-

摘要:

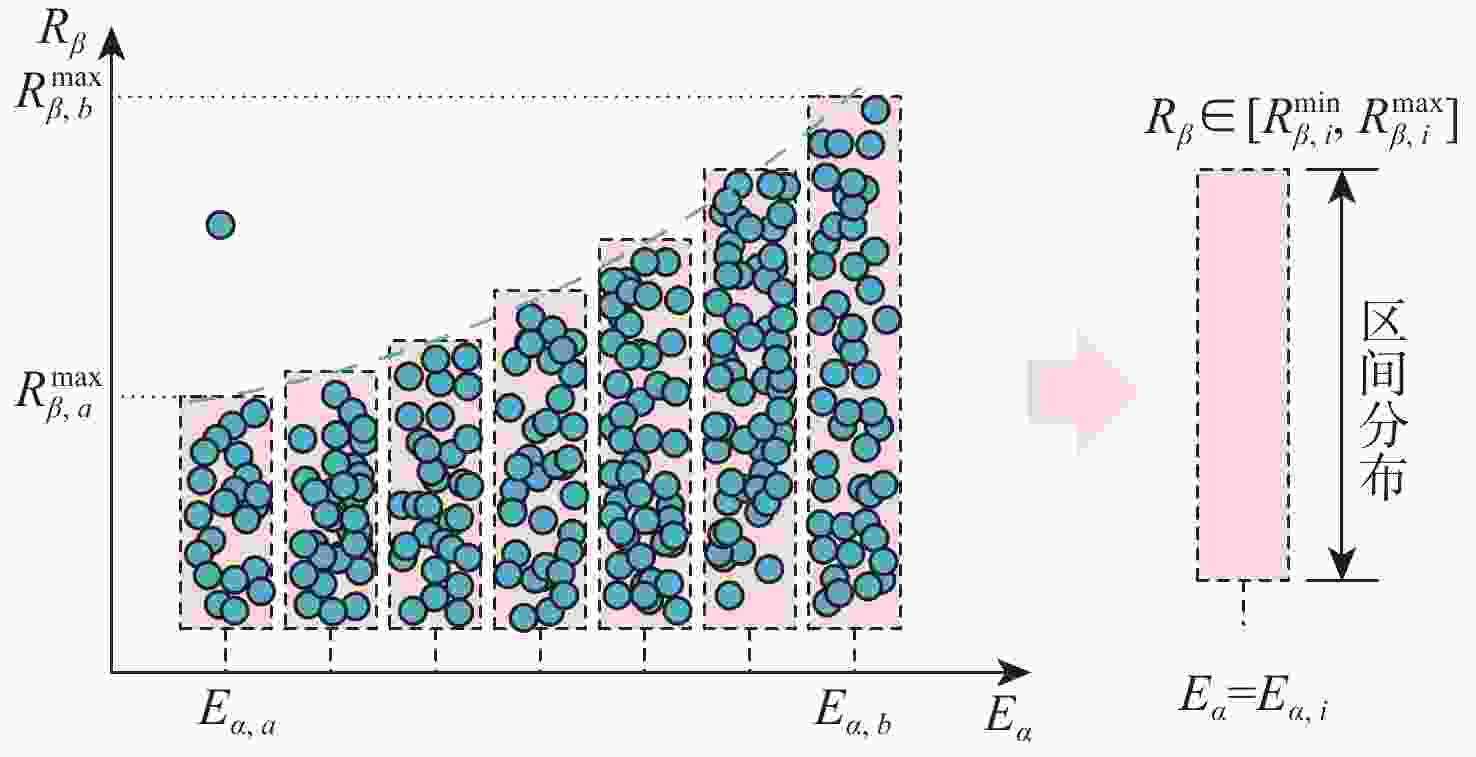

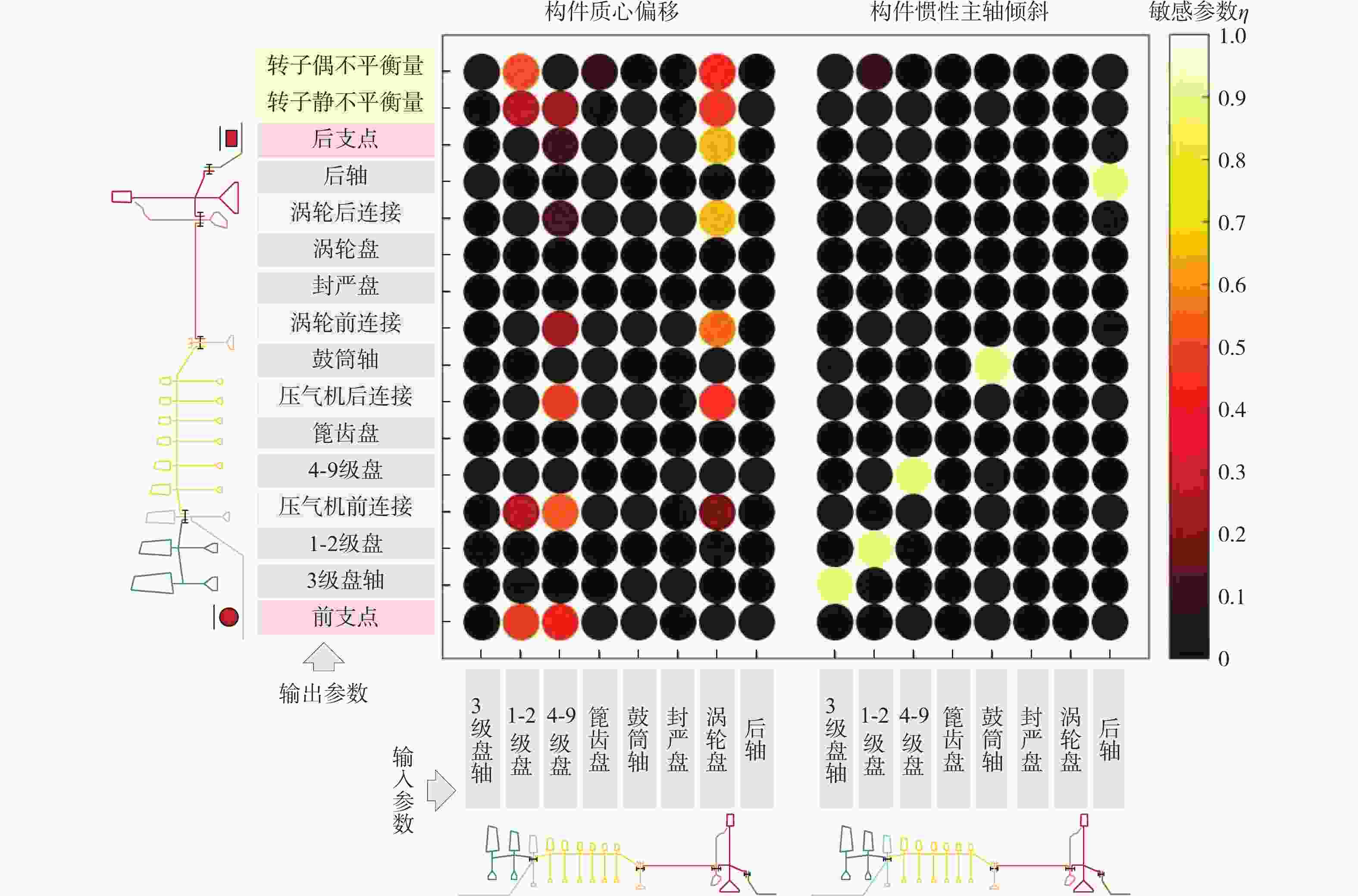

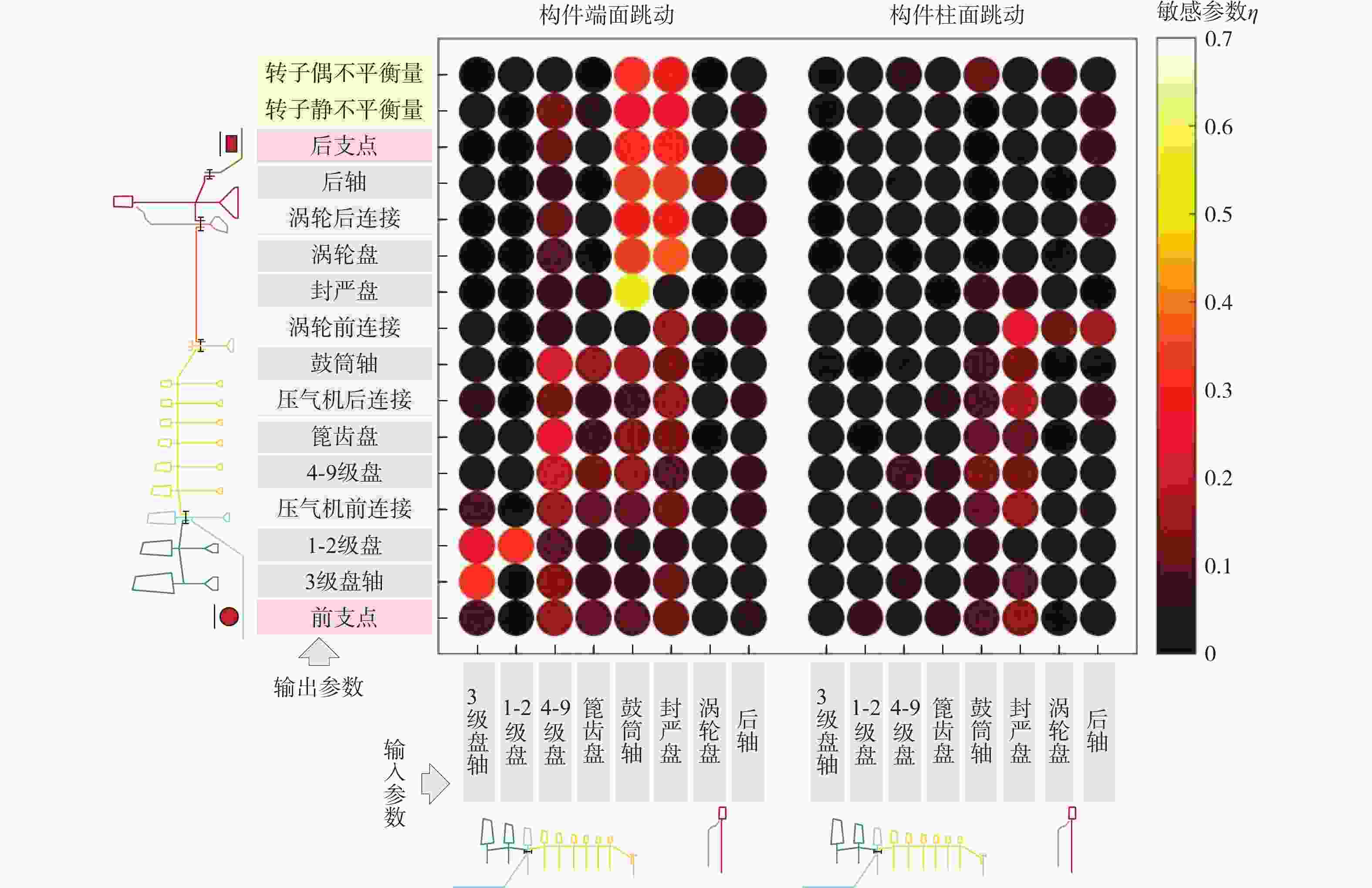

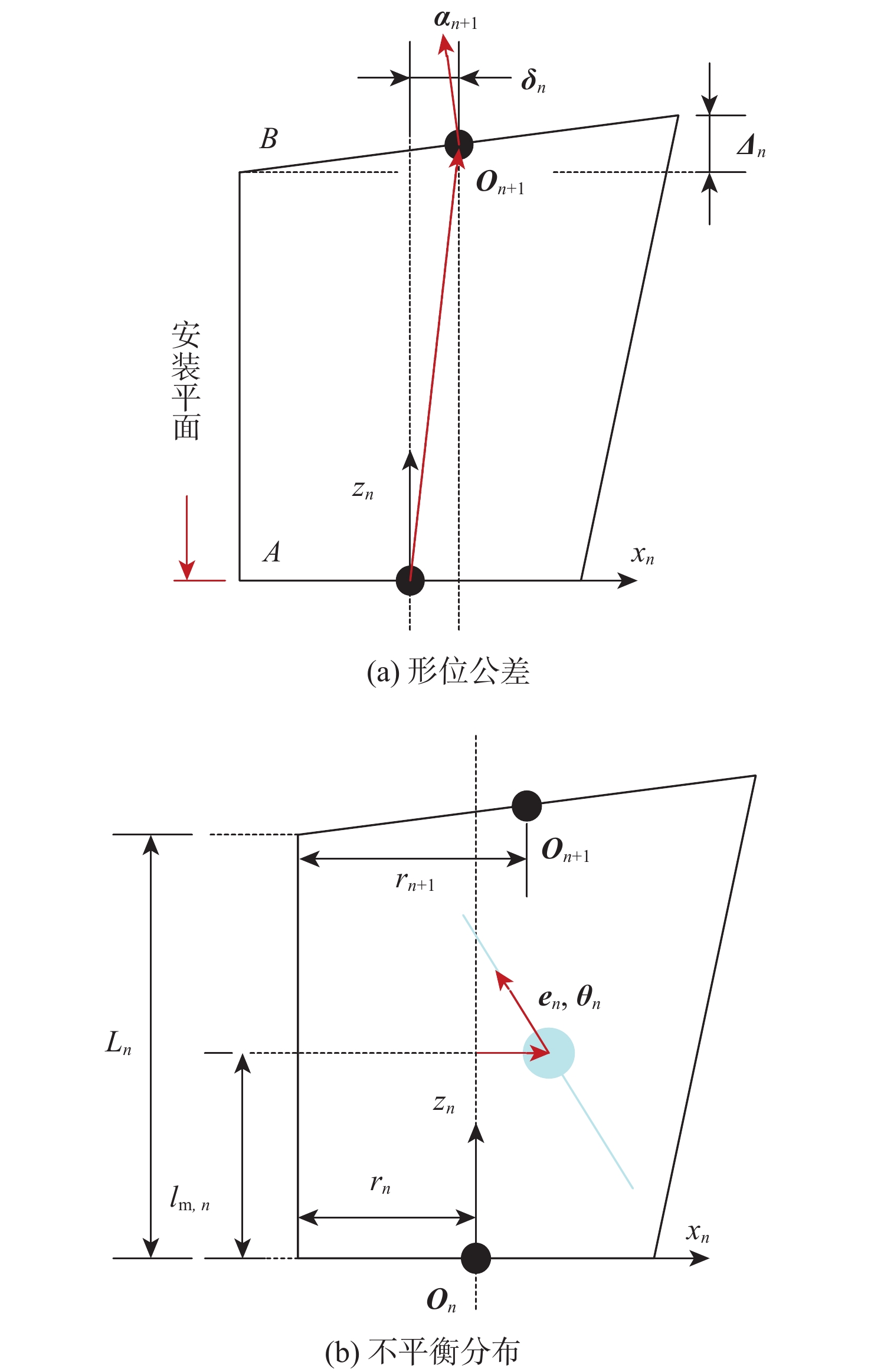

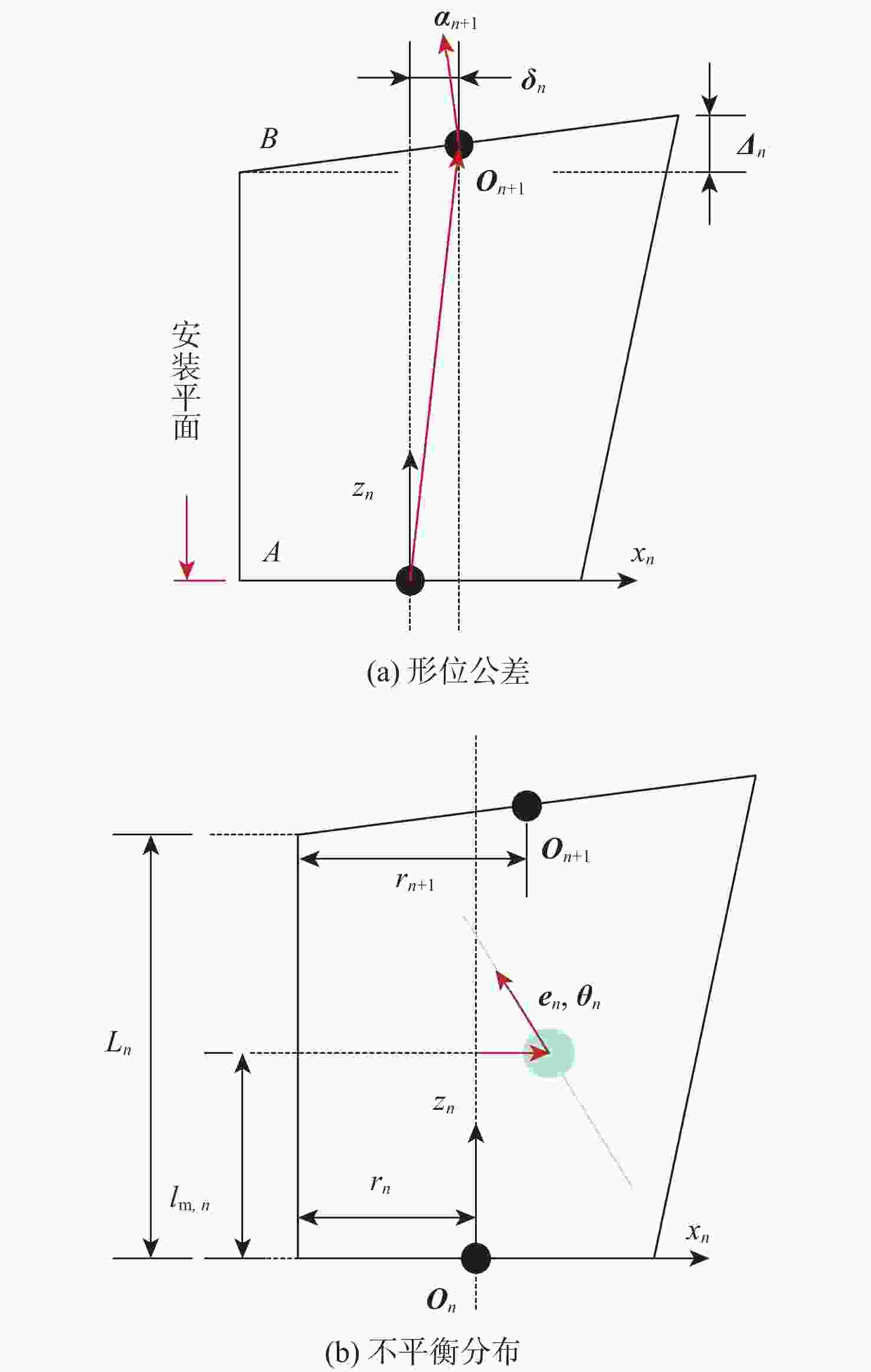

针对先进航空发动机转子数字装配和不平衡分布控制问题,提出了转子不平衡分布数字孪生模型的建模方法。开展了构件装配参数对转子不平衡分布状态影响的敏感度评估,判定出大质量构件的静不平衡和位于转子中部构件端面跳动是影响转子不平衡分布优劣的关键因素。基于数据融合方法,结合某大涵道比发动机核心机转子多台次装配统计数据,成功识别并修正了该转子不平衡分布数字孪生模型中关键参数的阈值,为进一步开展转子结构状态控制和动力响应预测提供了模型基础。

Abstract:In response to the intricate challenges of digital assembly and unbalanced distribution control for advanced aero-engine rotors, this paper proposes a digital twin model to characterize the rotor’s unbalanced distribution. After a thorough sensitivity analysis of the assembly parameters, it was determined that the run-out of the end-face of the intermediate components and the static unbalance of the heavy mass components were the main factors influencing the rotor’s unbalanced distribution. The study effectively identified and adjusted the parameter thresholds in the digital twin model by using a data fusion technique using the collected assembly statistics data from many high-pressure rotors. This correction provides a robust model foundation for further initiatives in rotor dynamic response prediction and control.

-

Key words:

- rotor assembly /

- unbalance distribution /

- digital twin /

- data fusion /

- aero-engine

-

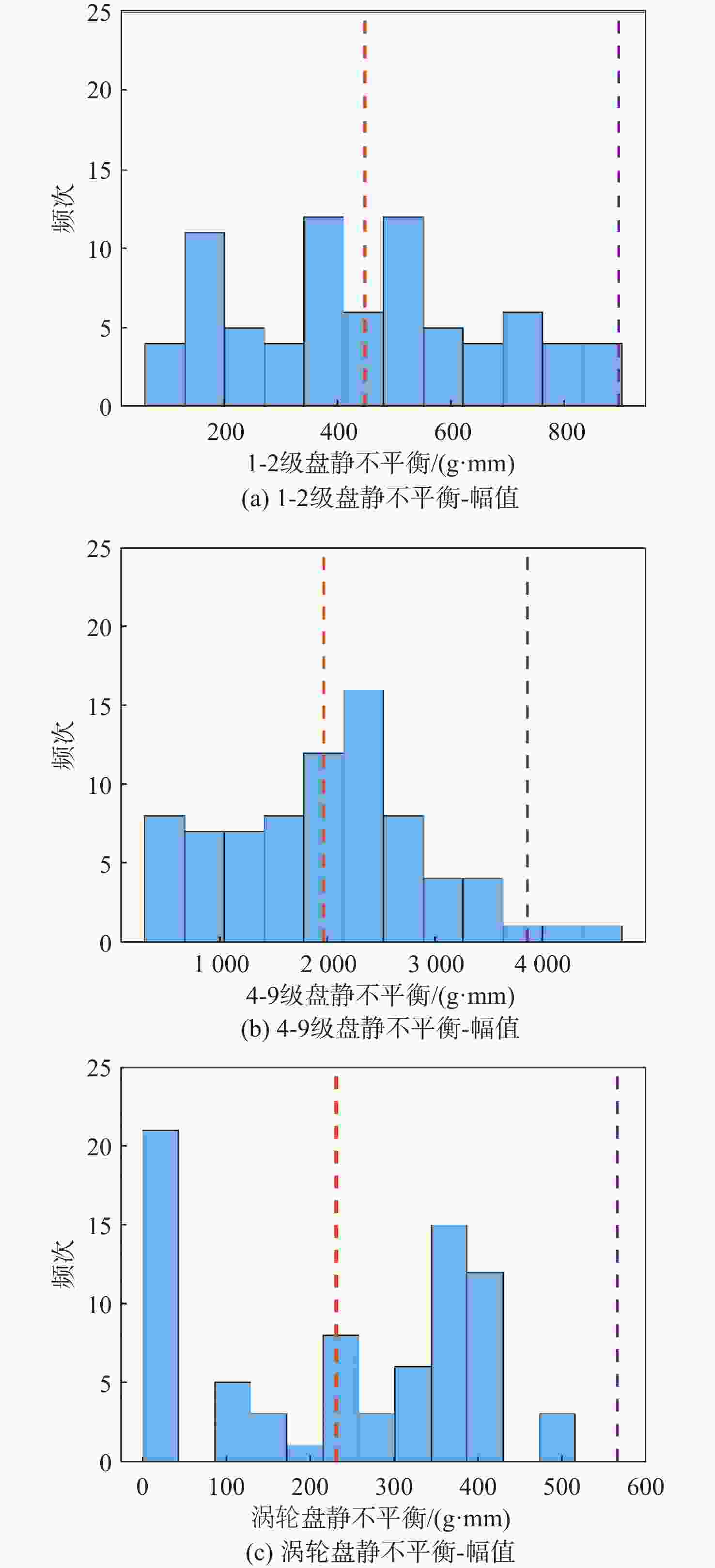

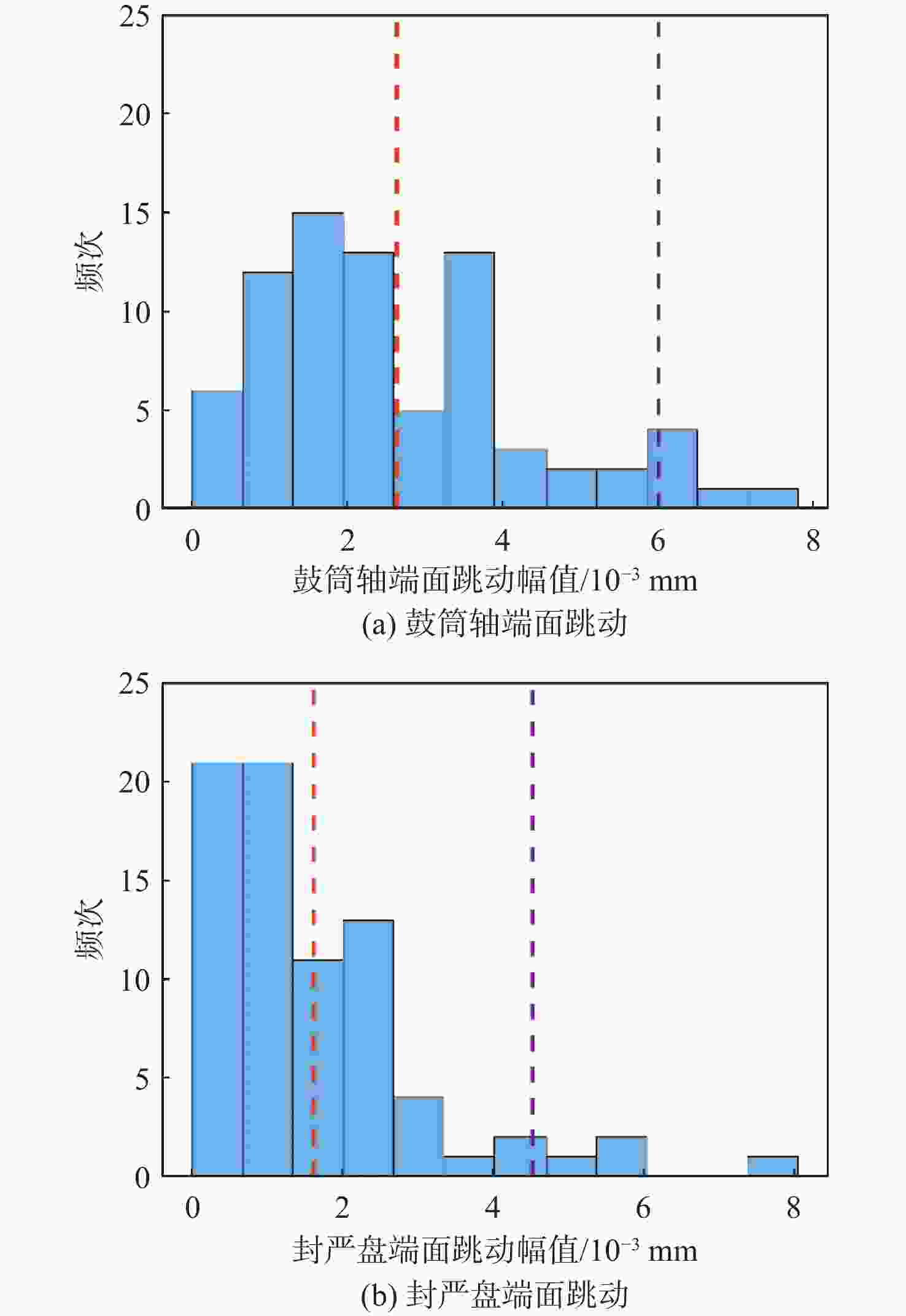

表 1 关键构件装配参数测量值统计值

Table 1. Statistical measurement values of key component assembly parameters

构件 平均值/(g·mm) 极限值/(g·mm) 最大值/(g·mm) ${\mu _{{\text{un}}}}$/% 静不

平衡1-2级盘 447 895 892 −0.6 4-9级盘 1964 3858 4679 41.8 涡轮盘 231 566 508 −25.3 构件 平均值/mm 极限值/mm 最大值/mm ${\mu _{{\text{un}}}}$/% 端面

跳动鼓筒轴 2.64×10−3 6.00×10−3 7.70×10−3 64.4 封严盘 1.62×10−3 4.53×10−3 8.00×10−3 214.9 -

[1] 洪杰, 马艳红, 张大义. 航空燃气轮机总体结构设计与动力学分析[M]. 北京: 北京航空航天大学出版社, 2014.HONG J, MA Y H, ZHANG D Y. Overall structural design and dynamic analysis of aviation gas turbine[M]. Beijing: Beihang University Press, 2014(in Chinese). [2] 宋兆泓. 航空发动机典型故障分析[M]. 北京: 北京航空航天大学出版社, 1993.SONG Z H. Typical fault analysis of aero-engine[M]. Beijing: Beihang University Press, 1993(in Chinese). [3] ZHANG C, SUN Q C, SUN W, et al. Performance-oriented digital twin assembly of high-end equipment: a review[J]. The International Journal of Advanced Manufacturing Technology, 2023, 126(11): 4723-4748. [4] ZHANG C, SUN Q C, SUN W, et al. A construction method of digital twin model for contact characteristics of assembly interface[J]. The International Journal of Advanced Manufacturing Technology, 2021, 113(9): 2685-2699. [5] CHEN T, LI C H, XIAO H, et al. A review of digital twin intelligent assembly technology and application for complex mechanical products[J]. The International Journal of Advanced Manufacturing Technology, 2023, 127(9): 4013-4033. [6] 陶飞, 刘蔚然, 刘检华, 等. 数字孪生及其应用探索[J]. 计算机集成制造系统, 2018, 24(1): 1-18.TAO F, LIU W R, LIU J H, et al. Digital twin and its potential application exploration[J]. Computer Integrated Manufacturing Systems, 2018, 24(1): 1-18(in Chinese). [7] ATTARAN M, CELIK B G. Digital twin: benefits, use cases, challenges, and opportunities[J]. Decision Analytics Journal, 2023, 6: 100165. doi: 10.1016/j.dajour.2023.100165 [8] JONES D, SNIDER C, NASSEHI A, et al. Characterising the digital twin: a systematic literature review[J]. CIRP Journal of Manufacturing Science and Technology, 2020, 29: 36-52. doi: 10.1016/j.cirpj.2020.02.002 [9] TAO F, CHENG J F, QI Q L, et al. Digital twin-driven product design, manufacturing and service with big data[J]. The International Journal of Advanced Manufacturing Technology, 2018, 94(9): 3563-3576. [10] YI Y, YAN Y H, LIU X J, et al. Digital twin-based smart assembly process design and application framework for complex products and its case study[J]. Journal of Manufacturing Systems, 2021, 58: 94-107. doi: 10.1016/j.jmsy.2020.04.013 [11] SÖDERBERG R, WÄRMEFJORD K, CARLSON J S, et al. Toward a digital twin for real-time geometry assurance in individualized production[J]. CIRP Annals, 2017, 66(1): 137-140. doi: 10.1016/j.cirp.2017.04.038 [12] MU X K, WANG Y L, YUAN B, et al. A New assembly precision prediction method of aeroengine high-pressure rotor system considering manufacturing error and deformation of parts[J]. Journal of Manufacturing Systems, 2021, 61: 112-124. doi: 10.1016/j.jmsy.2021.08.010 [13] 李志刚, 张直明. 不平衡质量的大小和分布对柔性转子-轴承系统稳定性的影响[J]. 振动与冲击, 1997, 16(1): 15-19.LI Z G, ZHANG Z M. The effect of magnitude and distribution of unbalance on stability of flexible rotor journal bearing system[J]. Journal of Vibration and Shock, 1997, 16(1): 15-19(in Chinese). [14] 李录平, 邹新元, 晋风华. 柔性转子的不平衡分布对摩擦振动行为的影响分析[J]. 动力工程, 2005, 25(6): 757-760.LI L P, ZOU X Y, JIN F H. Influence of unbalance distribution on frictional vibration behavior of flexible rotors[J]. Power Engineering, 2005, 25(6): 757-760(in Chinese). [15] 郝建山, 韩磊, 张智伟, 等. 分布多质量转子系统的不平衡响应特征[J]. 机械设计与制造, 2006(7): 34-36. doi: 10.3969/j.issn.1001-3997.2006.07.015HAO J S, HAN L, ZHANG Z W, et al. Unbalance response characteristics of distributed multi-mass rotor system[J]. Machinery Design & Manufacture, 2006(7): 34-36(in Chinese). doi: 10.3969/j.issn.1001-3997.2006.07.015 [16] 董惠敏, 张安师, 舒浩, 等. 转子分布不平衡和轴承特性参数同时辨识方法[J]. 哈尔滨工业大学学报, 2022, 54(7): 128-135.DONG H M, ZHANG A S, SHU H, et al. Simultaneous identification method of rotor distributed unbalance and bearing characteristic parameters[J]. Journal of Harbin Institute of Technology, 2022, 54(7): 128-135(in Chinese). [17] 赵立, 张昊随, 柳亦兵, 等. 存在轴向分布不平衡质量多盘拉杆转子非线性动力学特性[J]. 噪声与振动控制, 2022, 42(4): 74-79.ZHAO L, ZHANG H S, LIU Y B, et al. Nonlinear dynamic characteristics of multi-disc rod fastening rotor with axial unbalance mass distribution[J]. Noise and Vibration Control, 2022, 42(4): 74-79(in Chinese). [18] 洪杰, 杨哲夫, 孙博, 等. 局部旋转惯性对转子系统动力特性的影响[J]. 航空动力学报, 2022, 37(4): 673-683.HONG J, YANG Z F, SUN B, et al. Influence of local rotary inertia on the dynamic properties of rotor systems[J]. Journal of Aerospace Power, 2022, 37(4): 673-683(in Chinese). [19] 洪杰, 闫琦, 丰少宝, 等. 界面连接多盘转子旋转惯性模型及动力响应特性[J]. 航空动力学报, 2022, 37(5): 897-908.HONG J, YAN Q, FENG S B, et al. Rotational inertia model and dynamic response characteristics of multi-disk rotor system with interface[J]. Journal of Aerospace Power, 2022, 37(5): 897-908(in Chinese). [20] 刘寒, 陈雪骑, 李超, 等. 转子惯性主轴倾斜分布力学模型及其影响因素分析[C]//第十届中国航空学会青年科技论坛. 北京: 科学普及出版社, 2022: 869-876.LIU H, CHEN X Q, LI C, et al. Mechanical model and analysis of influencing factors for the tilting distribution of the inertial spindle of rotor[C]// Proceedings of the 10th China Aviation Society Youth Science and Technology Forum. Beijing: Popular Science Press, 2022: 869-876(in Chinese). -

下载:

下载: