-

摘要:

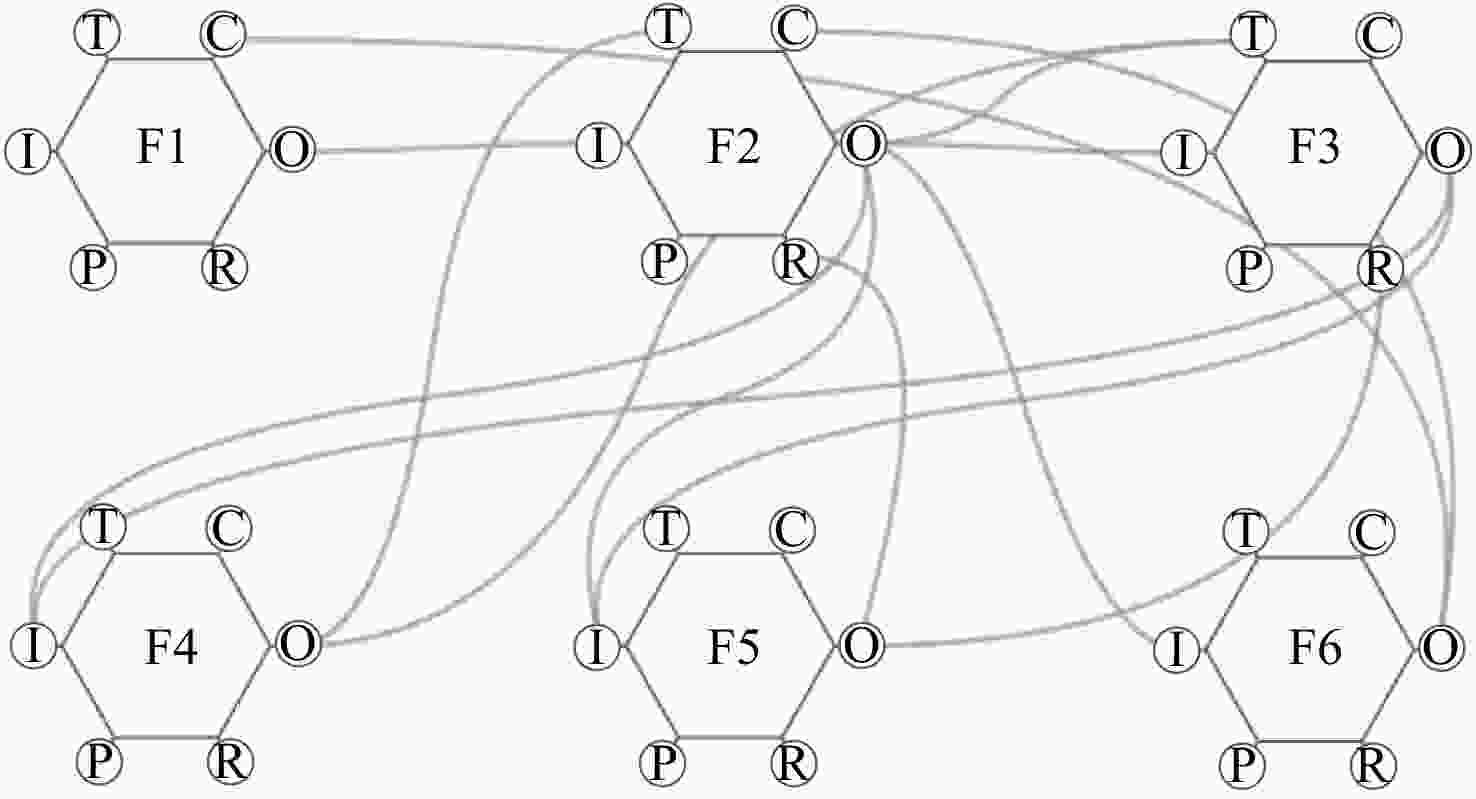

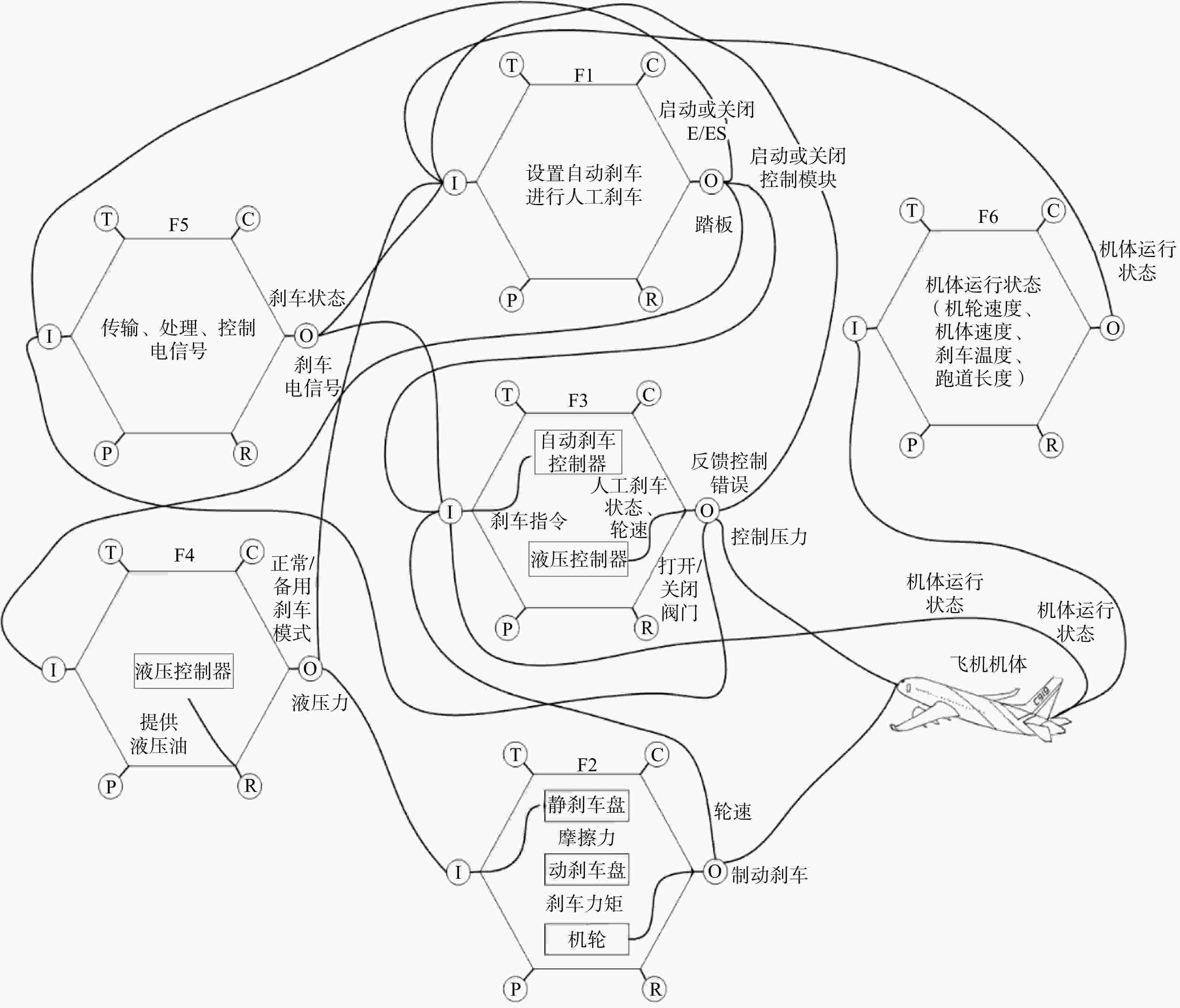

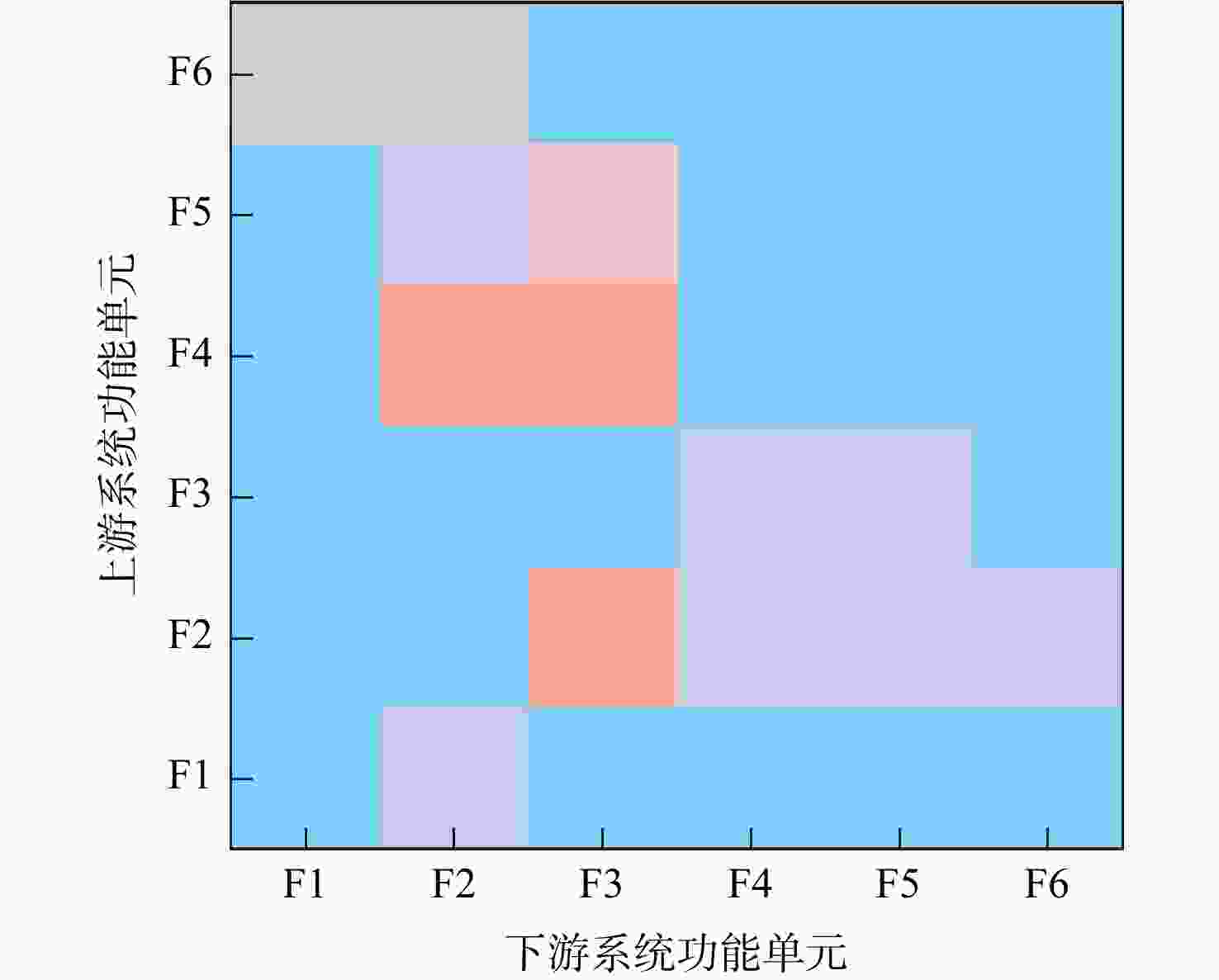

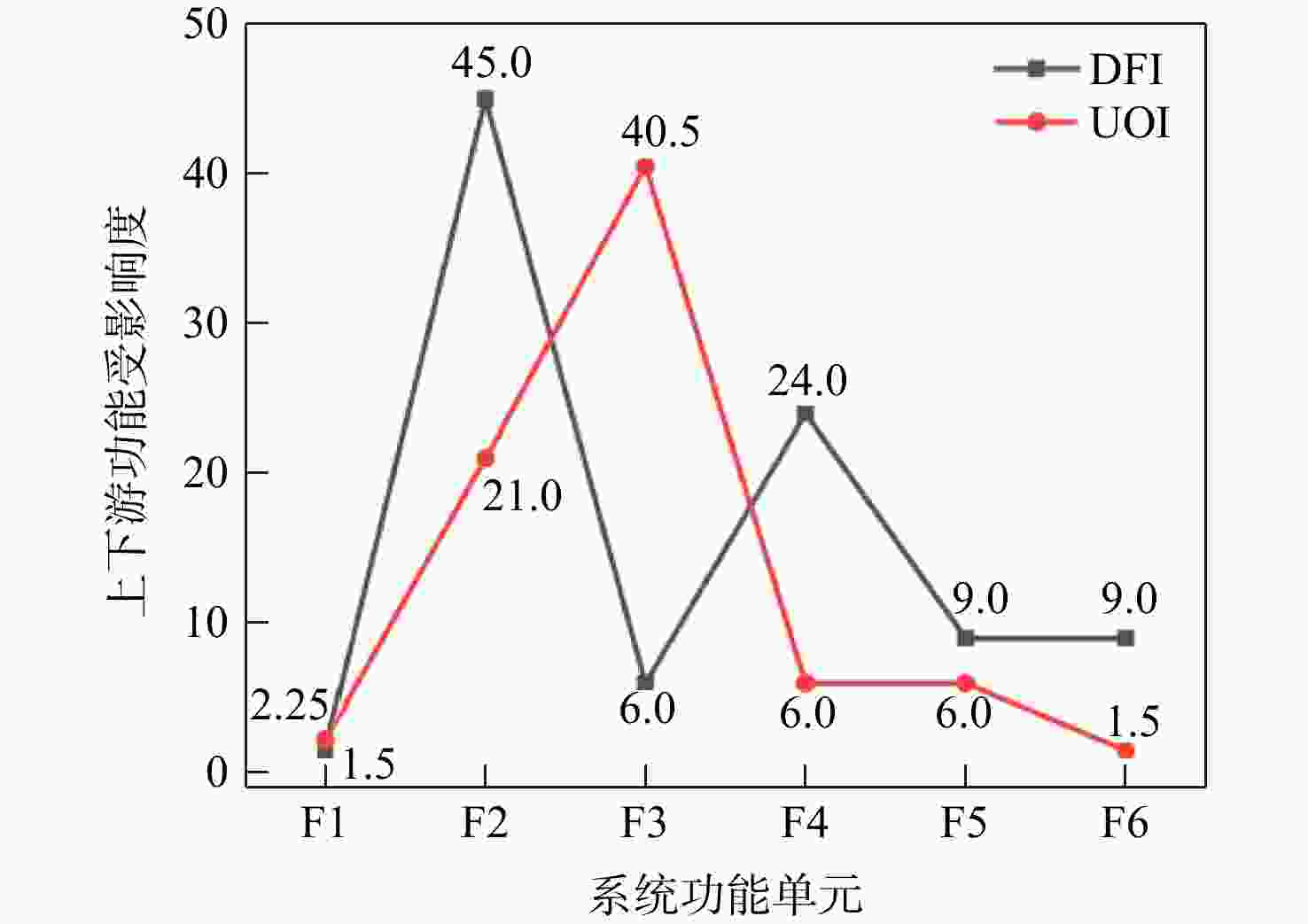

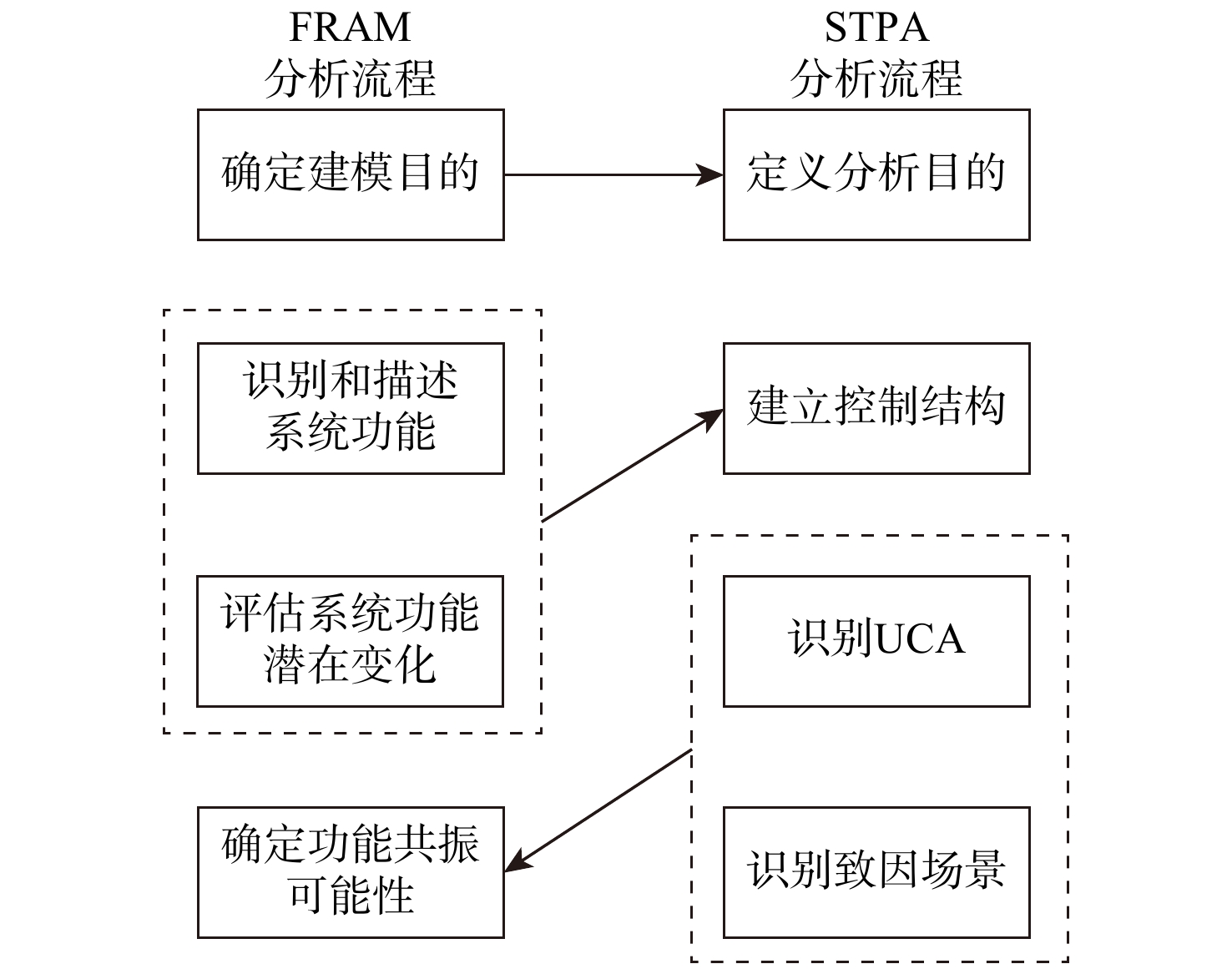

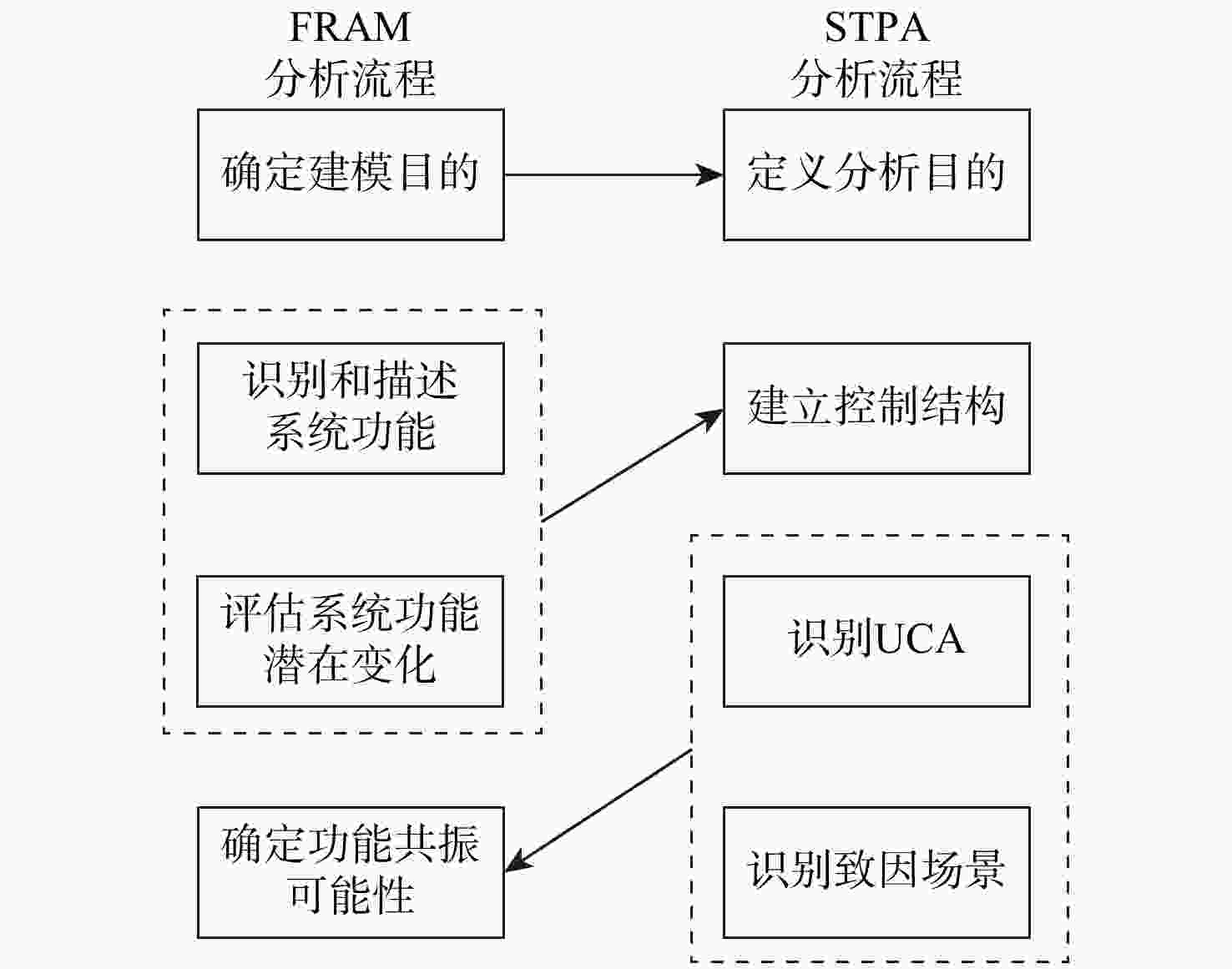

随着民机系统综合化程度的不断提高,各系统主体之间交互关系复杂、涌现性突出。传统的安全性分析方法以线性逻辑为主,未能完全满足系统风险高效识别的要求。为此,提出一种基于改进FRAM-STPA的民机系统安全性分析方法。构建融合模型,实现民机系统图形化功能建模与耦合分析;根据建模得到的功能单元潜在变化表型和系统潜在危险控制动作,生成系统全局功能影响关系,并通过量化功能模块的可变性风险识别系统安全运行关键功能模块。以民机刹车系统为例展开分析,并使用Word2Vec挖掘维修文本信息,验证分析结果的准确性,为民机安全性分析提供理论和方法参考。

Abstract:As civil aircraft systems increasingly integrate, the complex interactions among various system components and the emergence of unforeseen issues have become prominent. Traditional safety analysis methods, primarily based on linear logic, have failed to fully meet the requirements for efficient identification of system risks. Therefore, an improved FRAM-STPA approach for the safety analysis of civil aircraft systems is proposed. In order to carry out graphical functional modeling and coupling analysis of the aviation system, an integrated model must be built. Based on the modeling results, including the latent phenotypes of functional units and potential unsafe control actions within the system, it establishes the system-wide functional impact relationships and quantifies the variability risk of functional modules. In order to verify the accuracy of the analysis results, Word2Vec is used to mine maintenance text information, and the airplane braking system is used as an example to illustrate the analysis. This approach provides theoretical and methodological references for civil aircraft safety analysis.

-

表 1 潜在UCA类型与功能单元潜在变化表型对应关系

Table 1. Correspondence between potential UCA types and potential phenotype changes of functional units

潜在UCA类型 标记 功能单元潜在

变化表型未提供控制行为 U1 可靠性 提供控制行为后导致危险 U2 提供可能安全的控制行为但提供节点过早 U3 时序性 提供可能安全的控制行为但提供节点过晚 U4 提供可能安全的控制行为但提供节点顺序错误 U5 控制行为持续太久 U6 持续性 控制行为停止过早 U7 表 2 功能特性评估指标

Table 2. Assessment indicators for functional characteristics

功能单元潜在变化表型 性能变化表征 量化得分 输入 资源 前提 控制 时间 可靠性 可靠 1 阻尼 阻尼 阻尼 阻尼 阻尼 可接受 3 阻尼 阻尼 阻尼 阻尼 阻尼 不可靠 5 放大 放大 放大 放大 放大 时序性 适中 1 无影响/放大 阻尼/无影响 放大 放大 放大 可接受 2 阻尼 阻尼 阻尼 阻尼 阻尼 较早/较晚 4 放大 放大 放大 放大 放大 时序错误 5 放大 放大 放大 放大 放大 持续性 稳定 1 阻尼/无影响 阻尼/无影响 放大 放大 放大 可接受 3 阻尼 阻尼 阻尼 阻尼 阻尼 不稳定 5 放大 放大 放大 阻尼 阻尼 表 3 不安全控制行为

Table 3. Unsafe control action

UCA类型 不安全控制行为 对应的功能单元

潜在变化表型未提供控制行为 自动刹车设置后,未自动执行着陆时的制动指令 可靠性 提供控制行为后导致危险 自动制动在着陆阶段提供了过多的制动指令;自动制动在着陆阶段提供了

不足的制动指令可靠性 提供可能安全的控制行为但提供节点过早 自动制动在飞机接地前执行制动指令 时序性 提供可能安全的控制行为但提供节点过晚 自动制动在飞机接地后延迟TBD(单位:s)秒才提供制动指令 时序性 提供可能安全的控制行为但提供节点顺序错误 自动制动在飞机接地前执行制动指令,在接地后延迟TBD(单位:s)才停止制动 时序性 控制行为持续太久 自动制动在飞机着陆后持续提供制动指令的时间过长 持续性 控制行为停止过早 自动制动在飞机达到TBD滑行速度前停止提供制动指令 持续性 注:TBD表示待定或尚未确定。 表 4 刹车系统各功能单元的FRAM六角特征分析

Table 4. FRAM hexagonal feature analysis for brake system functional units

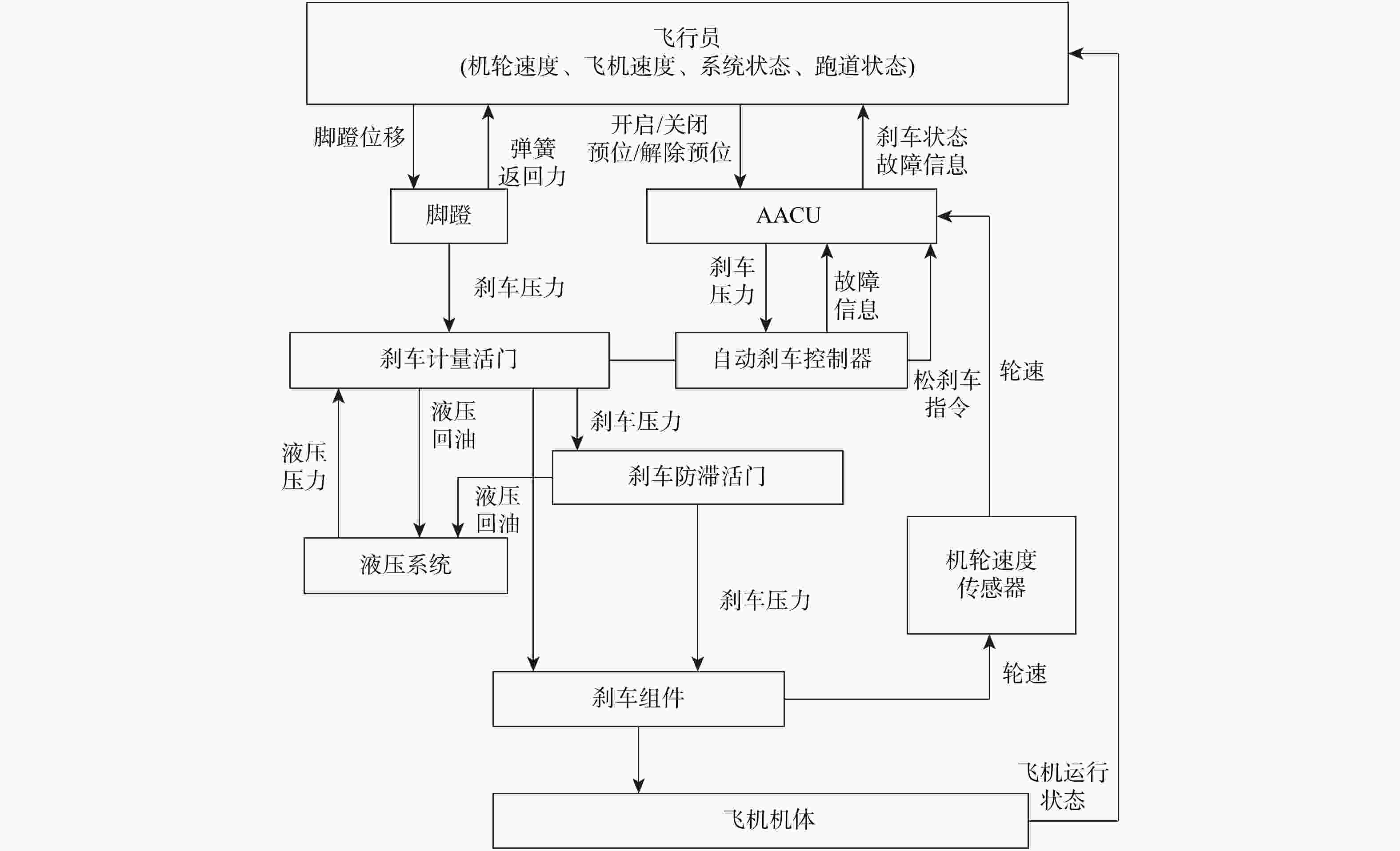

功能 描述 输入 输出 前提 资源 控制 时间 F1 PCM 飞行员的踏板或

手柄输入BAC接收的指令 飞行员需要进行

刹车操作飞行员的操作能力 飞行员踏下踏板或

操作手柄实时控制 F2 BAC PCM发出的指令 刹车施加力度 PCM发出指令 BAC、HS BSCU控制 实时控制 F3 BCM BAC的输出 BAC控制指令 BAC的输出 BSCU BSCU控制 实时控制 F4 HS BAC的输出 提供液压动力 BAC的输出 液压泵、液压油箱、

液压阀液压阀门控制 实时控制 F5 E/ES BAC和BCM的

输出电能供应 BAC和BCM的

输出电源供应、电气线缆

和连接器电气线缆和连接器 实时控制 F6 WIS BCM和HS的

状态信息飞行员的警告和

指示信息BCM和HS的

状态信息显示屏、指示灯 BSCU控制 实时控制 注:BSCU为刹车系统转弯控制组件。 表 5 功能模块关联组件

Table 5. Associated components of functional modules

功能 描述 关联组件 F1 PCM 机组 F2 BAC 静刹车盘、动刹车盘、机轮、其他控制

(转向、反推、气动刹车等)F3 BCM 自动刹车控制器、液压控制器、其他控制

(转向、反推、气动刹车等)F4 HS 液压控制器、刹车系统相关液压模块、液压油 F5 E/ES 自动刹车控制器 F6 WIS 机组 表 6 刹车系统在可靠性、时序性和持续性上的表型

Table 6. Phenotypes of brake system in reliability, temporality, and continuity

功能 可靠性 时序性 持续性 F1 可接受 可接受 稳定 F2 可接受 可接受 稳定 F3 可接受 可接受 稳定 F4 可接受 适中 稳定 F5 可接受 适中 稳定 F6 可接受 可接受 可接受 表 7 安全性分析方法综合对比

Table 7. Comprehensive comparison of security analysis methods

分析方法 定性

分析定量

分析多因素交互

过程分析潜在风险

路径分析预防性

分析FRAM √ √ STPA √ FRAM-STPA √ √ √ √ 改进FRAM-STPA √ √ √ √ √ FMEA √ FTA √ 表 8 维修记录

Table 8. Maintenance records

序号 故障描述 纠正措施 1 3号主轮扎伤超标 参考手册,更换3号主轮 2 航后检查发现左外侧主轮磨损超标 参考手册,更换主轮,检查正常 3 内轮刹车储压器不能保持 参考技术解决方案,更换内轮刹车储压器,并完成充气勤务后,测试正常 $ \vdots $ $ \vdots $ $ \vdots $ 表 9 刹车系统风险组件及相似度

Table 9. Risk components and similarities of brake system

刹车系统风险组件 对应相似度 刹车盘 0.812 刹车片 0.784 刹车阀 0.769 刹车控制器 0.758 刹车液压单元 0.701 刹车蓝环 0.639 刹车电路 0.602 刹车传感器 0.591 刹车警告灯 0.578 刹车系统故障 0.549 -

[1] 陈磊, 焦健, 赵廷弟. 基于模型的复杂系统安全分析综述[J]. 系统工程与电子技术, 2017, 39(6): 1287-1291. doi: 10.3969/j.issn.1001-506X.2017.06.16CHEN L, JIAO J, ZHAO T D. Review for model-based safety analysis of complex safety-critical system[J]. Systems Engineering and Electronics, 2017, 39(6): 1287-1291(in Chinese). doi: 10.3969/j.issn.1001-506X.2017.06.16 [2] KHAKZAD N, KHAN F, AMYOTTE P. Safety analysis in process facilities: comparison of fault tree and Bayesian network approaches[J]. Reliability Engineering & System Safety, 2011, 96(8): 925-932. [3] EKRAMIPOOYA A, BOROUSHAKI M, RASHTCHIAN D. Application of natural language processing and machine learning in prediction of deviations in the HAZOP study worksheet: a comparison of classifiers[J]. Process Safety and Environmental Protection, 2023, 176: 65-73. doi: 10.1016/j.psep.2023.06.004 [4] OUYANG L H, CHE Y S, YAN L, et al. Multiple perspectives on analyzing risk factors in FMEA[J]. Computers in Industry, 2022, 141: 103712. doi: 10.1016/j.compind.2022.103712 [5] HOLLNAGEL E. FRAM: the functional resonance analysis method: modelling complex socio-technical systems[M]. Aldershot: Town Publishing Ltd. , 2012. [6] HOLLNAGEL E, WEARS R L, BRAITHWAITE J. From Safety-Ⅰ to Safety-Ⅱ: a white paper[R]. Sydney: Australian Institute of Health Innovation, 2015. [7] VEIBÄCK C, OLOFSSON J, LAUKNES T R, et al. Learning target dynamics while tracking using Gaussian processes[J]. IEEE Transactions on Aerospace and Electronic Systems, 2020, 56(4): 2591-2602. doi: 10.1109/TAES.2019.2948699 [8] TIAN W L, CAPONECCHIA C. Using the functional resonance analysis method (FRAM) in aviation safety: a systematic review[J]. Journal of Advanced Transportation, 2020, 2020: 8898903. [9] STUDIC M, MAJUMDAR A, SCHUSTER W, et al. A systemic modelling of ground handling services using the functional resonance analysis method[J]. Transportation Research Part C: Emerging Technologies, 2017, 74: 245-260. doi: 10.1016/j.trc.2016.11.004 [10] CLAY-WILLIAMS R, HOUNSGAARD J, HOLLNAGEL E. Where the rubber meets the road: using FRAM to align work-as-imagined with work-as-done when implementing clinical guidelines[J]. Implementation Science, 2015, 10(1): 125. doi: 10.1186/s13012-015-0317-y [11] SALEHI V, VEITCH B, SMITH D. Modeling complex socio-technical systems using the FRAM: a literature review[J]. Human Factors and Ergonomics in Manufacturing & Service Industries, 2021, 31(1): 118-142. [12] ROSA L V, HADDAD A N, DE CARVALHO P V R. Assessing risk in sustainable construction using the functional resonance analysis method (FRAM)[J]. Cognition, Technology & Work, 2015, 17(4): 559-573. [13] PATRIARCA R, DI GRAVIO G, COSTANTINO F. A Monte Carlo evolution of the functional resonance analysis method (FRAM) to assess performance variability in complex systems[J]. Safety Science, 2017, 91: 49-60. doi: 10.1016/j.ssci.2016.07.016 [14] 李耀华, 巩子瑜. 基于改进FRAM的民机系统安全性分析[J]. 航空学报, 2020, 41(12): 324083.LI Y H, GONG Z Y. Safety analysis of civil aircraft system based on improved FRAM[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(12): 324083(in Chinese). [15] LEVESON N. A new accident model for engineering safer systems[J]. Safety Science, 2004, 42(4): 237-270. doi: 10.1016/S0925-7535(03)00047-X [16] CHEN L, JIAO J, ZHAO T D. A novel hazard analysis and risk assessment approach for road vehicle functional safety through integrating STPA with FMEA[J]. Applied Sciences, 2020, 10(21): 7400. doi: 10.3390/app10217400 [17] 李耀华, 高源. 基于STPA-ANP模型的民机系统安全性分析[J]. 系统工程与电子技术, 2022, 44(9): 2986-2994.LI Y H, GAO Y. Safety analysis of civil aircraft systems based on the STPA-ANP model[J]. Systems Engineering and Electronics, 2022, 44(9): 2986-2994(in Chinese). [18] ASARE P, LACH J, STANKOVIC J A. FSTPA-Ⅰ: a formal approach to hazard identification via system theoretic process analysis[C]//Proceedings of the ACM/IEEE International Conference on Cyber-Physical Systems. Piscataway: IEEE Press, 2013: 150-159. [19] DAKWAT A L, VILLANI E. System safety assessment based on STPA and model checking[J]. Safety Science, 2018, 109: 130-143. doi: 10.1016/j.ssci.2018.05.009 [20] THAPALIYA A, KWON G. Realization of combined systemic safety analysis of adverse train control system using model checking[C]//Proceedings of the International Conference on Frontier Computing. Berlin: Springer, 2018: 419-430. [21] NAEINI A M, NADEAU S. Proposed integrated FRAM/STPA risk analysis of data gloves in assembly 4.0 system[J]. Robotics and Computer-Integrated Manufacturing, 2023, 81: 102523. doi: 10.1016/j.rcim.2022.102523 [22] HOLLNAGEL E, HOUNSGAARD J, COLLIGAN L. FRAM-the functional resonance analysis method: a handbook for the practical use of the method[M]. Boca Raton: CRC Press, 2014. [23] ATASOY V E, CETEK C. Enhanced cruise range prediction for narrow-body turbofan commercial aircraft based on QAR data[J]. The Aeronautical Journal, 2021, 125(1286): 672-701. doi: 10.1017/aer.2020.121 [24] BENSACI C, ZENNIR Y, POMORSKI D, et al. Collision hazard modeling and analysis in a multi-mobile robots system transportation task with STPA and SPN[J]. Reliability Engineering & System Safety, 2023, 234: 109138. [25] AHN S I, KURT R E, TURAN O. The hybrid method combined STPA and SLIM to assess the reliability of the human interaction system to the emergency shutdown system of LNG ship-to-ship bunkering[J]. Ocean Engineering, 2022, 265: 112643. doi: 10.1016/j.oceaneng.2022.112643 [26] ARIF-UZ-ZAMAN K, CHOLETTE M E, MA L, et al. Extracting failure time data from industrial maintenance records using text mining[J]. Advanced Engineering Informatics, 2017, 33: 388-396. doi: 10.1016/j.aei.2016.11.004 [27] XU Z Z, CHEN B, ZHOU S H, et al. A text-driven aircraft fault diagnosis model based on a Word2Vec and priori-knowledge convolutional neural network[J]. Aerospace, 2021, 8(4): 112. doi: 10.3390/aerospace8040112 [28] ZHOU S H, WEI C F, LI P, et al. A text-driven aircraft fault diagnosis model based on Word2Vec and stacking ensemble learning[J]. Aerospace, 2021, 8(12): 357. doi: 10.3390/aerospace8120357 [29] 贾宝惠, 姜番, 王玉鑫, 等. 基于民机维修文本数据的故障诊断方法[J]. 航空学报, 2023, 44(5): 326598.JIA B H, JIANG F, WANG Y X, et al. Fault diagnosis method based on civil aircraft maintenance text data[J]. Acta Aeronautica et Astronantica Sinica, 2023, 44(5): 326598(in Chinese). -

下载:

下载: