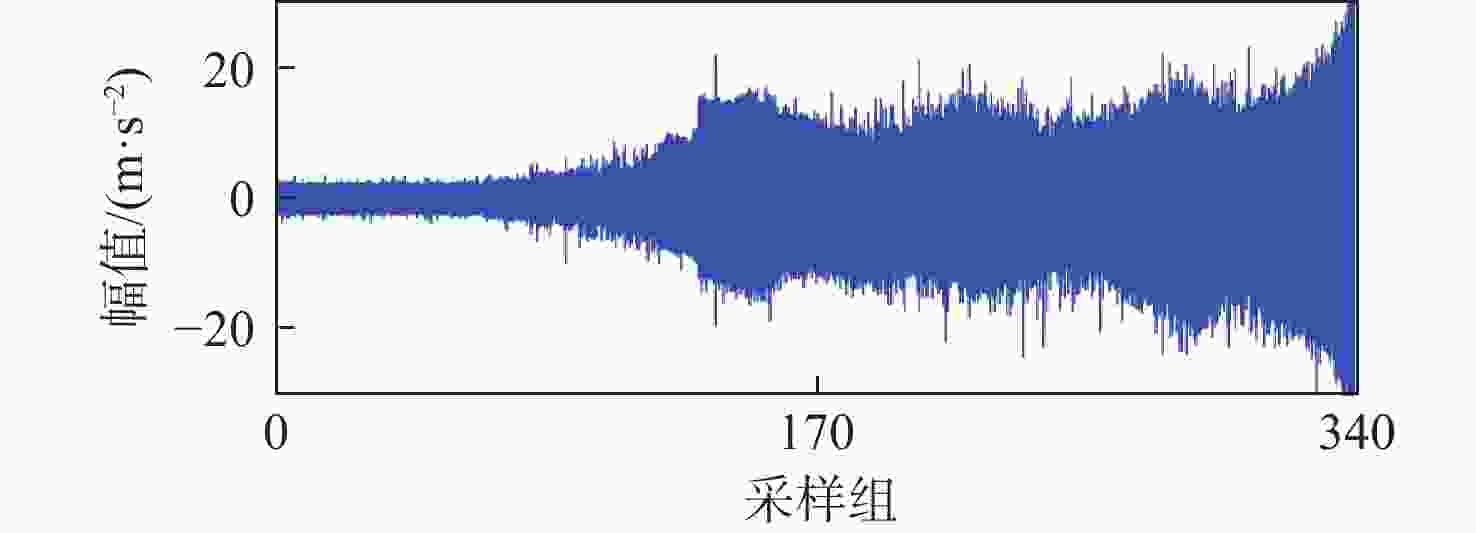

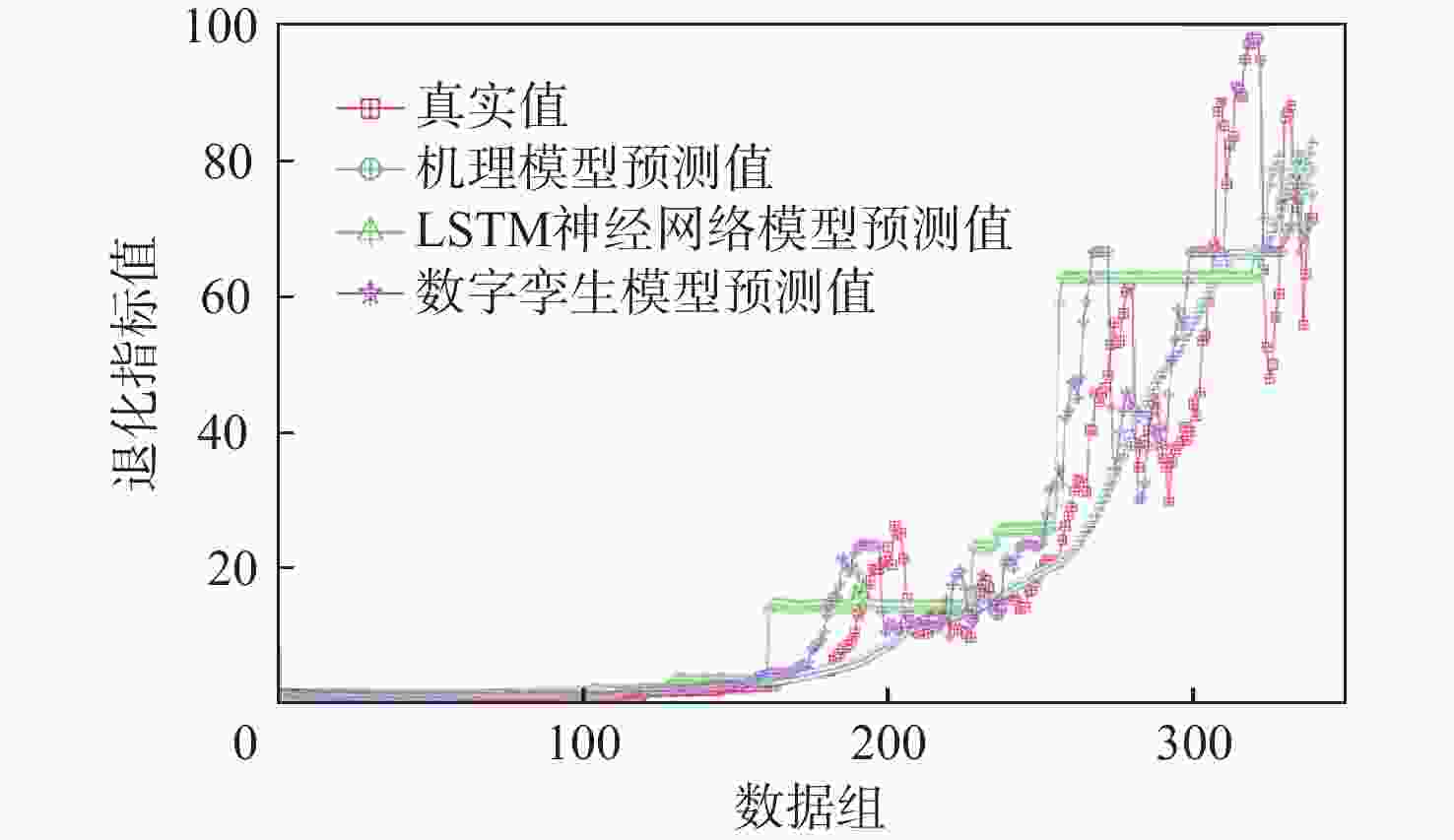

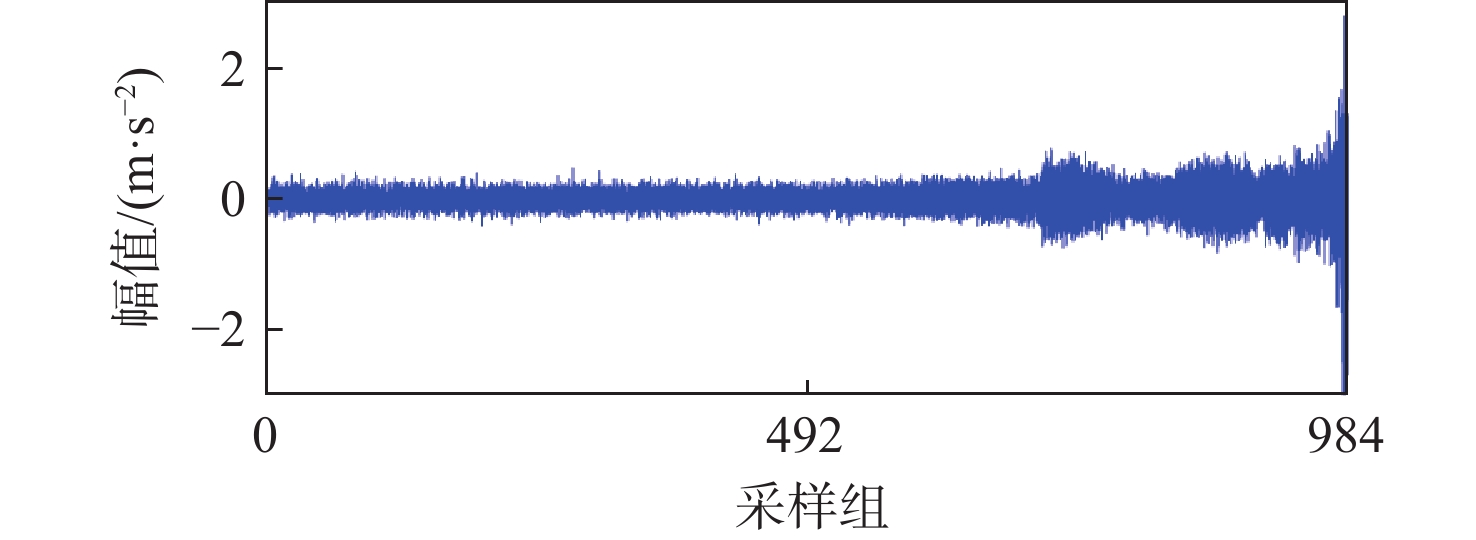

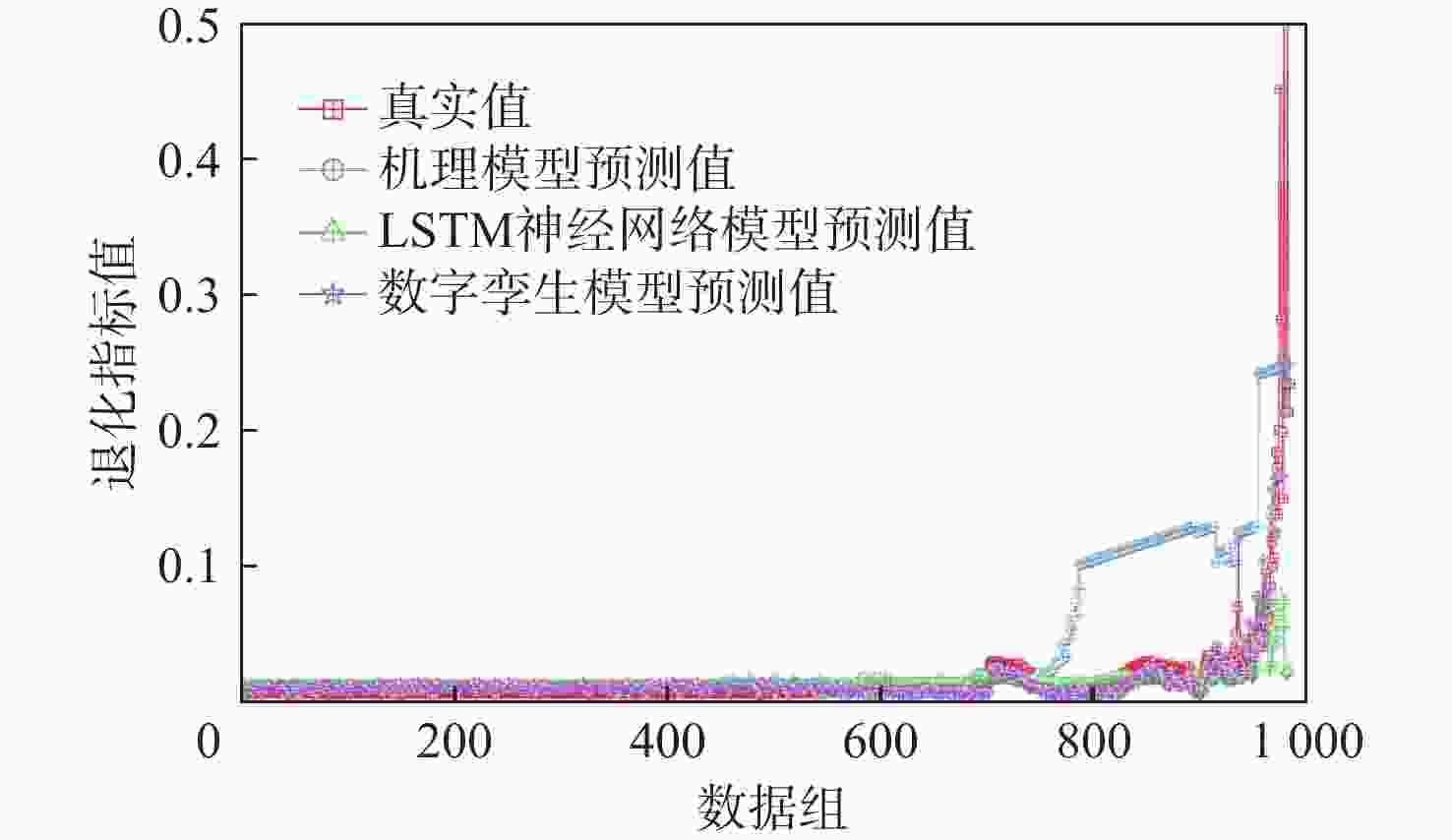

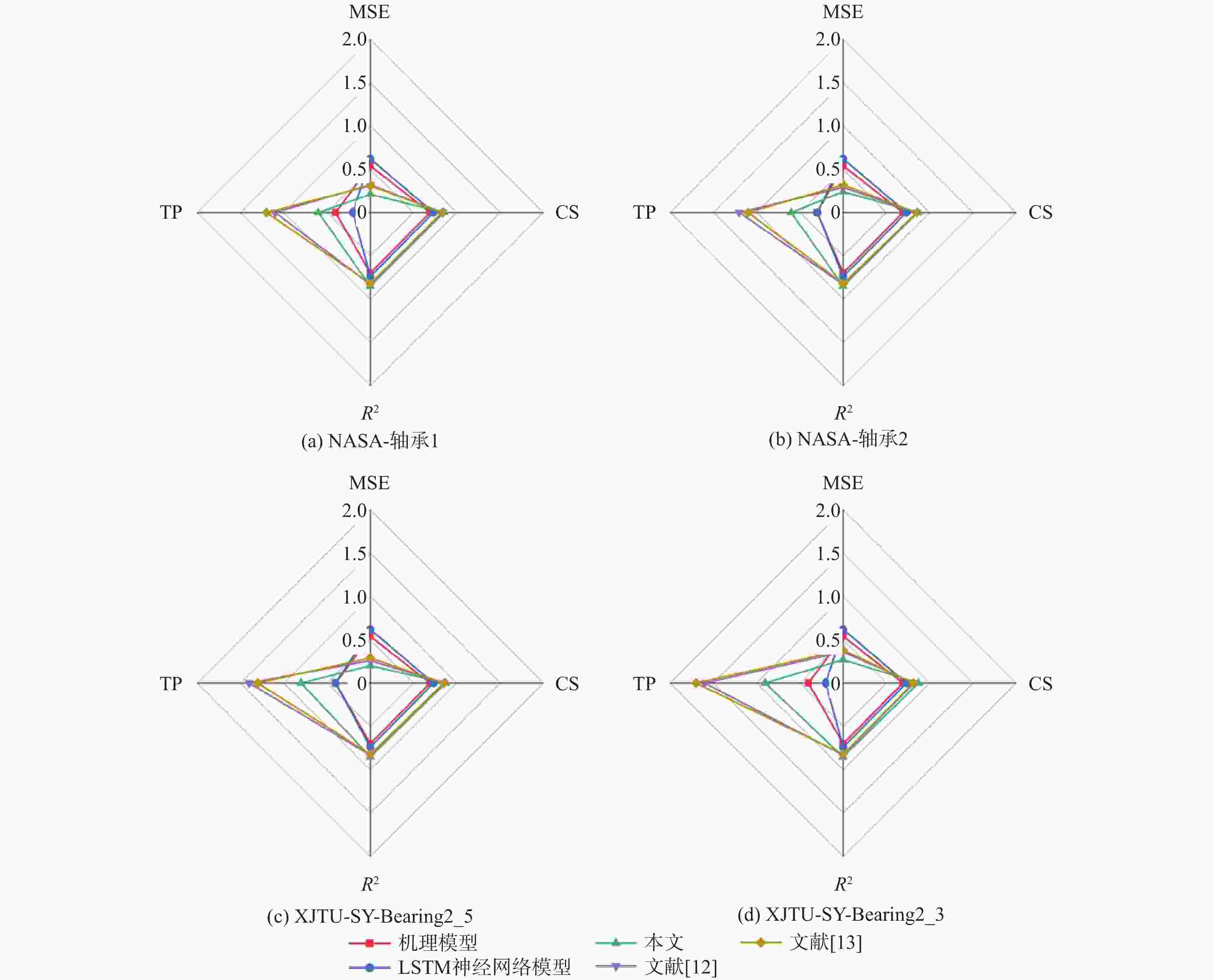

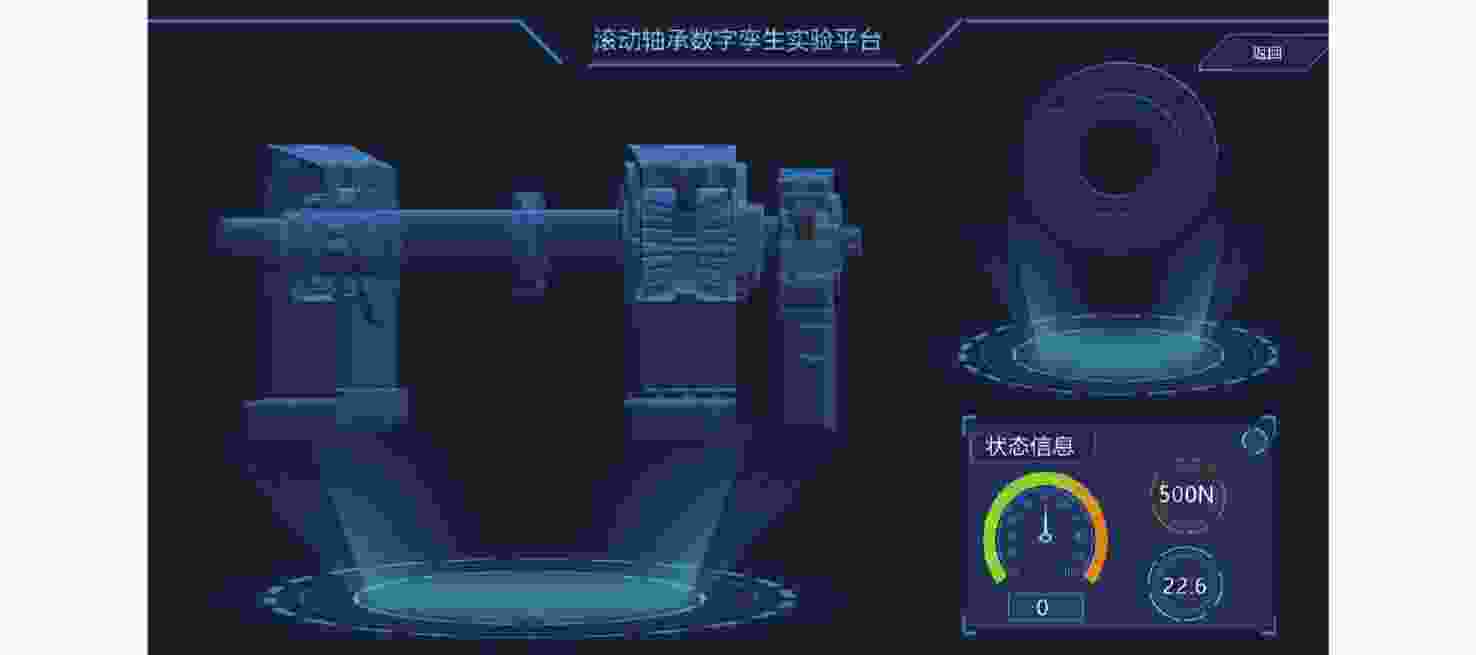

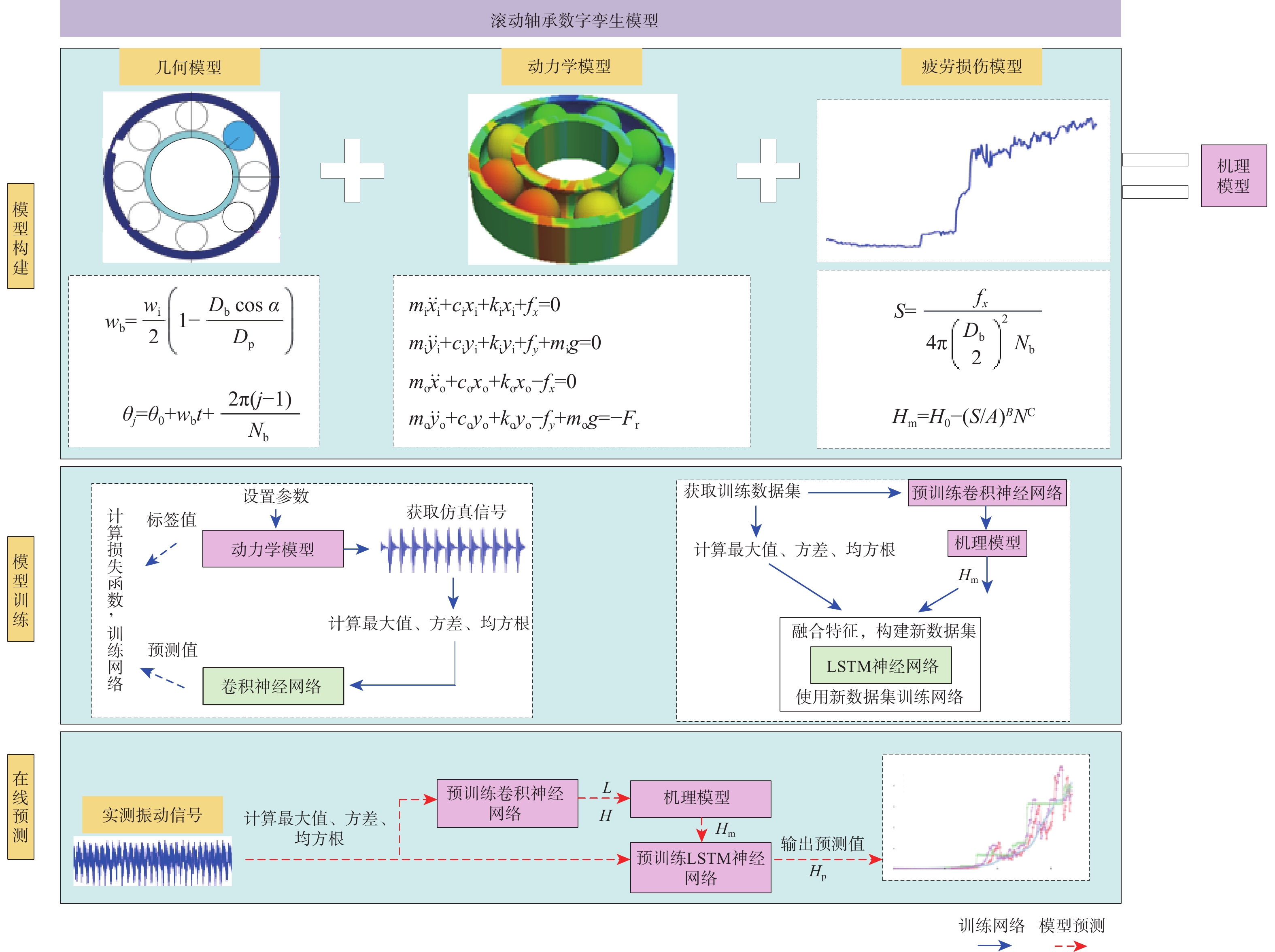

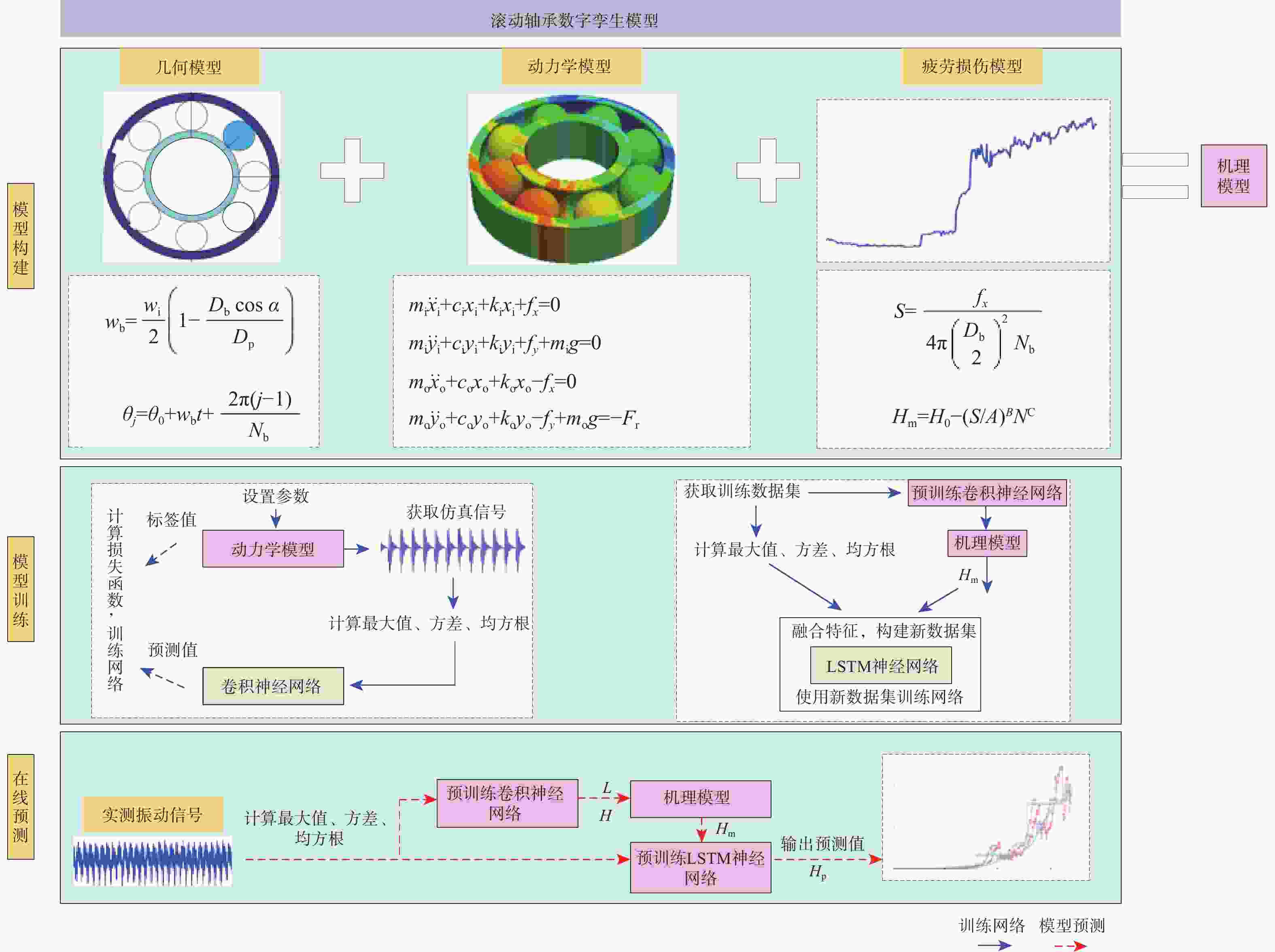

针对在线场景下现有滚动轴承性能退化趋势预测方法难以准确预测的问题,提出一种融合数字孪生模型的滚动轴承性能退化趋势预测方法。在现有动力学模型基础上,考虑接触力引起的接触疲劳损伤对滚动轴承退化特性的影响,构建可预测滚动轴承退化趋势的机理模型。设计基于卷积神经网络(CNN)和长短时记忆(LSTM)神经网络的模型更新方法,解决实测振动信号与机理模型的融合问题,进而建立机理与数据融合的数字孪生模型,实现滚动轴承性能退化趋势的预测。利用XJTU-SY、NASA滚动轴承振动实验数据集完成方法有效性验证。实验结果表明:相较于融合动态贝叶斯网络、融合卷积自编码器等数字孪生方法,所提方法预测准确性与快速性上实现了提升。

Abstract:Aiming at the problem that the existing rolling bearing performance degradation trend prediction method is difficult to predict accurately in the online scene, a rolling bearing performance degradation trend prediction method based on a digital twin model is proposed. This study builds a mechanism model that can forecast the rolling bearing degradation trend based on the current dynamic model. It also examines the impact of contact fatigue damage brought on by contact force on the rolling bearing degradation features. A model updating method based on a convolutional neural network and a long short-term memory neural network is designed to solve the fusion problem of measured vibration signal and mechanism model, and then a digital twin model of mechanism and data fusion is established to predict the performance degradation trend of rolling bearings. Lastly, the National Aeronautics and Space Administration (NASA) and Xi'an Jiaotong University-Changxing Shengyang Technology Co., Ltd. (XJTU-SY) experimental rolling bearing vibration data set are used to confirm the method's validity. The experimental results show that compared with the digital twin methods, such as fusion dynamic Bayesian network and fusion convolutional autoencoder, the prediction accuracy and rapidity of the proposed method and the rapidity are improved.

-

表 1 模型参数

Table 1. Model parameter

参数 数值 内圈等效刚度ki/(N·m) 5.24×104 外圈等效刚度ko/(N·m) 1.51×107 滚动体等效刚度kb/(N·m) 1.89×108 内圈等效质量mi/kg 2.12 外圈等效质量mo/kg 4.34 内圈等效阻尼ci/(N·s·m−1) 3376 外圈等效阻尼co/(N·s·m−1) 2310 表 2 卷积神经网络模型参数

Table 2. CNN model parameter

层名称 参数设置 输入层 包含3个神经元 全连接层1 包含10个神经元,使用ReLU激活函数 卷积层 采用1维卷积方式,卷积核大小:3 池化层 采用最大池化方式,池化窗口大小:2,步长:2 全连接层2 包含10个神经元,使用ReLU激活函数 输出层 包含2个神经元 表 3 长短时记忆神经网络模型参数

Table 3. LSTM model parameter

参数 参数设置 输入特征维度(input_size) 4 输出特征维度(output_size) 1 LSTM层数(num_layers) 2 隐藏层维度(hidden_size) 128 序列长度(sequence_length) 10 丢弃率(dropout) 0.2 学习率(learning_rate) 0.001 表 4 模型评价结果

Table 4. Model evaluation results

表 5 训练参数

Table 5. Training parameter

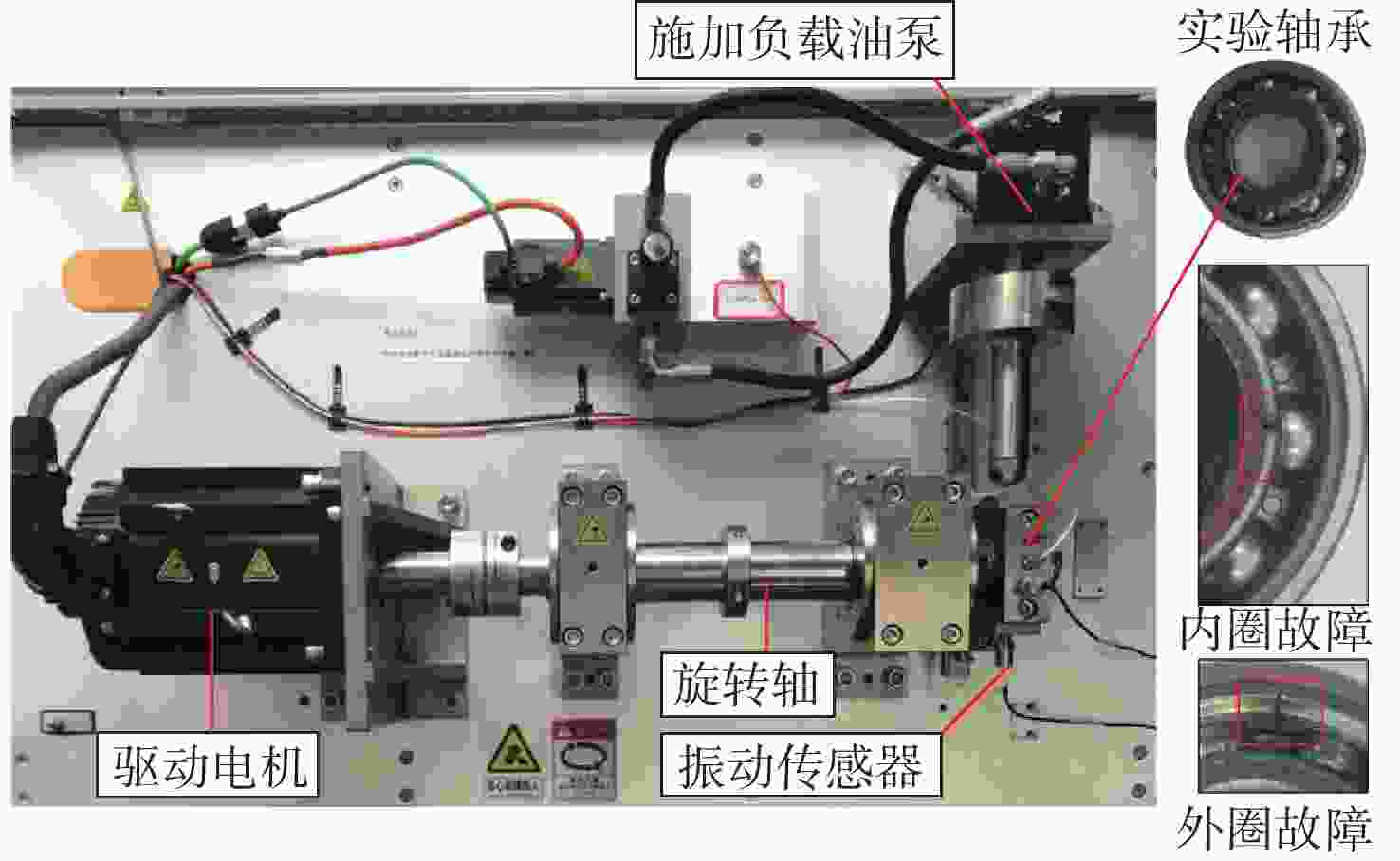

神经网络 模型输入 CNN rm、va、ma LSTM rm、va、ma、Hm 表 6 实验数据参数

Table 6. Experimental data parameters

名称 参数 轴承型号 LDK UER204 节圆直径/mm 34.55 滚动体直径/mm 7.92 滚动体数量 8 接触角/(°) 0 采样频率/kHz 37.5 载荷/kN 11 表 7 实验数据参数

Table 7. Experimental data parameters

名称 参数 轴承型号 RexnordZA- 2115 节圆直径/mm 71.5 滚动体直径/mm 8.40 滚动体数量 16 接触角/(°) 15.17 采样频率/kHz 20 载荷/kN 26.6 电机转速/(r·min−1) 2000 表 8 实验数据参数

Table 8. Experimental data parameters

名称 参数 轴承型号 SKF6205 节圆直径/mm 39 滚动体直径/mm 8 滚动体数量 9 接触角/(°) 0 采样频率/kHz 12 载荷/kN 1 电机转速/(r·min−1) 1797 -

[1] 雷春丽, 焦孟萱, 马淑珍, 等. 基于MTF-SPCNN的小样本滚动轴承变工况故障诊断方法[J]. 北京航空航天大学学报, 2024, 50(12): 3696-3708.LEI C L, JIAO M X, MA S Z, et al. Fault diagnosis method of small sample rolling bearing under variable working conditions based on MTF-SPCNN[J]. Journal of Beijing University of Aeronautics and Astronautics, 2024, 50(12): 3696-3708(in Chinese). [2] YANG C Y, MA J, WANG X D, et al. A novel based-performance degradation indicator RUL prediction model and its application in rolling bearing[J]. ISA Transactions, 2022, 121: 349-364. doi: 10.1016/j.isatra.2021.03.045 [3] 刘禹清, 陈再刚, 閤鑫, 等. 复杂机车振动环境下牵引电机轴承服役寿命评估[J]. 力学学报, 2022, 54(7): 1820-1829. doi: 10.6052/0459-1879-21-545LIU Y Q, CHEN Z G, GE X, et al. Service life evaluation of traction motor bearings in complicated vibration environment of a locomotive[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(7): 1820-1829(in Chinese). doi: 10.6052/0459-1879-21-545 [4] 关健, 王黎钦. 考虑载荷大小变化次序的球轴承寿命修正模型[J]. 吉林大学学报(工学版), 2016, 46(4): 1182-1189.GUAN J, WANG L Q. Modified life model of ball bearing considering load changing sequence[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(4): 1182-1189(in Chinese). [5] 李胜远, 郑龙席. 脉冲爆震轴向载荷对双半内圈球轴承疲劳寿命的影响[J]. 推进技术, 2021, 42(10): 2349-2357.LI S Y, ZHENG L X. Effects of pulse detonation axial load on fatigue life of split inner ring ball bearing[J]. Journal of Propulsion Technology, 2021, 42(10): 2349-2357(in Chinese). [6] YU A D, HUANG H Z, LI Y F, et al. A modified nonlinear fatigue damage accumulation model for life prediction of rolling bearing under variable loading conditions[J]. Fatigue & Fracture of Engineering Materials & Structures, 2022, 45(3): 852-864. [7] WANG H, TANG G, ZHOU Y G, et al. A novel multiscale deep health indicator with bidirectional LSTM network for bearing performance degradation trend prognosis[J]. Shock and Vibration, 2020, 2020(1): 8871981. [8] 张典震, 陈捷, 王华, 等. 基于卷积自编码与密集时间卷积网络的回转支承退化趋势预测[J]. 振动与冲击, 2021, 40(23): 9-16.ZHANG D Z, CHEN J, WANG H, et al. Prediction of slewing support degradation trend based on CAE and DTCN[J]. Journal of Vibration and Shock, 2021, 40(23): 9-16(in Chinese). [9] XIANG W, LI F, WANG J X, et al. Quantum weighted gated recurrent unit neural network and its application in performance degradation trend prediction of rotating machinery[J]. Neurocomputing, 2018, 313: 85-95. doi: 10.1016/j.neucom.2018.06.012 [10] 陈强强, 戴邵武, 戴洪德, 等. 基于SPA-FIG与优化ELM的滚动轴承性能退化趋势预测[J]. 振动与冲击, 2020, 39(19): 187-194.CHEN Q Q, DAI S W, DAI H D, et al. Performance degradation trend prediction of rolling bearings based on SPA-FIG and optimized ELM[J]. Journal of Vibration and Shock, 2020, 39(19): 187-194(in Chinese). [11] 吴梦蝶, 程龙生, 陈闻鹤. 基于自适应马氏空间与深度学习的滚动轴承退化趋势预测[J]. 系统工程与电子技术, 2023, 45(10): 3338-3349.WU M D, CHENG L S, CHEN W H. Degradation trend prediction of rolling bearing based on adaptive Mahalanobis space and deep learning[J]. Systems Engineering and Electronics, 2023, 45(10): 3338-3349(in Chinese). [12] 付洋, 曹宏瑞, 郜伟强, 等. 数字孪生驱动的航空发动机涡轮盘剩余寿命预测[J]. 机械工程学报, 2021, 57(22): 106-113. doi: 10.3901/JME.2021.22.106FU Y, CAO H R, GAO W Q, et al. Digital twin driven remaining useful life prediction for aero-engine turbine discs[J]. Journal of Mechanical Engineering, 2021, 57(22): 106-113(in Chinese). doi: 10.3901/JME.2021.22.106 [13] 张诚, 马梓玮, 刘斌, 等. 数字孪生驱动的小样本旋转机械剩余寿命预测[J]. 西安交通大学学报, 2023, 57(12): 168-178. doi: 10.7652/xjtuxb202312017ZHANG C, MA Z W, LIU B, et al. Digital twin driven few-shot prediction of remaining useful life for rotating machinery[J]. Journal of Xi’an Jiaotong University, 2023, 57(12): 168-178(in Chinese). doi: 10.7652/xjtuxb202312017 [14] 陶飞, 刘蔚然, 刘检华, 等. 数字孪生及其应用探索[J]. 计算机集成制造系统, 2018, 24(1): 1-18.TAO F, LIU W R, LIU J H, et al. Digital twin and its potential application exploration[J]. Computer Integrated Manufacturing Systems, 2018, 24(1): 1-18(in Chinese). [15] 陶飞, 刘蔚然, 张萌, 等. 数字孪生五维模型及十大领域应用[J]. 计算机集成制造系统, 2019, 25(1): 1-18.TAO F, LIU W R, ZHANG M, et al. Five-dimension digital twin model and its ten applications[J]. Computer Integrated Manufacturing Systems, 2019, 25(1): 1-18(in Chinese). [16] ZHANG H, QI Q L, TAO F. A multi-scale modeling method for digital twin shop-floor[J]. Journal of Manufacturing Systems, 2022, 62: 417-428. doi: 10.1016/j.jmsy.2021.12.011 [17] WANG D, CAO H R, YANG Y, et al. Dynamic modeling and vibration analysis of cracked rotor-bearing system based on rigid body element method[J]. Mechanical Systems and Signal Processing, 2023, 191: 110152. doi: 10.1016/j.ymssp.2023.110152 [18] 王震, 杨正伟, 何浩浩, 等. 非规则轴承故障的动力学建模与仿真[J]. 北京航空航天大学学报, 2021, 47(8): 1580-1593.WANG Z, YANG Z W, HE H H, et al. Dynamic modeling and simulation of irregular bearing failure[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(8): 1580-1593(in Chinese). [19] 雷宏卫, 成建联. 考虑滑动和热膨胀的球轴承局部故障动力学建模[J]. 振动与冲击, 2022, 41(11): 149-155.LEI H W, CHENG J L. Dynamic modeling for local fault of ball bearing considering sliding and thermal expansion[J]. Journal of Vibration and Shock, 2022, 41(11): 149-155(in Chinese). [20] 罗茂林, 郭瑜, 伍星. 考虑冲击力的球轴承外圈剥落缺陷双冲击现象动力学建模[J]. 振动与冲击, 2019, 38(14): 48-54.LUO M L, GUO Y, WU X. Dynamic modeling of the dual-impulse behavior produced by a spall on the outer race of a ball bearing considering impact forces[J]. Journal of Vibration and Shock, 2019, 38(14): 48-54(in Chinese). [21] 国家市场监督管理总局, 国家标准化管理委员会. 滚动轴承 损伤和失效 术语、特征及原因: GB/T 24611—2020[S]. 北京: 中国标准出版社, 2020.Standardization Administration of the People’s Republic of China. Rolling bearings—Damage and failures—Terms, characteristics and causes: GB/T 24611—2020[S]. Beijing: Standards Press of China, 2020(in Chinese). [22] 全国滚动轴承标准化技术委员会. 滚动轴承 额定动载荷和额定寿命: GB/T 6391—1995[S]. 北京: 中国标准出版社, 2021.Technical Committee for Standardization of Rolling Bearings of the People Republic of China. Rolling bearings--Dynamic load ratings and rating life: GB/T 6391—1995[S]. Beijing: Standards Press of China, 2021. [23] 涂文兵, 王佳明, 杨本梦, 等. 载荷波动工况下滚动轴承接触特性分析[J]. 振动与冲击, 2023, 42(12): 227-235.TU W B, WANG J M, YANG B M, et al. Analysis of contact characteristics of rolling bearings under load fluctuation[J]. Journal of Vibration and Shock, 2023, 42(12): 227-235(in Chinese). [24] 黄华, 李嘉然, 赵秋舸, 等. 基于混合驱动的进给系统数字孪生模型自适应更新法[J]. 计算机集成制造系统, 2023, 29(6): 1840-1851.HUANG H, LI J R, ZHAO Q G, et al. Adaptive update method of digital twin model for feed system based on hybrid drive[J]. Computer Integrated Manufacturing Systems, 2023, 29(6): 1840-1851(in Chinese). [25] 尹杰, 刘博, 孙国兵, 等. 基于迁移学习和DAE-LSTM的锂离子电池剩余寿命预测[J/OL]. 电工技术学报, 2024, 39(1): 289-302.YIN J, LIU B, ZHANG G B, et al. Transfer learning DAE-LSTM for remaining useful life prediction of Li-Ion batteries[J/OL]. Transactions of China Electrotechnical Society, 2024, 39(1): 289-302(in Chinese). [26] 张辰源, 陶飞. 数字孪生模型评价指标体系[J]. 计算机集成制造系统, 2021, 27(8): 2171-2186.ZHANG C Y, TAO F. Evaluation index system for digital twin model[J]. Computer Integrated Manufacturing Systems, 2021, 27(8): 2171-2186(in Chinese). [27] WANG B, LEI Y G, LI N P, et al. A hybrid prognostics approach for estimating remaining useful life of rolling element bearings[J]. IEEE Transactions on Reliability, 2020, 69(1): 401-412. doi: 10.1109/TR.2018.2882682 [28] 雷亚国, 韩天宇, 王彪, 等. XJTU-SY滚动轴承加速寿命试验数据集解读[J]. 机械工程学报, 2019, 55(16): 1-6. doi: 10.3901/JME.2019.16.001LEI Y G, HAN T Y, WANG B, et al. XJTU-SY rolling element bearing accelerated life test datasets: a tutorial[J]. Journal of Mechanical Engineering, 2019, 55(16): 1-6(in Chinese). doi: 10.3901/JME.2019.16.001 [29] ZOU C L, YIN G S, FENG L, et al. Nonparametric maximum likelihood approach to multiple change-point problems[J]. The Annals of Statistics, 2014, 42(3): 970-1002. -

下载:

下载: